Rieber TWF-C 3.0 User manual

Issue: 2018-03-07

Design example TWF-C 3.0

Design example TWF-C 3.0-PK

… longer lasting cooling effect with cooling pellets

Tray Transport Trolley

Diverse selection of tray transport trolleys for your special requirements.

Diverse additional features

The illustrations show examples of versions, which do not necessarily have to be included in the scope of supply.

Observe the operating instructions

Translation of the Original Operating Instructions

DOWNLOAD: USER MANUAL

QR code on type plate

EN

Contents

2

Rieber GmbH & Co. KG

Our solutions provide quality, safety

and, in particular, a high level of energy efficiency and cost effectiveness.

CHECK HACCP –In the area of HACCP documentation the CHECK CLOUD

platform offers the CHECK HACCP digital system, for simple, safe and transparent

temperature detection.

In addition to this, further digital features are possible in the area of hygiene and

service management. The automated digital answer to the analogue paper trail.

Contents

1Revision Index .................................................................................................................................................4

2Important information .....................................................................................................................................4

2.1 The components of the technical documentation................................................................................................ 4

2.2 Using this guide ................................................................................................................................................... 4

2.3 Representation conventions in the text................................................................................................................ 5

2.4 Structure of safety instructions ............................................................................................................................ 6

2.5 Navigation aid for making selections for your specific requirements................................................................... 6

3Safety instructions ..........................................................................................................................................7

3.1 General behaviour ............................................................................................................................................... 7

3.2 On use of electrical appliances............................................................................................................................ 7

3.3Operator's duties.................................................................................................................................................. 8

3.4 Personnel qualification requirements................................................................................................................... 9

3.5 Provide personal protective equipment (PPE) for personnel ............................................................................ 10

3.6 Appliance-specific safety instructions................................................................................................................ 10

3.6.1 Risks due to unstable position ...................................................................................................................... 10

3.6.2 Risks during transport of the appliance......................................................................................................... 10

3.6.3 Risks due to electricity .................................................................................................................................. 11

3.6.4 Risks due to trapped moisture and mould formation .................................................................................... 12

3.6.5 Risks of slipping/falling.................................................................................................................................. 12

3.6.6 Risks of tilting/toppling over .......................................................................................................................... 13

3.6.7 Risks due to being enclosed or suffocation in the appliance........................................................................ 13

3.6.8 Risks concerning the use of the appliance by children................................................................................. 13

3.6.9 Safety and monitoring devices...................................................................................................................... 14

3.7 Note the product identification and ensure its preservation .............................................................................. 15

3.8 Information about regulations to be followed..................................................................................................... 16

3.9 Instructions on behaviour in an emergency....................................................................................................... 16

4Designated use..............................................................................................................................................18

4.1 Generally, the following are intended uses for the product ............................................................................... 18

4.2 Prevent any predictable misuse and abuse....................................................................................................... 18

4.3Special intended use for TWF-H-AWT appliances............................................................................................ 19

4.4 Special intended use for TWF-AK appliances................................................................................................... 19

4.5 Tray solution for closed facility........................................................................................................................... 20

Contents

Rieber GmbH & Co. KG

3

5Description of appliance............................................................................................................................... 20

5.1 Designations ...................................................................................................................................................... 20

5.2 Technical data.................................................................................................................................................... 22

5.2.1 General information ...................................................................................................................................... 22

5.2.2 Types TWF-C 3.0.......................................................................................................................................... 23

5.2.3 Types TWF-C 3.0-PK.................................................................................................................................... 24

5.2.4 Types TWF-H-AWT ...................................................................................................................................... 26

5.2.5 Tray solution for closed facilities................................................................................................................... 27

5.3 Optional features, accessories .......................................................................................................................... 28

5.4 Rieber system crockery ..................................................................................................................................... 32

5.4.1 Thermotray 1 and Thermotray 2 ................................................................................................................... 32

5.4.2 Combitray - insulated crockery ..................................................................................................................... 33

6Things to know at delivery ........................................................................................................................... 36

7Use ................................................................................................................................................................. 38

7.1 Safety information with regard to use................................................................................................................ 38

7.2 General instructions for use............................................................................................................................... 39

7.3 Types TWF-AK .................................................................................................................................................. 40

8Cleaning, Maintenance and Care ................................................................................................................. 42

8.1 Safety information relating to cleaning, maintenance and care ........................................................................ 42

8.2 Cleaning agents for stainless steel.................................................................................................................... 43

8.3 Choose the correct cleaning method................................................................................................................. 44

8.4 Overview............................................................................................................................................................ 46

9Troubleshooting............................................................................................................................................ 47

9.1 Notes on troubleshooting................................................................................................................................... 47

9.2 Disposing of your product.................................................................................................................................. 48

10 Warranty and liability .................................................................................................................................... 49

11 Excerpt from the EU Declaration of Conformity......................................................................................... 49

12 Index............................................................................................................................................................... 50

13 Contact Details .............................................................................................................................................. 51

Important information

4

Rieber GmbH & Co. KG

1Revision Index

Revision

Change

2016-03-30

Provisional new edition

2017-12-06

Series C has been changed; mobile kitchen company logo

2018-03-07_f1

Adjusted to new reconstruction

2Important information

2.1 The components of the technical documentation

Operating instructions for tray transport trolley

Separate instructions for CHECK HACCP

www.rieber.de

Select "Service" at the top of the display list.

Spare parts and necessary instructions.

www.rieber.de

Select "Customer Service" at the top of the display list.

The Rieber price guide provides information about a wide variety of accessories.

www.rieber.de

At the top of the display list, select: Search price guide

Or: Contact the manufacturer, Rieber, or your dealer

Do you wish to have the operating instructions in another language?

www.rieber.de

Select "Customer Service" at the top of the display list.

2.2 Using this guide

This guide contains important information about how you can use the appliance safely and

correctly.

Read the operating instructions before first using the product.

Keep this guide in a safe place and pass it onto the next owner should you

wish to part with the product.

Our customers often express the wish to have one compact guide instead of a number of different

guides for these product variants, which have similar functions.

If there are any shortcomings in your opinion, please do not hesitate to let us know. We endeavour

to become even better with your help.

Important information

Rieber GmbH & Co. KG

5

Please add your notes here

2.3 Representation conventions in the text

Lists are represented in this way.

Instructions on certain actions are represented in this way.

▌The result of the action is represented in this way.

See ‘. . . ’ cross-references are represented in this way.

NOTE

indicates potential damage to property without any personal injury.

Failure to observe this note can lead to material damage.

User tip

Useful information or tip

# Explanation of graphic symbols used

Empty weight

Maximum loading

Important information

6

Rieber GmbH & Co. KG

2.4 Structure of safety instructions

The signal words DANGER - WARNING - CAUTION classify the degree of risk of bodily injury in an actual

situation. You can avoid injury by complying with the behavioural rules provided.

The warning triangle symbol indicates a "General Danger".

DANGER

indicates imminent danger.

Failure to follow these warning instructions will result in serious bodily

injury or even death.

WARNING

indicates a potentially hazardous situation.

Failure to follow these warning instructions may cause serious bodily

injury or even death.

CAUTION

indicates a potentially harmful situation.

Failure to follow these warnings may cause minor bodily injury.

2.5 Navigation aid for making selections for your specific requirements

# Advantages at a glance

Diverse selection of tray transport trolleys for your special requirements.

CHECK HACCP –the digitisation and organisation system from Rieber, for a safe,

transparent and traceable process.

# Note for your order

The order no. can be supplemented by the order numbers of optional features.

Select accessories such as *Rieber system tableware' separately.

‘Optional features, accessories’, Page 28 et seqq.

Safety instructions

Rieber GmbH & Co. KG

7

3Safety instructions

This section covers residual risks and hazards associated with the intended use of the appliance. We have

provided a list of all generally valid safety instructions which must be followed.

In the following section, safety information relating to a particular operation or situation is placed before the

appropriate operation step or description of the situation.

The information provided here such as ‘Basic rules of conduct’, ‘Operator's obligations’ etc. only refers to the

legally required observance of requirements such as the Workplaces Ordinance (ArbStättV) according to

German law.

3.1 General behaviour

This appliance meets the current state of the art and complies with all acknowledged technical

safety-related regulations. Nevertheless hazards may still arise.

Only use this appliance when it is in fault-free condition and according to the

instructions in this user guide.

During all phases of the appliance's life please ensure that the appliance is safely

integrated into its environment.

Refrain from rearranging or changing the device.

3.2 On use of electrical appliances

Safety instructions according to EN 60745-1:

Work area

Keep your work area clean and tidy. A messy or unlit work area can cause accidents.

Keep children and other people away from the area when work is being carried out.

Electrical safety

The plug on the unit must fit in the socket. Do not modify the plug in any way. Never use an adapter

in combination with earthed appliances. Using an unmodified plug and a suitable socket will reduce

the risk of an electric shock.

Avoid bodily contact with earthed surfaces such as pipes, heating units, cookers and refrigerators.

The risk of an electric shock is greater when your body is earthed.

Keep the device away from rain or moisture. Allowing water to get into an electric appliance will

increase the risk of electric shock.

Do not use the cable for anything other than the intended purpose to disconnect the plug from the

socket. Always remove whilst holding onto the plug. Keep the cable away from heat, oil, sharp edges

or the moving parts of other appliances. Using damaged or tangled cables increases the risk of

electric shock.

When working with an electrical appliance outdoors, only use extension cables which are permitted

for outdoor use. Using an extension cable suitable for outdoor use reduces the risk of electric shock.

Potential risk of fire due to heat build-up. Unwind the cable from the cable drum to prevent a possible

heat build-up and/or cable fire. The coupling must have splash protection, must be made of rubber or

be rubber-coated.

Safety instructions

8

Rieber GmbH & Co. KG

Safety guidelines for persons

Be attentive and pay attention to what you are doing, act rationally when working with an electrical

appliance. Do not use the appliance when tired or under the influence of drugs, alcohol or

medication.

Just one moment of inattention whilst using the appliance can result in serious injury.

Make sure the appliance cannot be switched on unintentionally. Double check that the main switch is

in the "OFF" position before inserting the plug in the socket. Connecting the appliance to the power

supply while it is switched on can cause an accident.

Careful handling and use of electrical appliances

Never use an electrical appliance with a faulty switch. An electrical appliance which can no longer be

switched on or off is dangerous and must be repaired.

Keep unused electrical devices away from children. Do not allow the appliance to be used by

persons who are not familiar with it or persons who are not familiar with this user guide. Electrical

appliances are dangerous when in the hands of inexperienced persons.

Treat the device with care. Check that moving parts are functioning properly and do not block; check

whether parts are broken or damaged and impairing the functioning of the device. Have any

damaged parts repaired before using the appliance. Many accidents are caused by poorly-

maintained electrical appliances.

Use electrical appliances, accessories etc in accordance with these instructions and in a manner that

is specified for this particular appliance type. When using the appliance, please take into account the

working conditions and the work being carried out. Using electrical appliances for other uses than

that intended can lead to hazardous situations.

Service

Only have the device repaired by qualified and authorised staff. Only use original spare parts. In this

way you can ensure that the appliance remains safe.

3.3 Operator's duties

Operator

The operator is the person who operates the appliance for commercial or economic purposes either

himself/herself or lets others use it and bears the legal appliance responsibility for protection of the

user, staff or any third parties during operation.

Operator's duties

The appliance is used in commercial applications. For this reason, the operator of the appliance

must meet all legal duties relating to work safety.

In addition to the safety instructions in this guide, the safety, accident prevention and environmental

protection regulation applying to the application of the appliance must be complied with.

In particular, the following shall apply:

The operator must be familiar with the applicable work safety regulations and

identify, by carrying out a risk analysis, any additional hazards which are due to the

place where the appliance is used. These hazards must be addressed in the form of

operating instructions governing the operation of the appliance.

Throughout the period of use of the device the operator must check that the

operating instructions which he has compiled comply with the current regulations

and adapt them if necessary.

The operator must clearly regulate and define the responsibilities for installation,

operation, troubleshooting, maintenance and cleaning.

The operator must ensure that all employees who use the device have read and

understood these instructions. In addition, the operator must train the personnel and

inform them of the hazards involved at regular intervals.

Safety instructions

Rieber GmbH & Co. KG

9

The operator must provide the personnel with the necessary protective equipment

and issue mandatory instructions on wearing it.

In addition, the operator must ensure that the appliance is always in a perfect technical condition.

For this reason, the following shall apply:

The operator must ensure that the maintenance intervals defined in this guide are

obeyed.

The operator must regularly check all safety devices for functionality and

completeness.

The operator must ensure that the appropriate media connections are present.

The operator must ensure that structural safety measures are performed.

3.4 Personnel qualification requirements

Safe operation requires certain technical skills and personal qualification of each person.

The responsibility for organization lies with the ‘Designated Representative’

(operator).

According to EN 50110-1 a work supervisor is ‘a person who is appointed to take

direct responsibility for the performance of work. If necessary, this responsibility can

be assigned partly to other persons. [...] The designated representative must instruct

all persons involved in the work on all hazards which may not be obvious for them’.

The work may only be performed by ‘instructed persons’ who have been trained

accordingly. Training, instructions must be repeated, proper understanding must be

verified (ideally by way of an appropriate test).

Only ‘Qualified Staff’ are allowed to carry out repair work.

According to IEC 60204-1, skilled workers are 'People who, due to their relevant

training and experience, are able to recognize risks and avoid potential hazards.'

Electrical work may only be carried out by trained and experienced electricians.

Electro-technically instructed persons may only work under the supervision of a

qualified electrician.

Work on the cooling unit should only be carried out by authorised skilled personnel

like a refrigeration specialist or a member of the Rieber Customer Service.

Repairs during the warranty period may only be carried out by the Rieber service

department, otherwise any resulting claims may lapse. Please contact the

manufacturer's service department at Rieber.

Chapter ‘Warranty and liability’, page 49

Safety instructions

10

Rieber GmbH & Co. KG

3.5 Provide personal protective equipment (PPE) for personnel

The requirements for safety shoes are regulated by standards. The safety shoes in this case are intended to

protect the toes. S1 safety shoes are protective shoes with the requirement that a protective toecap is present.

As with S2 and S3 safety shoes, the protective toecap has a load capacity of 200 joules. These requirements

are regulated in EN 20345:2004 for safety shoes.

Ensure that the personnel wear the personal protective equipment appropriate to the

relevant situation.

Wear safety shoes to prevent injuries during transport of the appliance.

3.6 Appliance-specific safety instructions

This chapter describes general, appliance-specific safety instructions. In the following section, additional safety

information relating to a particular operation or situation is placed before the appropriate operation step or

description of the situation.

3.6.1 Risks due to unstable position

Avoid unintentional moving of the appliance and the resulting risks. Prevent the

appliance from rolling away accidentally using the two parking brakes. Only park the

device on flat surfaces.

Observe general rules for safety against overturning:

Load the appliance from bottom to top to increase safety against overturning.

Unload the appliance from top to bottom.

3.6.2 Risks during transport of the appliance

Keep the doors closed during transport.

Push the appliance using the pushing handles; this gives you direct access to the

casters and retainers.

Move the appliance with 2 people if necessary.

Risks due to uncontrollable forces and overall weight of the appliance. Do not use

the appliance on a sloping surface, only move it on a flat surface.

Avoid unintentional moving of the appliance and the resulting risks. Prevent the

appliance from rolling away accidentally using the two parking brakes. Only park the

appliance on flat surfaces.

Safety instructions

Rieber GmbH & Co. KG

11

Only park the appliance on objects if a guard rail (optional) is provided. Make

realistic decisions when ensuring that deposited objects cannot fall. Secure objects

if necessary, for example with lashing straps or transport straps. Do not exceed the

maximum loading on the top, maximum 20 kg.

NOTE

Do not lift or transport the appliance with material handling equipment or a lift truck,

as this could damage the underside.

Wear personal protective equipment (PPE) such as safety shoes to prevent injuries

such as crushing, for example due to toes being run over.

NOTE

Note the permissible step height, maximum 4 mm, otherwise the casters may be

damaged.

NOTE

Do not lift the appliance using the pushing handle, as this could cause damage.

3.6.3 Risks due to electricity

→ Applies to types TWF-AK (… with cooling device, active convection cooling)

Danger of electric shock. Always disconnect the power cable before transporting the

appliance.

Danger of electric shock. Keep the device away from rain or moisture. Allowing

water to get into an electric appliance will increase the risk of electric shock.

Install the electric connection cable in such a way that risks like falling over or

tearing off the cable, etc. are avoided.

Safety instructions

12

Rieber GmbH & Co. KG

3.6.4 Risks due to trapped moisture and mould formation

Water jet can wet insulation materials on the side, which would impair the insulation effect; mould

formation, unpleasant odours etc. could result.

TWF-C 3.0, TWF-C 3.0-PK, TWF-AK may only be wiped down with a moist cloth.

Do not expose to water jets.

In the event of moisture damage, dry the appliance in the heating cabinet if

necessary.

Maximum permissible temperature +45 °C.

In the event of mould formation, lock the appliance and arrange for a hygiene

specialist to carry out the necessary measures.

Take suitable measures against human error, for example against the risk of

confusing appliances with each other, as when cleaning.

‘Operator's duties’, page 8

3.6.5 Risks of slipping/falling

!

→ Applies to types TWF-C 3.0-PK

Collection tank for condensation

Slipping hazard. Risk of falling. Empty the collection tank for condensation in due

time.

The device can be brought to the right temperature in advance in a cold chamber or

heat cabinet, between +2 °C and +45 °C. Do not allow it to go below +2 °C.

Safety instructions

Rieber GmbH & Co. KG

13

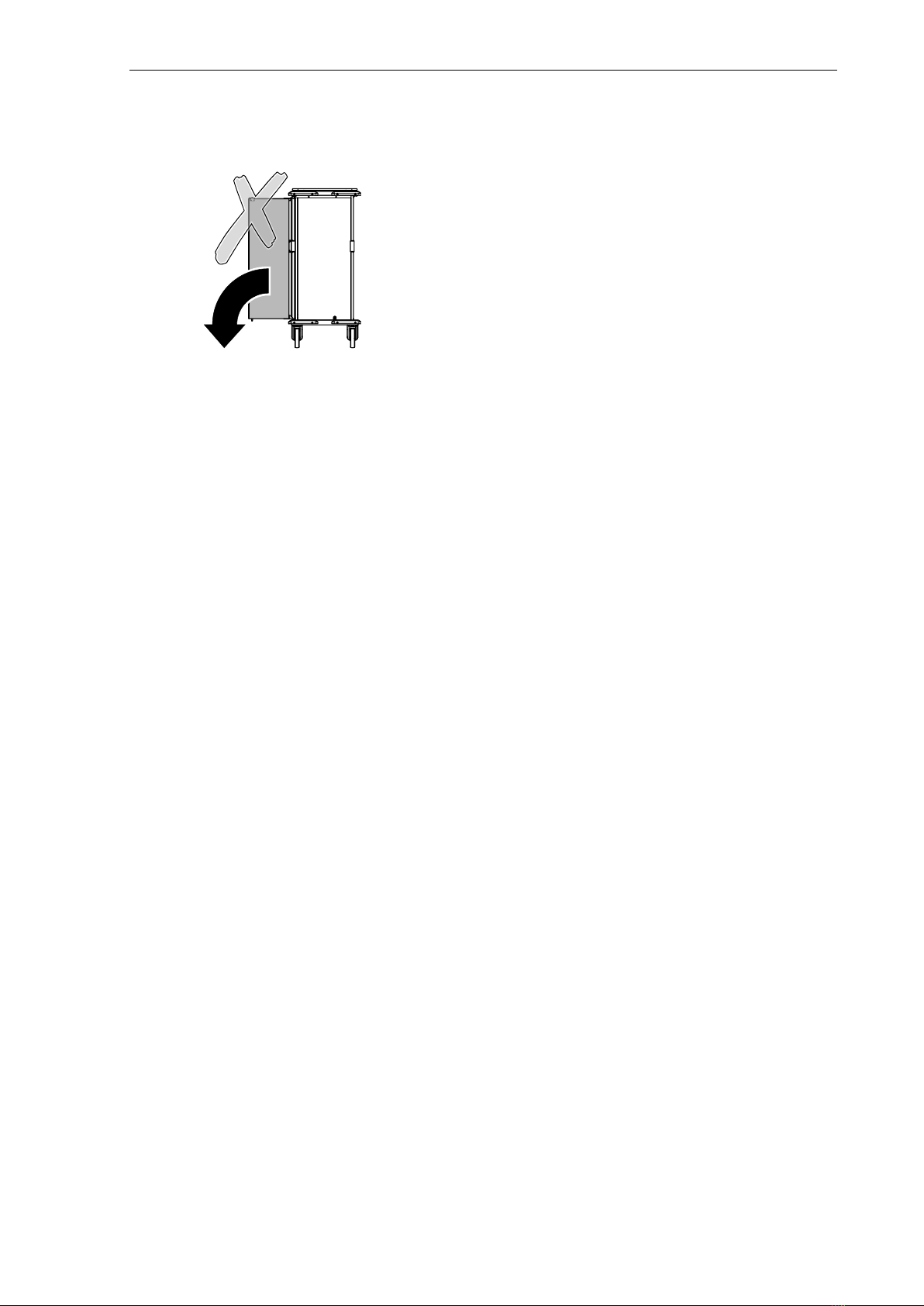

3.6.6 Risks of tilting/toppling over

!

Secure the position of the door at the end positions with a door lock.

Do not tilt the device at the open door.

3.6.7 Risks due to being enclosed or suffocation in the appliance

→ applies to all appliances

Danger of suffocation if persons get shut inside the appliance. Secure the appliance

against children at play and people with limited sensory and mental abilities. Use in

public areas or for self-service is only permitted under constant supervision.

→ Applies to types TWF-AK (… with cooling device, active convection cooling)

Danger of suffocation if persons get locked in the appliance. Make sure persons with

limited sensory and mental ability have no access to the appliance.

3.6.8 Risks concerning the use of the appliance by children

This appliance may be used by children over 12 and by persons with limited

physical, sensory and intellectual abilities or a lack of experience and/or knowledge

if they are supervised or if they have been instructed in the safe use of the appliance

and have understood the resulting dangers.

Children may not play with the appliance. They could shut themselves inside it.

Cleaning and user maintenance may not be carried out by children without

supervision.

Safety instructions

14

Rieber GmbH & Co. KG

3.6.9 Safety and monitoring devices

# General

Design example TWF-C 3.0-PK

1 2x swivel casters with parking brake → secure appliance in position to prevent it from rolling

away and act as an ‘emergency brake’.

2 Collecting tank for condensation → Condensation running of the cooling pellets is collected.→

Applies to types TWF-C 3.0-PK.

3 Handle → for pushing the appliance. → Push the appliance using the pushing handle; this

gives you direct access to the casters and the parking brakes. If necessary ask someone to

help you.

There are two movable, long guard rollers on the grips to move the device. These are to

protect against pinching/squashing fingers/hands and also against damage from banging

against door locks.

4 Door rod with handle → The door self-locks. Open the door by taking hold of the handle and

pulling it up. Door stop in ed positions.

5 Ledges to fix position and prevent the tray from tipping

The lower 'encompassing bumper rail' protects against impact and avoids property

damage.

The upper 'encompassing bumper rail' (optional) provides additional protection

against property damage, e.g. during transportation by car.

# → Applies to types TWF-AK (… with cooling unit, active convection cooling)

The product switches itself off automatically in the event of a fault in the control

system..

To increase your safety we recommend that you install a residual current device

with a tripping current of 30 mA upstream of the appliance.

Every 6 hours an automatic defrosting operation takes place, which prevents the

evaporator from icing up; the condensation evaporates. The defrosting phase takes

around 20 minutes when the power to the appliance is switched on.

The defrosting LED (3) lights up.

‘Types TWF-AK’, page 40

Safety instructions

Rieber GmbH & Co. KG

15

3.7 Note the product identification and ensure its preservation

TWF-C 3.0

TWF-C 3.0-PK

TWF-AK

TWF-H-AWT

These product identifications can be ordered by request.

Safety instructions

16

Rieber GmbH & Co. KG

The 'collection tank for condensation' and its position in the appliance are not

marked.

The own weight of the appliance as well as the permissible loading are not marked

on the device.

3.8 Information about regulations to be followed

In addition to this user guide there are a range of health and safety and other regulationsthat are

relevant for the operation of this cooking station; these include HACCP food hygiene regulations for

example.

Maximum keep-warm time according to HACCP is 2 hours.

3.9 Instructions on behaviour in an emergency

Prepare first-aid measures. Scenarios:

Crushing of tips of toes due to being run over

Crushing of parts of the body during movement of the appliance

Contusions, stab and cut injuries from falling tableware; cutlery or sharp, sharp-

edged object.

Risk of burns and scalds from hot parts such as food, soups etc.

Sliding/falling Draining condensation can make the floor slippery if the collection

tank for condensation is not emptied.

An emergency could be a fire in the proximity. Make sure you take precautionary measures.

For electrical appliances: Switch the appliance off immediately in an emergency. Unplug the mains

plug. Switch off the fuse if necessary.

Store the emergency equipment, including the relevant instructions, at a readily accessible place

near the place of use.

Instructions on dealing with faults in the refrigeration system

→ Applies to types TWF-AK (… with cooling device, active convection cooling)

Work at the cooling unit may only be carried out by refrigeration experts.

Refrigerant in the cooling circuit: Contact can cause eye irritation and cardiovascular disorders.

Fire-fighting measures:

Use water spray jet or water mist, alternatively carbon dioxide or powder

extinguisher.

Call the fire brigade; Use self-contained breathing apparatus.

Safety instructions

Rieber GmbH & Co. KG

17

Information on the insulating material between inner and outer sheet / carcass:

Polyurethane rigid foam board

This information is intended for the operator in the event of a large fire.

In the event of a fire thick black smoke develops, which contains hazardous decomposition

products. Breathing in the decomposition products can cause a health hazard. In the event of a fire

wear self-contained breathing apparatus if necessary.

Suitable extinguishing media: Alcohol-resistant foam, carbon dioxide (CO2), dry powder, water

spray jet

Information on Armaflex insulation material

→ Applies to types TWF-AK (… with cooling device, active convection cooling)

This information is intended for the operator in the event of a large fire.

This appliance contains around 1 m2Armaflex, for sealing lines. Armaflex insulation material can

burn and release toxic fumes.

First-aid measures:

Call a doctor.

Move to fresh air after inhalation.

In the event of contact with the skin wash off with water and soap.

After eye contact remove contact lenses, hold eyelids open and rinse for at least

15 minutes with plenty of clean, running water.

Call a doctor.

Fire-fighting measures:

Water spray jet; Carbon dioxide (CO2); Dry powder; Foam

Use self-contained breathing apparatus. Wear protective suit.

Designated use

18

Rieber GmbH & Co. KG

4Designated use

This chapter provides information on the intended use of the product and warns against foreseeable misuse or

abuse, for your safety.

4.1 Generally, the following are intended uses for the product

For mobile meal services in chain and general catering, hotels and restaurants; also

for managed care facilities and schools. Food delivery / food distribution in building.

Only keep either hot or cold food in an appliance at any one time.

To prevent injuries, any use in public and/or for self-service is only allowed under

supervision.

Push the appliance using the pushing handle.

Only spare parts that have been approved and specified by the manufacturer may

be used. Certain repairs may only be carried out by the Rieber service department.

The intended use includes compliance with the technical data.

The person responsible for the work, e.g. the chef, defines how the tray transport

trolley is actually used and is responsible for such use.

For use only by appropriately trained and suitable operating personnel.

4.2 Prevent any predictable misuse and abuse

Water jet can wet insulation materials on the side, which would impair the insulation effect; mould

formation, unpleasant odours etc. could result.

→ Applies to: TWF-C 3.0, TWF-C 3.0-PK, TWF-AK

TWF-C 3.0, TWF-C 3.0-PK, TWF-AK should only be wiped with a moist cloth and

be kept away from the effects of liquids. Do not expose to water jets.

Page 15, 38, 42

Deliver/distribute food packaged/wrapped.

Do not lift the appliance using the pushing handle, as this could cause damage.

Push the appliance using the pushing handle.

Do not pull or push the appliance over sharp edges, danger of material damage.

Do not use this appliance on poor floor conditions.

▌We are not able to rule out the possibility of marks appearing on the floor due to friction

with casters or the formation of scratches due to split cracks in the casters, for example.

▌We are not able to rule out the possibility that the casters may be damaged or become

unusable due to thresholds or sharp edges on the floor.

Only transport the appliance in its correct position (operating position).

Designated use

Rieber GmbH & Co. KG

19

Machine-aided transport, using fork lift trucks or lift trucks, is not permitted. The

transportation of TWF-H-AWT may differ depending on the specific order.

Not intended for private domestic use.

Do not use the appliance in aggressive ambient conditions, for example extremely

salt-laden air such as close to the sea or at a swimming pool with a chlorinated

atmosphere, as this could damage the stainless steel.

Incorrect cleaning can substantially and irreparably damage the stainless steel

surfaces.

‘Choose the correct cleaning method’, page 44

4.3 Special intended use for TWF-H-AWT appliances

# Intended uses of the product are as follows:

TWF-H-AWT stands for order-specific special versions in hygiene design H3 for

'automatic goods transport'. This can be, for example, a flexible transport system

(FTS) or an electric overhead conveyor (EHB).

Use the device only for the contractually agreed designation.

# Avoid incorrect use and misuse:

A frequently requested use of the product is the transportation of trays of all

variants, sterile goods, pharmaceutical goods, dirty and dirty laundry and waste.

Only use the appliance for the intended or contractually agreed purpose.

The operator of the appliance must meet all legal duties relating to work safety. It

may be necessary to provide special instructions for the operating staff. A special

product identification may be advisable; If necessary, contact the manufacturer.

‘Operator's duties’, page 8

4.4 Special intended use for TWF-AK appliances

# Intended uses of the product are as follows:

For keeping portioned (refrigerated) food cold, not for cooling food down.

The appliance can be brought to temperature beforehand in a cold chamber, down

to +2 °to C.

This appliance is intended for use up to an altitude of 4000 metres above sea level.

# Avoid incorrect use and misuse:

Fill TWF-AK with sufficiently pre-chilled food. Otherwise condensation could run off

and damage the parquet floor. Slipping hazard.

automatic defrosting process. Comply with the HACCP regulations.

‘Types TWF-AK’, page 40

Description of appliance

20

Rieber GmbH & Co. KG

4.5 Tray solution for closed facility

# Intended uses of the product are as follows:

For close facilities, for example a hospital for the mentally ill or a prison. Special

solution.

Safe meal trays, containers, lids, set

Chapter ‘Tray solution for closed facilities’, page 27

5Description of appliance

This chapter has interesting facts about the set-up and functionality of this appliance

5.1 Designations

Design example TWF-C 3.0-PK

Design example TWF-C 3.0

1 2x caster with parking brake → secures appliance in position to prevent it from rolling away

and acts as 'emergency brake'

2 Collection tank for condensation →applies to TWF-C 3.0-PK

3 Cooling pellets for chilling (accessories) → applies to TWF-C 3.0-PK

4 Pushing handle →for pushing the TWF

5 Door rod with handle →The door self-locks. Otherwise, take hold of the handle and

open/close. Door stop in ed positions.

6 Guard rail (optional)

7 Bumper rail → to prevent damage to property during collisions,

(impact protection at top is optional)

8 Dividing wall → filled with cooling pellets for type TWF-C 3.0-PK

9 Deep-drawn support ledges and anti-tipping mechanisms, to prevent the tray from tipping

10 Fixed caster, 2x

This manual suits for next models

1

Table of contents