191679

SAFETY PRECAUTIONS

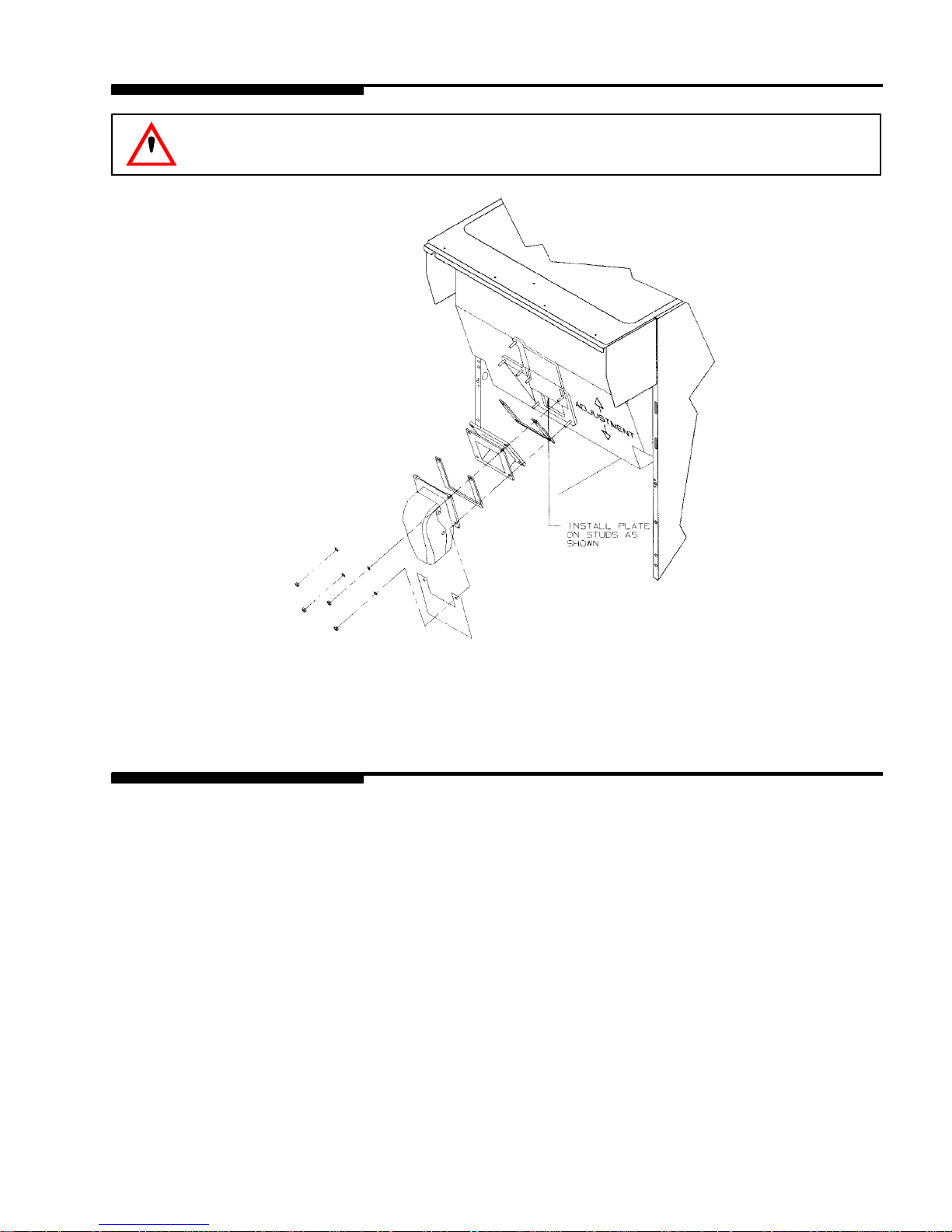

Always disconnectpowertothe dispenserbeforeservicing orcleaning.

Neverplace handsinside ofhopperorgate area withoutdisconnecting powertothe dispenser.Agitator rotation

occursautomaticallywhen the dispenserisenergized!

Thisice dispenserhasbeen specificallydesigned to provide protection againstpersonal injuryand eliminates

contamination ofice.Toinsurecontinued protection and sanitation,observethe following

ALWAYS be surethe removablelidisproperlyinstalled to preventunautho-

rized access tothe hopperinteriorand possiblecontamination ofice.

ALWAYS be surethe upperand lowerfrontpanelsaresecurelyfastened.

ALWAYS keep area around the dispenserclean oficecubes.

CAUTION:Dispensercannotbeusedwithcrushed orflakedice.

Use ofbaggedice which has frozenintolarge chunks canvoidwarranty.Thedispenser

agitatorisnotdesignedto be anice crusher.Use oflarge chunks ofice which“jamup”

insidethehopperwill cause failureof the agitator motorand damagetothehopper. Ifbaggedice

isused, itmustbe carefully and completelybrokenintosmall, cube-sized pieces beforefilling into

thedispenserhopper.

GENERALDESCRIPTION

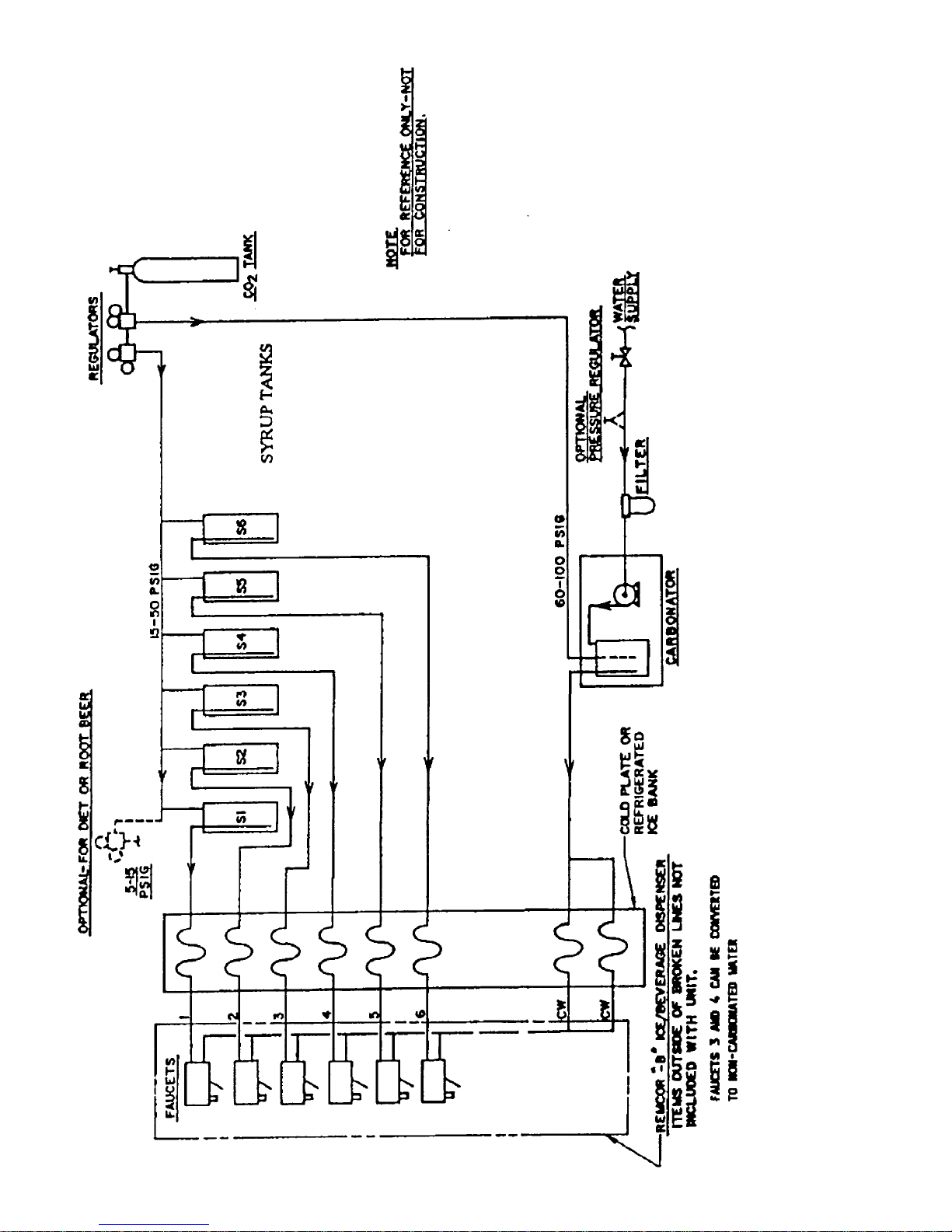

The Remcor“DB”seriesofice dispensers solveyourice and beverage service needsinasanitary,spacesav-

ing,economical way.Designed tobemanuallyfilled withicefromanyremoteicemaking source, these

dispenserswill dispensecubes(up 1-1/4”insize),cubeletsand hard-chipped orcracked ice.

“B”modelsalsocontain beverage faucetsand mustbe supplied withcold product fromanyremotecold plate or

refrigerated soda factory.

“BC”unitsinclude bothfaucetsand cold platesand are designed tobesupplied direct fromsyrup tanks and car-

bonator,with no additionalcooling required.

Table 1.Specifications

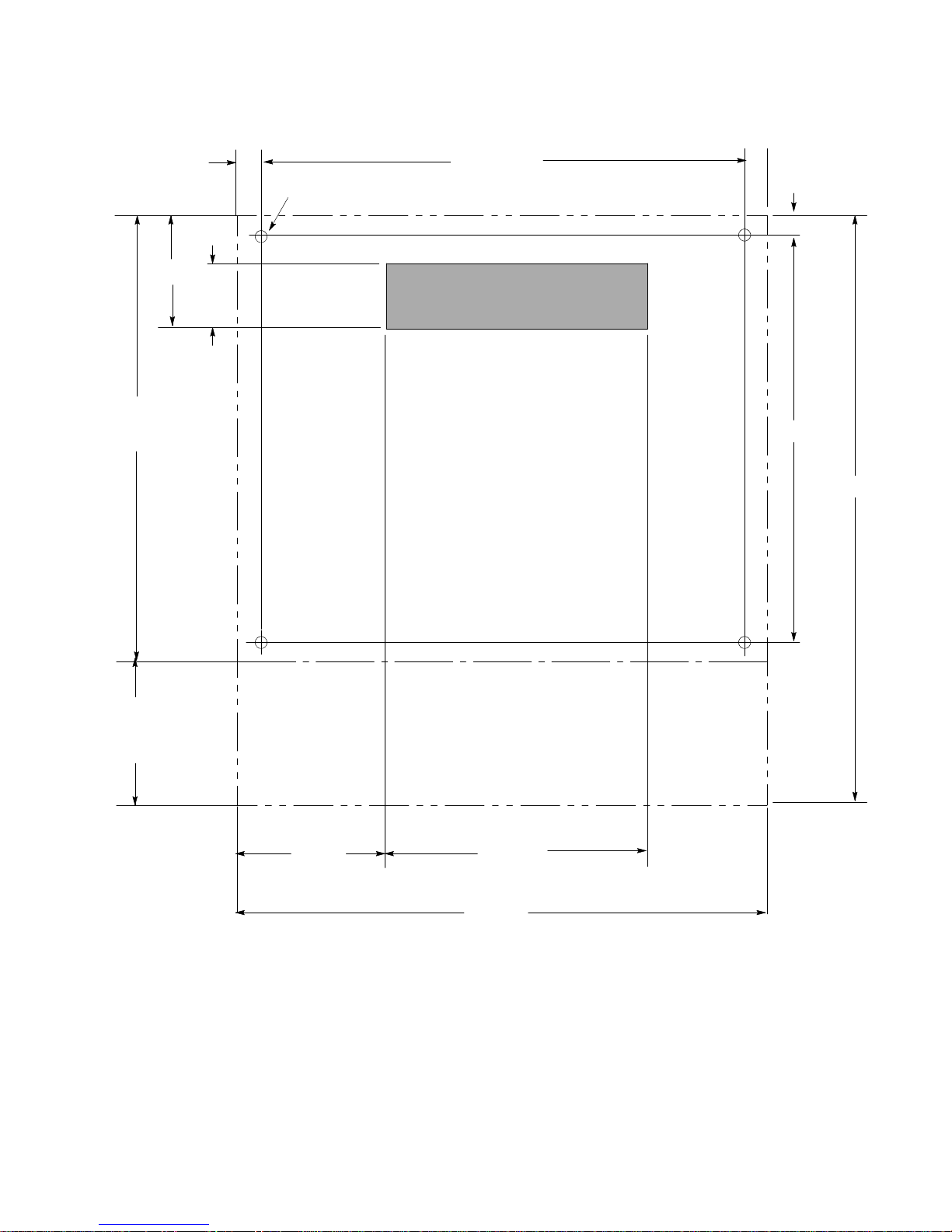

Model:DB200SDB220SDB275S

IceStorage:200 lbs.220 lbs.275 lbs.

MaximumNumberofFaucetsAvailable:N/AN/AN/A

Built-inColdPlate:NoNoNo

Dimension:30Wx30Dx33H30Wx30Dx36H30Wx30Dx40H

Model:DB200S-BDB220S-BDB275S-B

IceStorage:200 lbs.220 lbs.275 lbs.

MaximumNumberofFaucetsAvailable:10 10 10

Built-inColdPlate:NoNoNo

Dimension:30Wx30Dx33H30Wx30Dx36H30Wx30Dx40H

Model:DB200S-BC DB220S-BC DB275S-BC

IceStorage:200 lbs.220 lbs.275 lbs.

MaximumNumberofFaucetsAvailable:10 10 10

Built-inColdPlate:YesYesYes

Dimension:30Wx30Dx33H30Wx30Dx36H30Wx30Dx40H

Electrical(forall models)120V,1ph., 5.5Amps

DrainConnection 7/8ID Hose