R

888 Porter Rd. Muskegon, MI 9 1 Phone: 231.798.8888 Fax: 231.798. 960 www.structuralconcepts.com

START-UP AND OPERATION

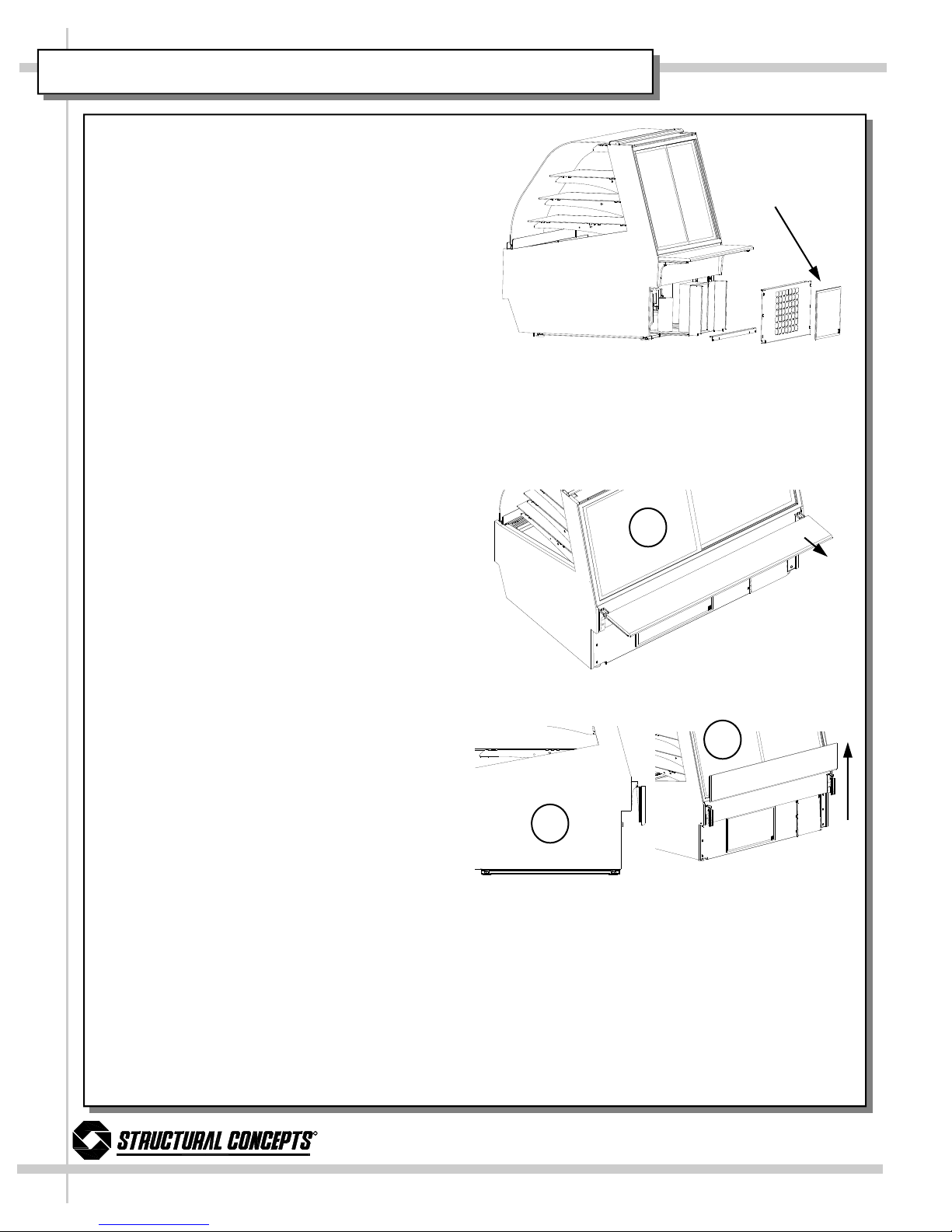

Raise the Curved Glass

• To raise the front curved glass, grab the lift

handle extrusion on the bottom edge of the

front curved glass and lift up.

• Gas cylinders hold the glass open for hands

free access to the interior of the case.

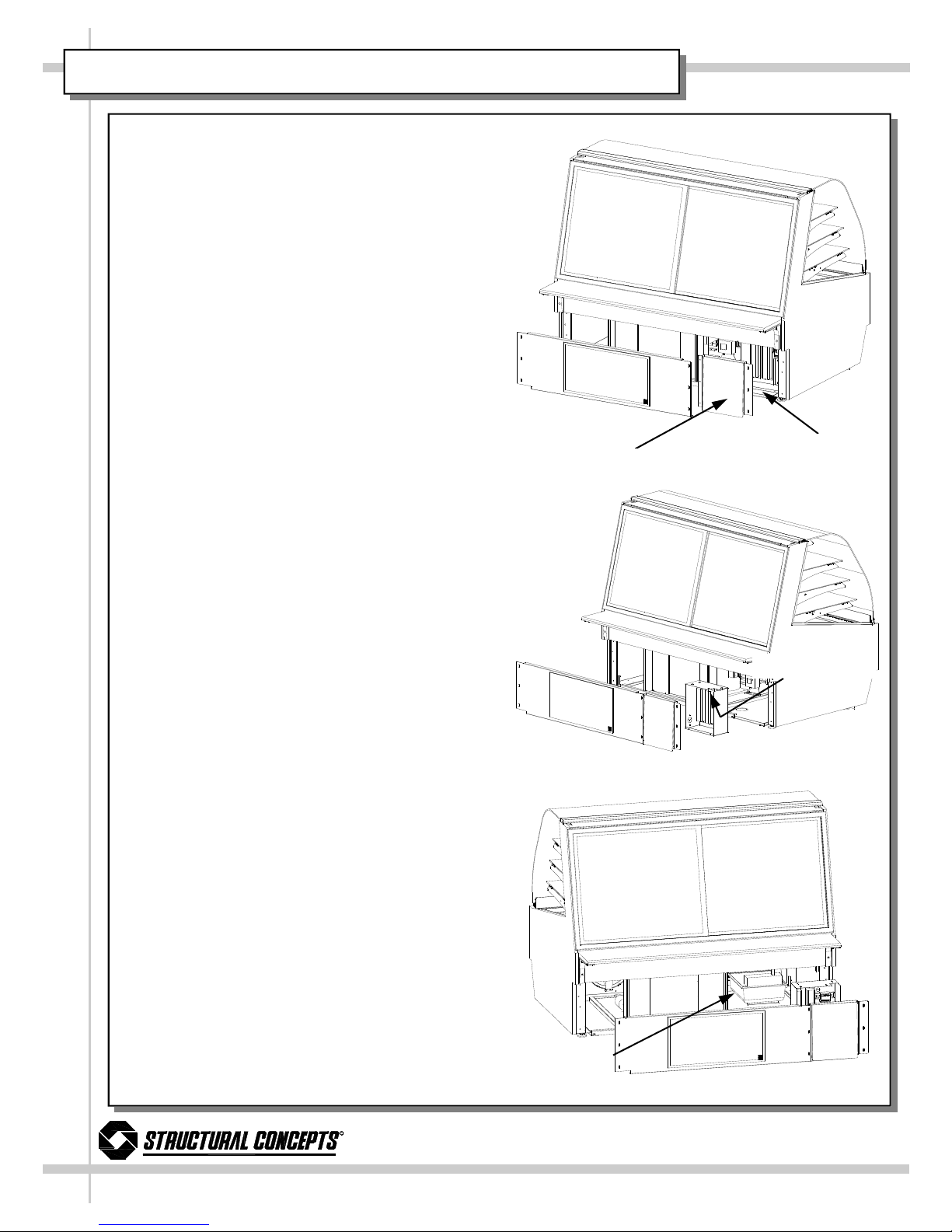

Merchandiser Start-Up

• Turn on the main power. Switch is on the

control panel at the rear right hand side of

base. Supply power will start evaporator coil

fan(s), the front fan and the evaporator/

condensate pan. It will supply power to the

light switch and thermostat, (self-contained

units).

• From the front of the case, raise the deck

pans and check to see that the coil fans are

all functioning properly.

• On the top of the front panel a register di-

rects air flow provided by the front fans,

(front air flow is to prevent condensation

from forming on the curved glass). Check

across the top of the front panel to see if air

is discharging across the entire front of the

case.

• Turn on the lights. Light switch is in the rear

control panel. First time lighting may require

a short warm up period for the bulbs. Slightly

dim or a flickering of new bulbs is normal. If

lights do not turn on, check all of the race-

way plugs. The lighting is wired in series so

all lights must be plugged in or recepta-

cles capped in order for the case to light.

Temperature Settings

The case temperature is set at the factory, as

determined by the case size. The temperature is

controlled by a thermostat. If a temperature

setting change is required, follow the Johnson

Control Quick Reference page 14 of this man-

ual

5

Main Power

Thermostat

Lights

Lift Handle

Front Curved Glass

Deck Pan

Coil Fan

Front Fan

Register