REV Robotics REV-31-1595 User manual

Control Hub Guide © REV Robotics, LLC 2020 1

fg

CONTROL HUB

USER'S MANUAL

Control Hub Guide © REV Robotics, LLC 2020 2

TABLE OF CONTENTS

1OVERVIEW............................................................................................................................................................................... 3

1.1 Control Hub Basics........................................................................................................................................................ 3

1.2 Port Pin Outs .................................................................................................................................................................. 4

1.3 Protection Features ....................................................................................................................................................... 5

1.4 Cables and Connectors ................................................................................................................................................. 5

1.4.1 XT30 –Power Cable.................................................................................................................................................. 5

1.4.2 JST VH –Motor Power ............................................................................................................................................. 6

1.4.3 JST PH –Sensors and RS485 .................................................................................................................................. 7

2QUICK START.......................................................................................................................................................................... 9

2.1 Required Materials......................................................................................................................................................... 9

2.2 System Wiring Diagram............................................................................................................................................... 10

2.3 Driver Station and Robot Controller Pairing ............................................................................................................... 10

2.4 Robot Configuration .................................................................................................................................................... 16

2.5 Adding an Additional Expansion Hub ......................................................................................................................... 20

2.6 Switching WiFi Channels............................................................................................................................................. 23

2.7 Updating Control Hub Operating System ................................................................................................................... 25

2.8 WiFi Reset .................................................................................................................................................................... 27

2.9 LED Blink Codes........................................................................................................................................................... 28

3INTEGRATED SENSORS ....................................................................................................................................................... 29

4LEGACY SENSOR SUPPORT ................................................................................................................................................ 29

4.1 Logic Level Converter .................................................................................................................................................. 29

4.2 Connnecting a 5V Motor Encoder............................................................................................................................... 30

4.3 Connecting a 5V Sensor .............................................................................................................................................. 30

4.4 Sensor Compatability Chart ........................................................................................................................................ 31

5DIMENSIONS......................................................................................................................................................................... 34

5.1 IMU Location................................................................................................................................................................ 35

5.2 WiFi Radio Antenna ..................................................................................................................................................... 35

Control Hub Guide © REV Robotics, LLC 2020 3

1OVERVIEW

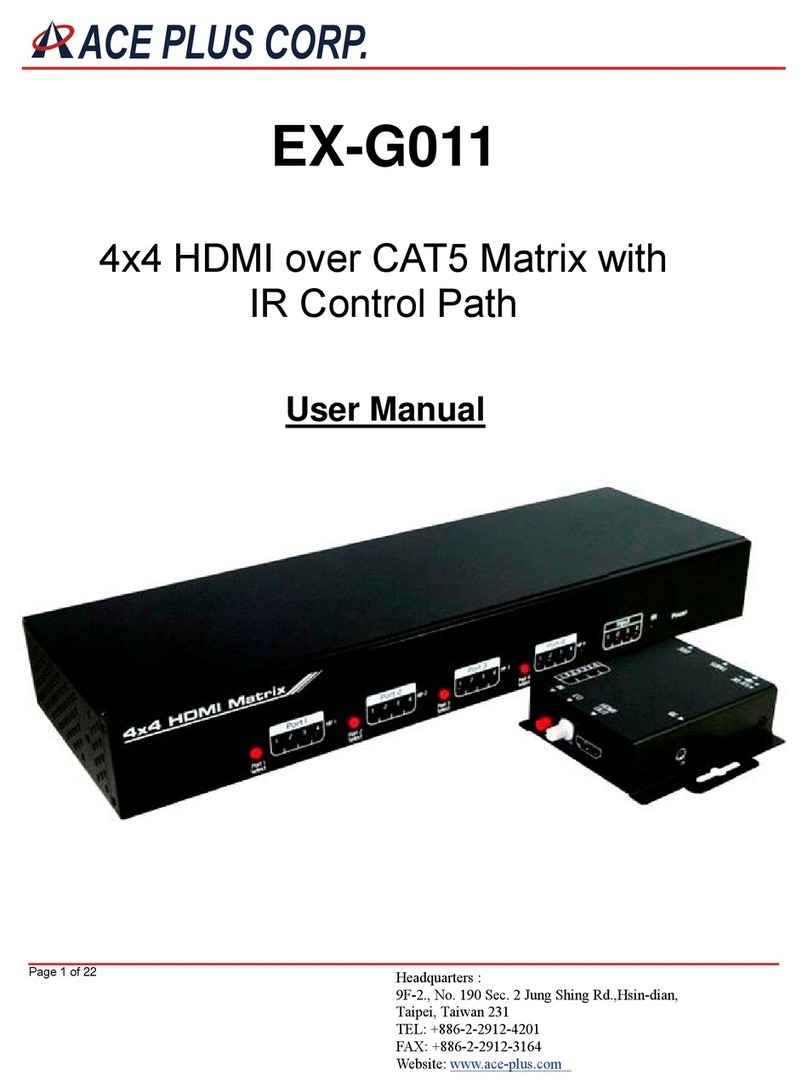

1.1 Control Hub Basics

The REV Robotics Control Hub is an affordable all in one educational robotics controller that provides the interfaces

required for building robots, as well as other mechatronics, with multiple programming language options. The Control Hub

was designed and built as an easy to use, dependable, and durable device for use in classroom and the competition. It

features an Android operating system, and a mature software package designed for both basic and advanced use cases.

When the Control Hub software is updated with performance enhancements and features, the controller can receive a

"field upgrade," through an update process that is fast and simple.

The Control Hub is an approved device for use in FIRST® Global and FIRST Tech Challenge.

•Physical Dimensions

o143mm X 103mm X 29.5 mm

oMounting holes on a 16mm spacing

•Input Voltage:

o12V Nominal (8-15VDC)

•Processors

oRK3328 Quad-core ARM® Cortex-A53

oTexas Instruments ARM® Cortex-M4

•3.3V Ports

o8x Digital I/O: 1A Source Max

o4x I2C 100kHz/400kHz Busses:

500mA Max

o4x 12-bit Analog Inputs: 500mA Max

o4x Quadrature Encoder Inputs:

500mA Max

•5V Ports

o5V Aux Power: 2A Max

oServos: 2A Maximum per Pair

oUSB 2.0: 1.5A Max

PORT

QTY

CONNECTOR

DESCRIPTION

Battery

2

XT30

Connect one 12V NiMh battery, add an Expansion Hub with second port

Motor

4

JST VH, 2-pin

Motor power output

Encoder

4

JST PH, 4-pin

Quadrature encoder input

Servo

6

0.1” Header

Extended range 5V servo output (500-2500ms)

5V Aux Power

2

0.1” Header

Auxiliary device 5V/2A

Analog

4

JST PH, 4-pin

Analog input 0-3.3V with two channels per connector

Digital

8

JST PH, 4-pin

Digital Input/Output with two channels per connector

I2C

4

JST PH, 4-pin

Four separate I2C busses, 400kHz bus speed

RS485

2

JST PH, 3-pin

Use this serial communication port to add another Expansion Hub

UART

2

JST PH, 3-pin

Debugging only

USB

1

C Type

Connect directly to the Control Hub via PC

USB

2

A Type

Connect USB Cameras and other USB peripherals to the Control Hub

HDMI

1

A Type

Supports 4k @ 60Hz

Control Hub Guide © REV Robotics, LLC 2020 4

1.2 Port Pin Outs

Control Hub Guide © REV Robotics, LLC 2020 5

1.3 Protection Features

•Reverse Battery Input Protection

•ESD Protection on all Connections

•Overcurrent PTC Protection

oDigital I/O Bus

oI2C Bus

oAnalog Bus

oUSB

oServos per Channel Pair

oEncoder Bus

•Over Current Monitoring for individual Motor Channels

•Keyed and Locking Connectors

•Failsafe Mode at Communication Loss

1.4 Cables and Connectors

The REV Robotics Control Hub connector selection provides a robust high-density solution for the user. All connectors

are keyed and locking except for the Servo, 5V auxiliary power, HDMI, and USB ports.

1.4.1 XT30 –Power Cable

The XT30 connector is used for connecting a battery and powering a Control Hub. Each Control Hub has both a Male and

Female XT30 connector. The male connector is the power in for the Control Hub while the female connector is power out

to power a connected secondary device, like an Expansion Hub, from a single battery source.

Most teams will want to use premade cables which can be sourced from the REV Robotics website directly (Table 1) for

convenience, but teams can also make their own cables. These connectors are solder cup style and do not require any

crimping tools; connectors are available from various online vendors. These connectors are an open design so they are

manufactured by a variety of sources and quality may vary. AMASS branded connectors are recommended, but there are

many other quality vendors available.

Table 1: Premade XT30 Cables and Accessories

Length

REV Robotics Part Number

XT30, Male

-

XT30, Female

30cm

REV-31-1392

XT30, Male

-

XT30, Female

50cm

REV-31-1393

XT30, Female

-

Tamiya

8cm

REV-31-1382

XT30, Female

-

Anderson Power Pole Style

8cm

REV-31-1385

Power Switch Cable (XT30 Male –XT30 Female)

REV-31-1387

XT30 Connector Pack –5 Pairs

-

REV-31-1399

Control Hub Guide © REV Robotics, LLC 2020 6

1.4.2 JST VH –Motor Power

Motor Power connections on the Control Hub use the JST VH style connector. This connector is keyed and locking with a

small latch (Figure 1) which must be depressed to release the cable.

Figure 1: How to Use a JST VH Cable

REV Robotics recommends in most cases that teams use pre-made cables because the quality of the crimp is better

when made using industrial tooling. These cables can be bought directly from the REV Robotics Website (Table 2) or

through other online vendors.

Table 2: Premade JST VH Cables and Accessories

Pins

Length

REV Robotics Part Number

JST VH

-

JST VH

2 pins

30cm

REV-31-1412

JST VH

-

JST VH

2 pins

50cm

REV-31-1413

JST VH

-

JST VH

2 pins

100cm

REV-31-1526

JST VH

-

Anderson Power Pole Type

2 pins

12cm

REV-31-1381

JST VH Cable Extension Board

2 pins

REV-31-1429

For teams that want to try crimping their own cables, or to find more information about the connectors, Table 3 lists the

appropriate part numbers.

Connector Specifications

•10A Continuous Current (16AWG)

•3.96mm Pitch

•Accepts 22-16AWG Wire

Table 3: JST VH Connector Part Number Reference

Manufacturer Part Number

DigiKey Part Number

Contact, JST VH, 18-22AWG

SVH-21T-P1.1

455-1133-1-ND

Contact, JST VH, 16-20AWG

SVH-41T-P1.1

455-1319-1-ND

Housing, JST VH, 2-pin

VHR-2N

455-1183-ND

Header, JST VH, 2-pin, Top Entry

B2P-VH

455-1639-ND

Header, JST VH, 2-pin, Side Entry

B2PS-VH

455-1648-ND

Connector Datasheet: http://www.jst-mfg.com/product/pdf/eng/eVH.pdf

Control Hub Guide © REV Robotics, LLC 2020 7

1.4.3 JST PH –Sensors and RS485

The JST PH style connector is used for motor encoder, analog, digital, I2C, RS485, and UART connections on the Control

Hub. These are all 4-pin connections except for the RS485 and UART which are 3 pin. The connectors are keyed (they only

insert in one orientation) and are friction locking. In Figure 2 the keying feature aligned with the cable is shown.

Figure 2: How to Use a JST PH Cable

REV Robotics recommends in most cases that teams use pre-made cables because the quality of the crimp is better

when made using industrial tooling. These cables can be bought directly from the REV Robotics Website (Table 4 and

Table 5) or through other online vendors.

Table 4: Premade 4-pin JST PH Cables and Accessories

Pins

Length

REV Robotics Part Number

JST PH

-

JST PH

4 pins

30cm

REV-31-1407

JST PH

-

JST PH

4 pins

50cm

REV-31-1408

JST PH

-

JST PH

4 pins

100cm

REV-31-1409

JST PH Cable Extension Board

4 pins

REV-31-1388

Table 5: Premade 3-pin JST PH Cables

Pins

Length

REV Robotics Part Number

JST PH

-

JST PH

3 pins

30cm

REV-31-1417

JST PH

-

JST PH

3 pins

50cm

REV-31-1418

JST PH

-

JST PH

3 pins

100cm

REV-31-1565

For teams that want to try crimping their own cables, or to find more information about the connectors, Table 6 lists the

appropriate part numbers.

Connector Specifications

•2A Continuous Current (24AWG)

•2.0mm Pitch

•Accepts 32-24AWG Wire

Control Hub Guide © REV Robotics, LLC 2020 8

Table 6: JST PH Connector Part Number Reference

Manufacturer Part Number

DigiKey Part Number

Contact, JST PH, 30-24AWG

SPH-002T-P0.5S

455-1127-1-ND

Contact, JST PH, 28-24AWG

SPH-002T-P0.5L

455-2148-1-ND

Housing, JST PH, 4-pin

PHR-4

455-1164-ND

Header, JST PH, 4-pin, Top Entry

B4B-PH-K-S

455-1706-ND

Header, JST PH, 4-pin, Side Entry

S4B-PH-K-S

455-1721-ND

Housing, JST PH, 3-pin

PHR-3

455-1126-ND

Header, JST PH, 3-pin, Top Entry

B3B-PH-K-S

455-1705-ND

Header, JST PH, 3-pin, Side Entry

S3B-PH-K-S

455-1720-ND

Connector Datasheet: http://www.jst-mfg.com/product/pdf/eng/ePH.pdf

Control Hub Guide © REV Robotics, LLC 2020 9

2QUICK START

2.1 Required Materials

Control Hub

REV-31-1595

12V NiMh Slim Battery *

REV-31-1302

Properly Configured Driver Station (DS) *

USB Game Pad *

USB A Female to Micro USB *

REV-31-1426

* Other FTC legal part numbers exist.

Optional Additional Materials needed to Connect an Expansion Hub:

•Expansion Hub (REV-31-1153)

•XT30 Extension Cable (REV-31-1392)

•JST PH 3-pin Communication Cable (REV-31-1417)

Control Hub Guide © REV Robotics, LLC 2020 10

2.2 System Wiring Diagram

Figure 3: System Wiring Diagram

2.3 Driver Station and Robot Controller Pairing

When you first receive your Control Hub, you will have to pair (link) your Driver Station (Android Device) to your Control

Hub. This procedure only needs to be performed once for each set of hardware. If you replace your Driver Station or

Control Hub, this procedure will need to be repeated. The steps below assume the FTC Driver Station Application or FIRST

Global Driver Station Application are installed on your Android device.

Pairing the Driver Staion with the Control Hub

1. Power on the Control Hub, by plugging the

12V Slim Battery into the XT30 connector

labeled “BATTERY” on the Control Hub.

2. The Control Hub is ready to pair with the

Driver Station when the LED turns green.

Note: the light blinks blue every ~5

seconds to indicate that the Control Hub

is healthy.

Control Hub Guide © REV Robotics, LLC 2020 11

3. Power on your Android Device by holding

down the power button.

4. Open the Driver Station application from

the HOME Screen.

Control Hub Guide © REV Robotics, LLC 2020 12

5. On the Driver Station page, open the menu

from the top right corner, then select

“Settings”.

6. Select, “Pairing Method”

Control Hub Guide © REV Robotics, LLC 2020 13

7. Select, “Control Hub”

8. Select, “Pair with Robot Controller”.

Control Hub Guide © REV Robotics, LLC 2020 14

9. Select “Wifi Settings”

10. Select the name of the Wifi network

generated by your Control Hub. The SSID

name starts with either “FIRST-“or “FTC-“.

Control Hub Guide © REV Robotics, LLC 2020 15

11. Enter the password to the Wifi network in

the password field. This defaults to

“password”. Press “CONNECT”.

After pressing connect, press the back

arrow at the bottom of the display until

you return to the main driver station

screen.

12. After a couple of seconds, the Driver

Station page will indicate the network

name, a ping time, and battery voltage.

Your Driver Station is now paired with your Control Hub!

Control Hub Guide © REV Robotics, LLC 2020 16

2.4 Robot Configuration

Every device connected to the Control Hub will need to be added to the Robot Configuration file before you can use the

device in your program. The Robot Configuration will allow you to give your sensors and actuators meaningful names that

you can reference while programming.

For this example, we will configure a simple two motor robot drivetrain (Figure 4).

Figure 4: The miniBot is a Simple 2-Motor Robot

Control Hub Guide © REV Robotics, LLC 2020 17

Configuring Your Robot for the First Time

1. Select the menu on either the Driver Station or

Robot Controller. Then select “Configure Robot”.

2. Select “New” in the top left hand corner.

3. Select “Expansion Hub Portal 1” (embedded).

4. Select “Expansion Hub 1”.

Control Hub Guide © REV Robotics, LLC 2020 18

5. Select “Motors”.

6. Select the Drop Down menu for “Port 0” then

select the motor type attached to the port. In the

case of the Minibot in Figure 4, select the “Rev

Robotics Core Hex Motor”.

7. Press “Enter motor name here” and name the

motor “left_drive”.

This is the name that you will use when you are

programming your robot to control this motor. Always use

descriptive names so that you can remember what a

device does when you are programming.

8. Repeat the process for “Port 1” and name the

motor “right_drive”.

Control Hub Guide © REV Robotics, LLC 2020 19

9. Press “Done”once to go back to the list of device

ports and then select I2C Bus 0.

10. Add the built-in REV Expansion Hub IMU. Name it

“imu”

11. Press the “Done” button (at the top left corner of the page) 3 times.

12. Press “Save”.

Control Hub Guide © REV Robotics, LLC 2020 20

13. Enter “miniBot” as your configuration name, then

select “OK”.

14. You now have an active configuration called

“miniBot”. Press the Android back button to return

to the Driver Station page.

2.5 Adding an Additional Expansion Hub

If you want to use more than 4 motors or 6 servos, you will need to add an Expansion Hub to your robot. An Expansion

Hub can be added to a Control Hub. The Expansion Hub has all of the same ports as the Control Hub but without the

wireless capability.

Control Hub vs Expansion Hub in FIRST

FIRST Tech Challenge

FIRST Global

FIRST Tech Challenge teams may use one (1) Control

Hub and may add one (1) Expansion Hub starting in

the 2020-2021 season. Read the official FTC Game

Manuals for complete game rules.

FIRST Global teams must use one (1) Control Hub

and may add one (1) Expansion Hub to their robot.

Read the official FIRST Global manual for complete

game rules.

Other manuals for REV-31-1595

1

Table of contents

Other REV Robotics Switch manuals

Popular Switch manuals by other brands

FIBERROAD

FIBERROAD FR-6R3204 user manual

Network Technologies

Network Technologies DVI-x Installation and operation manual

Moxa Technologies

Moxa Technologies IKS-6728 Series Hardware installation guide

Enterasys

Enterasys Enterasys Gold Distributed Forwarding Engine... Hardware installation guide

MiLAN

MiLAN TR-TP-HB-1600 user guide

Novus

Novus NV-108S/P+ user manual