Translation of the Original Instruction Manual

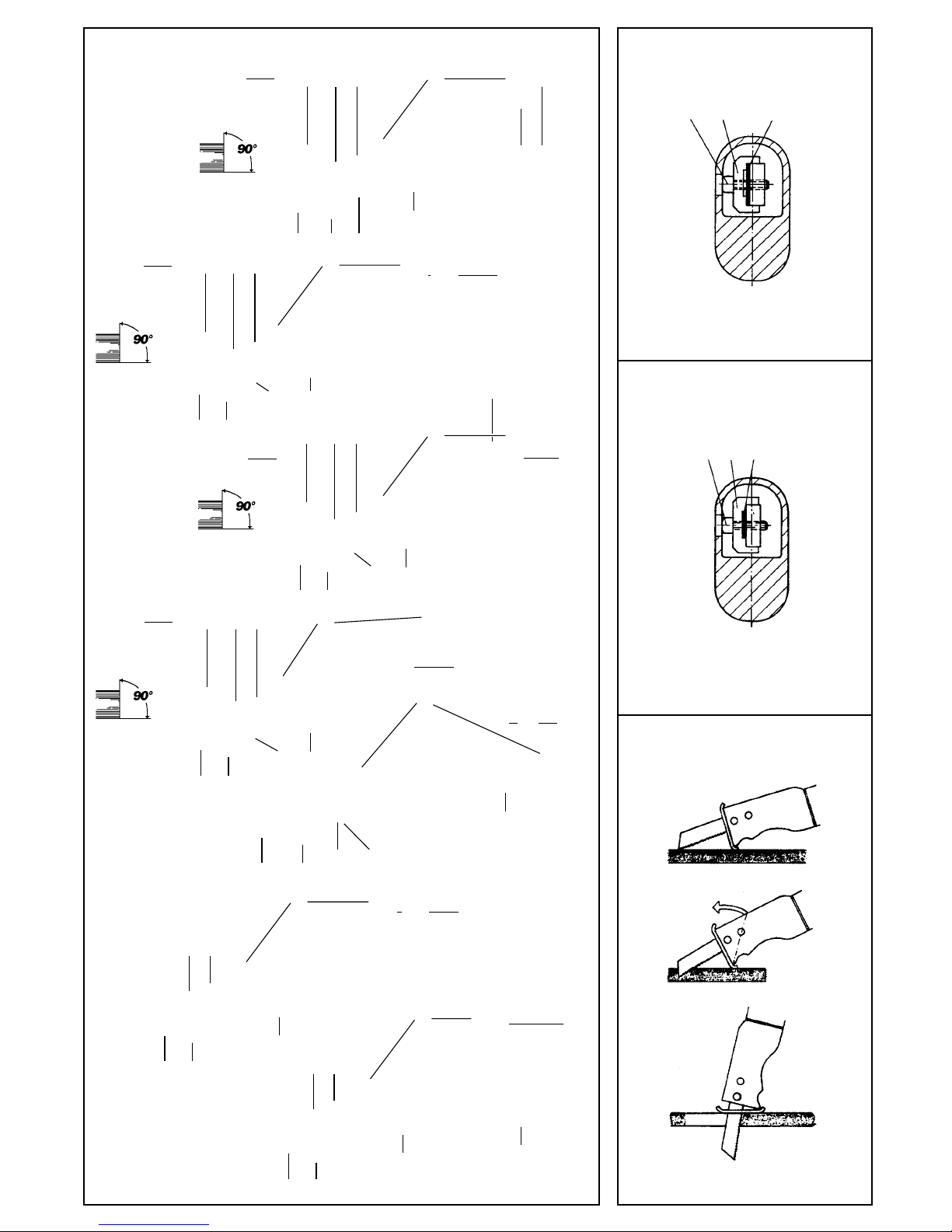

Fig. 1 – 3

1 Clamping spindle with feed screw

2 Guide holder

3 Bearing pin

4 Saw blade pressure piece

5 Saw blade

6 Tiltable support shoe (REMS Puma

VE continuously adjustable in length)

7 Safety switch on/off

8 Overload protection

(only REMS Tiger ANC)

9 Clamping screw

10 Stepless safety switch

(accelerator switch)

11 Lever with latch

12 Thumbwheel

13 Battery

14 Saw blade clamping lever (only

REMS Puma VE)

15 Holder for Allen key

16 Clamping screws

"A" Insulated handles

General Safety Warnings

WARNING

Read all safety warnings and all instructions. Failure to follow the warnings and

instructions may result in electric shock, re and/or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mains-operated (corded) power

tool or battery-operated (cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the

presence of ammable liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions

can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any way.

Do not use any adapter plugs with earthed (grounded) power tools. Unmo-

died plugs and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces, such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric shock

if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power

tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplug-

ging the power tool. Keep cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric

shock.

f) If operating a power tool in a damp location is unavoidable, use a residual

current device (RCD) protected supply. Use of an RCD reduces the risk of

electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when opera-

ting a power tool. Do not use a power tool while you are tired or under the

inuence of drugs, alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-position before

connecting to power source and/or battery pack, picking up or carrying the

tool. Carrying power tools with your nger on the switch or energising power

tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A

wrench or a key left attached to a rotating part of the power tool may result in

personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables

better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewellery or long

hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust col-

lection can reduce dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application.

The correct power tool will do the job better and safer at the rate for which it was

designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power

tool that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from

the power tool before making any adjustments, changing accessories, or

storing power tools. Such preventive safety measures reduce the risk of star-

ting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power

tool. Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired before use. Many

accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with

sharp cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in accordance with these

instructions, taking into account the working conditions and the work to

be performed. Use of the power tool for operations different from those intended

could result in a hazardous situation.

5) Battery tool use and care

a) Recharge only with the charger specied by the manufacturer. A charger

that is suitable for one type of battery pack may create a risk of re when used

with another battery pack.

b) Use power tools only with specically designated battery packs. Use of any

other battery packs may create a risk of injury and re.

c) When battery pack is not in use, keep it away from other metal objects, like

paper clips, coins, keys, nails, screws or other small metal objects, that

can make a connection from one terminal to another. Shorting the battery

terminals together may cause burns or a re.

d) Under abusive conditions, liquid may be ejected from the battery; avoid

contact. If contact accidentally occurs, ush with water. If liquid contacts

eyes, additionally seek medical help. Liquid ejected from the battery may cause

irritation or burns.

6) Service

a) Have your power tool serviced by a qualied repair person using only

identical replacement parts. This will ensure that the safety of the power tool

is maintained.

Safety instructions for REMS reciprocating saws

WARNING

Read all safety warnings and all instructions. Failure to follow the warnings and

instructions may result in electric shock, re and/or serious injury.

Save all warnings and instructions for future reference.

●

Hold the power tool by the insulated handles ("A") when performing work

where the tool can come into contact with concealed electric cables or its

own power cable. Contact with a live cable can also put metal tools under voltage

and lead to electric shock.

●

Hold the power tool tightly with both hands when working and make sure

you have a rm footing. The power tool can be controlled more safety with two

hands.

●

Use personal safety equipment, e.g. protective glasses. Hot chips y off to

all sides when sawing. Keep other persons away.

●

Please note that health hazardous dusts could be produced when sawing.

Use suitable dust extractors, a respirator and disposable overalls if necessary.

Observe the national regulations.

●

Use suitable nders to locate concealed supply lines or consult the local

supply company. Contact with electric cables can cause res and electric shock.

Damage to a gas pipe can cause explosions. Penetration of a water pipe can

cause property damage or electric shock.

●

Make sure when sawing pipes carrying water that no leaking water can get

into the motor. There is a danger of electric shock.

●

Clamp the material tightly. Do not support the workpiece with your hand

or foot. There is a danger of injury.

●

Secure the workpiece. It is safer to hold the workpiece with a clamping device

or vice than with your hand.

●

Do not touch any objects or the ground with the running saw. There is a

danger of recoil.

●

Keep your hands away from the sawing area. Do not reach underneath the

workpiece. Contact with the saw blade can cause injury

●

Keep highly inammable materials away from hot sawing chips during

sawing. There is a danger of re!

●

Make sure that the tiltable support shoe (6) is always in contact with the

workpiece when sawing. The saw blade can jam and lead to loss of control

over the power tool.

●

When you have nished the work, switch off the power tool and do not

remove the saw blade from the cut until it has come to a standstill. This

avoids recoil and allows you to put down the power tool safely.

●

Only use undamaged, awless saw blades. Bent or blunt saw blades can

break or cause recoil.

●

Do not slow down the saw blade after switching off by pressing against

the side. The saw blade could be damaged, break or cause recoil.

●

Wait until the power tool has come to a standstill before you put it down.

The inserted tool can jam and lead to loss of control over the power tool.

●

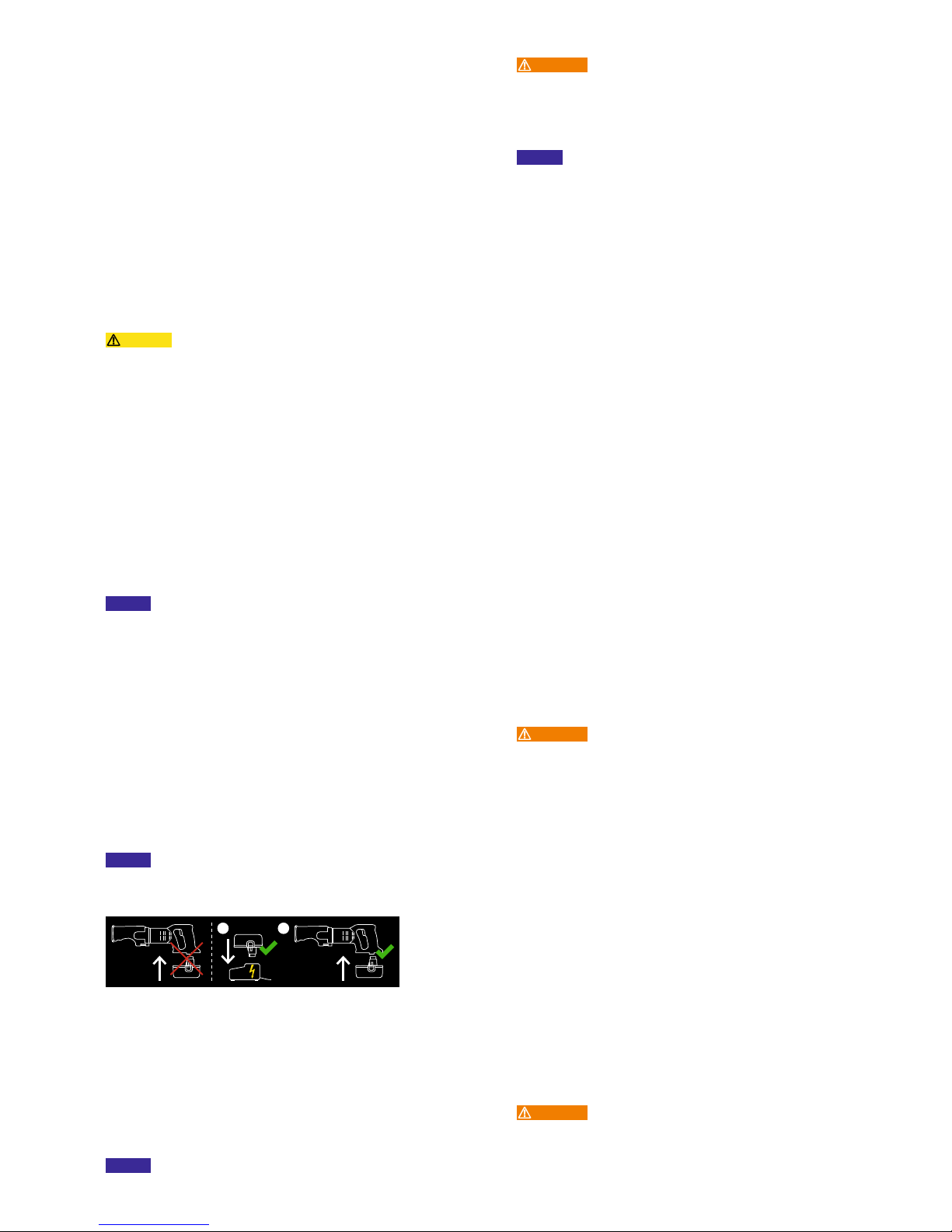

Pull out the mains plug or remove the battery before attaching/detaching

the saw blade. There is a danger of injury.

●

Pull out the mains plug or remove the battery before adjusting the support

shoe. There is a danger of injury.

●

Children and persons who, due to their physical, sensory or mental abilities

or lack of experience and knowledge are unable to operate the power tool

safely may not use this power tool without supervision or instruction by a

responsible person. Otherwise there is a risk of operating errors and injuries.

●

Only allow trained persons to use the power tool. Apprentices may only use

the power tool when they are over 16, when this is necessary for their training

and when they are supervised by a trained operative.

eng eng

Translation of the Original Instruction Manual

Fig. 1 – 3

1 Clamping spindle with feed screw

2 Guide holder

3 Bearing pin

4 Saw blade pressure piece

5 Saw blade

6 Tiltable support shoe (REMS Puma

VE continuously adjustable in length)

7 Safety switch on/off

8 Overload protection

(only REMS Tiger ANC)

9 Clamping screw

10 Stepless safety switch

(accelerator switch)

11 Lever with latch

12 Thumbwheel

13 Battery

14 Saw blade clamping lever (only

REMS Puma VE)

15 Holder for Allen key

16 Clamping screws

"A" Insulated handles

General Safety Warnings

WARNING

Read all safety warnings and all instructions. Failure to follow the warnings and

instructions may result in electric shock, re and/or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mains-operated (corded) power

tool or battery-operated (cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the

presence of ammable liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions

can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any way.

Do not use any adapter plugs with earthed (grounded) power tools. Unmo-

died plugs and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces, such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric shock

if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power

tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplug-

ging the power tool. Keep cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric

shock.

f) If operating a power tool in a damp location is unavoidable, use a residual

current device (RCD) protected supply. Use of an RCD reduces the risk of

electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when opera-

ting a power tool. Do not use a power tool while you are tired or under the

inuence of drugs, alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-position before

connecting to power source and/or battery pack, picking up or carrying the

tool. Carrying power tools with your nger on the switch or energising power

tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A

wrench or a key left attached to a rotating part of the power tool may result in

personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables

better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewellery or long

hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust col-

lection can reduce dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application.

The correct power tool will do the job better and safer at the rate for which it was

designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power

tool that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from

the power tool before making any adjustments, changing accessories, or

storing power tools. Such preventive safety measures reduce the risk of star-

ting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power

tool. Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired before use. Many

accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with

sharp cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in accordance with these

instructions, taking into account the working conditions and the work to

be performed. Use of the power tool for operations different from those intended

could result in a hazardous situation.

5) Battery tool use and care

a) Recharge only with the charger specied by the manufacturer. A charger

that is suitable for one type of battery pack may create a risk of re when used

with another battery pack.

b) Use power tools only with specically designated battery packs. Use of any

other battery packs may create a risk of injury and re.

c) When battery pack is not in use, keep it away from other metal objects, like

paper clips, coins, keys, nails, screws or other small metal objects, that

can make a connection from one terminal to another. Shorting the battery

terminals together may cause burns or a re.

d) Under abusive conditions, liquid may be ejected from the battery; avoid

contact. If contact accidentally occurs, ush with water. If liquid contacts

eyes, additionally seek medical help. Liquid ejected from the battery may cause

irritation or burns.

6) Service

a) Have your power tool serviced by a qualied repair person using only

identical replacement parts. This will ensure that the safety of the power tool

is maintained.

Safety instructions for REMS reciprocating saws

WARNING

Read all safety warnings and all instructions. Failure to follow the warnings and

instructions may result in electric shock, re and/or serious injury.

Save all warnings and instructions for future reference.

●

Hold the power tool by the insulated handles ("A") when performing work

where the tool can come into contact with concealed electric cables or its

own power cable. Contact with a live cable can also put metal tools under voltage

and lead to electric shock.

●

Hold the power tool tightly with both hands when working and make sure

you have a rm footing. The power tool can be controlled more safety with two

hands.

●

Use personal safety equipment, e.g. protective glasses. Hot chips y off to

all sides when sawing. Keep other persons away.

●

Please note that health hazardous dusts could be produced when sawing.

Use suitable dust extractors, a respirator and disposable overalls if necessary.

Observe the national regulations.

●

Use suitable nders to locate concealed supply lines or consult the local

supply company. Contact with electric cables can cause res and electric shock.

Damage to a gas pipe can cause explosions. Penetration of a water pipe can

cause property damage or electric shock.

●

Make sure when sawing pipes carrying water that no leaking water can get

into the motor. There is a danger of electric shock.

●

Clamp the material tightly. Do not support the workpiece with your hand

or foot. There is a danger of injury.

●

Secure the workpiece. It is safer to hold the workpiece with a clamping device

or vice than with your hand.

●

Do not touch any objects or the ground with the running saw. There is a

danger of recoil.

●

Keep your hands away from the sawing area. Do not reach underneath the

workpiece. Contact with the saw blade can cause injury

●

Keep highly inammable materials away from hot sawing chips during

sawing. There is a danger of re!

●

Make sure that the tiltable support shoe (6) is always in contact with the

workpiece when sawing. The saw blade can jam and lead to loss of control

over the power tool.

●

When you have nished the work, switch off the power tool and do not

remove the saw blade from the cut until it has come to a standstill. This

avoids recoil and allows you to put down the power tool safely.

●

Only use undamaged, awless saw blades. Bent or blunt saw blades can

break or cause recoil.

●

Do not slow down the saw blade after switching off by pressing against

the side. The saw blade could be damaged, break or cause recoil.

●

Wait until the power tool has come to a standstill before you put it down.

The inserted tool can jam and lead to loss of control over the power tool.

●

Pull out the mains plug or remove the battery before attaching/detaching

the saw blade. There is a danger of injury.

●

Pull out the mains plug or remove the battery before adjusting the support

shoe. There is a danger of injury.

●

Children and persons who, due to their physical, sensory or mental abilities

or lack of experience and knowledge are unable to operate the power tool

safely may not use this power tool without supervision or instruction by a

responsible person. Otherwise there is a risk of operating errors and injuries.

●

Only allow trained persons to use the power tool. Apprentices may only use

the power tool when they are over 16, when this is necessary for their training

and when they are supervised by a trained operative.