ALL TO ALL

Installation Guide Page

10

Make sure you've read Pages 1 -3 first

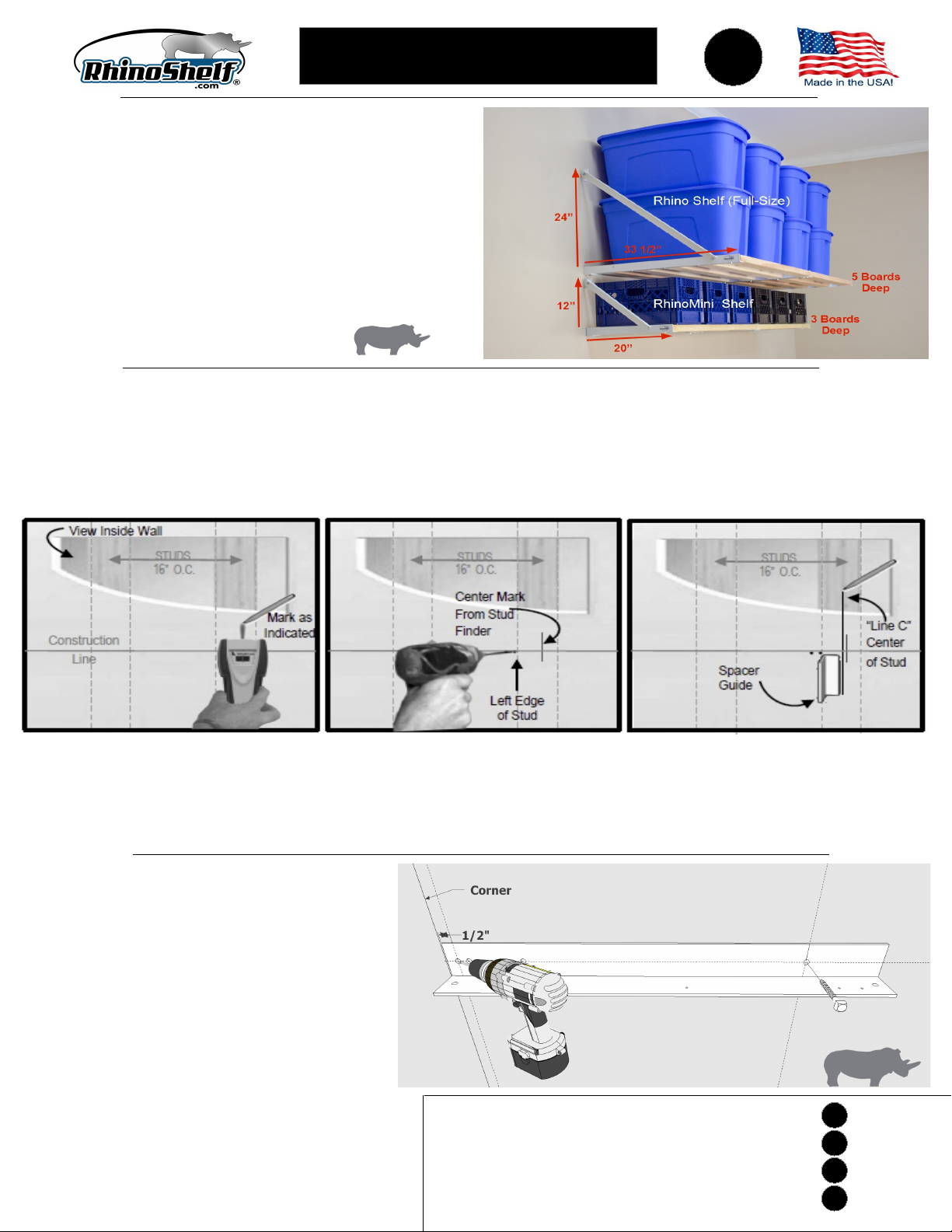

Left-End Assembly Remove nut & bolt from Left End

Assembly to get Left all Start

Left Wall Start

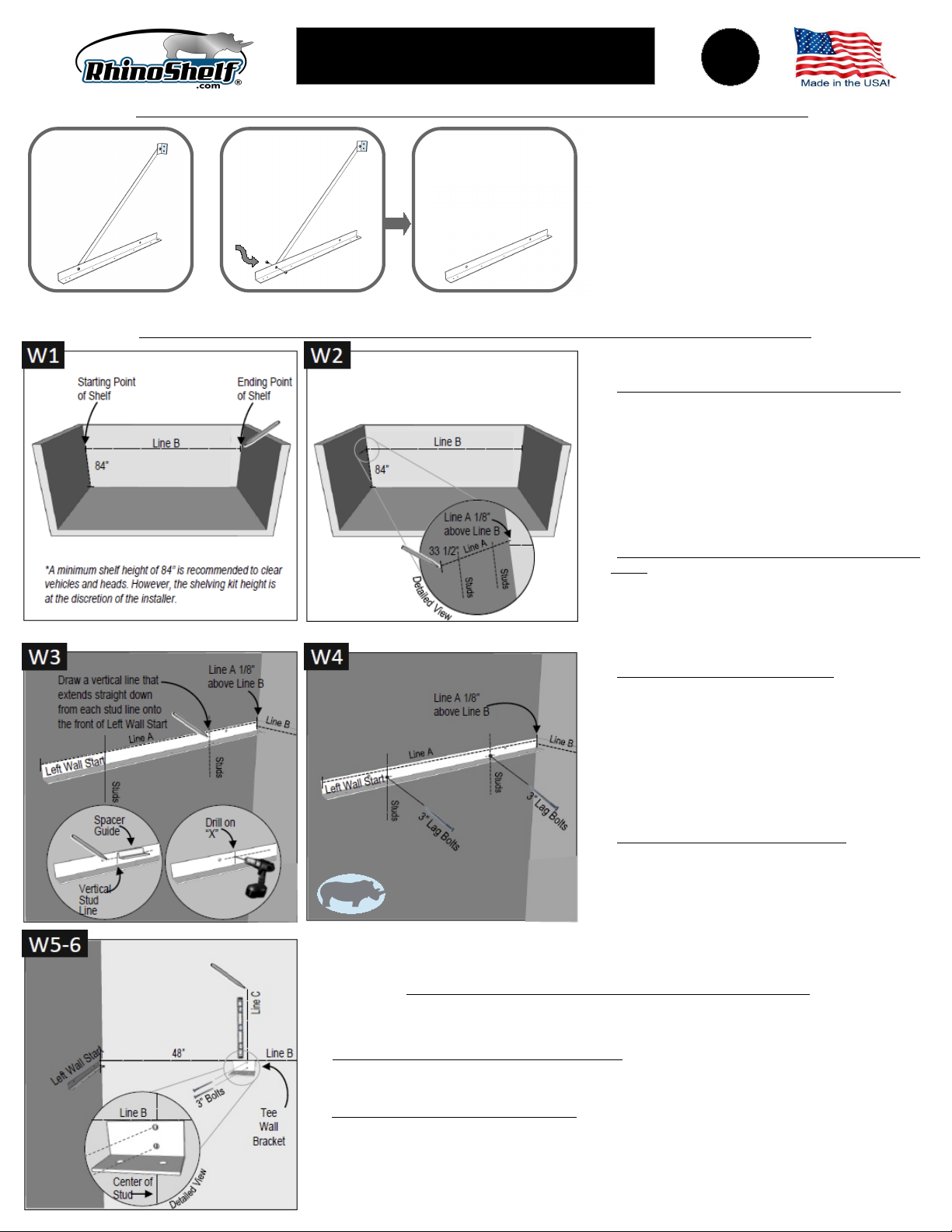

FIRST, DISASSEMBLE LEFT END ASSEMBLY TO

OBTAIN LEFT WALL START Remove the diagonal

support arm from the Left End Assembly by removing the

5/16" nut and bolt connecting the diagonal to the 33 1/2"

angled component This give you the Left Wall Start

component Set aside

DO THE SAME THING TO THE RIGHT END ASSEMBLY

TO OBTAIN RIGHT WALL START Save this piece for

later You will not be using the diagonals you have

removed

INSTALL LEFT WALL START

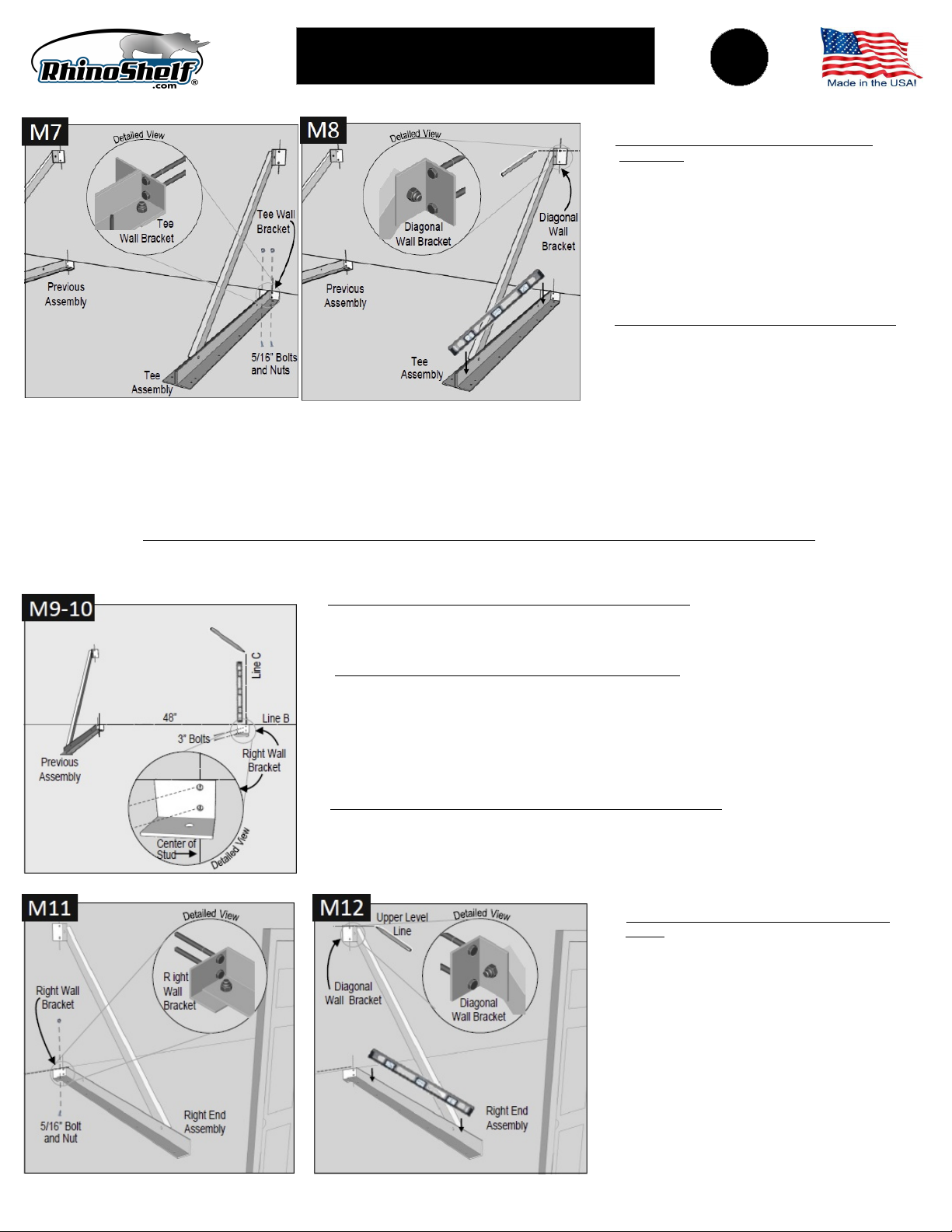

W1 MARK LOCATION OF SHELF ON FRONT WALL To

determine the starting point, in the left corner of the wall,

measure 84” from the floor and make a small mark This

will be your starting point From that point, draw a level

and horizontal line the length of the kit you ordered This

line will be referred to as Line B For example, if you

purchased a 12’ kit, from the starting point you would

draw a 12’ horizontal level line Locate the nearest stud

to the end of this line It may be to the left or right of this

point This stud will be your stopping point

W2 MARK LOCATION OF LEFT WALL START ON LEFT

WALL Starting from left corner, referencing Line B,

make a small horizontal mark on left wall 1/8” above

Line B From this mark, use a level to draw a 33 1/2”

horizontal line onto the left wall This is Line A Locate

and mark the center of each stud along Line A See

“How To Locate Center of Stud” on Page 2

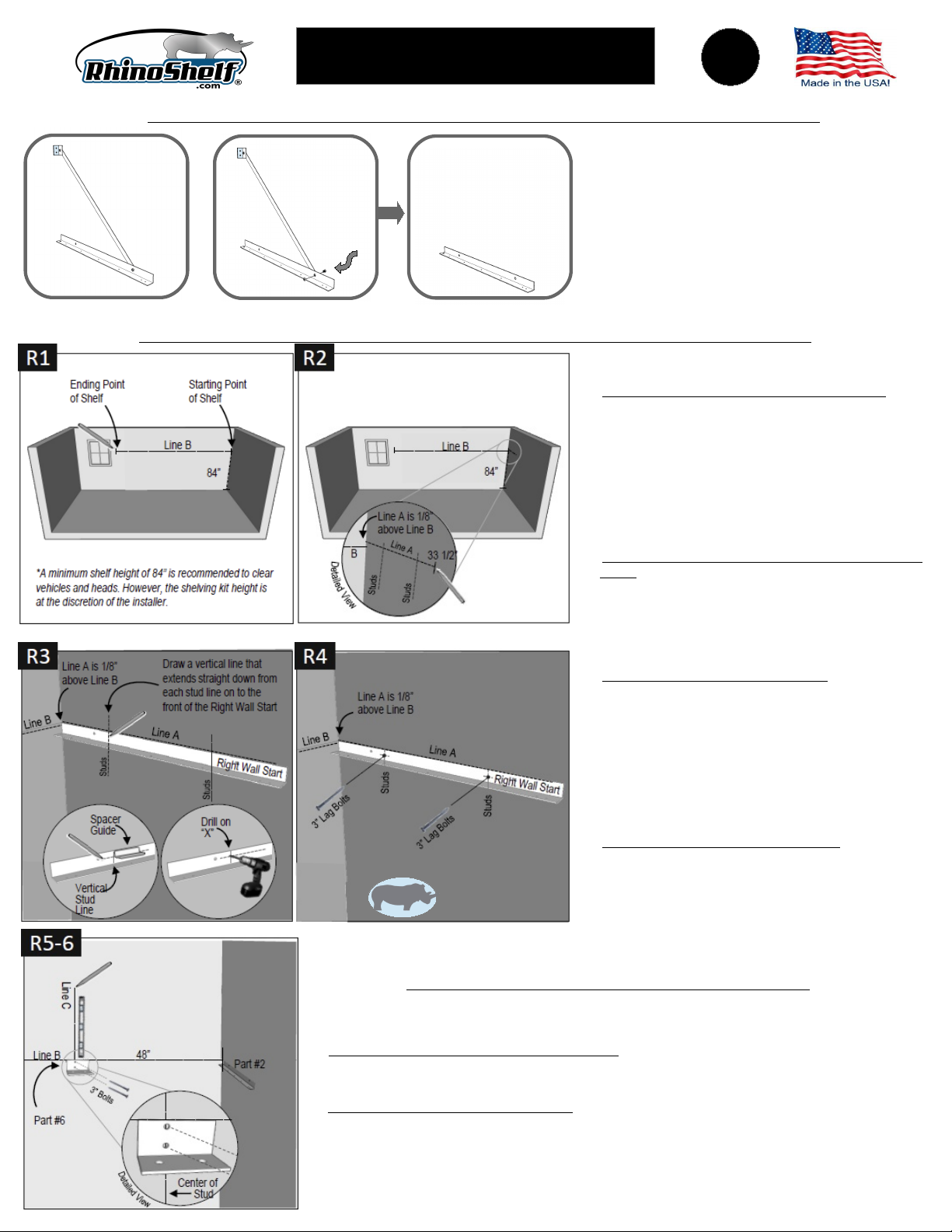

W3 DRILL HOLES IN LEFT WALL START Align the top of

the Left Wall Start with Line A making sure the side with

only two holes is against the wall Place it 1/8” from

corner Holding the part in position, draw a vertical line

that extends straight down from each stud line onto the

front of the part Place the Left Wall Start on a scrap

piece of wood Use the 3/4” side of the Spacer Bar to

draw a perpendicular line across each vertical line on

the front of the part Drill holes through front of the Left

Wall Start on each “x” using a 1/4” drill bit

W4 FASTEN LEFT WALL START TO WALL Align the Left

Wall Start’s top edge with Line A, placing it 1/8” from

corner Make sure that the new 1/4” holes on the front

of the Left Wall Start are aligned with the center of stud

lines Holding the part in position, use a 3/16” bit to pre-

drill pilot hole through left 1/4” hole Use a 7/16” socket

wrench or nut driver to attach the Left Wall Start to the wall with 3” lag bolt Tighten until snug but movable

Ensure the part is level and that its top edge is aligned with Line A Drill second pilot hole through right

1/4” hole and attach second 3” lag bolt Level the part and tighten both 3" bolts

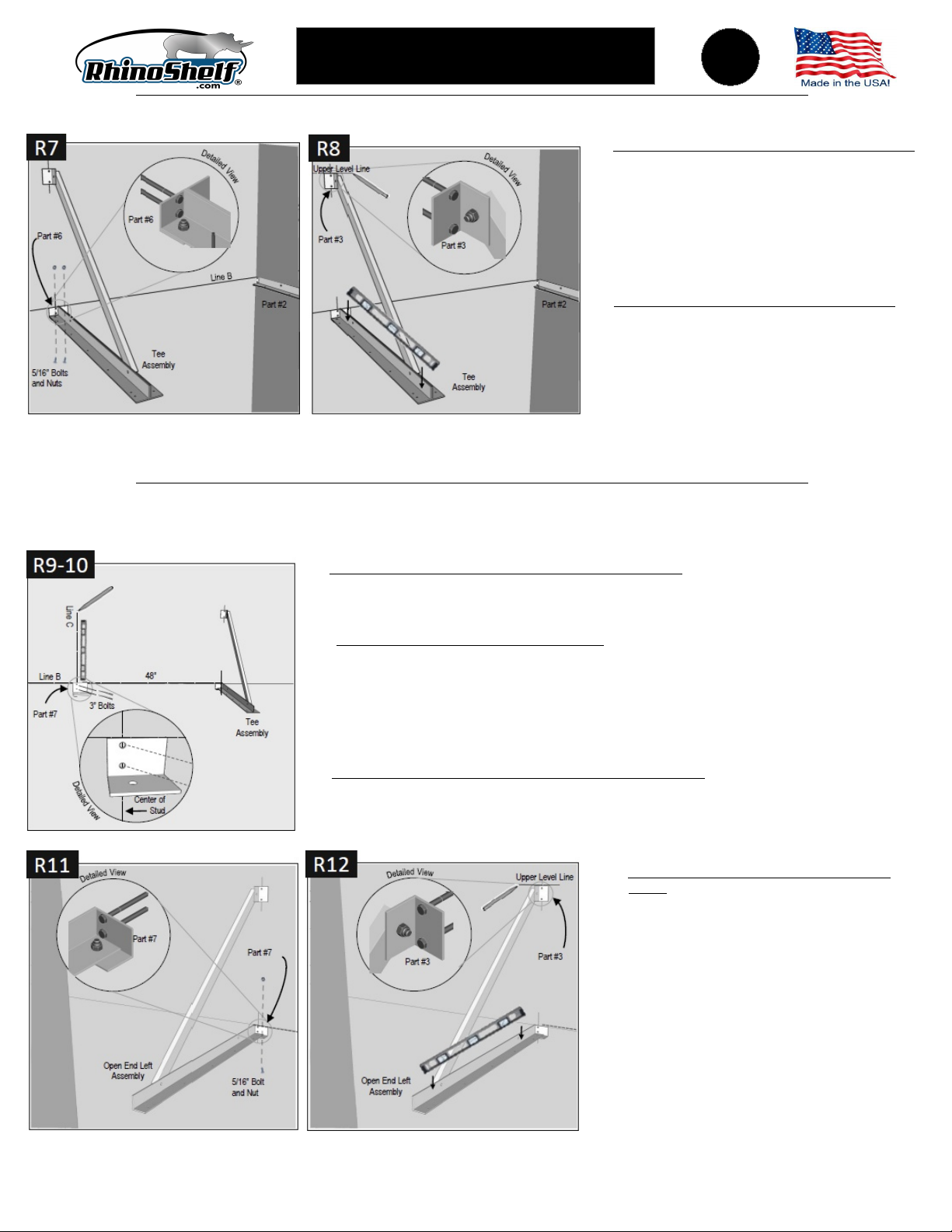

INSTALL TEE ASSEMBLY(IES) - IF YOUR KIT IS THE 4’ MODEL, SKIP TO STEP W9

W5 MARK LOCATION OF TEE ASSEMBLY ON WALL Along Line B find the first available stud nearest 48”

from the corner (or previously installed assembly) Locate the center of the stud and mark with a 2” vertical

mark (Line C)

W6 ATTACH TEE WALL BRACKET TO WALL Place bottom of 2’ level on Line B aligning with the edge of

Line C Make a 2” plumb (vertical) mark at top of the level Place the top of the Tee Wall Bracket on

horizontal Line B and align the center of the two holes on vertical Line C Holding the Tee Wall Bracket in

position, drill pilot hole in top hole using 3/16” drill bit Use a 7/16” socket wrench or nut driver to attach the

Tee Wall Bracket to wall with 3” lag bolt Tighten until snug but movable Ensure the Tee Wall Bracket is

level, drill second pilot hole and attach second 3” lag bolt Tighten both lag bolts

FOR RHINO MINI M3 AND M4 SEE “SPECIAL INSTRUCTIONS” BOTTOM OF PAGE 3

MINI Special Instruction

For Rhino Mini Pg 3