Operating Manual

Breite: 170

Höhe:8,15

Oben Links

278,5 20

RIFOX - Hans Richter GmbH Spezialarmaturen Fon: +49 (0) 421 499 75 - 0 Internet: www.rifox.de

Bertha-von-Suttner

-Str

.

9

D-28207

Bremen

Fax:

+49

(0)

421

499

75

-

40

Email:

[email protected]05/2020

Page 4 of 5

-Di. Subject to modifications

5 Observation and check

The function’s failure can be observed either as condensate blockage or as gas/ steam leakage.

■Condensate blockage can be determined by a): loosen the control screw (4) for a quarter rotation, while no condensate

leakage should occur; and by b): a surface thermometer on the housing for steam applications (if necessary, please consult

with Rifox).

■Gas / steam leakage: can be determined by an ultrasonic measuring device, and for steam applications by a surface

thermometer. In case of steam leakage, open the condensate trap according to Section 6.1. Make sure that float can be easily

moved. If necessary, disassemble and clean the float control assembly. If damages/ wears are detected on parts or on the

sealing surface, the complete float control assembly should be replaced.

6 Maintenance / inspection

6.1 Opening the condensate trap and dismantling the float control

■The condensate trap must be depressurized. Shut off the system in front of and behind the condensate trap.

■Release any residual pressure by loosening the screw (4) by only a quarter turn.

■Loosen hexagon nuts (5) evenly crosswise and take off sealing plug (3) (approx.

8 kg).

■Loosen and screw off protective cap (14).

■Loosen support screw (10) and unscrew 1 - 2 turns.

■The control is detached from the conical housing seat by means of gentle blows

with a hammer on the front end of the support screw (10).

■Screw out the support screw (10) completely. Remove float control.

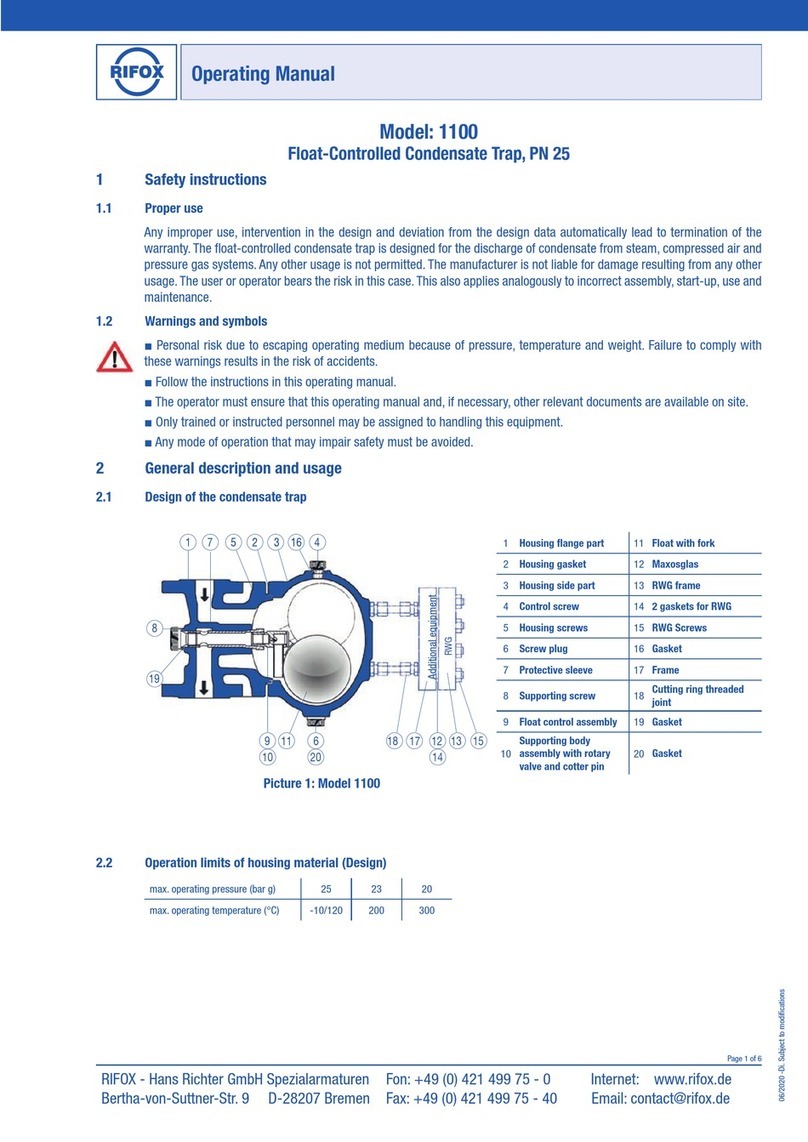

6.2 Disassembling and cleaning the float control (Picture 6)

■After removing the cotter pin (s), the rotary valve (d) is simply pulled out to the

side.

■Clean the parts using, for example, benzine.

■Check the rotary valve (d) for wear along the sealing edge. If wear is detected, the support body (t) together with the rotary

valve (d) must be replaced. A precise leakage test must be carried out by Rifox.

■During assembly ensure that the notch in the rotary valve (d) points to the punch mark on the support body (t) and the

cotter pin (s) is inserted and secured again carefully.

■The float must be able to move up and down without resistance.

6.3 Installing the control and assembling the condensate trap

■The complete float control is inserted into the conical housing seat with the support body (8). It is important to ensure that

the immersion tube is vertically downwards

■The support body (8) is fixed in place by means of a light tap with a plastic hammer on the front end of the immersion tube

in the conical housing seat.

■Screw in support screw (10) with gasket (11) and tighten with a standard ring wrench. Tightening torque according to

Section 6.5.

■Screw in protective cap (14) and fix with a locknut using moderate force.

■Check the housing gasket (2) and replace necessary.

■Tighten the housing screws (10) evenly crosswise. Tightening torque according to Section 6.5.

6.4 Care and maintenance

■In the case of a great risk of dirt accumulation, the housing should be rinsed thoroughly from time to time, but while de-

pressurized. If necessary, the float control should also be checked according to point 6.2.

■Dirt that has collected in the housing can be removed after taking off the screw plug (12).

■In special cases, it may be advisable to install a separate upstream dirt trap.

■The float control usually does not require special care; maintenance primarily depends on the wear resistance of the valve

seal. See points 6.1 and 6.2 in this connection.

Picture 6