INSTALLATION INSTRUCTIONS

R4184D; R8184G,M,N,P

Protectorelay® Oil Primary Controls

APPLICATION

The intermittent ignition R4184D and R8184G,M,N,P Oil

Primary Controls operate the oil burner, oil valve (if

desired) and the ignition transformer in response to a

call for heat from the thermostat.

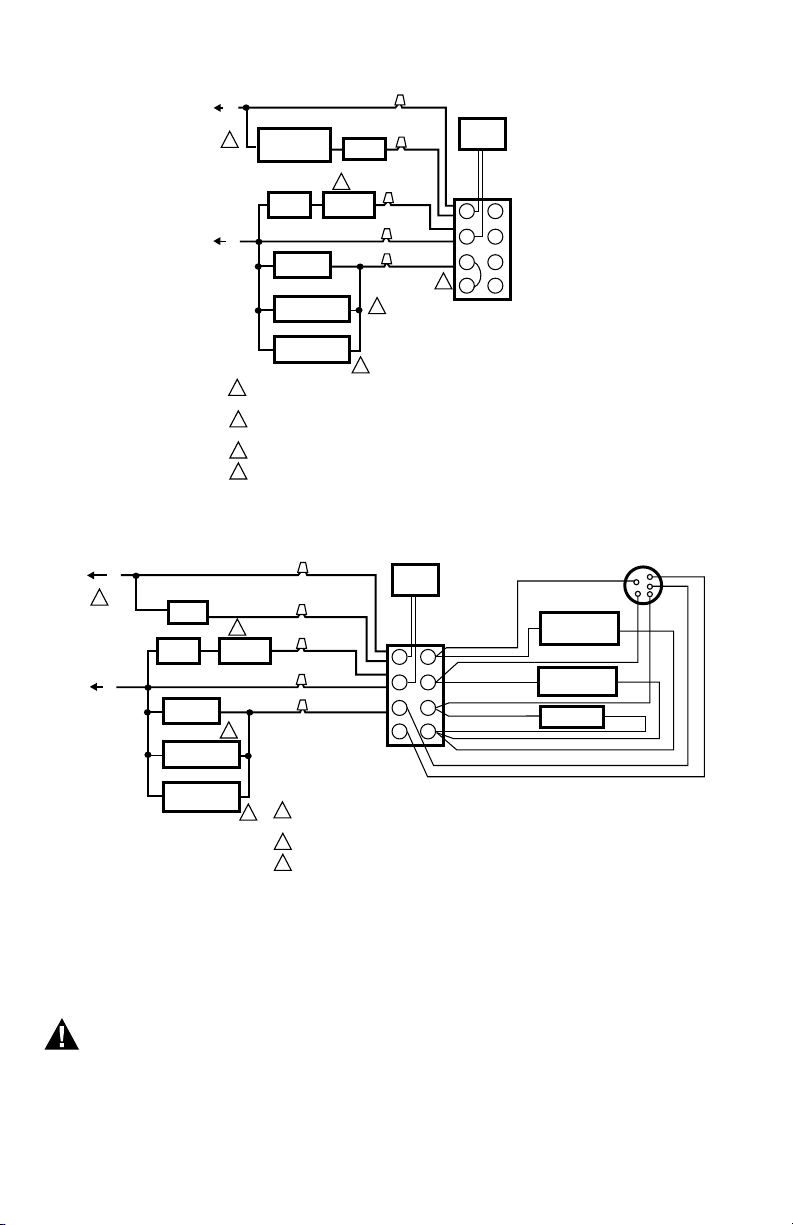

The R8184M also provides automatic, nonrecycling

control of cooling systems and low voltage thermostat.

The R8184P provides 15-second valve on delay and

selectable 0-, 2-, 4-, 6-minute blower off delay for

hydronic and warm air systems. Select models have 30-

minute blower off delay timing.

All models use the C554A Cadmium Sulfide (cad cell)

Flame Detector to monitor the burner flame and shut

down the system on ignition failure or on flame failure

during the run cycle. A manual reset button is provided

to reset the safety switch after lockout. Clock

thermostats (not available on R8184P) that power the

clock through the primary control transformer lose time

during lockout unless backup batteries are installed.

All models (except the R8184G1310 and R8184G1328)

are Underwriters Laboratories Inc. component

recognized and meet flammability test requirements for

a final enclosure.

NOTE: R8184P is intended for use on oil burning appli-

ances that do not require a safety rated pre-

purge and postpurge function as defined in UL

296. The valve on delay and blower off delay in

this control are only intended to help establish

draft and reduce oil after drip-related problems.

INSTALLATION

When Installing This Product…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a haz-

ardous condition.

2. Check the ratings given in these instructions to

make sure the integrated furnace control is suit-

able for your application.

3. Installer must be a trained, experienced service

technician.

4. After completing the installation, use these

instructions to check out the product operation.

1. Disconnect the power supply before beginning

installation to prevent electrical shock or

equipment damage.

2. Be sure the combustion chamber is free of oil

or oil vapor before starting the system.

Location

1. Mount on a 4 x 4 junction box, directly on the main

burner housing or inside the appliance cabinet.

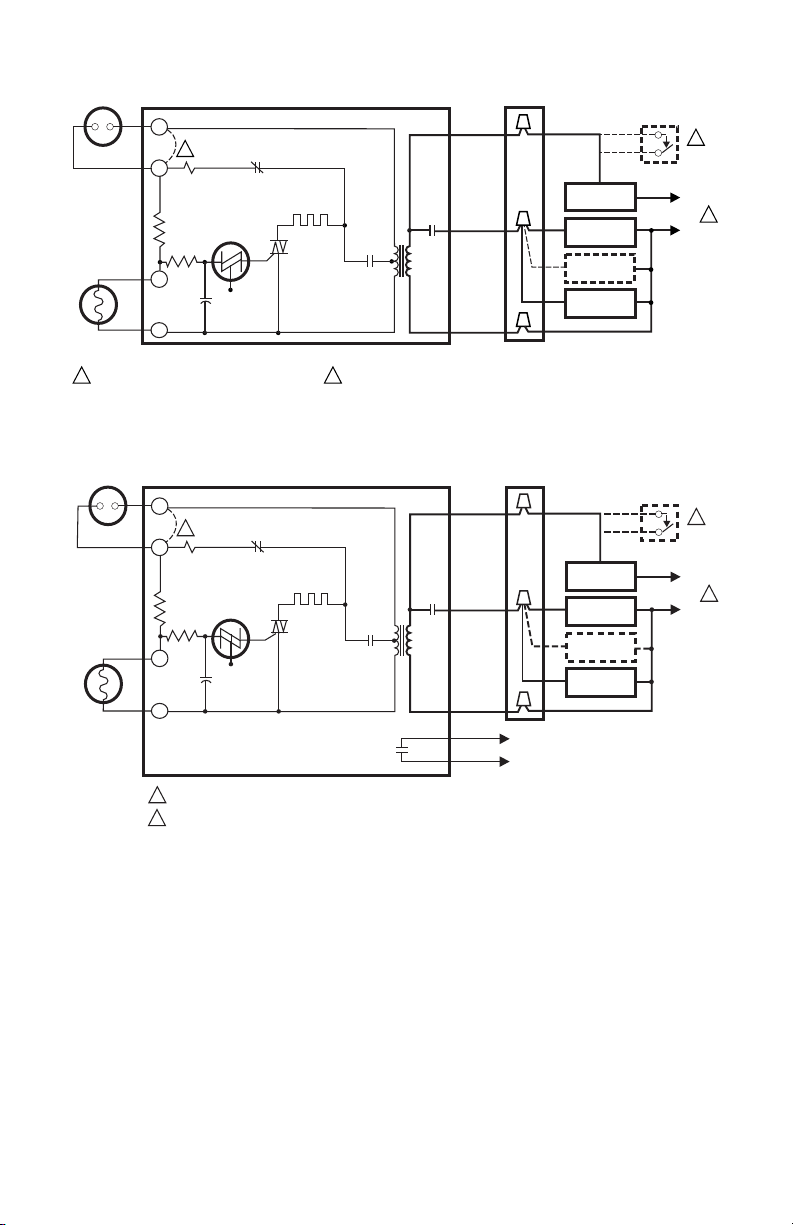

See Fig. 1.

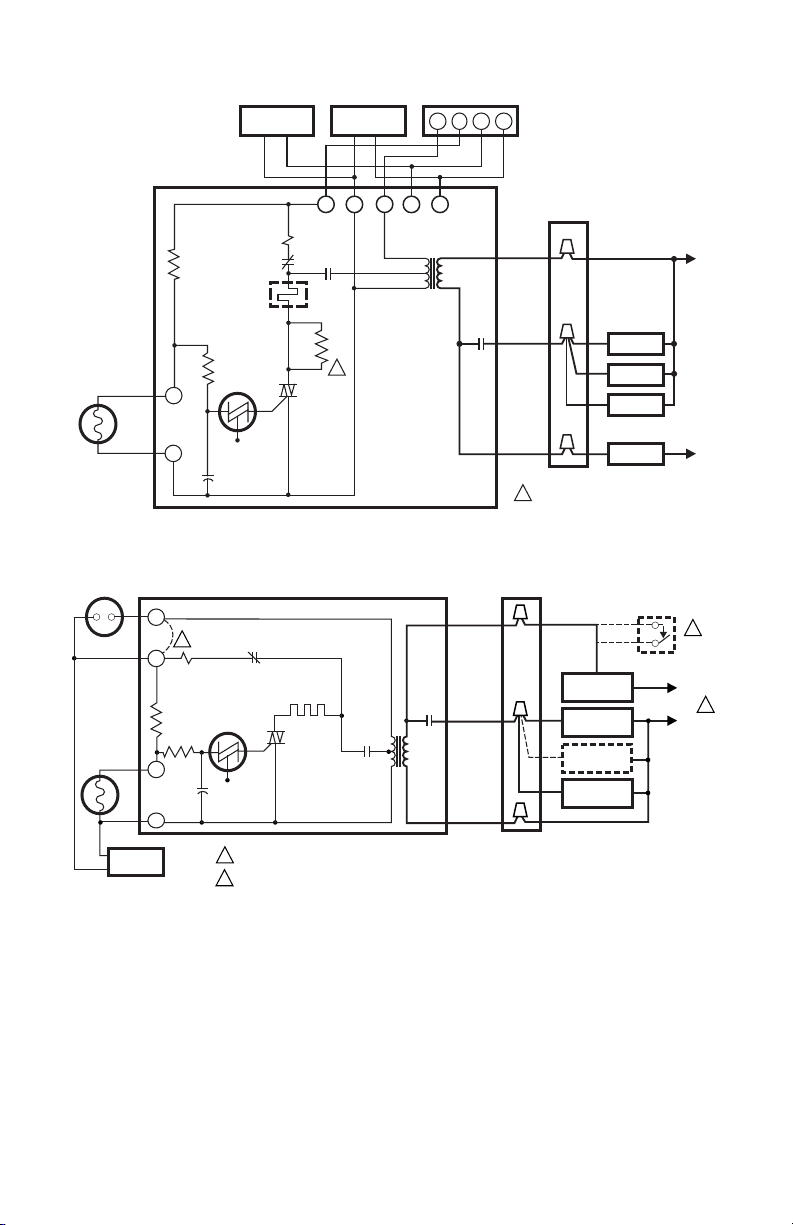

2. Be sure that operating temperatures are between

-40°F and +130°F (-40°C and +54°C). Select

R8184G,P models have a maximum temperature

of 150°F (66°C), but must be mounted parallel to

the ground to achieve 150°F (66°C). See Fig. 2.

Fig. 1. Wire and mount 130°F (54°C) maximum ambient

temperature oil primary control.

CAD

CELL LEADS

LINE

VOLTAGE LEADS MOUNTING

SCREW HOLE

RED RESET

BUTTON

4 x 4 JUNCTION

BOX

HOLE OR KNOCKOUT FOR

CAD CELL LEADS

LOW VOLTAGE

TERMINAL STRIP

1STRIP WIRES 3/8 in. (9.5 mm); INSERT FROM SIDE, ABOVE OR BELOW.

T-T TERMINALS ON R8184G; T1-T2 TERMINALS ON R8184N.

1

2

2

M1643D