RE 95156/02.2017, Bosch Rexroth AG

BODAS Pressure sensor | PR4

Technical data

3

Technical data

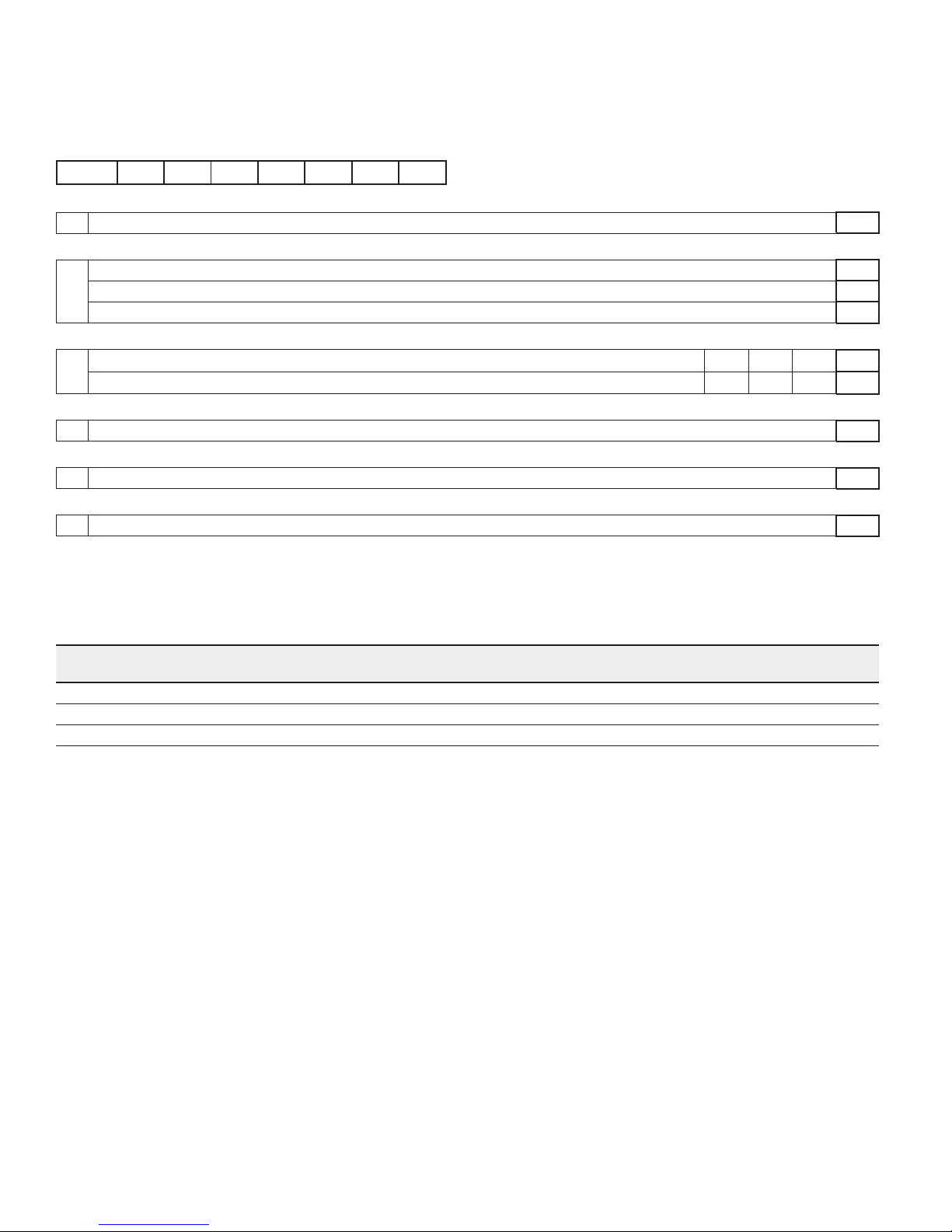

Type PR4 280

GB05

420

GB05

600

MB05

Measurement range 0 ... 280 bar 0 ... 420 bar 0 ... 600 bar

Overload limit1) 400 bar 560 bar 800 bar

Bursting pressure2)4) 2500 bar 3750 bar 5250 bar

Output signal 0.5V ... 4.5V, ratiometric (at 5 V supply)

Supply voltage Us5V ±0.25V

Maximum supply voltage 18V (maximum 1h)

Short circuit signal output to GND or supply voltage US,short = 0 … 18 V, (max. 8 h) in case of simultaneous supply of USwith US, short

Sensor output impedance Rdifferntial at

0.1Us<Uout<0.9Us

typical: 5 Ω

maximum: 10 Ω

Current consumption

Typical at 5V supply voltage 12 mA

Maximum without load ≤15mA

Maximum at reverse connection 260 mA

Connector Bosch Compact 1.1a

Parts contacting measuring materials X5CrNiCuNb16-4

Housing material PBT-GF30/CrNi steel

Response time (10 ... 90 %) ≤1.0 ms

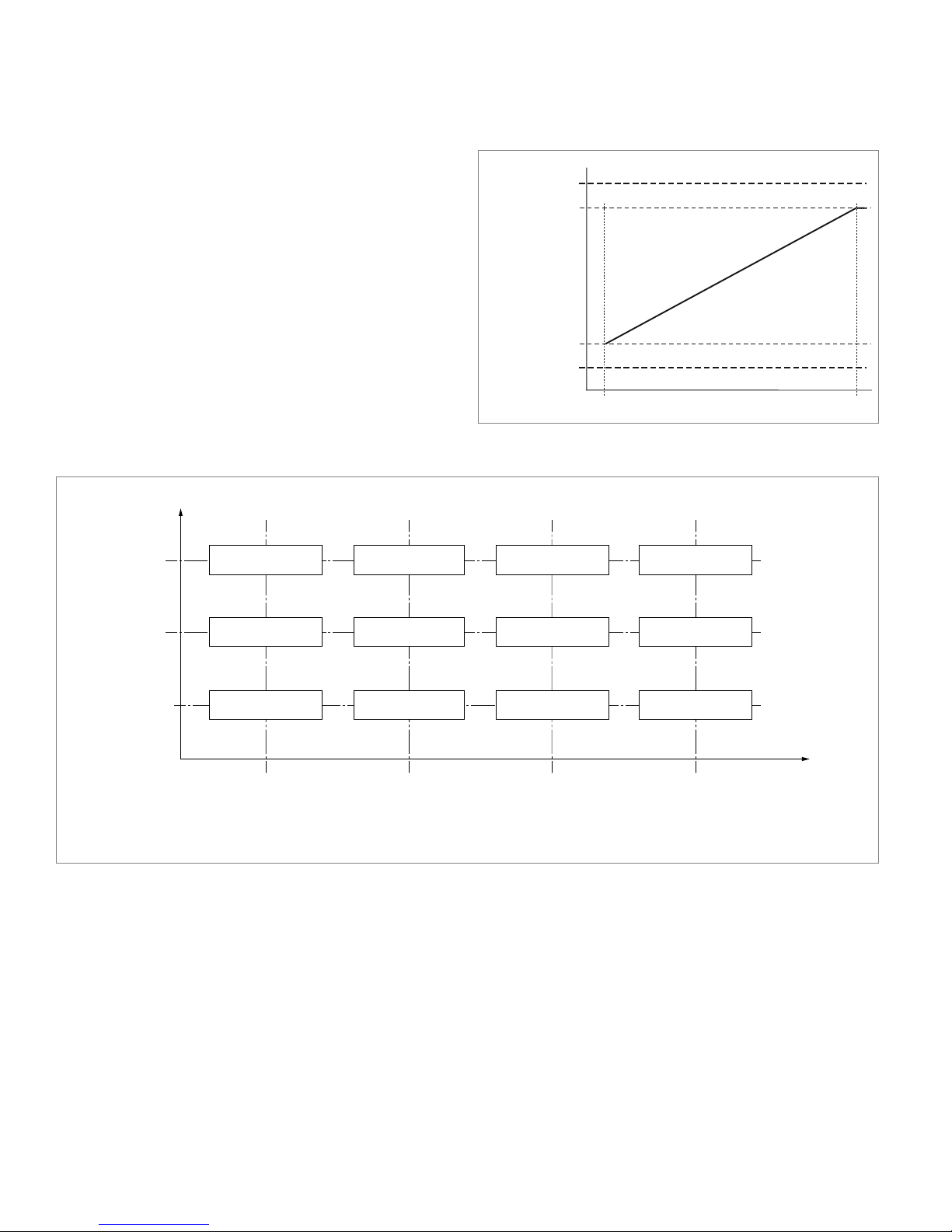

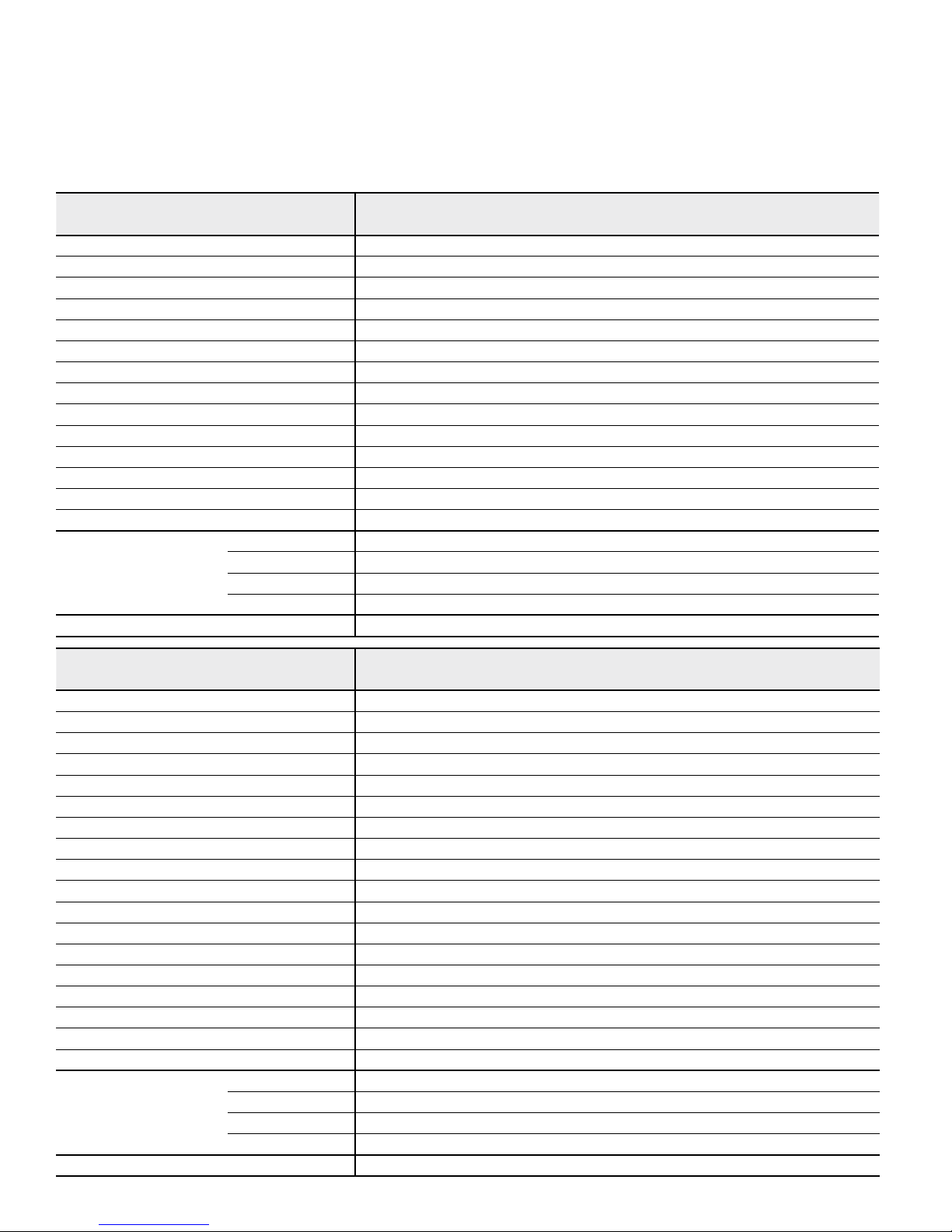

Overall accuracy ≤1.5%, refer to table "tolerance over temperature, pressure and life time"

Medium temperature range3) –40 °C ... +140°C

Ambient temperature range –40°C ... +100°C

Storage temperature range –30°C ... +60°C at 0 ... 80% relative humidity and 5 years

Transportation conditions, Conditions deviating from the storage conditions are allowed for the transport:

Duration, max. 48 h temperature –40 °C ... +80 °C

Relative humidity 0 % ... 80 %

Service life 10000 operating hours or 15 years

Different values, depending on operational conditions on request

Pressure cycles over service life 10 million cycles

Shock resistance 50g (DIN EN 60068-2-27, 11ms), 500g (DIN EN 60068-2-27, 1ms)

Vibration resistance

Amplitude of the deflection s = 0.25 mm in the range 70 Hz ... 147 Hz

Amplitude of the acceleration a = 210 m/s2in the range 147 Hz ... 1350 Hz

a = 175 m/s2in the range 1350 Hz ... 2000 Hz

Frequency change 0.5 octave/min

Duration of excitation 100 h in each spatial direction with the same test specimen

Drop test

Controlled drop from 1 m height onto concrete in accordance with ISO 16750-3. One

drop event per axial direction. The component must then be fully functional or visually

damaged

CE conformity According to EMC directive 2014/30/EU (EN ISO 14982 and EN 13309)

E1 Type approval UN ECE 10 Rev4

Electromagnetic compatibility EMC ISO 11452-2, -4, -5 as well as according to IEC61000

BCI up ... 200 mA open and closed loop according ISO 11452-4 up ... 400 MHz.

Antenna > 150 V/m according ISO 11452-2 from 200 MHz - 3.2 GHz

Electrical protection Protection from voltage reversal, short circuits and undervoltage;

protection from overvoltage in the defined supply voltage range

Type of protection with installed mating connector IP67 and IPX9K according to ISO 20653 (2006-08-15)

Weight approx. G 1/4: 48g, M14: 52 g

1) maximum 15 minutes at Pnto Pmax

2) maximum 15 minutes at Pnto Pberst

3) 150°C: 250h over live time

4) The specifield bursting pressure is valid for the device only.

This value does not include the mechanical interface - the thread between the sen-

sor and the hydraulic component