4

Electrical

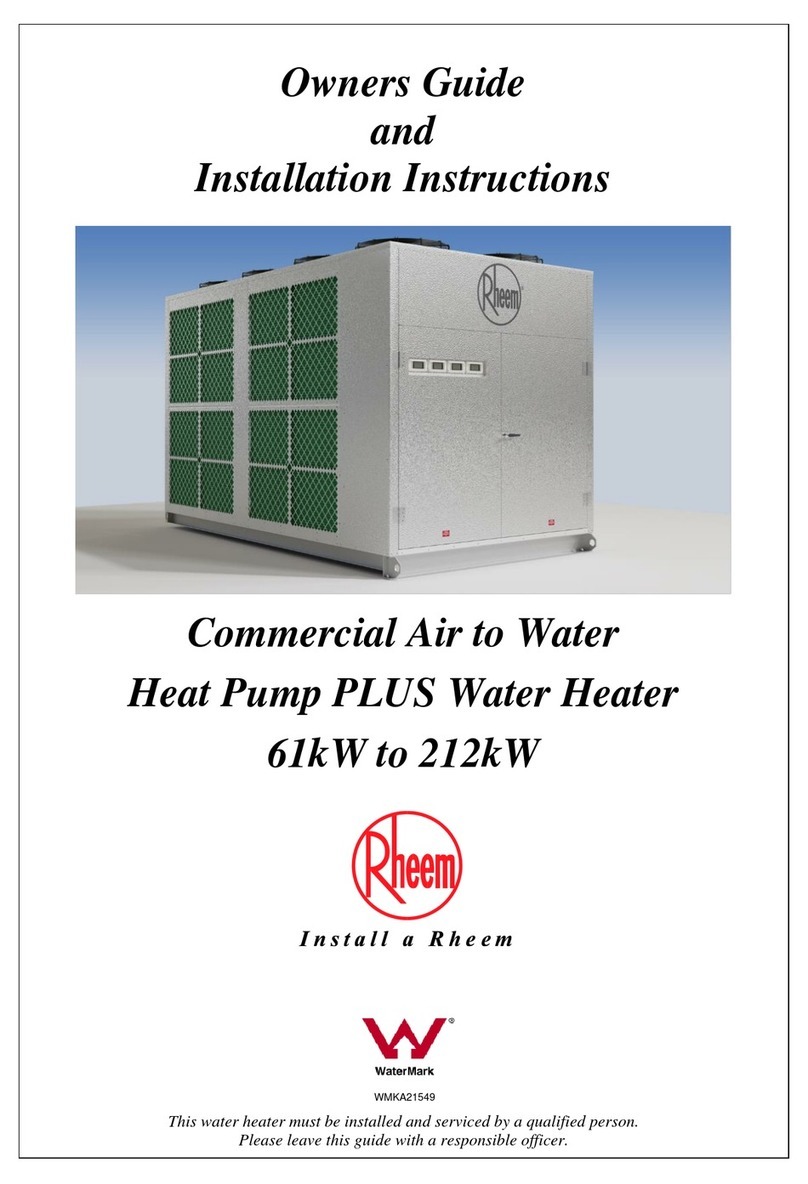

All electrical work must be carried out by licensed electricians and all the wiring should be carried

out to AS/NZS3000 latest edition wiring standards.

Refer to the internal electrical wiring diagram supplied with the units before proceeding with

electrical work. As a minimum, cable and fuse sizing must be correct relative to the unit’s

specified requirements. Rheem Thermal’s technical specification for each model nominates

electrical demand information and minimum circuit size.

An isolating switch must be fitted adjacent to the Heat Pump

To connect power, remove the electrical service panel. Enter wire through the conduit entrance.

Ground to lug. Line voltage to contactor terminals L1 and L2 and L3 if unit is three phase. L1

and N for single phase.

Water must be running through the unit before it is able to be switched on.

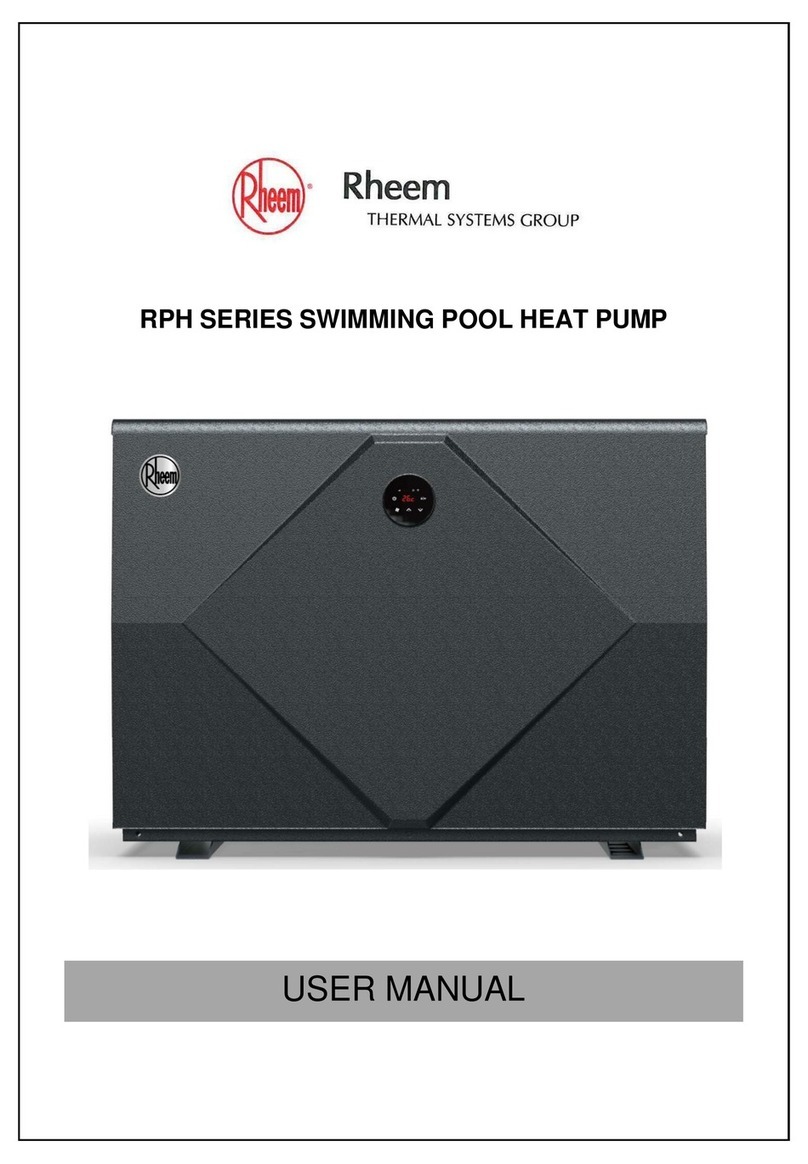

Control Design for Pool Heating

Heat pumps intended for individual installation to a pool are manufactured with in-built thermostat

control and flow switch.

The thermostat is mounted either on the outside panel or internally in the compressor

compartment. The controller displays entering water temperature, with the sensor being located

in a well to the inlet water pipe inside the unit.

The flow switch is a safetyfeature to ensure that the Heat Pump runs only when there is adequate

water flow. If water flow is disturbed by backwashing, etc., or inadequate, the unit will lock-out

by this safety feature. The unit must be manually reset, by turning OFF, then ON. (See

Troubleshooting).

In commercial settings, it is important that the heat pump is isolated during backwashing to avoid

lock-out or potential short-cycling. Ideally, the unit would be switched off, either at the main

switch, the isolating switch located on or adjacent to the unit or at a control sub-board.

For systems comprised of multiple Heat Pump units, the thermostat sensor and well may be provided

as follows depending on client requirement:

Provided loose to allow installation of thermostat controller display in heat pump control panel

(located separately to the heat pumps) with well and probe installed in the pool pipe work on the

inlet side of the heat pumps or balance tank.

Provided in the nominated lead-unit (i.e. the control heat pump) with relays fitted to the lag unit(s)

to allow control wiring to be run to these units.

Link between Heat Pump, Water Pump and Thermostat for Pool Heating

The thermostat sensor is the controlling device in the heating system. This determines whether the

heat pump unit should run and is activated in response to the parameters set for pool temperature

control. That is, the heat pump will run when the entering water temperature (EWT) is less than the

desired set point (normally with a -0.5C split) and stop running when the EWT is a set point. In

simple terms, this means that the heat pump must be provided with constant water flow in order to

achieve temperature measurement. Likewise the heat pump will not run without water flow.

In situations where the heat pump is installed into the existing pool filtration system, the operation of

the heat pump will be controlled by pool temperature at times when the recirculating pump is running.

If the recirculating pump is time-clocked to suit filtration routines, then the period of power supply to

the filter pump may need to be progressively expanded with cooler air temperatures (as the heater

will need to run longer hours than filtration needs in cooler months). If not automated, chlorination

settings may also need adjustment.