10

100

0,1 1 10

Flow rate in kg/h

Pressure difference in bar (with reference to atmospheric pressure)

300

5

200

12

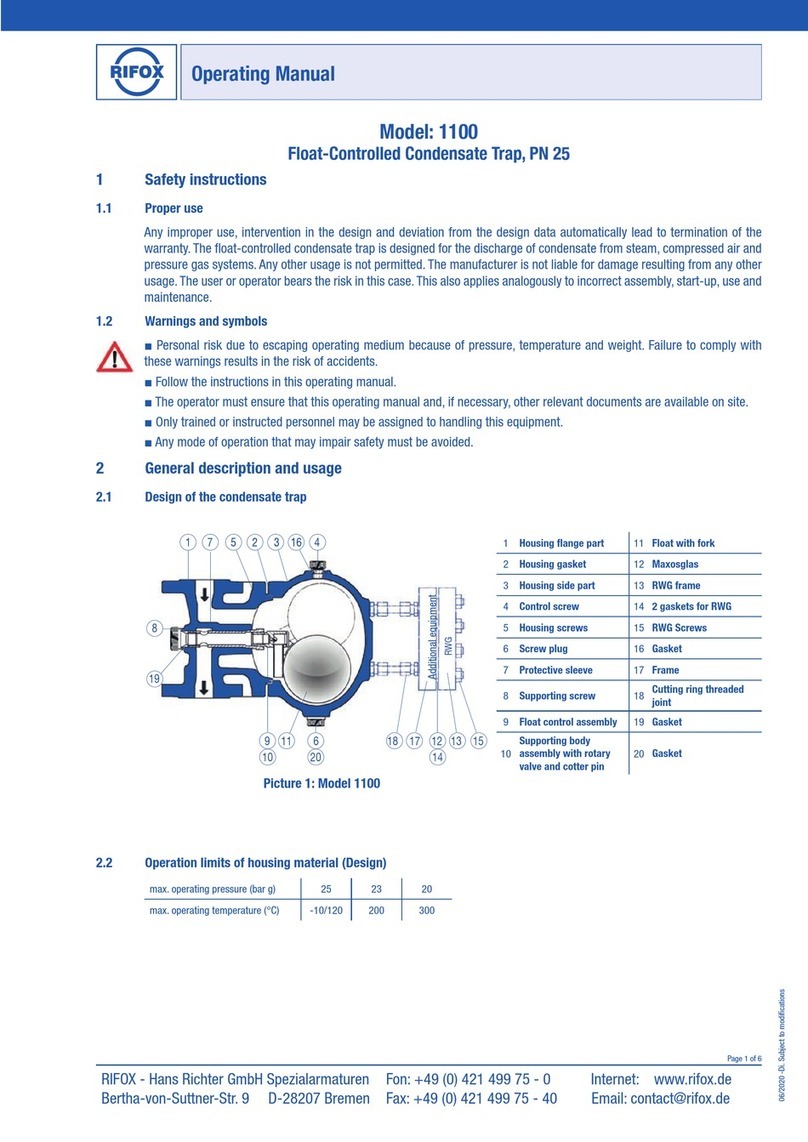

2.4 Discharge capacity

Picture 3

For very low pressures:

Pressure difference in bar g Discharge capacity in kg/h

0,02 23

0,04 32

0,06 40

0,08 46

2.5 Function

■ Due to the gravity the condensate flows downwards to the lowest point, which is the condensate trap housing. In the

lowest position of the float the outlet cross-section is close. Rising of the liquid level lifts the float and opens the outlet.

Condensate will be discharged through the upturned immersion tube. Decreasing condensate level closes the outlet again.

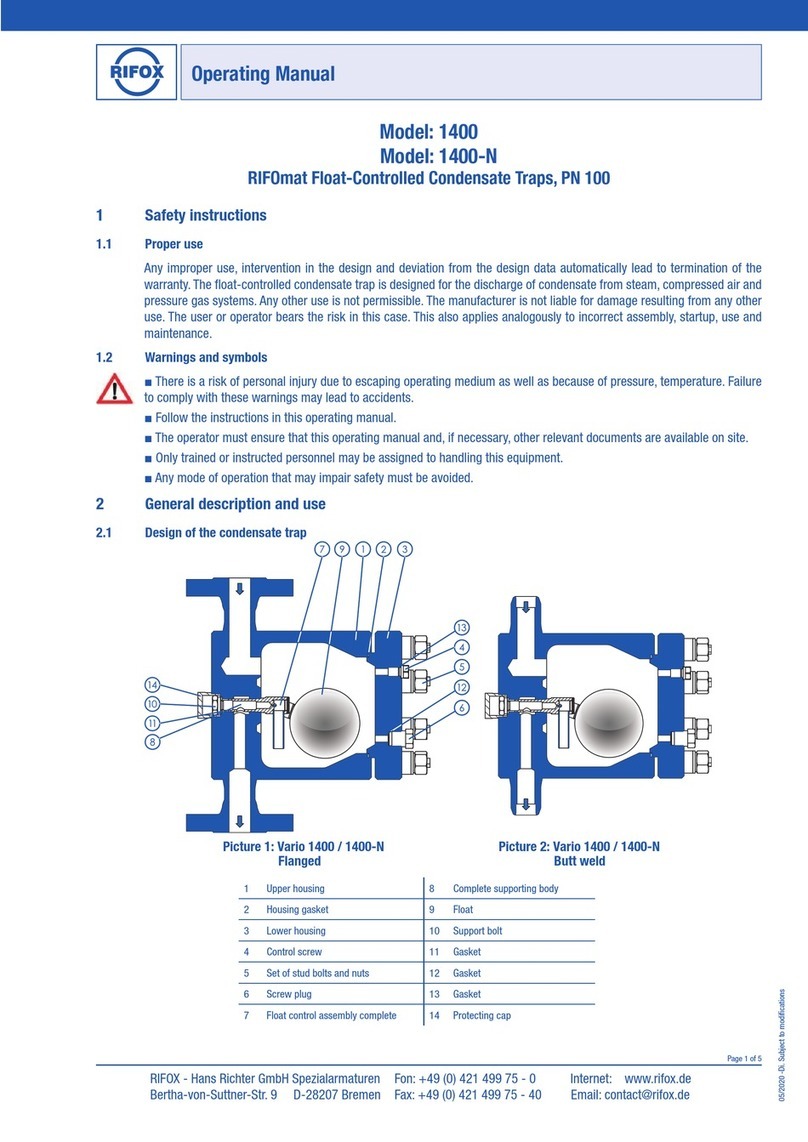

2.6 Submerged gastight control unit (Picture 4)

■ The condensate trap must be filled with water before start-up. The required water

trap is automatically adjusted during the proper operation. (Picture 4, Point ①) The

water seal is shown as dimension X in Picture 4.

■ The permanent presence of the minimum condensate level in the condensate trap

is a prerequisite for the complete gas tightness. When the condensate level sinks

under the cross-section (water seal does not exist), the gas tightness is no longer

guaranteed.

■ To ensure permanent gas tightness, it is required that condensate always drops in

the condensate trap. (Picture 4, Point ②) If there are for hours or days no condensate,

gas may leak through the closed valve.

■ The pressure peaks are absorbed by the condensate trap.

When using submerged-gastight control units, please note:

The valve orifice is always under an condensate surface.

If the gas is mixed or dissolved with the condensate, there can be no separation inside the steam trap.

Small amounts of gas can separate from the condensate at the outlet.

In these cases a degassing line at the outlet towards uncritical areas (via the roof for example) may be recommended.

A horizontal inflow can calm the condensate flow and support the self-degassing to separate the gas from the condensate.

When using an angular version (EF) condensate enters from above and can also bring gas into the housing.

With an inlet from below, the degassing happen before the trap, the automatic degassing is most effective.

Traps with submerged-gastight control units should not be used at above 90°C or its use should be clarified with RIFOX in

advance.

1

Min.

2

X: Water Seal

Cross Section

Picture 4

Tabel 1

Operating Manual

Breite: 170

Höhe:8,15

Oben Links

278,5 20

RIFOX - Hans Richter GmbH Spezialarmaturen Fon: +49 (0) 421 499 75 - 0 Internet: www.rifox.de

Bertha-von-Suttner

-Str

.

9

D-28207

Bremen

Fax:

+49

(0)

421

499

75

-

40

Email:

[email protected]05/2020

Page 2 of 6

-Di. Subject to modifications