1. Summary

1. 1 Product introduction:

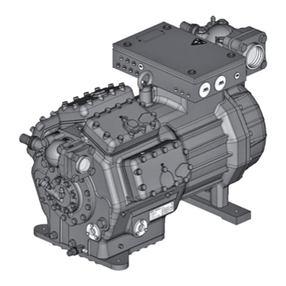

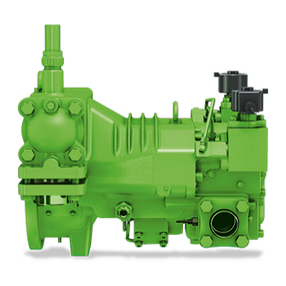

SLG&SLD series products are low-temperature special screw refrigeration compressors

carefully developed by RFC in recent years to integrate low-temperature refrigeration market

applications and customer needs, and learn from the experience of domestic and foreign

counterparts. The product is designed with excellent performance, simple structure and

convenient use. It focuses on the application needs of the low temperature market and is

widely used in agriculture, fishing, meat, food industry, process cooling, freeze drying and

other industries.

There are 32 models of SLG&SLD semi-hermetic screw compressors. SL series

compressors from 30HP to 300HP (displacement volume at 50Hz: 102, 128, 145, 158, 188,

205, 235, 248, 293, 354, 416, 520, 641, 812, 908, 1006m³ /h), each type of compressor has

two different built-in volume ratios, which are suitable for occasions with low evaporating

temperature and medium and high evaporating temperature respectively. Therefore, the user

can choose the ideal compressor according to the actual application, so as to obtain the best

compression efficiency.

SL series compressors all use external oil separators. The use of external oil separators

can provide greater flexibility in design and structural arrangement. In the parallel combination

system of multiple compressors (from 2 to 6 units) ) can only use a common oil separator. In

addition, the use of oil cooling has broadened the compressor application limits so that it can

operate under harsh operating conditions.

A complete set of accessories required for the oil return line (from the oil separator to the

compressor) is available as standard. In addition all matching oil separators and oil coolers are

also available.

Due to the minimal vibration and no exhaust pulsation, the use of shock absorbers and

flexible nozzles is not necessary. Plus, the lower noise concentrated in the mid-to-high

frequencies is very easy to isolate.

The characteristics of SL series compressors are: the oil-injected twin-screw design is

adopted, the male rotor is directly connected to the motor (2 poles, about 2960 rpm), and the

perfect rotational motion makes it run extremely smoothly. The rotor profile is asymmetrically

designed (the number of teeth of the male rotor is 5, and the number of teeth of the female

rotor is 6). .

Oil pressure driven spool valve cooling capacity control enables the compressor to have

high compression efficiency under partial load, making SL series compressors especially

suitable for those occasions that need to work under partial load for a long time.

The cycle efficiency (COP) can be further achieved by using an economizer (ECO) cycle

that increases the refrigerant liquid subcooling