3

RICKARD 2018

MLM RF OPERATION MANUAL

MLM RF Overview

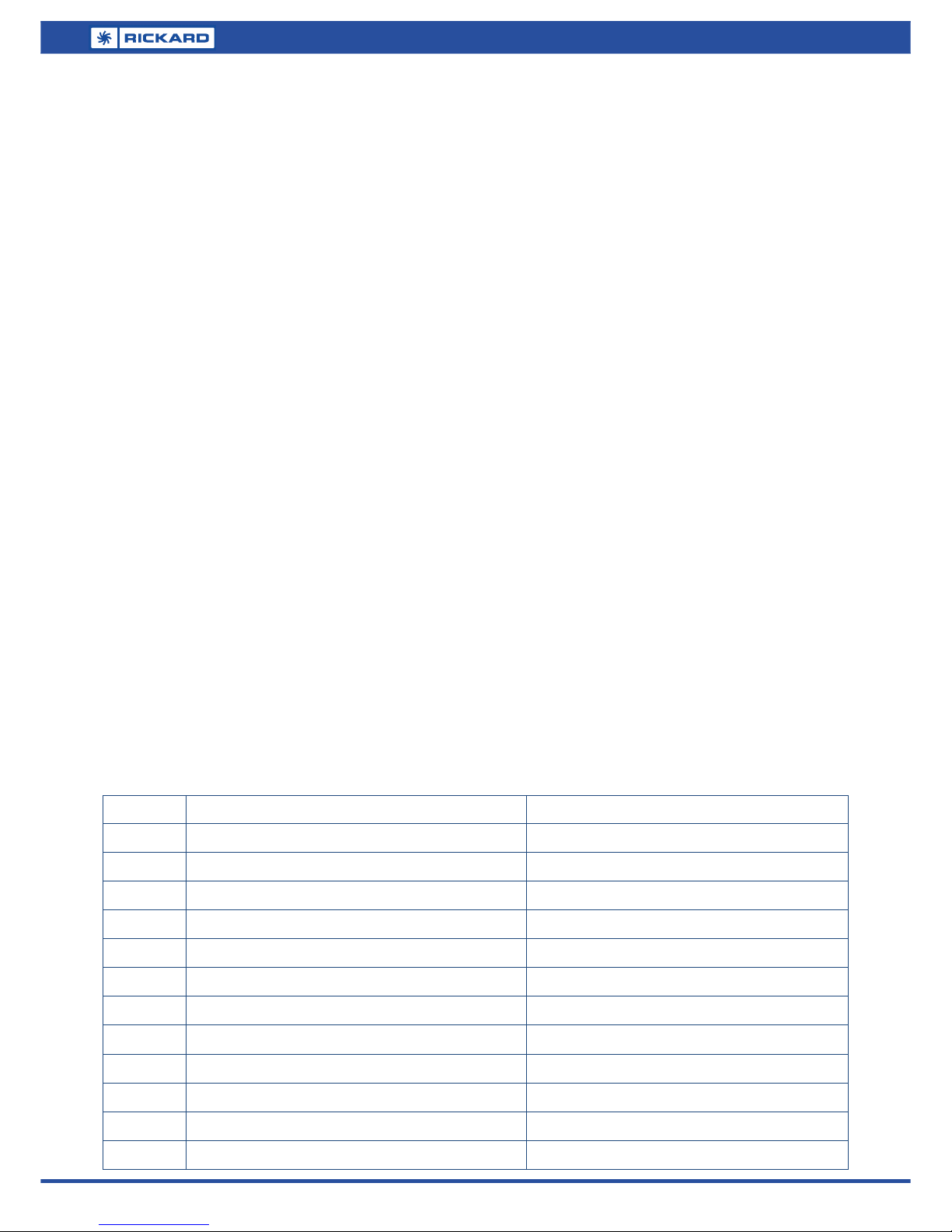

The MLM RF consists of the following hardware units: an Access Point, the RF Wall Thermostat (Wallstat) and a RF

POD Sensor. This hardware unit in combination with the MLM Tool application software, revision 8.16 or later, com-

prise the MLM RF system.

The MLM RF system allows for the remote placement of Wall thermostats and POD sensors without any cabling re-

strictions. The installation will typically comprise of one Access point per Power Supply Unit connecting remotely to a

maximum of 15 Wall Thermostats or POD Sensors, allowing for up to 60 remote units per MCU. See ‘MLM 24 RF In-

stallation Diagram’ below:

The Access point is powered by the MLM bus. The remote RF units are each powered by a pair of Lithium AAA bat-

teries, with a typical operational life of 3- 5 years. To conserve power, the RF communication between units is adap-

tive and could vary between 1 and a maximum of 20 minutes (the default maximum is set at 10 minutes), depending

on the operational requirements of the control system. During commissioning however, this period is reduced to

once a minute.

Adaptive Communication

In order for the RF End Device (ED) to conserve power an adaptive communication interval has been implemented

between the ED and AP.

For a room temperature between 0.5°C above and 1.5°C below Setpoint, the ED response is more ‘active’. In this sce-

nario, the ED will transmit information to the Access Point for every 0.2°C change in room temperature, at 1 minute

intervals. If the temperature change is less than 0.2 °C for the entire duration of the Maximum Communication Trans-

mit Interval (MCTI), the ED will transmit every MCTI minutes. The MCTI can be set via MLM Application for each ED

to a maximum of 20 minutes.

For a room temperature above 0.5°C and below 1.5°C from Setpoint, the ED response is more ‘passive’. The ED will

transmit information to the Access Point for every 0.5°C temperature change in room temperature, at 1 minute inter-

vals. If the temperature change is less than 0.5°C for the entire duration of the Maximum Communication Transmit

Interval (MCTI), the ED will transmit every MCTI minutes.

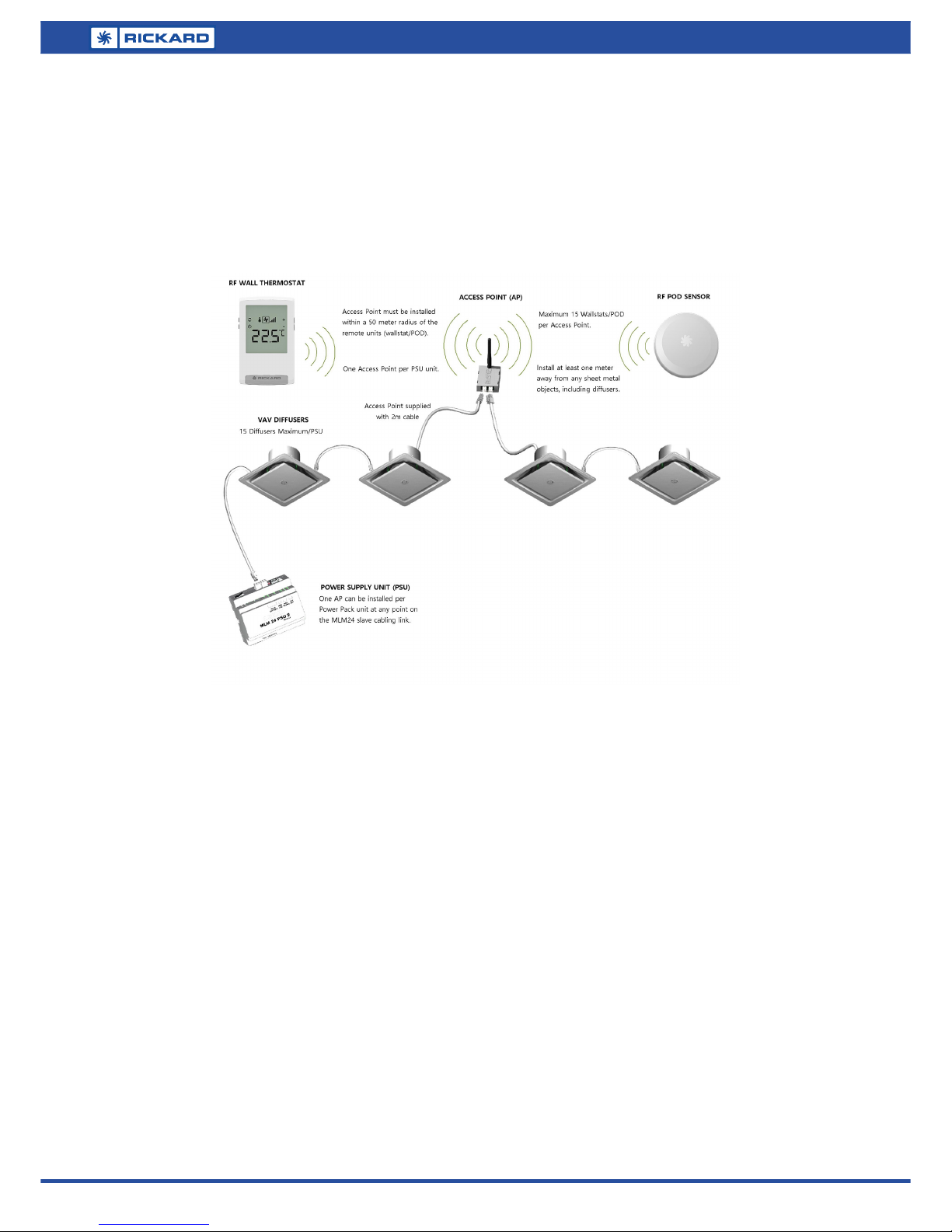

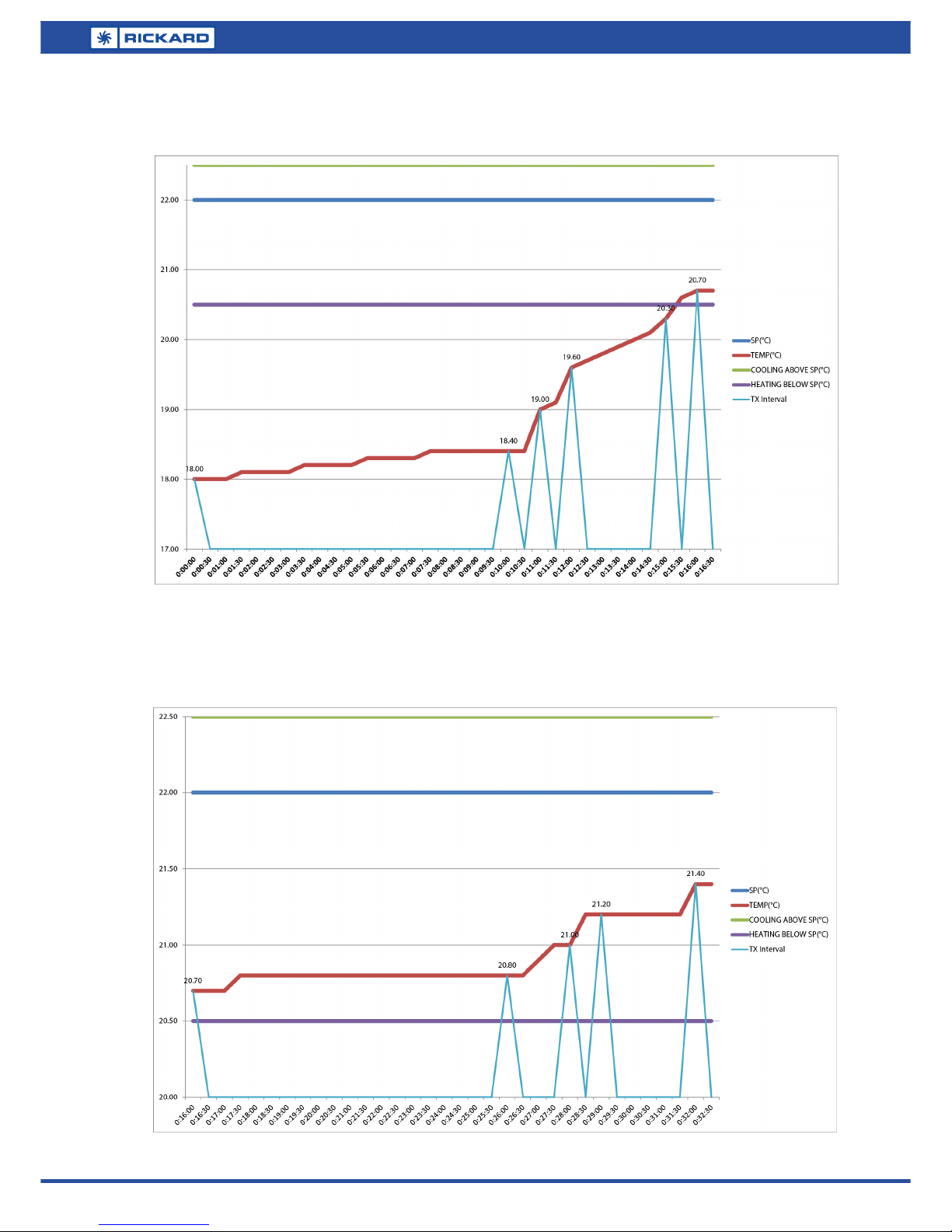

The two graphs below shows communication in the ‘active and ‘passive’ regions. In this instance the MCTI is set to

the default of 10 minutes, but can be set between 1 and 20 minutes. Increasing the MCTI value will significantly in-

crease the battery life of the ED.