Table of Contents

1Notes on the manual............................................................................................................................. 5

1.1 Explanations of the Safety Instructions ............................................................................................. 5

1.2 General Safety Instructions ............................................................................................................... 6

1.3 Repairs............................................................................................................................................... 7

1.4 Confirmation Form for the Managing Operator.................................................................................. 7

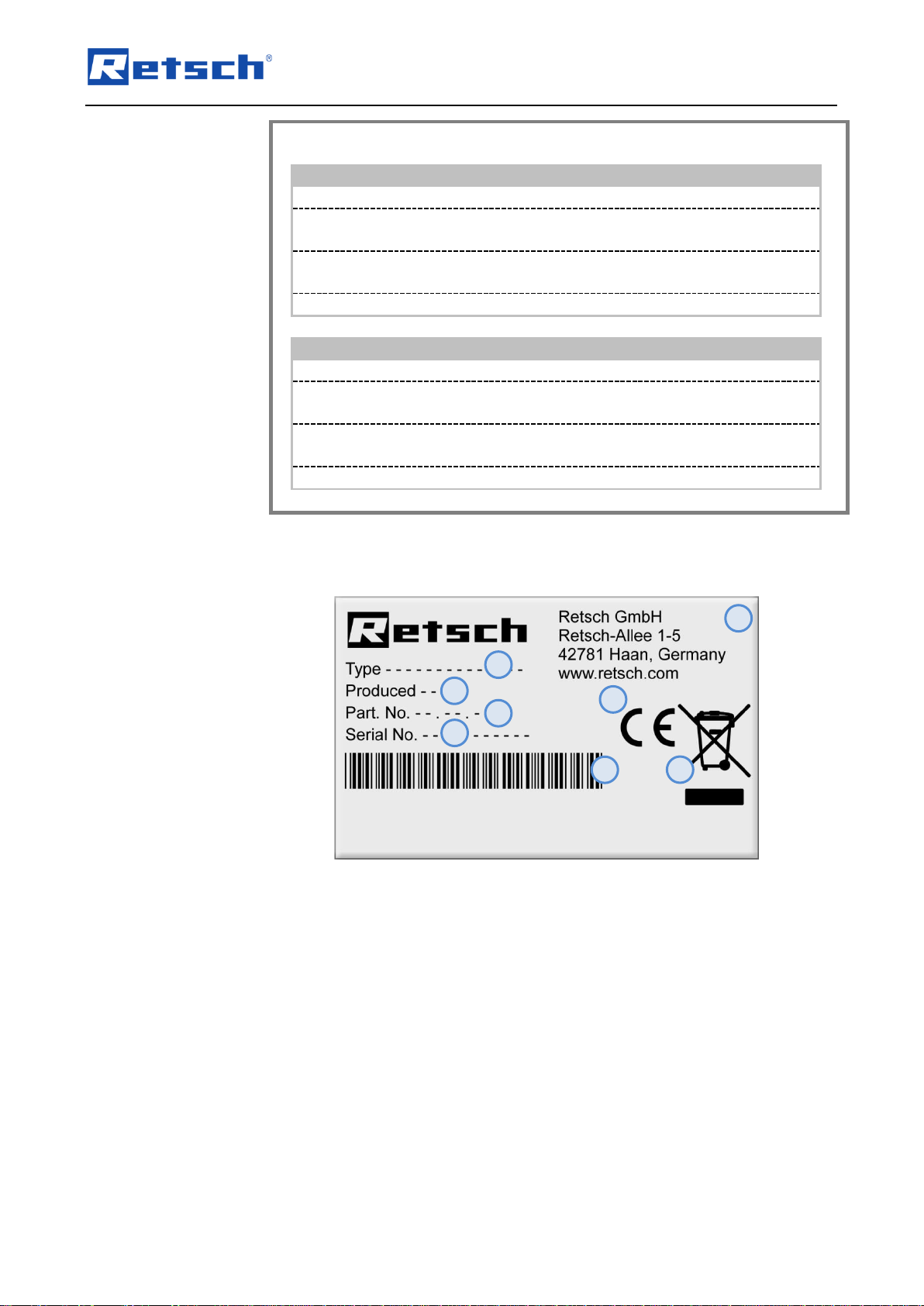

1.5 Type Plate Description....................................................................................................................... 8

2Safety and occupational health instructions...................................................................................... 9

2.1 General.............................................................................................................................................. 9

2.2 Safety instructions on the handling of liquid nitrogen...................................................................... 10

2.3 Safety instructions on the handling of liquid nitrogen (Oxygen deficiency)..................................... 10

2.3.1 Dangers ....................................................................................................................................... 10

2.3.2 Causes......................................................................................................................................... 10

2.3.3 Recommendations....................................................................................................................... 10

2.3.4 General conduct in the case of an accident ................................................................................ 11

2.4 Safety instructions on the handling of liquid nitrogen (Cryogenic burns) ........................................ 11

2.4.1 Dangers ....................................................................................................................................... 11

2.4.2 Causes......................................................................................................................................... 11

2.4.2.1 Burns through splashes....................................................................................................... 11

2.4.2.2 Burns through contact.......................................................................................................... 11

2.4.3 Recommendations....................................................................................................................... 11

2.4.4 General rules of conduct for splashes with liquid nitrogen.......................................................... 12

2.4.4.1 To the eyes.......................................................................................................................... 12

2.4.4.2 On the skin........................................................................................................................... 12

2.5 Danger of explosion......................................................................................................................... 12

2.5.1 Dangers ....................................................................................................................................... 12

2.5.2 Causes......................................................................................................................................... 12

2.5.3 Recommendations....................................................................................................................... 12

2.5.4 General conduct in the case of an accident ................................................................................ 12

2.6 Oxygen enrichment.......................................................................................................................... 13

2.6.1 Dangers ....................................................................................................................................... 13

2.6.2 Causes......................................................................................................................................... 13

2.6.3 Recommendations....................................................................................................................... 13

2.7 Surrounding area of the machine .................................................................................................... 13

2.7.1 Rooms.......................................................................................................................................... 13

3Operating the Device .......................................................................................................................... 14

3.1 Views of the device.......................................................................................................................... 14

3.2 Overview table of the parts of the device ........................................................................................ 15

3.3 Technical Data................................................................................................................................. 16

3.4 Vacuum closure and safety device.................................................................................................. 16

3.5 Level Display ................................................................................................................................... 17

3.6 Filling the vessel .............................................................................................................................. 19

3.7 Pressure build-up............................................................................................................................. 20

3.8 Withdrawal of liquid nitrogen............................................................................................................ 20

3.9 Pressure relief.................................................................................................................................. 20

3.10 Transport.......................................................................................................................................... 20

3.11 Maintenance .................................................................................................................................... 21

3.12 Admitting the test pressure.............................................................................................................. 22

3.13 Checking the seat tightness............................................................................................................. 22

3.14 Checking the response pressure..................................................................................................... 22

4Index ..................................................................................................................................................... 23