REYMSA COOLING TOWERS, INC.

www.reymsa.com

The

All-Fiberglass

Cooling Towers

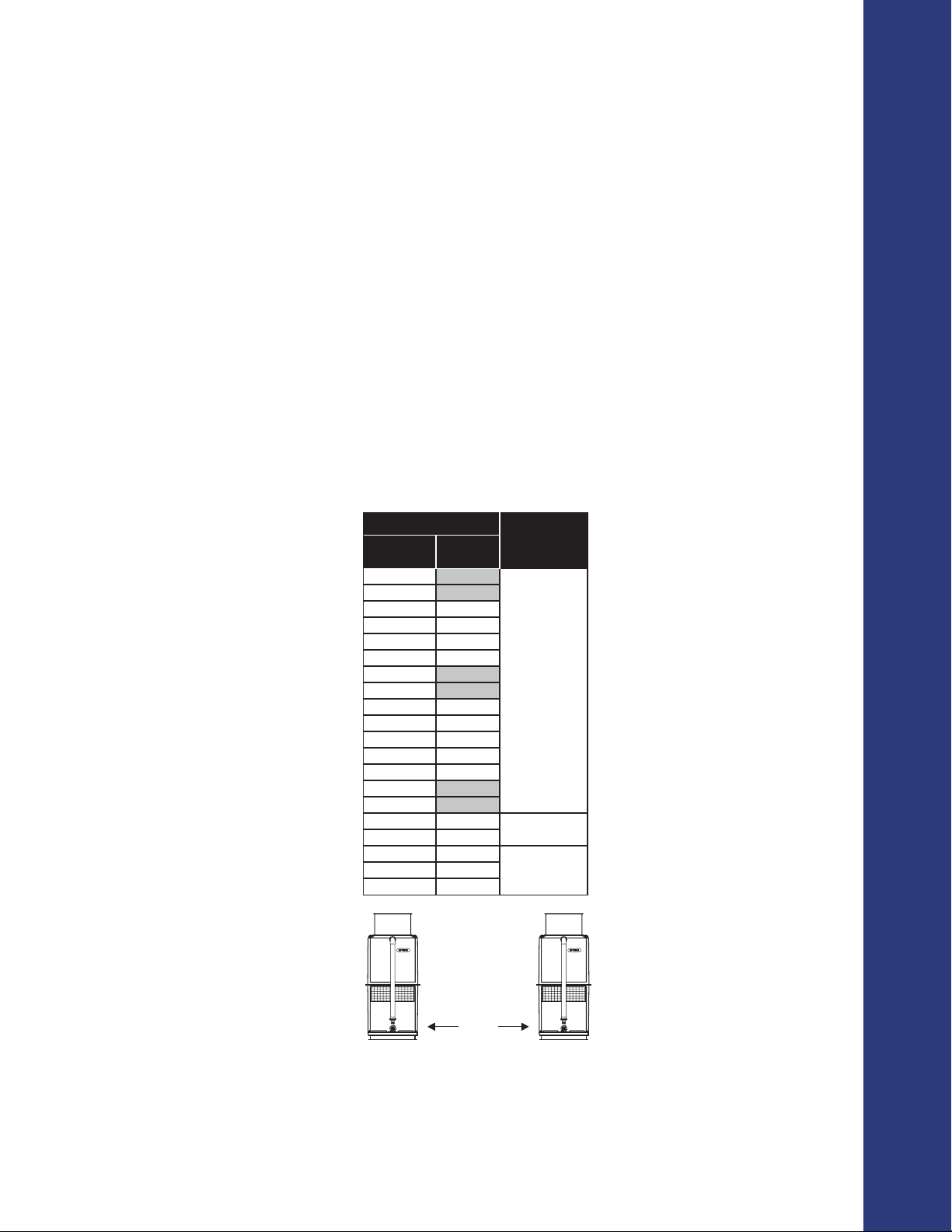

Index

Table A-5: Flanges recommended torque 15

Table B-1: Operation and Start-up basin level 32

Table C-1: Maximum operating temperatures 39

Table C-2: Maximum operating pressure 39

Table C-3: Water chemistry guidelines 40

Table C-4: Cycle of concentration 42

Table C-5: Recommended solution freezing protection temperature 44

Table D-1: Recommended Tower and optional equipment maintenance schedule 47

Table D-2: Oil capacity for gear reducer models 52

Table D-3: Copper coil unit(s) weight by model 55

FIGURES

Figure A-1 : Minimum recommended distance between towers 1

Figure A-2: Recirculation 2

Figure A-3: Single Fan Tower Fork lifting 3

Figure A-4: Single Fan Tower Crane Lifting 3

Figure A-5: Fan Duct Lifting 3

Figure A-6: Typical anchorage for a single fan tower 4

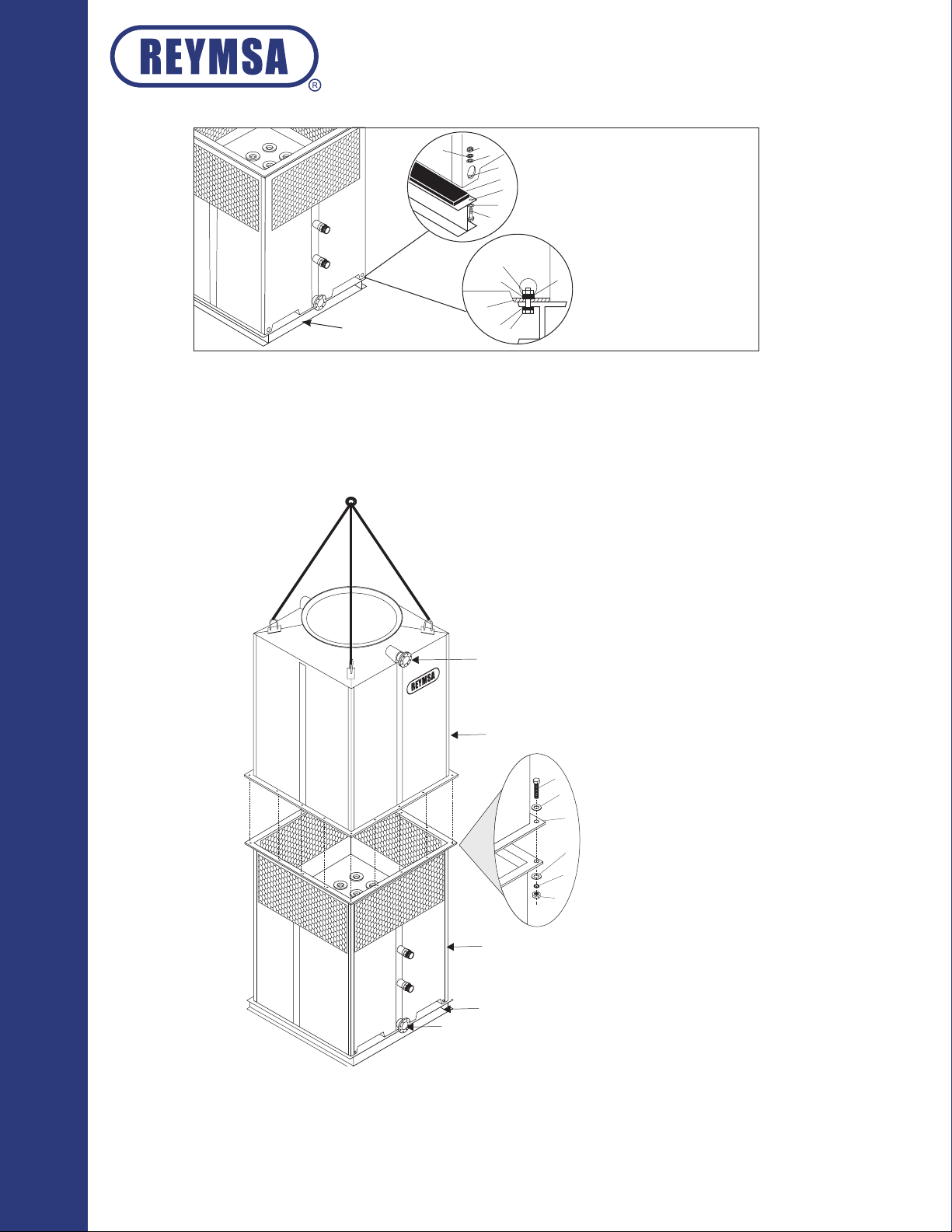

Figure A-7: Upper and lower parts installation 4

Figure A-8: Fan duct assembly for a single tower 5

Figure A-9: Fan duct alignment for a single tower 5

Figure A-10: Double fan tower fork lifting 6

Figure A-11: Double fan tower crane lifting 6

Figure A-12: Fan Duct Lifting 6

Figure A-13: Basin lifting (optional) 7

Figure A-14: Typical anchorage for a double fan tower 7

Figure A-15: Fan duct, upper and lower parts installation 7

Figure A-16: Fan duct assembly for a double fan tower 8

Figure A-17: Fan duct alignment for a double fan tower 8

Figure A-18: Double fan tower fork lifting 9

Figure A-19: Double fan tower crane lifting 9

Figure A-20: Fan duct lifting 9

Figure A-21: Basin lifting (optional) 10

Figure A-22: Typical anchorage for a quadruple fan tower 10

Figure A-23: Lower section installation for quadruple fan tower 10

Figure A-24: Upper section 1 quadruple fan tower 10

Figure A-25: Upper section 1 & 2 for a quadruple fan tower on plane 11

Figure A-26: Fan duct installation for a quadruple fan tower 12

Figure A-27: Fan duct alignment for a quadruple fan tower 12

Figure A-28: Lifting for HFC-F models 13

Figure A-29: Typical anchorage for HFC-F models 13

Figure A-30: Upper body section installation for HFC-F models 14

Figure A-31: Fan duct assembly for HFC-F models 14

Figure A-32: Screen mesh assembly for HFC-F models 14

Figure A-33: Spray pump and water return pipes assembly to tower 15

Figure A-34: Copper coil unit 16

Figure A-35: Fan adaptor in a single fan tower 17

Figure A-36: Fan adaptor installation 17

Figure A-37: Fan adaptor alignment 17

Figure A-38: Fan adaptor 2 installation 18

Figure A-39: Fan duct installation on a fan adaptor 18

Figure A-40: Fan duct alignment 18

Figure A-41: Fan duct installation in a fan adaptor for a quadruple fan tower 18

Figure A-42: Optional accessories by REYMSA 19

Figure A-43: Optional safety accessories 20

Figure A-44: Vibration switch recommended location 21

Figure A-45: Internal switches 21

Figure A-46: Typical electric diagram 21

Figure A-47: Vibration switch detail 22

Figure A-48: Sensitivity adjustment 22

Figure A-49: Basin heater system 23

Figure A-50: Recommended basin heater mounting 23

Figure A-51: Basin heater control panel diagram 24

Figure A-52: Electrical water level control system 25

Figure A-53: Electrical Connections & Water Level Control Parts 25

Figure A-54: Motor Shaft Grounding Ring 26

Figure A-55: Motor Shaft Grounding Ring Path to Ground 26

Figure A-56: Example of a base support 27