Radio Frequency SystemsHandbook No: 49.53678.008

Issue 01 Commercial in Confidence v

CONTENTS

Page

Copyright, Quality Assurance, Authorisation for Issue .............................................................................................ii

Cautions and Warnings.............................................................................................................................................iii

Amendments .............................................................................................................................................................iv

List of Illustrations......................................................................................................................................................vi

Acronyms and Abbreviations ....................................................................................................................................vi

SECTION

1 SCOPE...................................................................................................................................................... 1-1

1.1 Antenna Type ........................................................................................................................................... 1-1

1.2 Antenna Identification ............................................................................................................................... 1-1

1.3 Antenna Input Capability .......................................................................................................................... 1-1

1.4 Broadcast Service and Coverage ............................................................................................................ 1-1

2 DESCRIPTION ......................................................................................................................................... 2-1

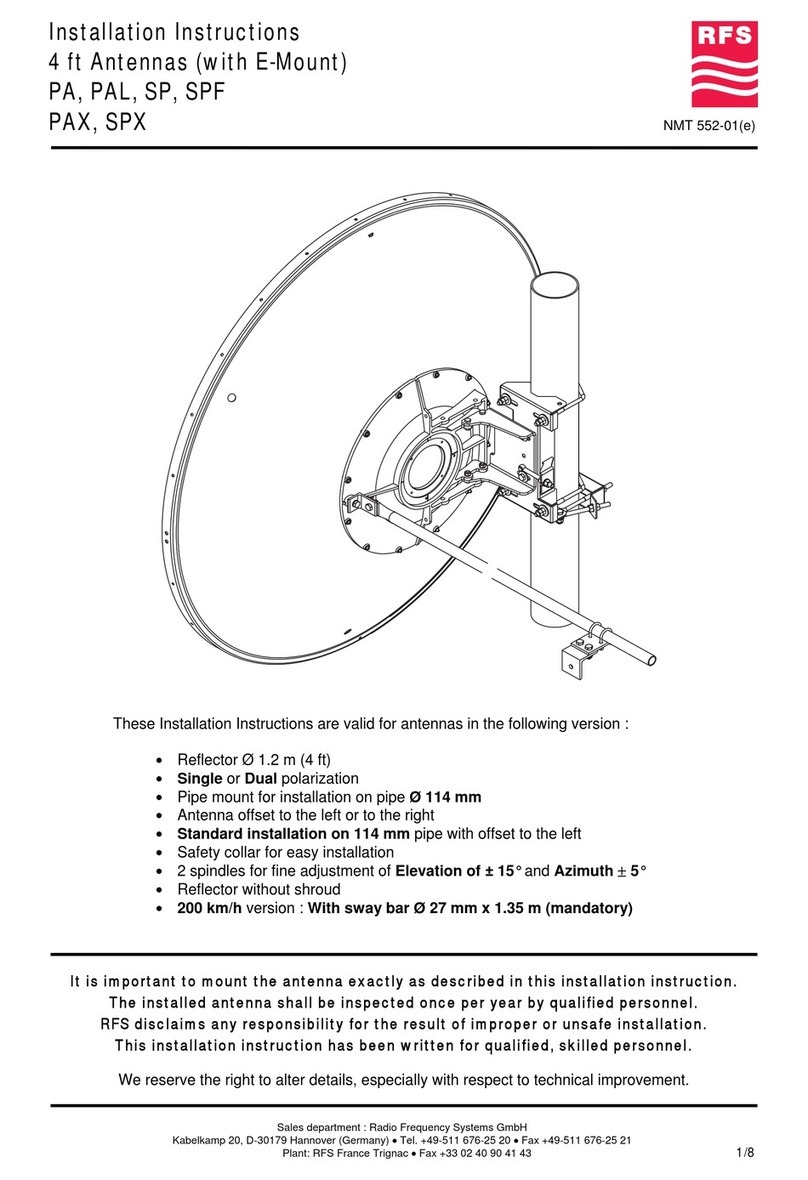

2.1 Mechanical Construction .......................................................................................................................... 2-1

2.2 Environmental Conditions ........................................................................................................................ 2-1

2.3 Electrical Characteristics .......................................................................................................................... 2-1

2.4 Performance Characteristics.................................................................................................................... 2-2

2.5 Power and Voltage Ratings and Safety Factors...................................................................................... 2-2

3 SYSTEM CONFIGURATION ................................................................................................................... 3-1

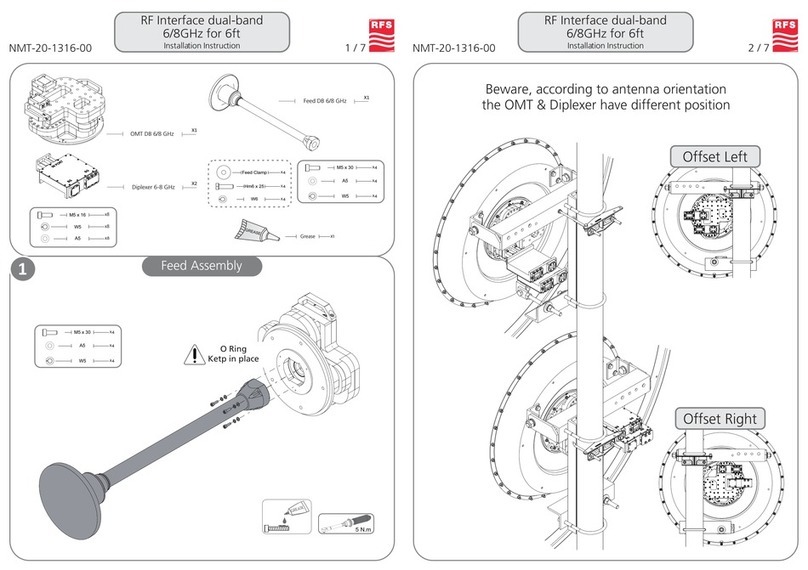

3.1 Antenna Orientation.................................................................................................................................. 3-1

3.2 Feed System, Power Distribution and Phasing Arrangement ................................................................ 3-1

4 INSTALLATION ....................................................................................................................................... 4-1

4.1 Precautions ............................................................................................................................................... 4-1

4.2 Delivery ..................................................................................................................................................... 4-1

4.3 Storage...................................................................................................................................................... 4-1

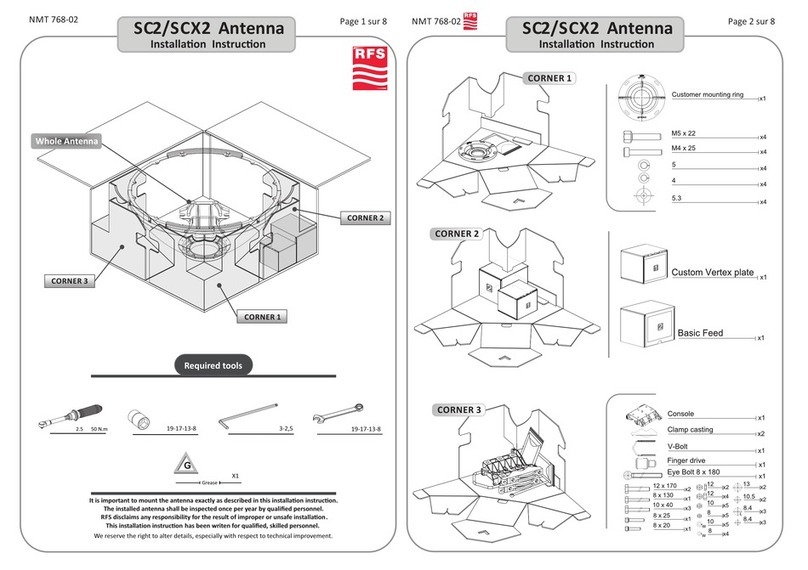

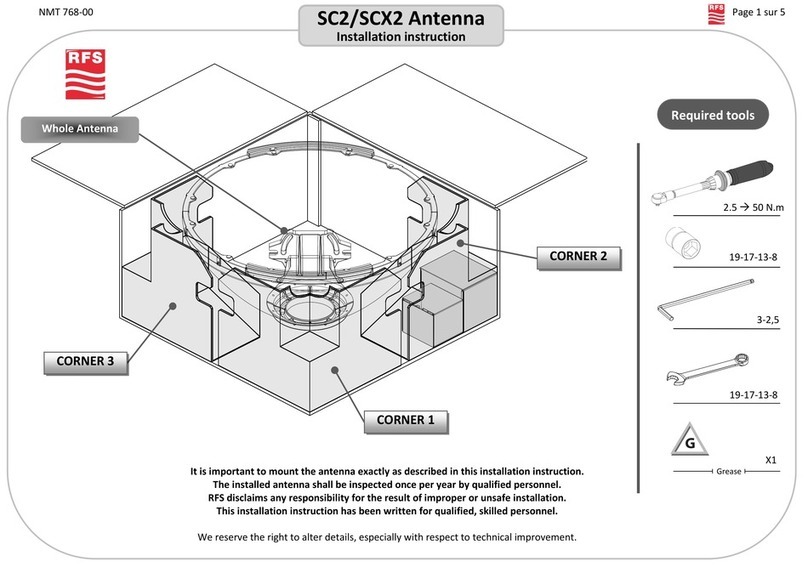

4.4 Unpacking ................................................................................................................................................. 4-2

4.5 Preparation ............................................................................................................................................... 4-2

4.6 Assembly & Installation ............................................................................................................................ 4-2

4.6.1 Install Power Divider Network .................................................................................................................. 4-2

4.6.2 Install Distribution Cables ......................................................................................................................... 4-2

4.6.3 Cellflex Installation Recommendations................................................................................................... 4-3

4.6.4 Main Feeder Connection .......................................................................................................................... 4-3

4.6.5 Half Antenna Operation............................................................................................................................ 4-3

4.7 Purge the Antenna and Feeder Cable..................................................................................................... 4-3

4.8 Earthing of Main Feeder Cable ................................................................................................................ 4-4

4.9 Assembly Check....................................................................................................................................... 4-4

4.10 Tuning ....................................................................................................................................................... 4-4

4.11 Commissioning ......................................................................................................................................... 4-4

4.12 Maintenance ............................................................................................................................................. 4-5

4.12.1 Working with Teflon .................................................................................................................................. 4-5

4.13 Warranty.................................................................................................................................................... 4-5

4.14 Recycling and Disposal of Components.................................................................................................. 4-5

- DRAFT COPY - PENDING TEST RESULTS