i91328

TABLEOFCONTENTS

Page...........................................................................

SAFETY PRECAUTIONS1...................................................

GENERALDESCRIPTION1..................................................

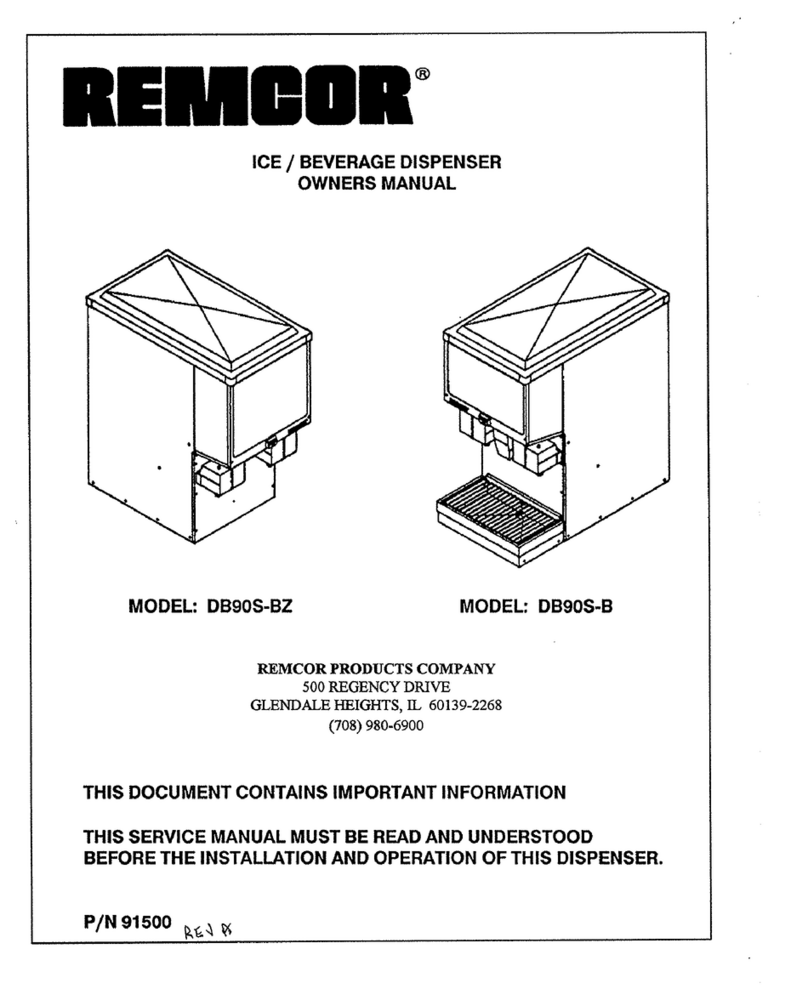

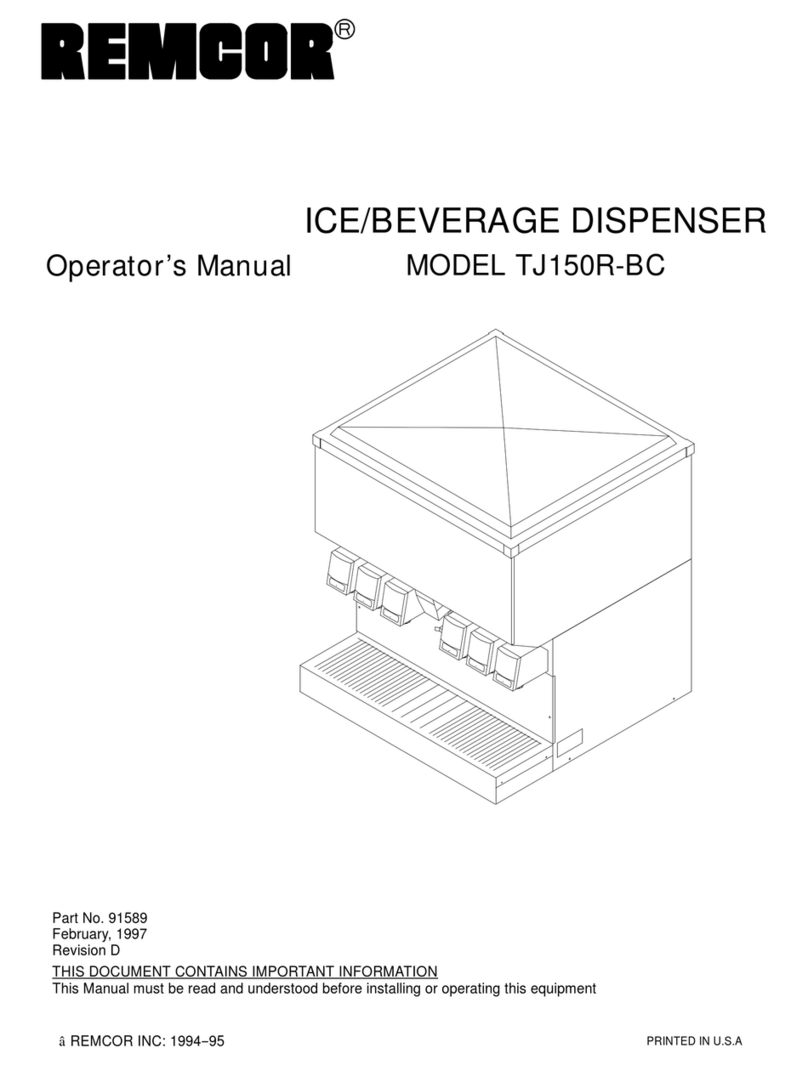

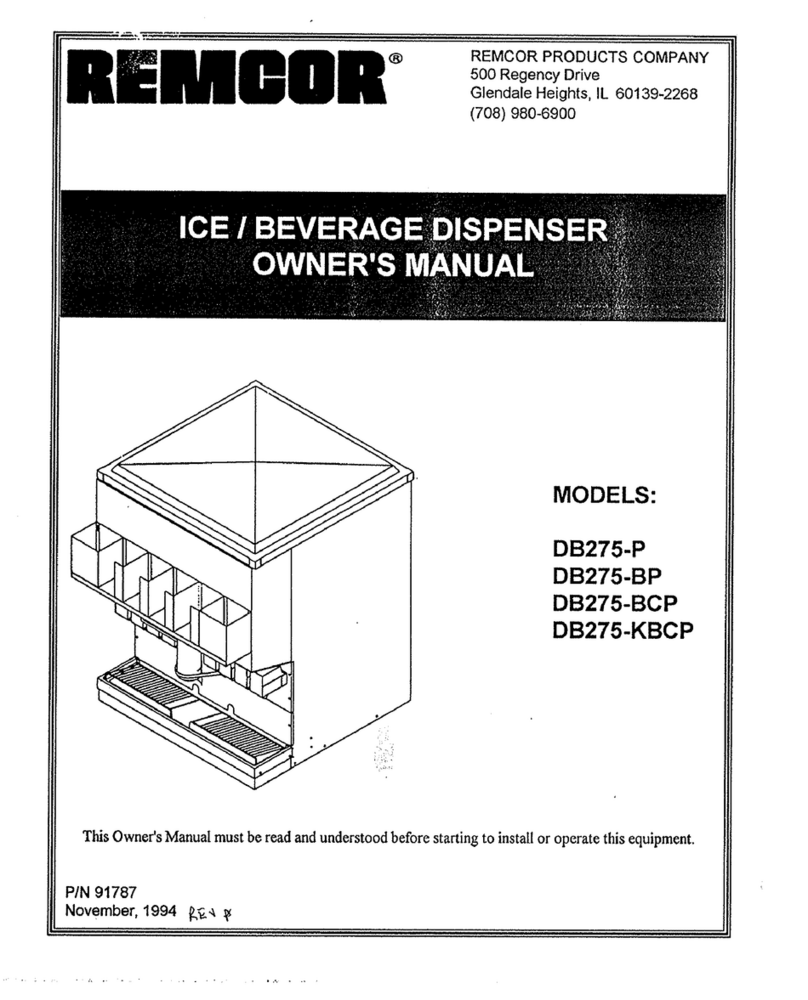

*CABINETOPTIONS2.......................................................

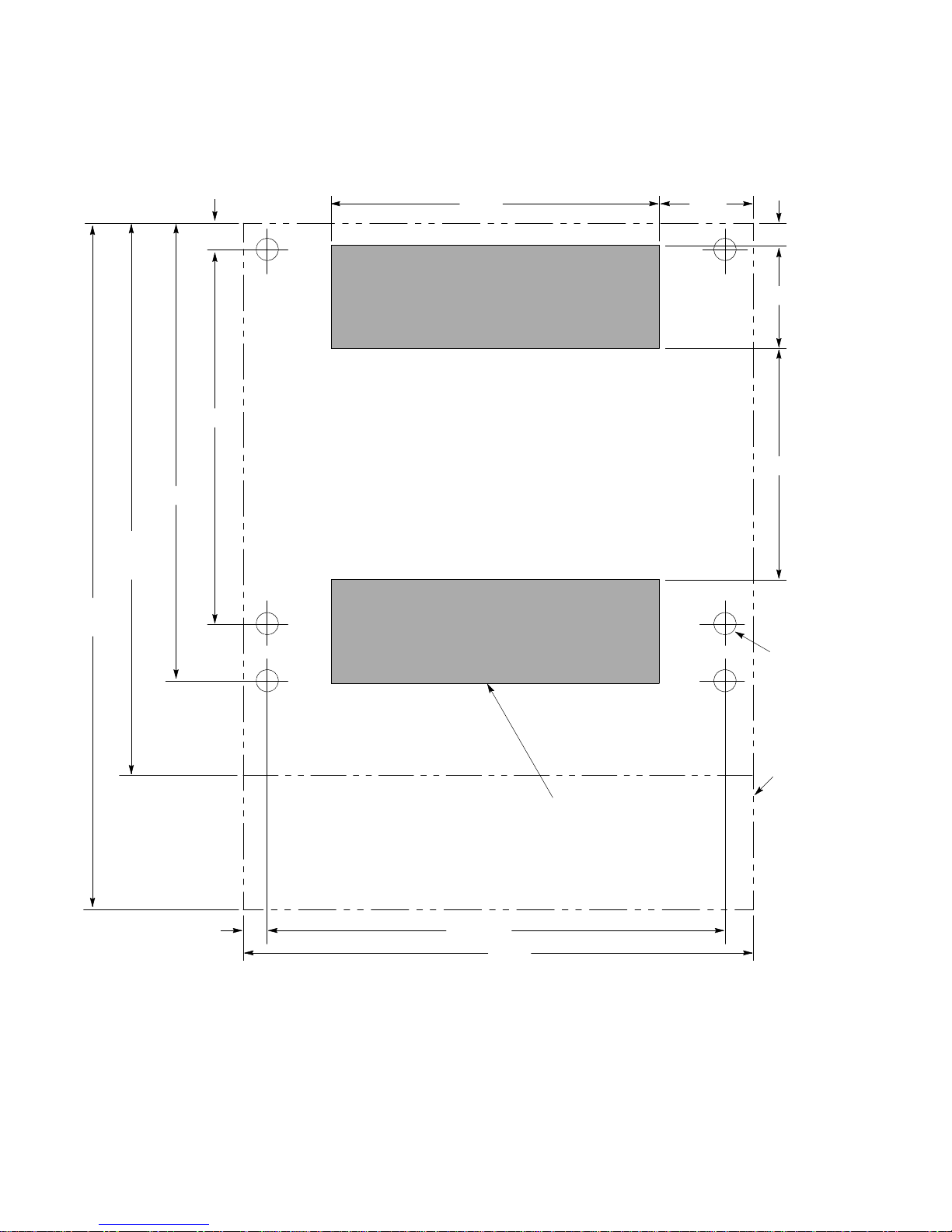

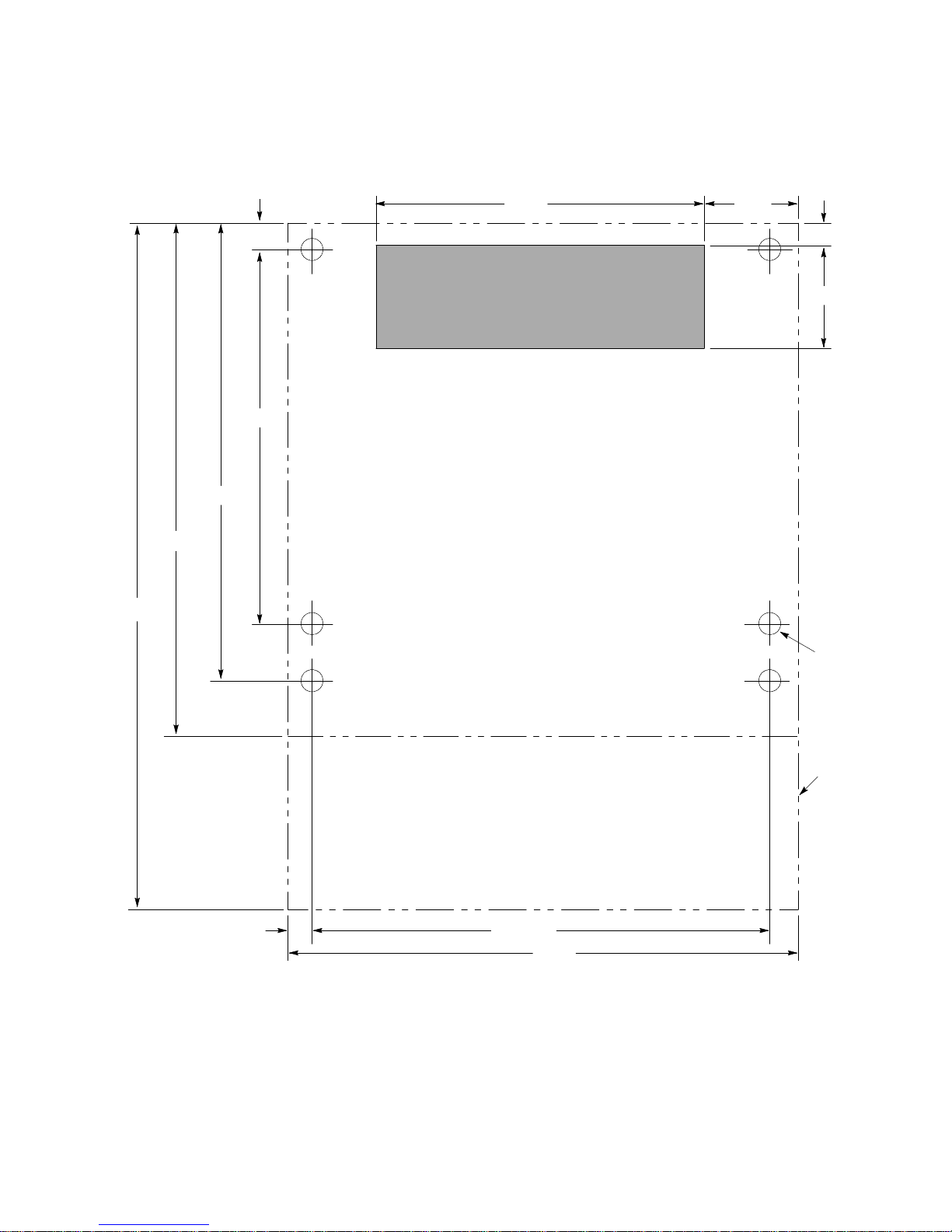

INSTALLATIONINSTRUCTIONS3............................................

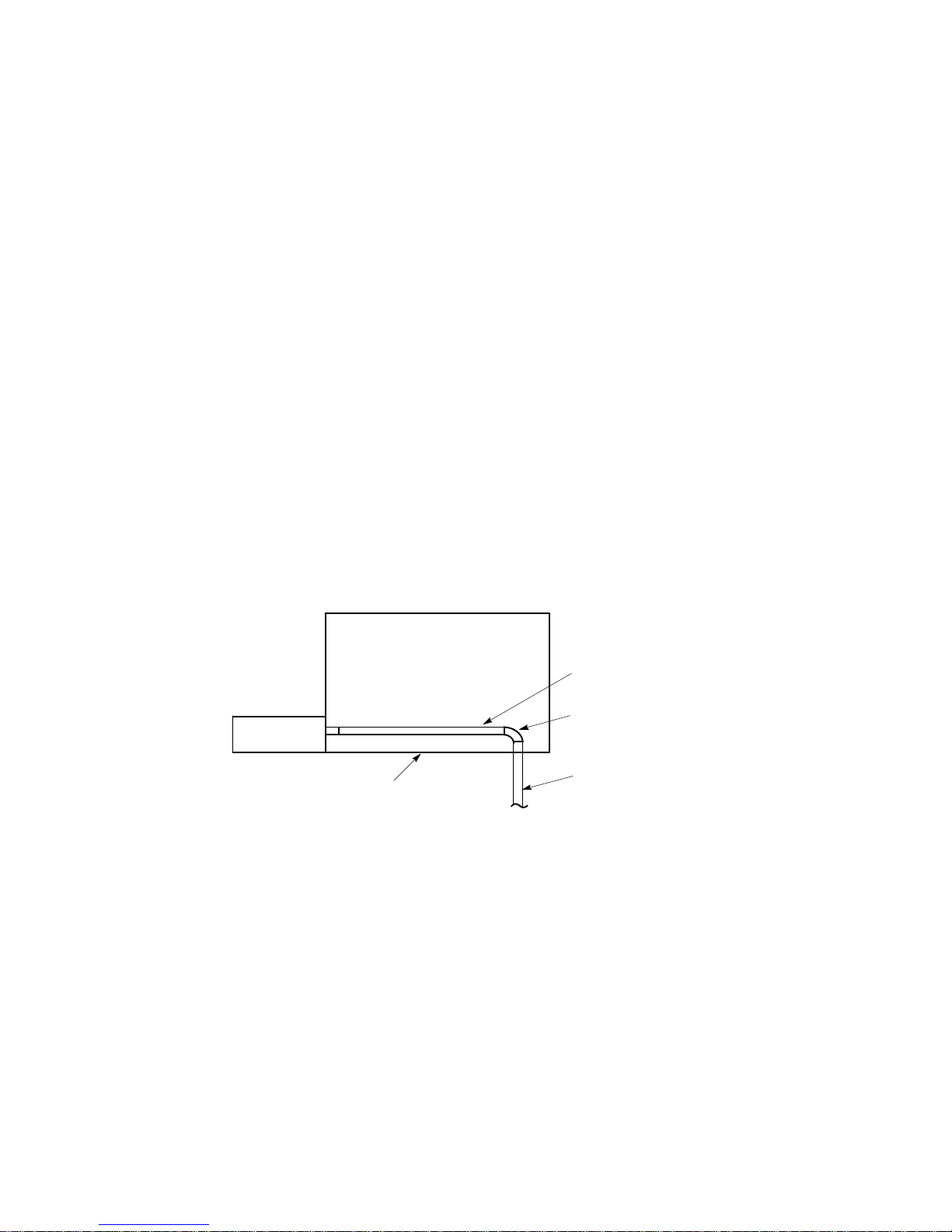

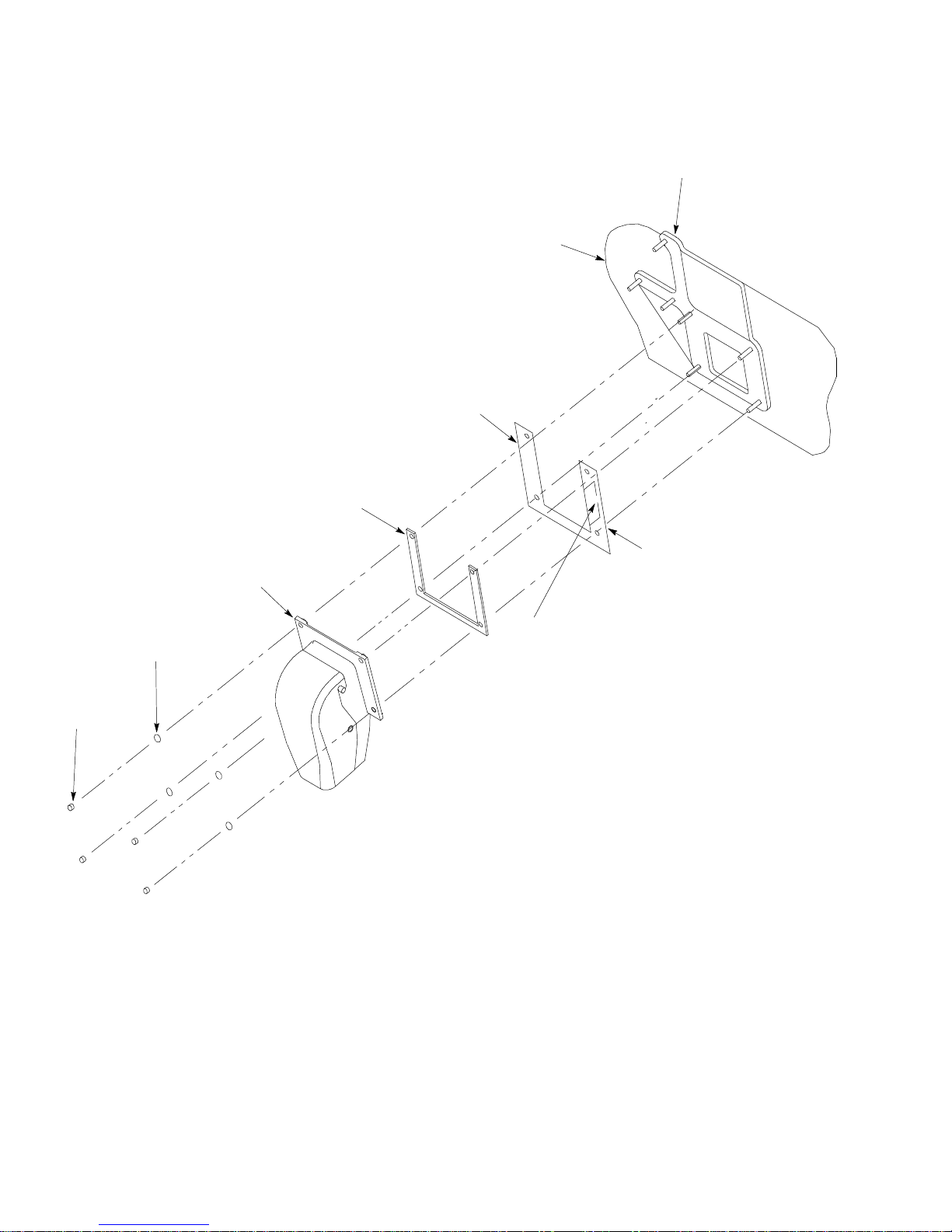

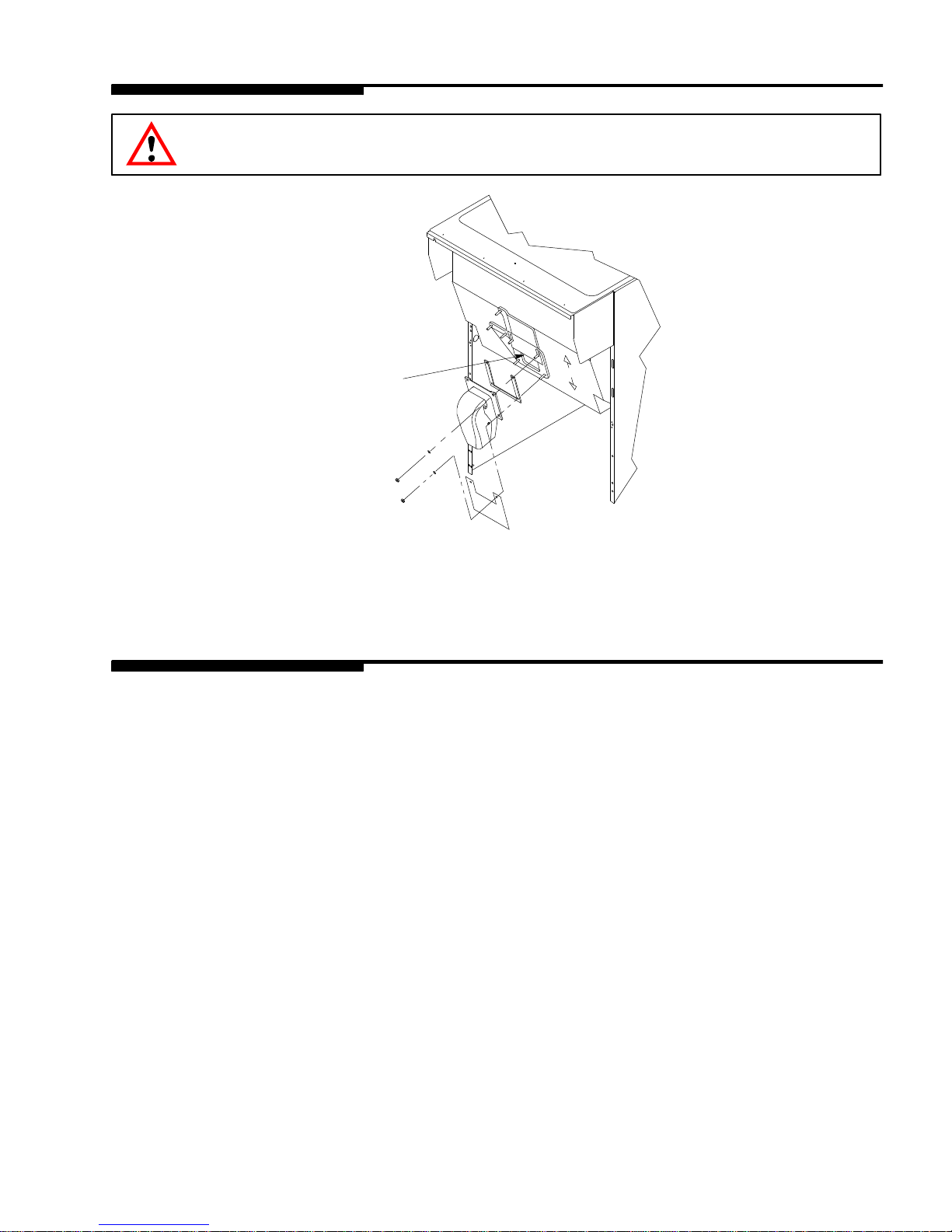

GATERESTRICTORPLATE5............................................

ADJUSTMENT5........................................................

MAINTENANCE9...........................................................

DAILY(ORAS REQUIRED)9.............................................

WEEKLY(ORAS REQUIRED)9..........................................

MONTHLY9............................................................

START-UP AND OPERATINGINSTRUCTIONS9...........................

CLEANING INSTRUCTIONS9................................................

DISPENSER(ALL MODELS)9...........................................

COLDPLATE(-BCMODELS)10...........................................

BEVERAGE SYSTEM(-B,-BCMODELS)10................................

TROUBLESHOOTING GUIDE12...............................................

BLOWNFUSE OR CIRCUITBREAKER12..................................

GATEDOES NOTOPEN.12...............................................

GATEDOES NOTOPENORIS SLUGGISH.AGITATORTURNS.12...........

GATEOPENS.AGITATOR DOES NOT TURN.12............................

ICEDISPENSES CONTINUOUSLY.12......................................

SLUSHYICE.WATERIN HOPPER.12......................................

BEVERAGES DONOTDISPENSE 12......................................

BEVERAGES TOO SWEET.12............................................

BEVERAGES NOTSWEETENOUGH.12...................................

BEVERAGES NOTCOLD(UNITSWITHBUILT-IN COLDPLATE).12...........

DB150 PARTSLIST15........................................................

WARRANTY18..............................................................