4

GENERAL

1 GENERAL

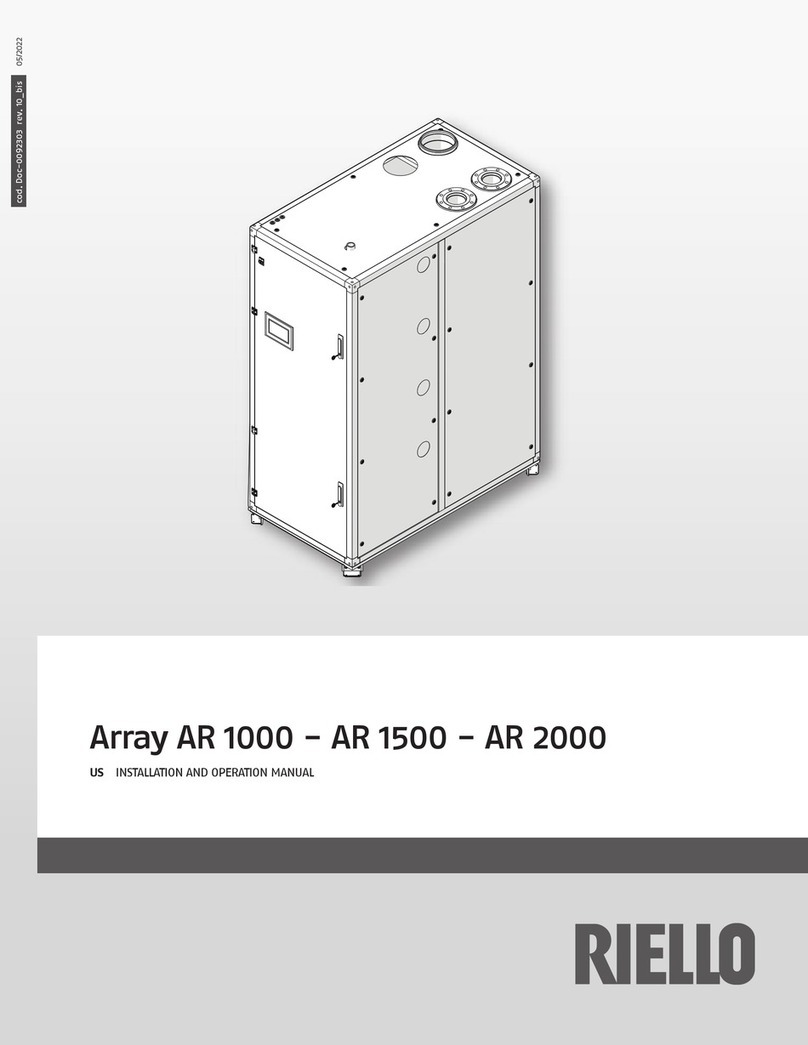

The RArray AR 1000, AR 1500 and AR 2000 MBH Boilers are

modulating and condensing units. They represent a true industry

advance that meets the needs of today’s energy and environmen-

tal concerns. Designed for application in any closed loop hydronic

system, the Array’s modulating capability relates energy input di-

rectly to uctuating system loads. The turn down ratio for these

models is 10:1 for AR 1000, 15:1 for AR 1500 and 20:1 for AR 2000.

These Array models provide extremely high efciency operation

and are ideally suited for modern low temperature, as well as,

conventional heating systems.

The Array Models AR 1000,AR 1500 and AR 2000 operate within the

following input and output ranges:

Array

model

Input Range (BTU/hr.) Output Range(*) (BTU/hr.)

Minimum Maximum Minimum Maximum

AR 1000 100,000 1,000,000 96,100 961,000

AR 1500 100,000 1,500,000 96,100 1,441,500

AR 2000 100,000 2,000,000 96,100 1,922,000

(*) The output of the boiler is a function of the unit’s ring rate,

return water temperature and BTU content of gas supply.

Array Series of hot water boilers has been designed in compliance

with the CSD-1 code.

When installed and operated in accordance with this Instruction

Manual, these boilers comply with the NOx emission standards

outlined in:

South Coast Air Quality Management District (SCAQMD), Rule 1146.2

Whether used in singular or modular arrangements, the AR 1000,

AR 1500 and AR 2000 offer the maximum venting exibility with

minimum installation space requirements. These Boilers are Cat-

egory IV, positive pressure appliances. Single and/or multiple

breeched units are capable of operation in the following vent

congurations:

− Conventional, Vertical Conventional,

− Sidewall Conventional, Direct Vent,

− Vertical Sealed, Direct Vent, Horizontal

These boilers are capable of being vented utilizing PP, CPVC, Stain-

less steel AL29-4C vent systems.

The Array’s advanced electronics are available in several selectable

modes of operation offering the most efcient operating methods

and energy management system integration.

9

IMPORTANT: Unless otherwise specied, all descriptions and

procedures provided in this Installation & Operation Manual

apply to the Array series of boiler.

1.1 Warnings & cautions

Installers and operating personnel MUST, at all times, observe all

safety regulations. The following warnings and cautions are gen-

eral and must be given the same attention as specic precautions

included in these instructions.

In addition to all the requirements included in this RInstruc-

tion Manual, the installation of units MUST conform with local

building codes, or, in the absence of local codes, ANSI Z223.1 (Na-

tional Fuel Gas Code Publication No. NFPA-54) for gas-red boilers

and ANSI/NFPASB for LP gas-red boilers.

Where applicable, the equipment shall be installed in accordance

with the current Installation Code for Gas Burning Appliances and

Equipment, CSA B149.1, and applicable Provincial regulations for

the class; which should be carefully followed in all cases.

Authorities having jurisdiction should be consulted before instal-

lations are made.

See pages 10 - 12 for important information regarding installation of

units within the Commonwealth of Massachusetts.

9

IMPORTANT: This Instruction Manual is an integral part of the

product and must be maintained in legible condition. It must

be given to the user by the installer and kept in a safe place

for future reference.

9

WARNING: Do not use matches, candles, ames, or other

sources of ignition to check for gas leaks.

9

WARNING: Fluids under pressure may cause injury to person-

nel or damage to equipment when released. Be sure to shut

off all incoming and outgoing water shutoff valves. Careful-

ly decrease all trapped pressures to zero before performing

maintenance.

9

WARNING: Before attempting to perform any maintenance on

the unit, shut off all gas and electrical inputs to the unit.

9

WARNING: The exhaust vent pipe of the unit operates under

a positive pressure and therefore must be completely sealed

to prevent leakage of combustion products into living spaces.

9

WARNING: Electrical voltages up to 120 vac maybe used in this

equipment. Therefore the cover on the unit’s power box (lo-

cated behind the front panel door) must be installed at all

times, except during maintenance and servicing.

9

CAUTION: Many soaps used for gas pipe leak testing are cor-

rosive to metals. The piping must be rinsed thoroughly with

clean water after leak checks have been completed.

0

CAUTION: DO NOT use this boiler if any part has been under wa-

ter. Call a qualied service technician to inspect and replace

any part that has been under water.