rigert PEGASUS-NOVA-mps2 Owner's manual

PEGASUS-NOVA mps 2

FAULT FINDING GUIDE

STAIRLIFT

rigert Ltd., Stairlifts Operating manual Nr.: AW4231

CH-6405 Immensee Fault finding PEGASUS-NOVA-mps2 Date: 13.03.06

Page: 2/22

Contents

1 Foreword .........................................................................................................................4

2 Fault finding guide..........................................................................................................6

2.1 Mains connection, Fuses, Frequency controller and travel recognition PCB............... 6

2.1.1 Check main supply on main control box ....................................................................... 6

2.1.2 Check fuses ......................................................................................................................7

2.1.3 Fuse blown or loose.........................................................................................................7

2.2 Check frequency converter (FC) (if applicable).................................................................8

2.2.1 Fault remedy on FC.......................................................................................................... 8

2.3 Check the travel recognition PCB ...................................................................................... 8

3 Adjustments....................................................................................................................9

3.1 Check setup..........................................................................................................................9

3.1.1 Reprogram “setup” parameters...................................................................................... 9

3.2 Check adjustments on carriage PCB ............................................................................... 10

3.2.1 Explanation of the possible adjustments ....................................................................10

4 Communication.............................................................................................................11

4.1 Check communication ....................................................................................................... 11

4.1.1 Search faults in “Modem Status” ................................................................................. 11

4.1.2 Communication with call stations ................................................................................ 12

5 Check safety circuit I and II ......................................................................................... 13

6 Status of call stations (RS) ..........................................................................................14

6.1 Check call stations.............................................................................................................14

6.1.1 Interpretation of call station status (RS) ...................................................................... 14

7 Status of carriage (FZ).................................................................................................. 15

7.1 Test carriage status ........................................................................................................... 15

7.1.1 Check drive order from hand hold control unit on carriage....................................... 15

7.1.2 Check safety switches on carriage...............................................................................15

7.1.3 Check landing recognition of carriage......................................................................... 15

7.1.4 Check platform position of carriage............................................................................. 16

7.1.5 Explanation of display for menu FZ status.................................................................. 17

7.2 Search for faults................................................................................................................. 18

7.2.1 Safety switches .............................................................................................................. 18

7.2.2 Position switches ........................................................................................................... 18

7.2.3 Switch locations on carriage......................................................................................... 19

8 Rail / Rope .....................................................................................................................21

8.1 Check for continuity rail / rope ......................................................................................... 21

8.1.1 Search for short circuit rail / rope................................................................................. 21

8.2 Check drive wheel..............................................................................................................21

8.3 Bridge rope / rail................................................................................................................. 22

9 Final remark ..................................................................................................................22

©2005 rigert Ltd., Stairlifts

All rights reserved.

No part of this document may be copied and/or published by means of print, photocopies, microfilms or any other method

without the prior written permission of the manufacturer. This also applies to the included drawings and/or diagrams and

plans.

rigert Ltd., Stairlifts Operating manual Nr.: AW4231

CH-6405 Immensee Fault finding PEGASUS-NOVA-mps2 Date: 13.03.06

Page: 3/22

The information in this document is based on the general information that belongs with the construction, material

characteristics and work methods that are known at the moment of publication, so that we retain the right to make changes

without prior notice. For this reason the information in this document must be viewed as a guideline for repair of the stairlift

that is shown on the cover.

This document applies to the stairlift in the standard model. The manufacturer therefore accepts no responsibility for any

form of loss or injury that might be the result of specifications that deviate from the standard model of the stairlift such as it is

delivered to you.

All possible care has been taken in the preparation of this document, but the manufacturer accepts no responsibility for

errors or for any consequences that might result from them.

Guarantee

This guarantee will become invalid:

– upon incorrect use.

– if one or more changes are made in the stairlift without the approval of the manufacturer.

– if one or more parts are replaced by third parties without the approval of the manufacturer.

– if the stairlift is not periodically inspected.

– if defects are not reported in writing.

rigert Ltd., Stairlifts Operating manual Nr.: AW4231

CH-6405 Immensee Fault finding PEGASUS-NOVA-mps2 Date: 13.03.06

Page: 4/22

1 Foreword

TAKE THE TIME TO READ THIS DOCUMENT THROUGH CAREFULLY BEFORE DOING

MAINTENANCE OR REPAIRS ON THE STAIRLIFT.

Use of this service manual

This service manual is intended to be used by authorised service engineers.

Authorised service engineers are people trained by rigert Ltd., Stairlifts, who have sufficient technical

and practical knowledge to be able to maintain and repair the stairlift referred to in this service manual

such as to facilitate its optimal use.

Authorised service engineers are trained for this purpose by rigert Ltd., Stairlifts and they are kept up

to date with regard to changes and adaptations so that they can carry out all repairs on all models.

Safety regulations and stipulations

General

The manufacturer accepts no responsibility for any loss or personal injury if the safety regulations and

the stated stipulations of this document are not adhered to, or if maintenance and repair of the stairlift

of this document is carelessly executed.

Depending on specific circumstances and accessories adapted safety instructions may be required.

Since the manufacturer cannot directly supervise specific uses, it is the responsibility of the

user/owner to assume local responsibility for health and safety. Please contact rigert Ltd., Stairlifts

immediately if you have encountered unsafe situations that are not described in this manual.

Read the below safety regulations that are relevant during cleaning, maintenance or repairs.

This document

The information and instructions contained in this document is based on use and environmental

conditions that are applicable at the time of transfer. Changes in environmental conditions can result

in certain information no longer being consistent with reality. In such cases contact the original

installer concerning the changes that have occurred.

Never change the sequence of the activities. Store this document carefully .

Use according to purpose1

The Pegasus-NOVA stairlift was designed solely for the transport of one seated person or one person

in a wheelchair (max. 225 kg) via a rail placed on the stairs and/or attached to a load bearing wall.

Every other or more extensive use is considered to be use not according to purpose. The

manufacturer accepts no liability whatsoever for loss or injury resulting from such use. The stairlift

meets applicable standards and regulations. Use the stairlift solely in perfect technical condition.

Changes

Changes in the stairlift are not permitted. This can influence the software of the programme. The

technical specifications must not be infringed upon.

Safety features

All safety features must be properly installed. If safety features do not function the stairlift cannot be

used: never bypass safety features!

rigert Ltd., Stairlifts Operating manual Nr.: AW4231

CH-6405 Immensee Fault finding PEGASUS-NOVA-mps2 Date: 13.03.06

Page: 5/22

Maintenance and repairs

Maintenance and repairs are the sole province of an authorised rigert Ltd., Stairlifts service engineer,

taking into consideration the safety regulations and instructions stated in this document.

Tools

Always use tools, original parts, materials and service techniques approved by the manufacturer.

Never use worn tools and put the tools away before doing a test run.

PC boards

The PC boards and the components on them represent electronic waste. Turn old PC boards in to

specialised companies for environmentally friendly processing.

Disposing of parts

Most parts of the stairlift are made of metal and can be disposed of in the regular manner as used metal. For

health and environmental reasons no asbestos has been used.

1 "Use according to purpose" as described in EN 292-1 is the use for which the product is technically suited, as specified by

the manufacturer and stated in the brochure of the manufacturer. In case of doubt this is the use that can be deduced from

the construction, the model and the function of the technical product, bearing in mind considerations of normal use. Use of

the stairlift within the limits of use according to purpose includes following the instructions contained in this document.

The stairlift shall be thoroughly examined at intervals not exceeding 12 months.

Symbols used in this manual

Visual inspection

Refer to an other manual

Use a tool / instrument

Useful hint / tip

Caution - Pay special attention – be careful

Before touching any electrical connections, terminals, ….. make sure by

an instrument that no power is present !

Drawing to refer to (see annex)

!

rigert Ltd., Stairlifts Operating manual Nr.: AW4231

CH-6405 Immensee Fault finding PEGASUS-NOVA-mps2 Date: 13.03.06

Page: 6/22

2 Fault finding guide

2.1 Mains connection, Fuses, Frequency controller and

travel recognition PCB

2.1.1 Check main supply on main control box

a) Single phase controller: Incoming tension

Measure between terminals:

b) 3-phase controller: Incoming tension

Measure between terminals:

If you measured these values, proceed to point 2.1.2

If not, search for faults within the mains supply ( RCD, Fuses, Wiring, …..)

L1 – N = 230 V

L1 – PE = 230 V

N – PE = 0 V

L1 – L2 = 400 V

L1 – L3 = 400 V

L2 – L3 = 400 V

L1 – N = 230 V

L2 – N = 230 V

L3 – N = 230 V

L2 – PE = 230 V

L3 – PE = 230 V

N – PE = 0 V

rigert Ltd., Stairlifts Operating manual Nr.: AW4231

CH-6405 Immensee Fault finding PEGASUS-NOVA-mps2 Date: 13.03.06

Page: 7/22

2.1.2 Check fuses

Switch off main switch, execute the work mentioned, switch on the main switch again

a) Fuses F1 and F2

Check whether tripped or not – press them in, if required

b) Fine-wire fuses on PCB

Take them out and check them for contuinity

if ok, proceed to point 2.2

if not, proceed to point 2.1.3

F1 / F2

2.1.3 Fuse blown or loose

a) Fine-wire fuse blown (on PCB)

- Check terminal 37 – 38 for continuity – if continuity, proceed to point 7

- Check isolating hose on end of support rope for damage or blank section (rope end

shall not make any metallic contact with parts like the guide rail or carriage).

Only if you have checked these points and they are ok, you may insert new fuses and

switch on the controller

Refer to the installation manual for correct placement of support rope end

b) If always a contactor trips when you switch on the controller, check wiring of safety circuit I

and II (Terminal 1 – 16 and 16 – 32) as well as its switches and relays K11, K22 and K3

for short circuit.

!

1.6A

3.15 A

rigert Ltd., Stairlifts Operating manual Nr.: AW4231

CH-6405 Immensee Fault finding PEGASUS-NOVA-mps2 Date: 13.03.06

Page: 8/22

2.2 Check frequency converter (FC) (if applicable)

Check whether the LED is blinking (not when you are

switching on/off the controller) (depending on the type

of FC you need to take off the cover) or if the error

code 33”WARN FU” appears in the display.

If this is the case, proceed to point 2.2.1, otherwise to

point 2.3

2.2.1 Fault remedy on FC

When the controller is switched off (min for 20 sec),

and switched on again, a failure reset takes place.

Whether the fault does not appear again is uncertain

as the cause can could be on the motor, its wiring or on the brake

Check motor (e.g. corrosion on terminals, water leaks, short circuit on motor housing) as

well as the brake for proper function and its wiring for damages.

If the FC fault is caused by overheating, the FC needs to cool down completely (this might

take sometimes several hours) ! Then the FC will be started up again in a state where he can

act again properly.

If this has been checked and everything is in order but no result has been achieved,

change the FC.

2.3 Check the travel recognition PCB

Switch off main switch, execute the work mentioned, switch on the main switch again

Unplug the 2 connectors

Check whether the fault is still present

If fault still present, plug in the

connectors again and proceed to point 3

If not, exchange the travel recognition PCB

!

rigert Ltd., Stairlifts Operating manual Nr.: AW4231

CH-6405 Immensee Fault finding PEGASUS-NOVA-mps2 Date: 13.03.06

Page: 9/22

3 Adjustments

3.1 Check setup

Check the setup menu for correct adjustments against the specification sheet (FO3161)

Encoder

Turn encoder till the menu “Setup” Turn the encoder and check whether

appears - then press it parameters comply with the

specifications

if parameters comply, proceed to point 3.2

otherwise proceed to 3.1.1

3.1.1 Reprogram “setup” parameters

Obviously, different parameters were found. You need to investigate the reason (new

requirements of the client; technical modifications; ….) for if they have not been already

mentioned on FO3161 in the column “changes”.

Unless there are reasons, reprogram the controller acc to the specification sheet FO3161.

For programming respectively reprogramming refer to FO3161.

Parameter 13 showing up Exit parameter

Indicating 2 landings (HS) “sichern” = safe parameter

If yes: Press encoder

rigert Ltd., Stairlifts Operating manual Nr.: AW4231

CH-6405 Immensee Fault finding PEGASUS-NOVA-mps2 Date: 13.03.06

Page: 10/22

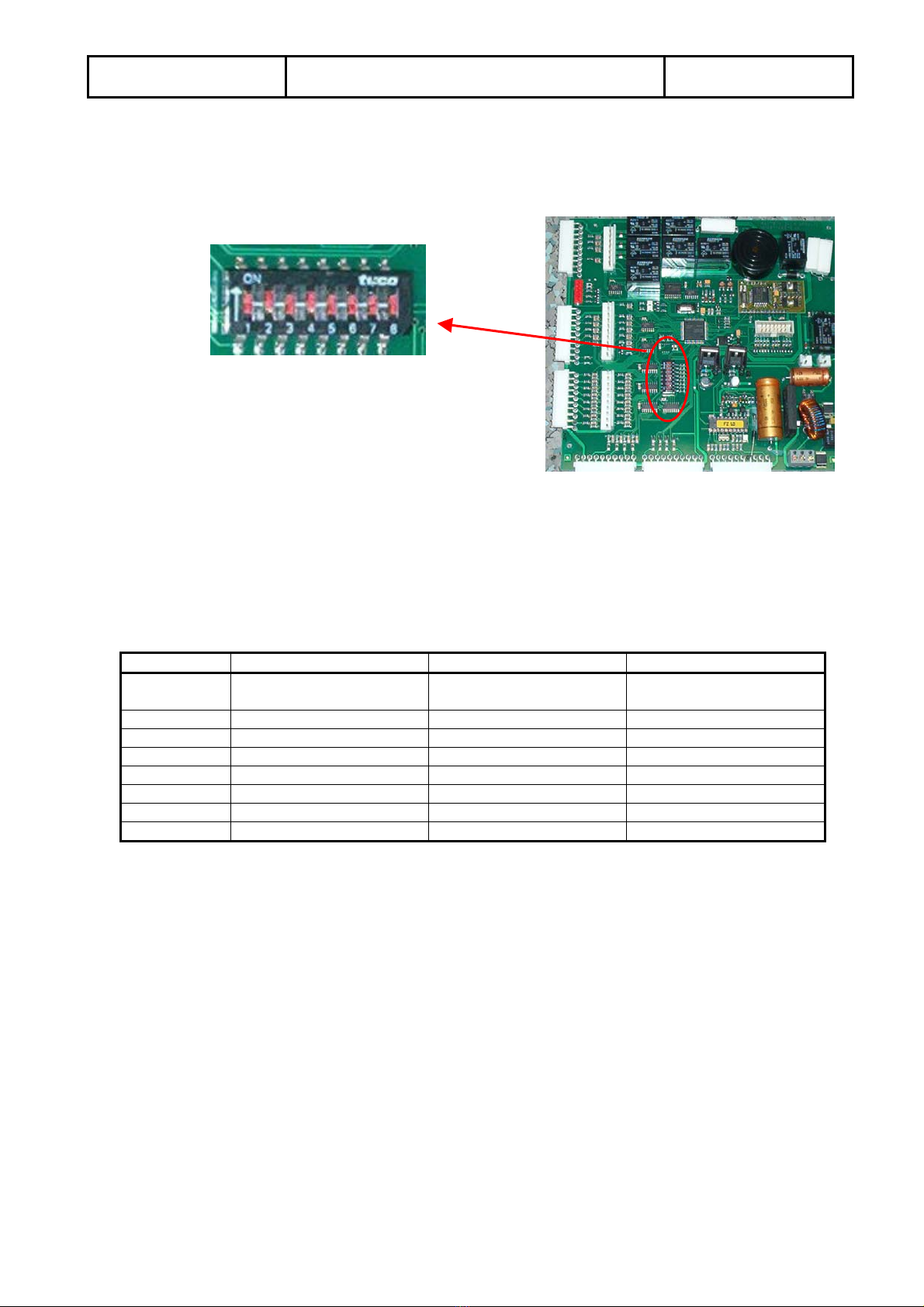

3.2 Check adjustments on carriage PCB

Check adjustments for compliance with the specification sheet FO3161 (at bottom of spec. sheet)

If adjustments comply, proceed to point 4

If not, go to point 3.2.1

3.2.1 Explanation of the possible adjustments

Before changing any Dip-switch position, check carefully that the option is built into the carriage !

Parameter ON OFF

Dip 1 Type of carriage SIRIUS (seated

version)

Pegasus (Platform)

Dip 2 1 Opt. powered carriage Powered manual

Dip 3 2 Opt. platform lock Yes: S47 built in Without

Dip 4 2, 3 Opt. barrier arm down Yes: S16 / S17 built in S16 / S17 not present

Dip 5 Opt. side access ramp Yes No

Dip6 Opt. button “beep” Yes No

Dip 7 Not used

Dip 8 Switch test Active Not active

1 For Sirius: powered footrest

2 For Sirius: Dip-switch always on OFF

3 Applied for all platform stairlifts

rigert Ltd., Stairlifts Operating manual Nr.: AW4231

CH-6405 Immensee Fault finding PEGASUS-NOVA-mps2 Date: 13.03.06

Page: 11/22

4 Communication

4.1 Check communication

Switch on the stairlift on the call station – key switch

Turn the encoder till “Modem Status” appears

Projected status:

“+”-symbols shown on lower line which change alternatively with “p”-symbols

If OK, proceed to point 5

if not, proceed to point 4.1.1

4.1.1 Search faults in “Modem Status”

1st “+”: Carriage (‘C)

2

nd and following “+”: call stations

The number of “+”depends on the number of call stations (min 2 pcs) !

Symbols:

“+” = present, ok

“p” = polling

“f” = 1st fault

“F” = Fault still present

“x” = not present but required

“-“ = not present, not required

if no communication with carriage present, proceed to point 7

if no communication with a call station, proceed to point 4.1.2

Modem Status

+ + + p + - - - - -

C 1s

t

4

th

rigert Ltd., Stairlifts Operating manual Nr.: AW4231

CH-6405 Immensee Fault finding PEGASUS-NOVA-mps2 Date: 13.03.06

Page: 12/22

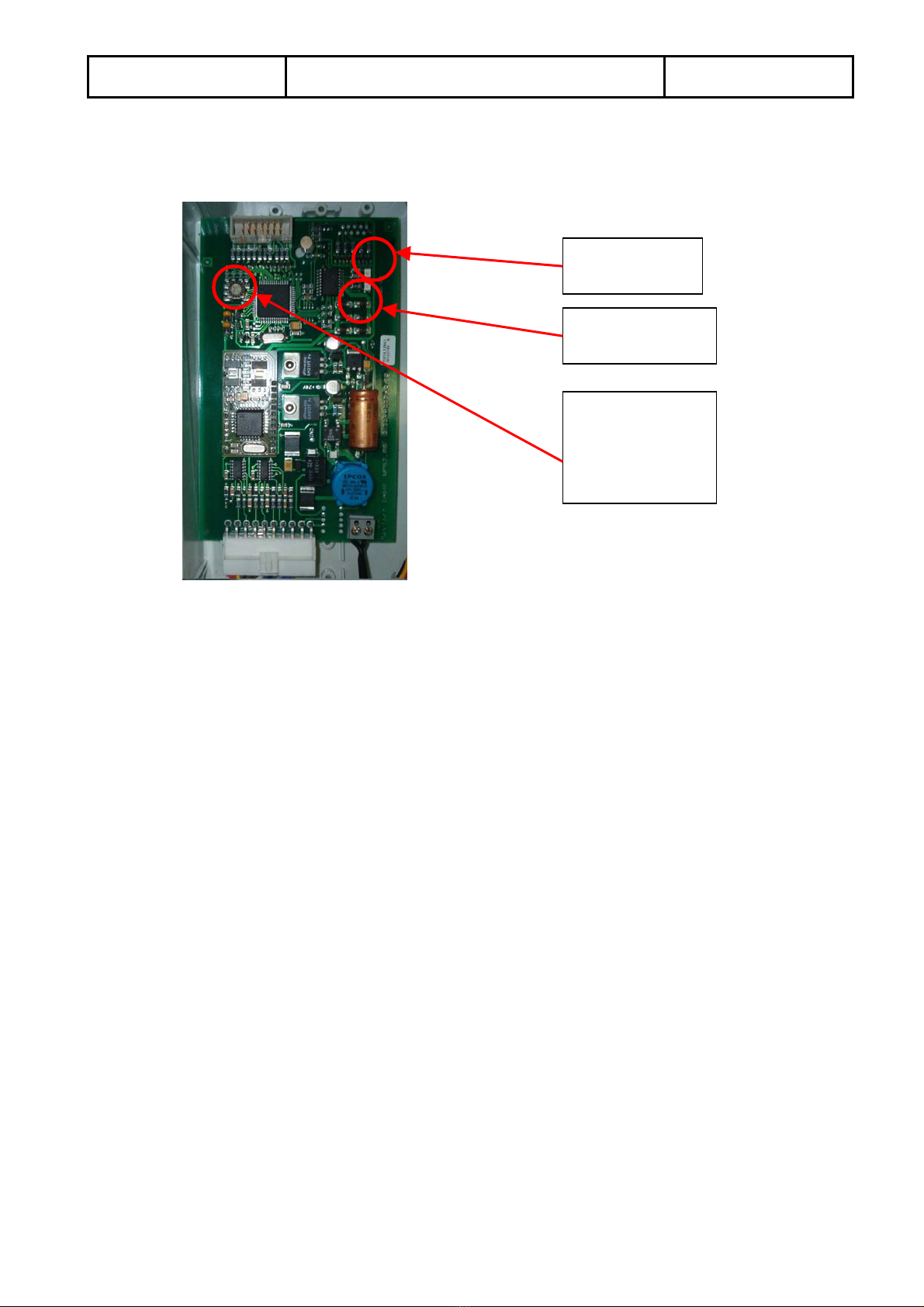

4.1.2 Communication with call stations

Take off the front cover of the call station which does not show communication

Check whether call station code complies with the number of the landing

Check whether LED’s are lighted permanently

If this is ok, take off the call station completely and connect it directly to the main controller

if function ok: wiring faulty

if function not ok: exchange call station PCB

LED ON:

tension present

LED ON:

communication ok

Code switch of

call station

(numbered from

bottom (=1), to top

of installation

rigert Ltd., Stairlifts Operating manual Nr.: AW4231

CH-6405 Immensee Fault finding PEGASUS-NOVA-mps2 Date: 13.03.06

Page: 13/22

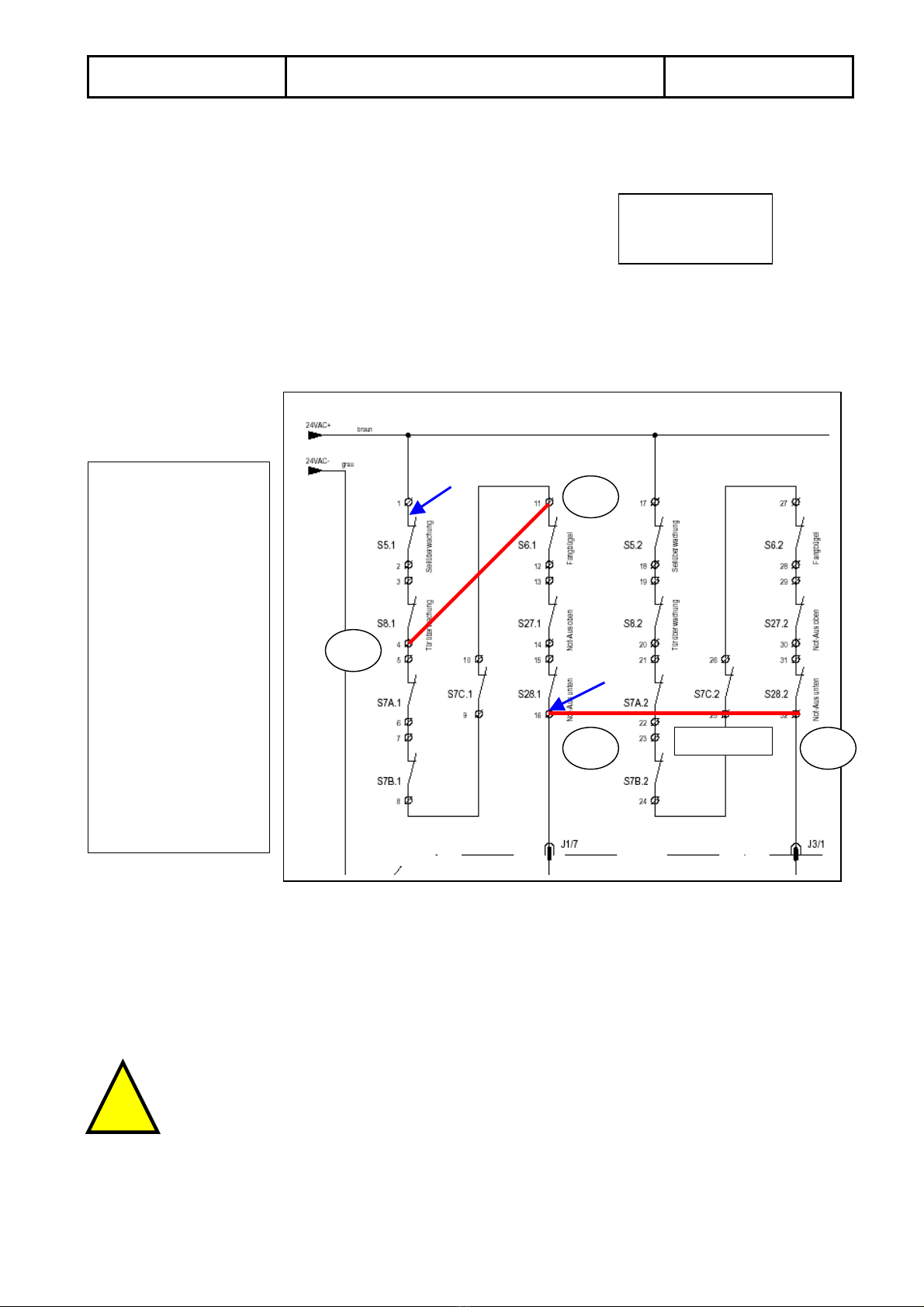

5 Check safety circuit I and II

Check the safety circuit along:

- Safety end limit switch top end

- Arrestor / overspeed governor

- Safety end limit switch bottom (if applied)

- Slack rope (if applied) (for drive 400 only)

- Drive cabinet door switch (if applied)

for continuity.

To check: Take off wire from terminal 1 and 16 (make sure other wires stay in place !!)

Measure continuity from the 2 taken off wires.

If continuity: proceed to point 6

if no continuity: Check switches and its wiring for faults (use diagram)

You might also bridge the safety circuit but bear in mind that you create a dangerous

situation:

- Take off the arrestor pawl (support rope might be damaged)

- Safety end limit switches out of operation (carriage could overtravel –collosion

between rail end ad carriage – worst case: damage of upper trolley and rope !)

apply a bridge between 1 – 16

if the installation runs, then, the fault has to be within the bridged circuit !

16 32

Brid

g

e

Any switch not

present, needs to

be bridged !!

Check and make sure:

- Bridge 16 – 32 is

installed

- Bridge 4 – 11 is

installed

- Not applied other

switches are bridged

- Bridges are installed

correctly

-

S7: Not applied

S8: only if drive

cabinet

S28: Not applied in

ti ti if

!

11

4

rigert Ltd., Stairlifts Operating manual Nr.: AW4231

CH-6405 Immensee Fault finding PEGASUS-NOVA-mps2 Date: 13.03.06

Page: 14/22

6 Status of call stations (RS)

6.1 Check call stations

Switch off installation by the key switch on the call station (LED OFF).

Turn the encoder till “FZ/RS Status” appears

Press the encoder to reach the sub-menu and turn it to reach the status of the single call

station (RS)

If everything is ok, the display shall show the same for

all call stations

If this is the case, proceed to 6.2, otherwise go to 6.1.2

6.1.1 Interpretation of call station status (RS)

Explanation of digits:

Display rs 1 v ok - - - - -

rs Non operative

RS This Call station is operative (other call stations nit active respectively occupied –

blinking LED)

1 Number of call station (1 up to 15)

v Non operative

^’ Shows send-direction (for mid-landings respectively at least 2 send buttons)

ok non operative, everything ok

em, eq Emergency stop pressed

er Fault in Call station (RS)

- - - non operative, everything ok

Ruf Call button pressed

Send Send button pressed

Zu Platform fold button pressed (CD-version of carriage only)

- - non operative, everything ok

SS Key switch is in operation

WT Key switch for material transport activated

rigert Ltd., Stairlifts Operating manual Nr.: AW4231

CH-6405 Immensee Fault finding PEGASUS-NOVA-mps2 Date: 13.03.06

Page: 15/22

If one of the indications above appears, even the relevant button is not activated, take off

the wire on the switch (not on the emergency stop – see diagram) and check again the call

station (RS) status. If the display of that has disappeared, change the button

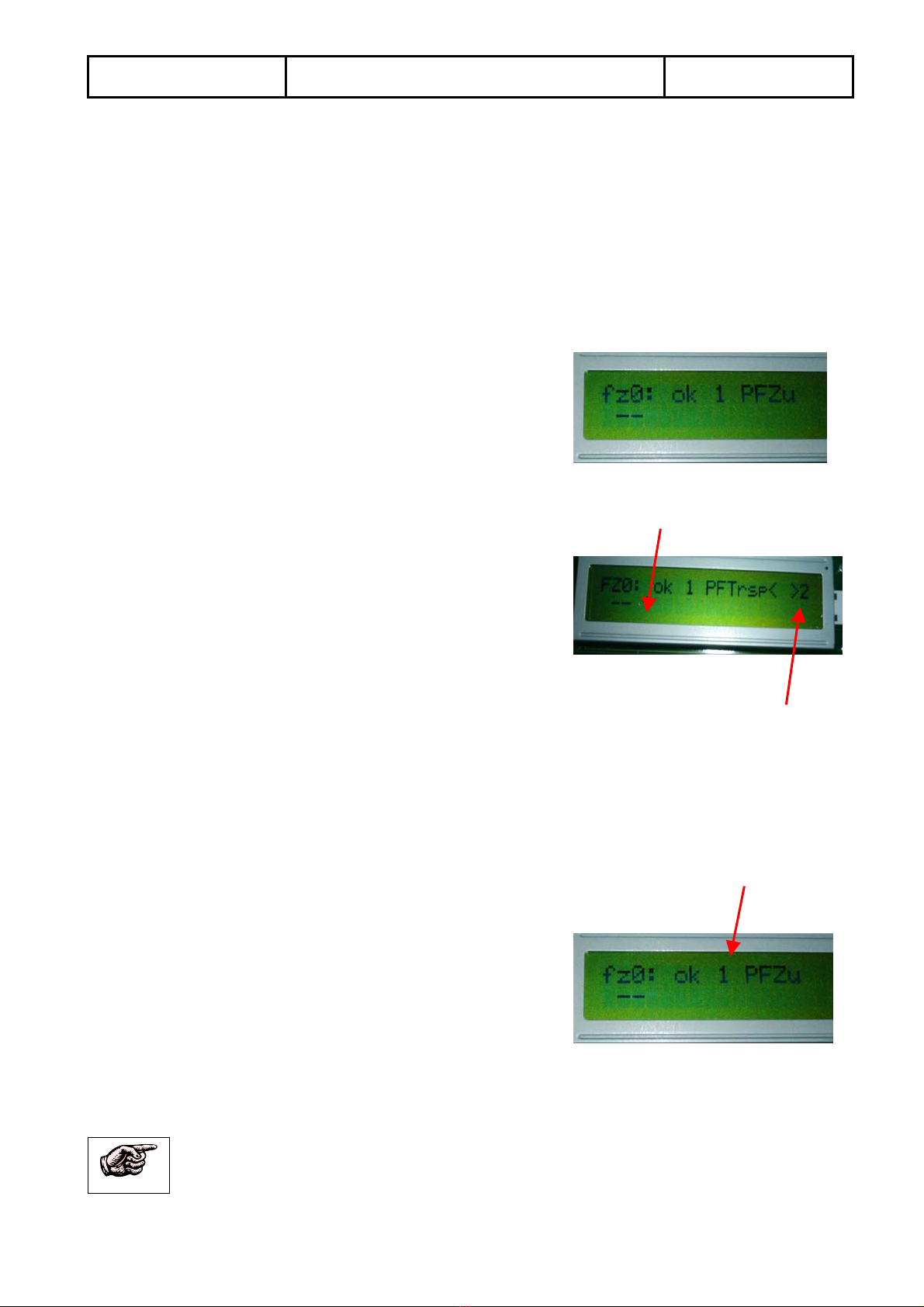

7 Status of carriage (FZ)

7.1 Test carriage status

Switch on installation by the key switch on the call

station (LED lighted).

Turn the encoder till “FZ/RS Status” appears - press

Turn the encoder till “fz0:” appears

7.1.1 Check drive order from hand hold control unit on carriage

Check whether this sign appears “

^’”

If this is not the case, go to 7.1.2

If it is the case, check whether one of the directional

buttons is pressed. If not, unplug the hand hold control unit and check again. If the

symbol does not appear, the fault must be on the control unit or on its wiring.

7.1.2 Check safety switches on carriage

Check whether this sign appears “

>2”

If this is not the case, go to 7.1.3

Otherwise check whether the carriage has run into an obstacle or into the floor.

If not, go to 7.2.1

7.1.3 Check landing recognition of carriage

Check whether the controller recognizes the

landing where the carriage is located

1 = number of landing

If ok, go to point 8

If not, check position of code-cams on landing plates.

Glide with a screw driver along the proximity switch to simulate a landing !

rigert Ltd., Stairlifts Operating manual Nr.: AW4231

CH-6405 Immensee Fault finding PEGASUS-NOVA-mps2 Date: 13.03.06

Page: 16/22

7.1.4 Check platform position of carriage

Check whether the controller recognizes the various positions of the platform.

Run the carriage onto a landing (maybe hand winding required)

Press the emergency stop (display changes from “ok” to “em”)

Now, fold up the platform (no damage will occur !)

Check the display for “PFZu”

Fold fully down the platform (leave the barriers down)

Check the display for “PFzws”

Fold up barriers (as if a user would like to board).

Unlock the emergency stop

Switch off the main controller for at least 20 sec. And switch it on again

Press one of the directional buttons on the hand hold control unit in direction to the

travelway end (if carriage on a mid-landing, press the open barrier button).

Check the display for “PFZus”

Travel a bit away from the landing (maybe hand winding required) and do the same thing

again. In this case, it does not matter which travel directional button you press.

Check the display for “PFTrsp”

If ok, proceed to point 8, otherwise to point 7.2.2

rigert Ltd., Stairlifts Operating manual Nr.: AW4231

CH-6405 Immensee Fault finding PEGASUS-NOVA-mps2 Date: 13.03.06

Page: 17/22

7.1.5 Explanation of display for menu FZ status

1

st row

2nd row

Display Fz0 Ok 1 PFTrsp < >2

Position No. 1 2 3 4 5

Display - - ^’

Position No. 6 7

1 Fzo Display menu

FZ0

Directional button pressed on carriage (Call stations

(RS) occupied)

2 ok Everything ok

er Fault on carriage

em

Emergency stop on carriage pressed

3 0 Carriage not on a landing

1 – 15

Carriage on the corresponding landing

4 PFZu Platform folded up

PFTrsp

Platform folded down and carriage located on a landing

PFBew

Carriage is moving

PFzws Intermediate position of platform

PFErr

Fault on carriage

<

Obstacle LH (sensitive edge side wall)

v

Obstacle below side wall (sensitive edge side wall)

>

Obstacle RH (sensitive edge side wall)

2

Obstacle RH, below, LH on chanel 2

6 - - Everything ok

On

Optional: Key switch on carriage activated

AL

Optional: Alarm button on carriage activated

7 ^’ Directional button upwards (on carriage)

S

Open barrier (on carriage)

v

Directional button downwards (on carriage)

1 2 3 4 5

67

rigert Ltd., Stairlifts Operating manual Nr.: AW4231

CH-6405 Immensee Fault finding PEGASUS-NOVA-mps2 Date: 13.03.06

Page: 18/22

7.2 Search for faults

7.2.1 Safety switches

“< , v, > “ Identifies a safety switch within safety circuit 1.

The controller recognizes the single switch.

“ 2 ” Identifies a safety switch within safety circuit 2.

The controller recognizes only safety circuit 2.

Check safety switch (switch test):

Switch OFF controller on main switch

Change Dip switches 6 and 8 on carriage PCB to ON

Switch ON controller on main switch

Activate with a screw driver all safety switches in safety circuit 1 (beep = this switch ok !)

Activate now one switch of the safety circuit 2 (beep = all switches ok !)

If no beep circuit 1: check the switch in detail and its wiring (check also diode built into

loom of S14/S15)

If no beep circuit 2:

Switch OFF main switch

Unplug looms on carriage PCB

Check all single switches within circuit 2 with a continuity checker.

If no continuity – change the switch

7.2.2 Position switches

The controller needs to receive the correct information as to define the state of “PFTrsp”,

“PFZus” and “Pfzu” – otherwise the controller shows “PFzws”.

Check position switch (switch test):

Switch OFF controller on main switch

Change Dip switches 6 and 8 on carriage PCB to ON

Switch ON controller on main switch

Activate with a screw driver all position switches (beep = this switch ok !)

If no beep: check the switch in detail and its wiring

Switch Signification Platform

down

Platform

upfolded

S11 Platform folded up Continuity No continuity

S12 Platform folded down No continuiuty Continuity

S25 Platform at 25° No continuity Continuity

S45 a + b Barrier locking upwards Continuità No continuity

S46 a + b Barrier locking downwards Continuità No continuity

S16 + S17 Barrier arm down position Continuità No continuity

rigert Ltd., Stairlifts Operating manual Nr.: AW4231

CH-6405 Immensee Fault finding PEGASUS-NOVA-mps2 Date: 13.03.06

Page: 19/22

7.2.3 Switch locations on carriage

RED = Safety switches I = Safety circuit I

BLUE = Position switches II = Safety circuit II

7.2.3.1 Side wall

S38

Speed control S17

Barrier arm – RH

Down

p

osition

Barrier locking

S46a RH upwards

S45a RH downwards

S23.I / S23.II

Safety edge RH

S22.I / S22.II

Safety edge LH

Barrier locking

S46b LH upwards

S45b LH downwards

S16

Barrier arm – RH

Down

p

osition

S37

Shunt RH

S36

Shunt LH

S15b.I / S15b.II

Ramp monitoring RH,

Platform folded u

p

S14b.I / S14b.II

Ramp monitoring RH,

Platform folded down

S14a.I / S14a.II

Ramp monitoring LH,

Platform folded down

S15a.I / S15a.II

Ramp monitoring LH,

Platform folded u

p

S24.I / S24.II

Safety edge bottom

1600.i.001

Side wall general

rigert Ltd., Stairlifts Operating manual Nr.: AW4231

CH-6405 Immensee Fault finding PEGASUS-NOVA-mps2 Date: 13.03.06

Page: 20/22

7.2.3.2 Platform

S10X.I / S10X.II

Activation safety bottom

S10C.I / S10C.II

Safety bottom

S10D.I / S10D.II

Safety bottom

S10A.I / S10A.II

Safety bottom

S10B.I / S10B.II

Safety bottom

S11

Platform up position

S25 (behind plate)

Platform 25° position

S18.I / S18.II

Ramp monitoring

Platform u

p

/ down

S12

Platform down position

1600.i.010

Platform general

Table of contents

Popular Stairlift manuals by other brands

Minivator

Minivator 1000 series user manual

vimec

vimec V65 B.I. Original instructions

Handicare

Handicare Simplicity+ installation manual

Access

Access HomeGlide user manual

Harmar Mobility

Harmar Mobility SL600 HD Owner's manual & warranty information

Harmar Mobility

Harmar Mobility Vantage SL400 Installation and service manual