2

INTRODUCTION I. SPECIFICATIONS

TABLE OF CONTENTS

!WARNING

Page No.

I. SPECIFICATIONS

Components 2

Unit Dimensions 3-5

Electrical & Physical Data 6-10

II. INSTALLATION

General 11

Location Considerations 11

Exhaust & Combustion

Hoods 12

Cover Panel Installation 12

Clearances 13

Rooftop 14

Ducting 14-15

Return Air 15

III. GAS SUPPLY & PIPING 16-18

IV. ELECTRICAL WIRING

Power Supply 19

Hook-up 20

Internal Wiring 20

Thermostat 20

V. FURNACE CONTROLS 21-23

VI. OPERATION INFO 23-24

VII. AIRFLOW 25-26

VIII. TROUBLESHOOTING 27-29

IX. WIRING DIAGRAMS 30-33

X. CHARGE CHARTS 34-36

XI. WARRANTY 40

THE MANUFACTURER’S WARRANTY

DOES NOT COVER ANY DAMAGE OR

DEFECT TO THE AIR CONDITIONER

CAUSED BY THE ATTACHMENT OR

USE OF ANY COMPONENTS,

ACCESSORIES OR DEVICES (OTHER

THAN THOSE AUTHORIZED BY THE

MANUFACTURER) INTO, ONTO OR IN

CONJUNCTION WITH THE AIR

CONDITIONER. YOU SHOULD BE

AWARE THAT THE USE OF

UNAUTHORIZED COMPONENTS,

ACCESSORIES OR DEVICES MAY

ADVERSELY AFFECT THE

OPERATION OF THE AIR

CONDITIONER AND MAY ALSO

ENDANGER LIFE AND PROPERTY.

THE MANUFACTURER DISCLAIMS

ANY RESPONSIBILITY FOR SUCH

LOSS OR INJURY RESULTING FROM

THE USE OF SUCH UNAUTHORIZED

COMPONENTS, ACCESSORIES OR

DEVICES.

This booklet contains the installation and

operating instructions for your

combination gas heating/electric cooling

unit. There are some precautions that

should be taken to derive maximum

satisfaction from it. Improper installation

can result in unsatisfactory operation or

dangerous conditions.

Read this booklet and any instructions

packaged with separate equipment

required to make up the system prior to

installation. Give this booklet to the

owner and explain its provisions. The

owner should retain this booklet for

future reference.

CHECKING PRODUCT

RECEIVED

Upon receiving the unit, inspect it for any

damage from shipment. Claims for

damage, either shipping or concealed,

should be filed immediately with the

shipping company. IMPORTANT: Check

the unit model number, heating size,

electrical characteristics, and

accessories to determine if they are

correct.

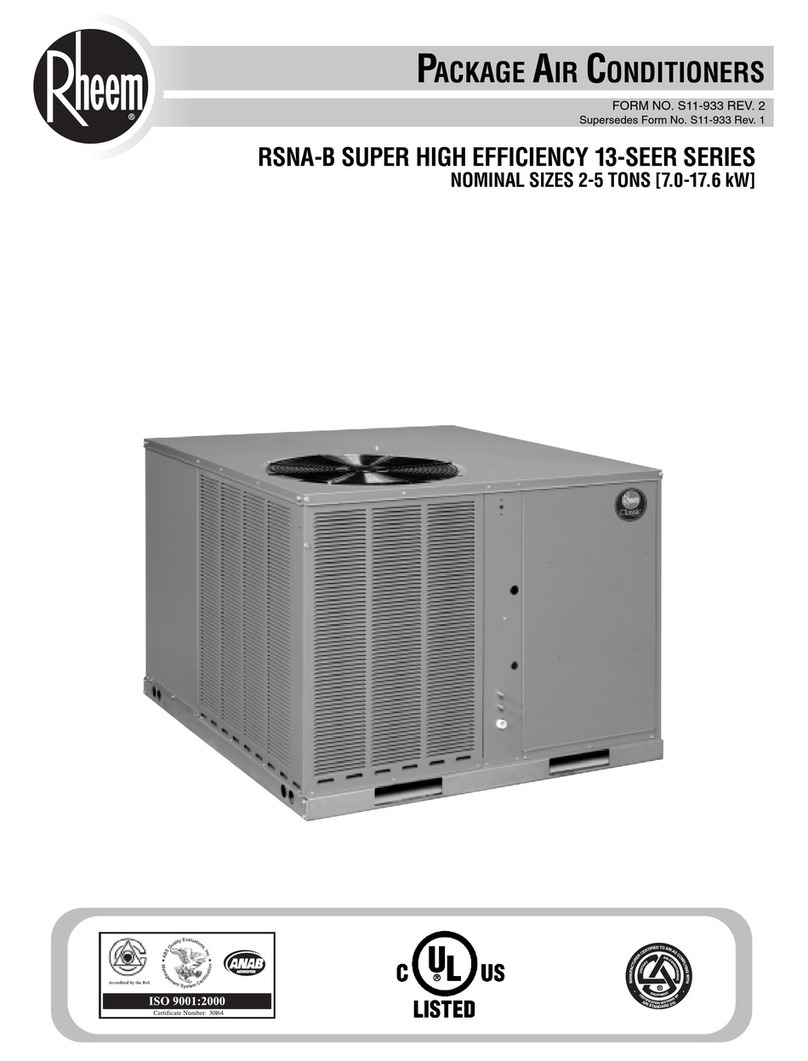

A. GENERAL

The Combination Gas Heating/Electric

Cooling Rooftop is available in 250,000

AND 350,000 BTUH heating input with

nominal cooling capacity of 15 tons.

300,000 and 400,000 BTUH heating inputs

are available in nominal cooling capacity of

20 & 25 tons. Units are convertible from

bottom supply and return to side supply

and return by relocation of supply and

return air cover panels. See cover

installation detail and Figures 10 &11.

The units are weatherized for mounting

outside of the building.

UNITS ARE NOT DESIGN CERTIFIED TO

BE INSTALLED INSIDE THE

STRUCTURE. DOING SO CAN CAUSE

INADEQUATE UNIT PERFORMANCE AS

WELL AS PROPERTY DAMAGE AND

CARBON MONOXIDE POISONING

RESULTING IN PERSONAL INJURY OR

DEATH.

B. MAJOR COMPONENTS

The unit includes a hermetically-sealed

refrigerating system consisting of a scroll

compressor, condenser coil, evaporator

coil with capillary tube assembly or TXV, a

circulation air blower, a condenser fan, a

heat exchanger assembly, gas burner and

control assembly, combustion air motors

and fan, and all necessary internal

electrical wiring. The cooling system of

these units is factory-evacuated, charged

and performance tested. Refrigerant

amount and type are indicated on rating

plate.

!WARNING