BMD-200 Evaluation Kit User Guide

August 10, 2016

BMD-200-EVAL-UG-V1.4 Page 2 of 20

Table of Contents

1. Overview ...............................................................................................................................................1

1.1. Key Features..........................................................................................................................................1

1.2. Useful Tools...........................................................................................................................................4

2. Hardware Kit..........................................................................................................................................4

3. Getting Started ......................................................................................................................................5

3.1. Evaluation Board with SEGGER J-Link.....................................................................................................5

3.1.1. Set up tool chain...........................................................................................................................5

3.1.2. Connect BMD-200 Evaluation Kit to computer ..............................................................................5

3.1.3. Program BMD-200 Evaluation Kit with the S130 Soft Device .........................................................6

3.1.4. Set up the Application Project.......................................................................................................7

3.2. Evaluation Board with CMSIS-DAP (mbed).............................................................................................9

3.2.1. Connect BMD-200 Evaluation Kit to computer ..............................................................................9

3.2.2. Program BMD-200 Evaluation Kit (Drag and Drop) ........................................................................9

4. Hardware Description ..........................................................................................................................11

4.1. Power..................................................................................................................................................12

4.2. Buttons ...............................................................................................................................................12

4.3. LEDs ....................................................................................................................................................12

4.4. Virtual COM Port ................................................................................................................................. 13

4.5. Accelerometer.....................................................................................................................................13

4.6. SPI EEPROM.........................................................................................................................................14

4.7. Ambient Light Sensor...........................................................................................................................14

4.8. 32kHz Crystal Oscillator .......................................................................................................................14

4.9. Current Sensing Header.......................................................................................................................15

4.10. Headers...............................................................................................................................................16

4.11. GPIO Jumpers......................................................................................................................................17

5. Schematic ............................................................................................................................................18

6. BMD-200 Pinout...................................................................................................................................19

7. Life Support Policy ...............................................................................................................................20

8. Document History ................................................................................................................................20

9. Related Documents..............................................................................................................................20

Table of Figures

Figure 1 –BMD-200 Evaluation Board (Top View) .............................................................................................4

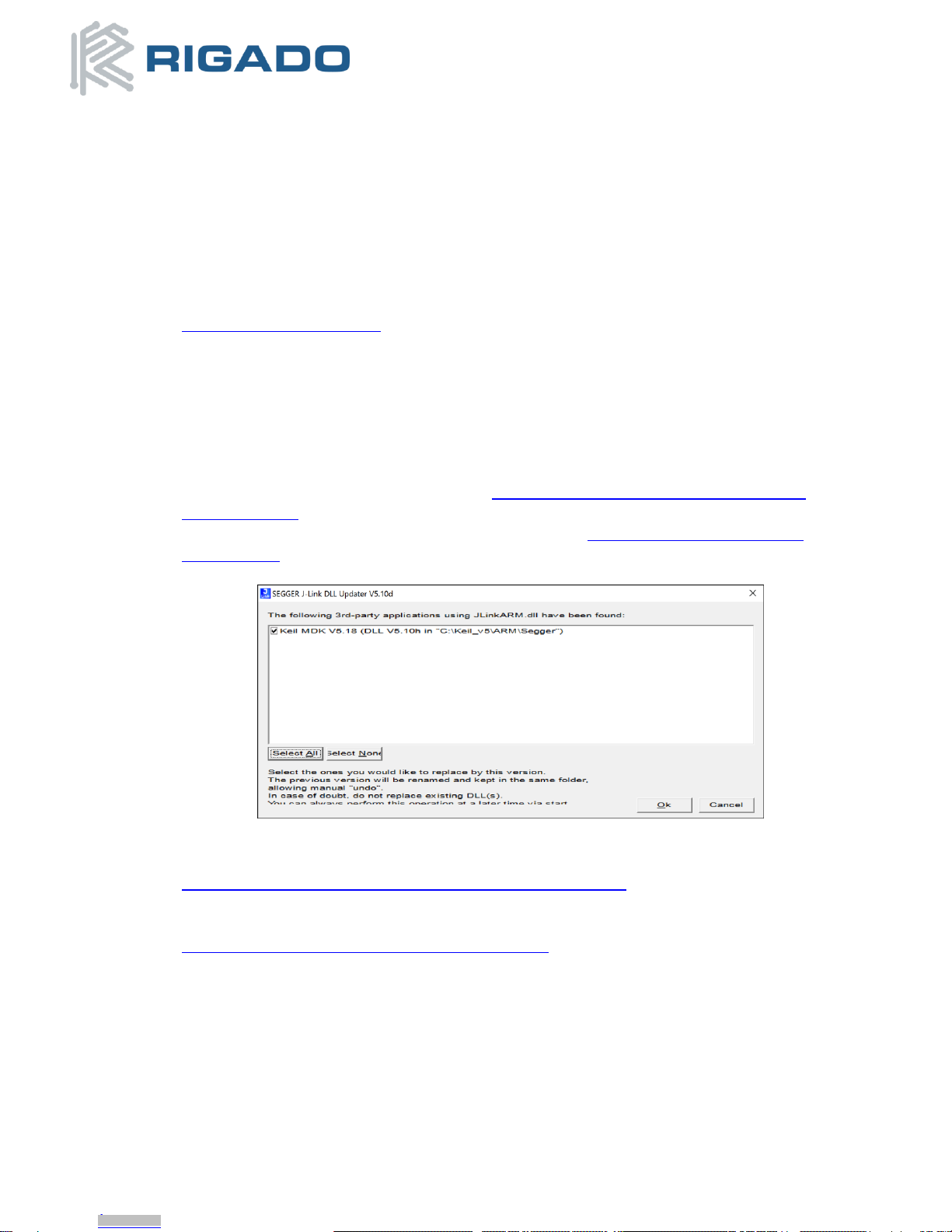

Figure 2 –Segger J-Link DLL Updater.................................................................................................................5

Figure 3 –nRFgo Studio SoftDevice Window.....................................................................................................6

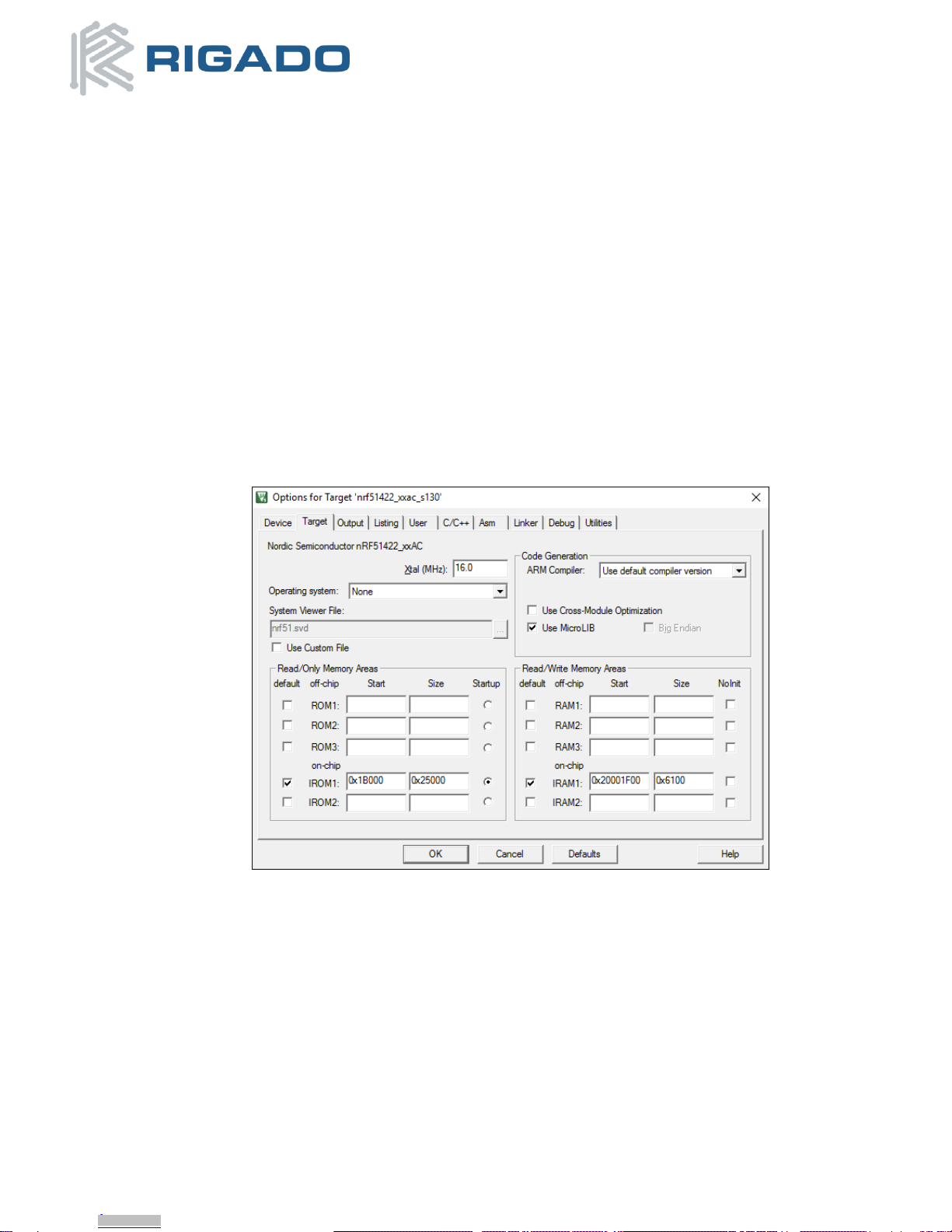

Figure 4 –Keil Flash Tools Target Window ........................................................................................................7

Figure 5 –Keil Flash Tools C/C++ Window .........................................................................................................8

Figure 6 –Keil Flash Tools Debug Window ........................................................................................................8

Figure 7 –Keil Flash Tools Debug Settings Window ...........................................................................................9

Figure 8 –Pin Out and Functions.....................................................................................................................11

Figure 9 –Assembly Drawing (Top View).........................................................................................................11

Figure 10 –LED Driver Layout & Circuit...........................................................................................................13

Figure 11 –Accelerometer Layout................................................................................................................... 13

Figure 12 –LED Driver Layout .........................................................................................................................14

Figure 13 –Ambient Light Sensor Layout ........................................................................................................14

Figure 14 –32KHz Crystal Oscillator Layout.....................................................................................................15

Figure 15 –Current Sensing Header Layout .....................................................................................................15

Figure 16 –Header Layout ..............................................................................................................................16