!

!

!"#!$%&'()*+,&-./%(+-,*""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""*0*

1"#!2','.%3*+,&-./%(+-,*"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""*4*

"#$!%&'()*+,*!%,-()&+*.(,!/0(1*!2--.3.4,35!6!%,7(()!/.)!81+9.*5!#################!:!

"#"

!;<43=.,>!?)(713*[email protected]!######################################################################!B!"#C!D(749!E1&04)!E(&4,39+*1)4!#################################################################!B!

"#F!/A+.9+094!D(749G!######################################################################################!H!

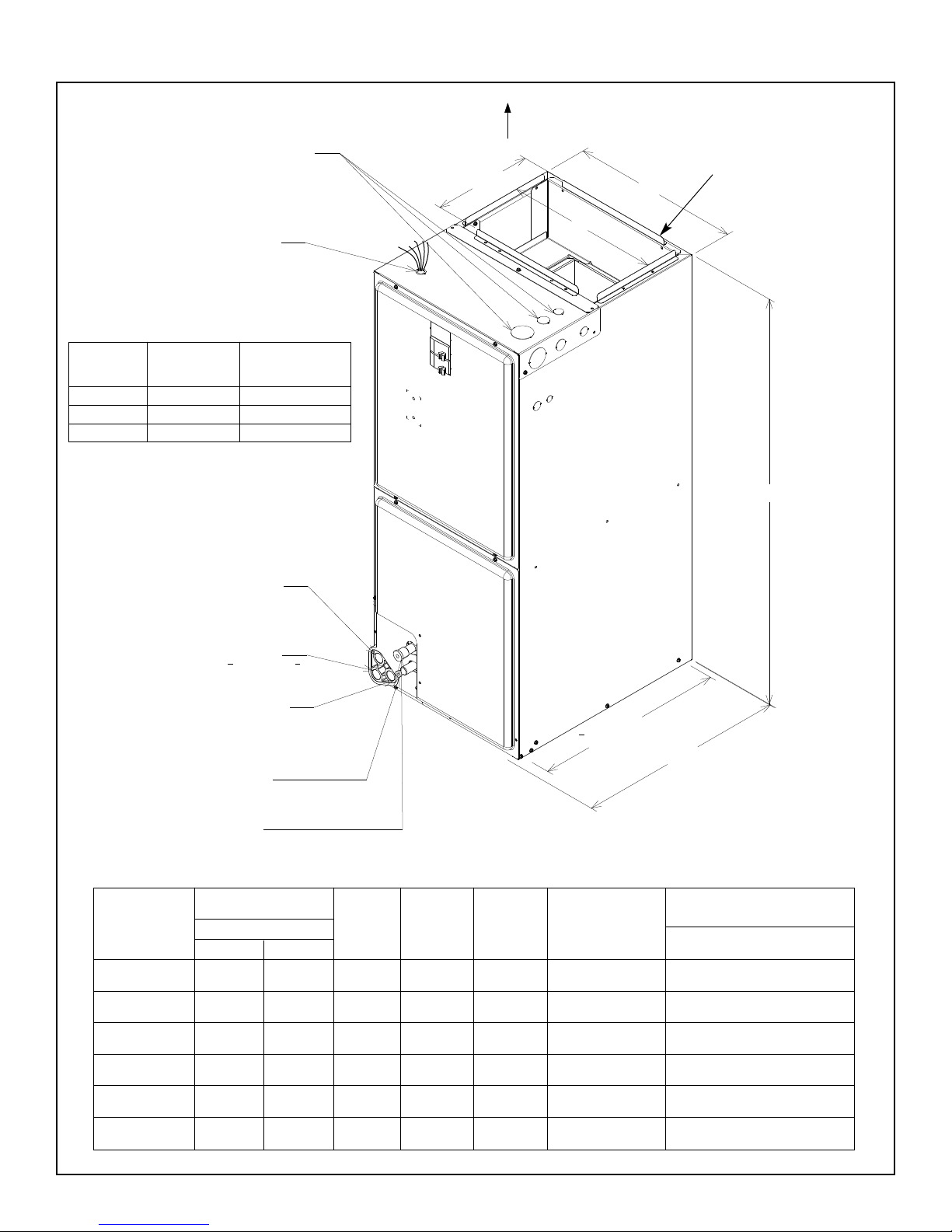

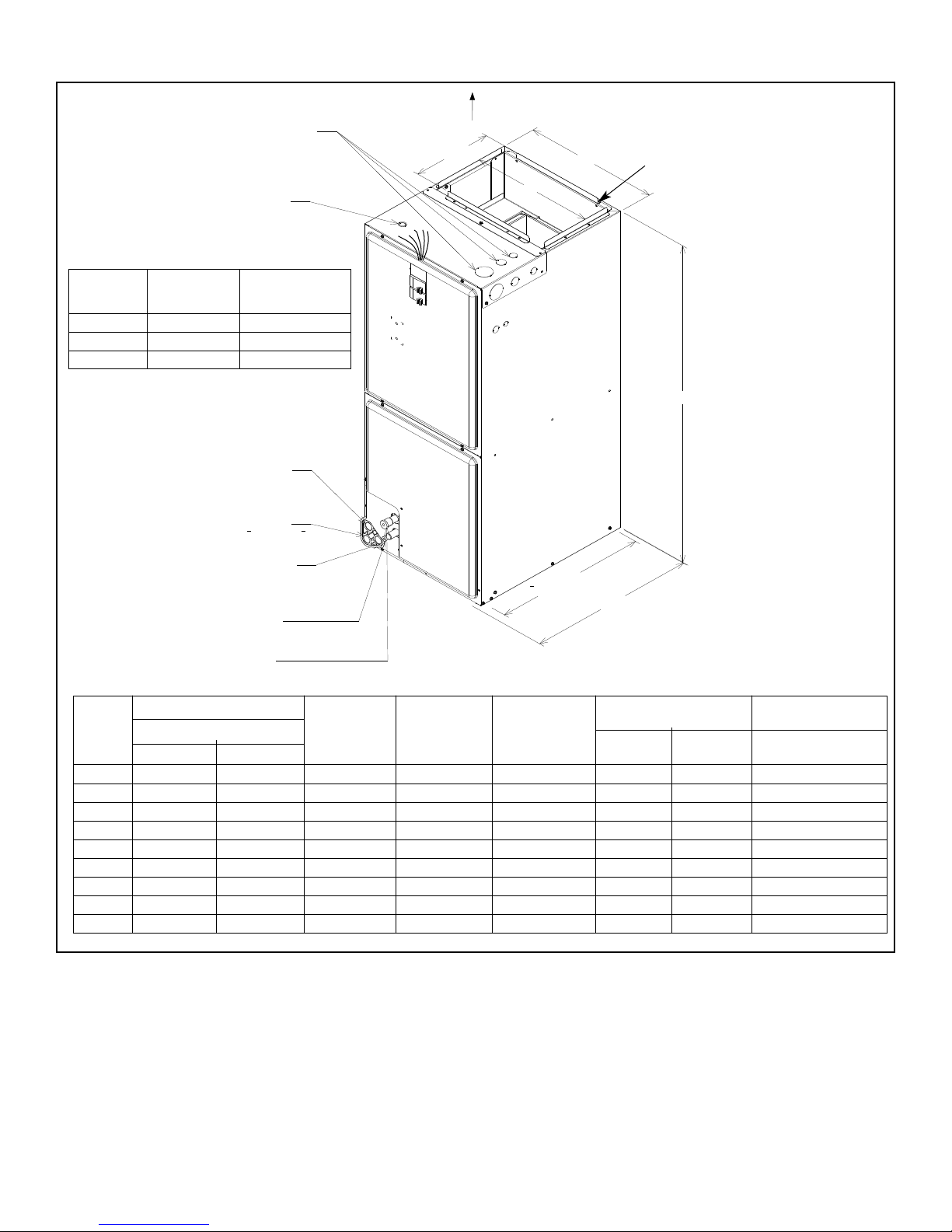

"#I!J.&4,G.(,G!6!K4.><*G!#############################################################################!L!

"#I#$!MNOP$?!##########################################################################################!L!

"#I#"!MNOP$Q!#########################################################################################!$R!

"#:!%&'()*+,34!(-!?)('4)!%,7(()ST1*7(()!D+*3<NU'G!###############################!$$!

"#B!%&'()*+,34!(-!+!81+9.*5!%,G*+99+*.(,!######################################################!$$!

5"#!+,$(%33%(+-,*""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""*!1*

C#$!Q((9G!6!@4-).>4)+,*!################################################################################!$"!

C#$#$!Q((9G!@4V1.)47!-()!%,G*+99.,>!6!W4)A.3.,>!@NF$R/!D(749G!#########!$"!

C#$#"!W'43.-.3+*.(,G!(-!@NF$R/!############################################################!$"!

C#$#C!81.3=!@4-4)4,34!X1.74!-()!@NF$R/!############################################!$"!

C#"!/''9.3+*.(,G!+,7!T).4,*+*.(,!#################################################################!$C!

C#"#$!Y4)*.3+9!U'-9(Z!6!P().[(,*+9!\4-*!J.G3<+)>4!#############################!$C!

C#"#"!Y4)*.3+9!J(Z,-9(Z!6!P().[(,*+9!@.><*!J.G3<+)>4!######################!$C!

C#"#C!%,G*+99+*.(,!.,!+,!U,3(,7.*.(,47!W'+34!#####################################!$I!

C#"#F!%,G*+99+*.(,!.,!D(0.94SD+,1-+3*1)47!P(&4G!############################!$:!

C#"#I!%,G*+99+*.(,!.,!;())(G.A4!2,A.)(,&4,*G!#####################################!$B!

C#C!/1].9.+)5!TA4)-9(Z!?+,!###########################################################################!$B!

C#F!;94+)+,34G!##############################################################################################!$B!

C#I!J13*!^9+,>4G!###########################################################################################!$B!

C#:!J13*Z()=!################################################################################################!$H!

C#B!@4*1),!/.)!^.9*4)!######################################################################################!$H!

C#H!T).-.34!W.[4!##############################################################################################!$L!

C#L!@4-).>4)+,*!\.,4!;(,,43*.(,G!6!;<+)>.,>!##############################################!$L!

C#L#$!?)4'+)+*.(,!################################################################################!$L!

C#L#"!\.V1.7!\.,4!^.9*4)!J).4)!###############################################################!$L!

C#L#C!_)+[.,>!#######################################################################################!$L!

C#L#F!\4+=!Q4G*.,>!###############################################################################!"R!

C#L#I!2A+31+*.(,!#################################################################################!"R!

C#L#:!@4-).>4)+,*!;<+)>.,>!#################################################################!"R!

C#$R!Q`Y!W4,G.,>!_190!/**+3<&4,*!#############################################################!"R!

C#$$!;(,74,G+*4!J)+.,!################################################################################!"R!

C#$"!Q<4)&(G*+*!##########################################################################################!""!

C#$C!2943*).3+9!K.).,>!##################################################################################!""!

C#$C#$!;(,-.>1).,>!U,.*!-()!"RH!Y(9*!?(Z4)!#########################################!""!

C#$C#"!X)(1,7.,>!##################################################################################!""!

C#$C#C!?(Z4)!K.).,>!#############################################################################!""!

C#$C#F!;(''4)!K.)4!W.[4!#######################################################################!"C!

C#$C#I!2943*).3+9!J+*+!a!_9(Z4)!D(*()!T,95!K.*<(1*!2943*).3!P4+*!#####!"C!

C#$C#I#$!MNOP$?!M?W;!D(*()O!##########################################################!"C!

C#$C#I#"!MNOP$Q!M;(,G*+,*!Q()V14!2;D!D(*()O!#############################!"C!

C#$C#:!2943*).3+9!J+*+!a!K.*<!2943*).3!P4+*!###########################################!"F!

C#$C#:#$!MNOP$?!M?W;!D(*()O!##########################################################!"I!

C#$C#:#"!MNOP$Q!M;(,G*+,*!Q()V14!2;D!D(*()O!#############################!"B!

C#$C#B!2943*).3!P4+*4)!b.*!W1''94&4,*+9!%,-()&+*.(,!##########################!CR!

C#$C#H!;(,*)(9!K.).,>!###########################################################################!C$!

C#$C#L!Q<4)&(G*+*!6!;(,*)(9!K.).,>!;(,,43*.(,G!###############################!C$!

C#$F!/.)N^9(Z!###############################################################################################!C$!

C#$F#$!X4,4)+9!/.)N^9(Z!T'4)+*.,>!\.&.*G!############################################!C"!

!