9

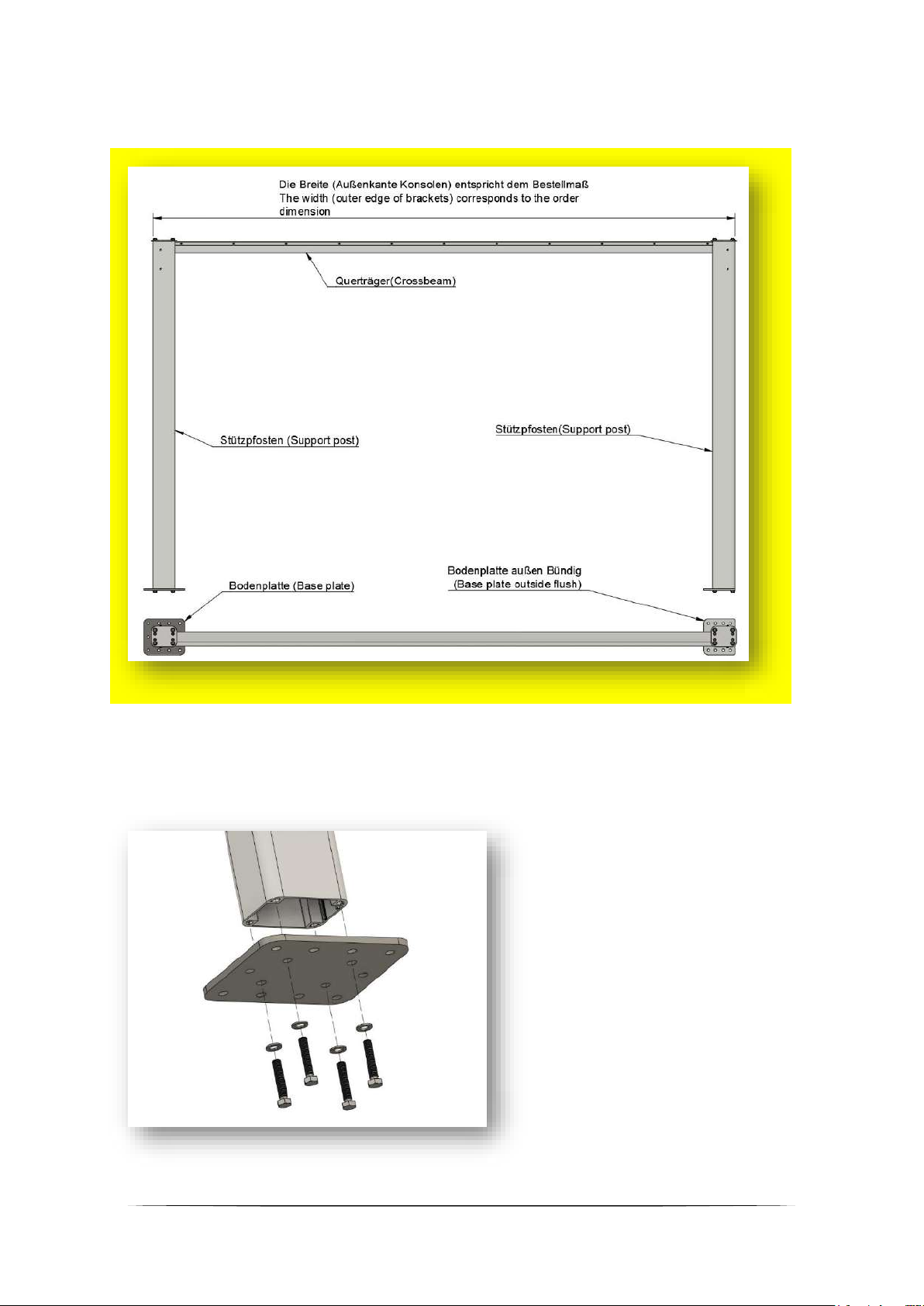

3.2 After aligning the balancers, drill the holes (4 per balancer) into the foundations (size at least

80x60x80cm HxWxD).

3.3 Recommended assembly with injection mortar and M12 threaded rods. (like point 2.6). After the

mortar has hardened, place a threaded nut on each of the threaded rods to adjust the balancer in all

directions.

3.4 Plumb the balancers using the nuts under the balancers.

3.5 Tighten all screws.

3.6 The balancer boxes are either completely covered or delivered without a cover, depending on the

order.

Make sure that the balancers should be accessible at all times in order to be able to carry out any

repairs or maintenance. If the cladding is installed on site, it must be possible to open it at any time.

Do not loosen any screws on the cable drum or try to open it. The balancers are already pretensioned

when delivered. There is a high risk of injury if handled incorrectly.

4. Extending and hanging in the awning sail

The end positions should be set with the balancer boxes open so that the steel cable on the

drum can be observed at all times during the setting phase.

4.1 The end points on the motor are not yet programmed into the awning sail. The end positions are

only programmed after the sail has been attached.

4.2 Extend the awning sail far enough to hook the carabiners into the rope eyelet of the balancer post.

Never loosen the clamp stone before retracting the awning sail !!!

4.3 Retract the awning sail until the clamp stone on the steel cable of the balancer post is approx. 10-

20cm away from the post and stop the awning sail.

Danger! The octagonal plate can fall down after retracting the awning sail. Remove/hold immediately

after retraction.