6

REMKO PG-T (S-Line) SERIES

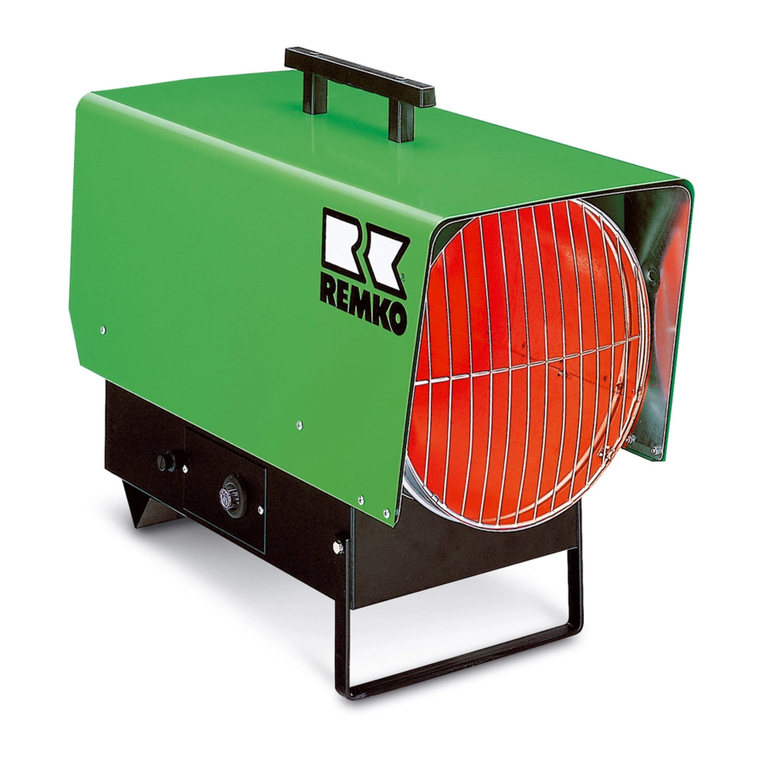

Unit description

The units are mobile fan-assisted

air heaters (WLE) directly fired

with liquid gas, without a heat

exchanger.

The units operate without an

exhaust gas connection and

are designed exclusively for

commercial use.

The units are equipped with

integrated power regulation

for the stepless control of the

heating capacity, quiet and low-

maintenance axial fans, robust

gas burners with thermal flame

monitoring, electric solenoid

valves, electric ignition, room

thermostat socket and mains cable

with earthed safety plug.

The units conform to the

fundamental health and safety

requirements of the appropriate

EU stipulations, and are simple to

operate.

The units are EC type-tested,

DVGW-registered and approved

for EU countries.

The units may be used among

other things for the following:

■

Drying newly completed

buildings

■

Spot heating of outdoor

workplaces

■

Spot heating workplaces

in open, non-flammable

manufacturing facilities and

halls

■

Temporarily heating enclosed

spaces with a sufficient fresh air

supply

■

De-icing machines, vehicles and

non-combustible warehoused

goods

■

Maintaining the temperature of

frost-sensitive parts

Operating sequence

Moving the operating switch

to the “I” position puts the

supply air fan into operation and

the program sequence for the

automatic burner is started.

After a few seconds, the electric

solenoid valve opens the gas

supply to the burner. The liquid

gas is transported through a nozzle

under pressure into the mixing

tube. Here, the gas is enriched

with a quantity of oxygen aligned

with the unit output.

The gas/air mixture is ignited

at the burner head by an

electric ignition spark. Ignition is

automatically ended as soon as

a flawless flame burns, and the

automatic burner has taken over

the flame monitoring.

Regulation of the min/max heating

capacity can be implemented on a

stepless basis during unit operation

on the integrated “power

regulation”.

Monitoring the units

It is possible to safely monitor all

functions with the safety devices

of the units.

In the event of irregularities or if

the flame is extinguished, the units

are switched off and interlocked.

Safety temperature limiter (STB)

The units are equipped with a

safety temperature limiter (STB),

which interrupts the gas supply in

case of overheating and electrically

interlocks the unit.

A manual reset of the STB can only

be implemented after the units

have cooled down.

The STB is reset by actuating the

reset key 2.

1. Unscrew the protective cap 1.

2. Push in key 2.

3. Screw the protective cap 1 back

on again.

Automatic burner

In the event of irregularities or

if the flame is extinguished, the

automatic burner switches off and

interlocks the units.

The unit's fault lamp will light up

in this case.

The automatic burner is unlocked

by pressing the malfunction

button.

The automatic burner can be

unlocked after a waiting time of

approx. 60 sec.

12

CAUTION

If the safety temperature

limiter has been triggered, the

cause of the malfunction must

be identified and rectified

before a reset is performed.

NOTE

Before resetting safety

equipment, the cause of the

malfunction must be identified

and rectified.

☞

!