91772

TABLE OF CONTENTS (cont’d)

Page

LIST OF FIGURES

FIGURE 1. ICE DIVERTER 4.............................................

FIGURE 2. GATE RESTRICTOR PLATE 5..................................

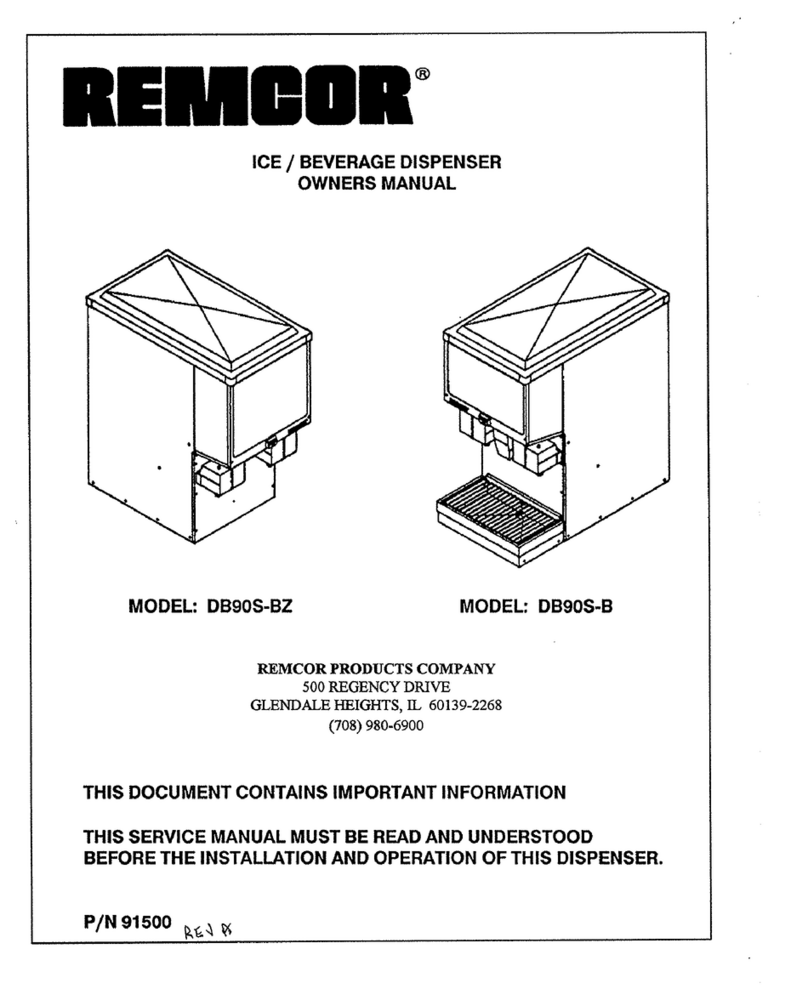

FIGURE 3. MOUNTING TEMPLATE DB90S--B STANDARD 6.................

FIGURE 4. MOUNTING TEMPLATE DB90S-B & --BZ 7......................

FIGURE 5. MOUNTING TEMPLATE DB90S--BC 8...........................

FIGURE 6. MOUNTING TEMPLATE DB90-BCZ 9...........................

FIGURE 7. BEVERAGE SYSTEM SCHEMATIC “--B”AND “--BZ”UNITS 10......

FIGURE 8. BEVERAGE SYSTEM SCHEMATIC --BC MODEL ( 4 VALVE) 11.....

FIGURE 9. BEVERAGE SYSTEM SCHEMATIC --BC MODEL ( 5 VALVE) 12.....

FIGURE 10. WIRING DIAGRAM DB 90 DISPENSER 17.......................

FIGURE 11. SOLENOID ASSEMBLY - EXPLODED VIEW & PARTS LIST 18.....

FIGURE 12. EXPLODED VIEW & PART LIST DB90-B 19......................

FIGURE 13. EXPLODED VIEW & PART LIST DB90-BZ (NO SINK) 20..........

FIGURE 14. EXPLODED VIEW & PARTS LIST DB90-BC

MERCHANDISER SECTION 21..................................

FIGURE 15. EXPLODED VIEW & PART LIST DB90-BC CABINET 22...........

FIGURE 16. EXPLODED VIEW & PARTS LIST DB90-BC

COLD PLATE SECTION 23......................................

FIGURE 17. EXPLODED VIEW & PARTS LIST DB90-BC ELECTRIC

BOX ASSEMBLY 24............................................

LIST OF TABLES

TABLE 1. SPECIFICATIONS 2............................................

Manufactured Under One or More of the following Patent Numbers: 3,211,336, 3,274,792, 3,393,839,3,517,860,

3,739,842, 4,215,803,4,227,377, 4,300,359, 4,346,824

Canadian Patent Numbers: 912,514 (10/72), 936,855 (11/73), 4,429,543, 4,921,149

Other Patents Pending