HiRO 160 Q User manual

Version 1.01

Installation instructions

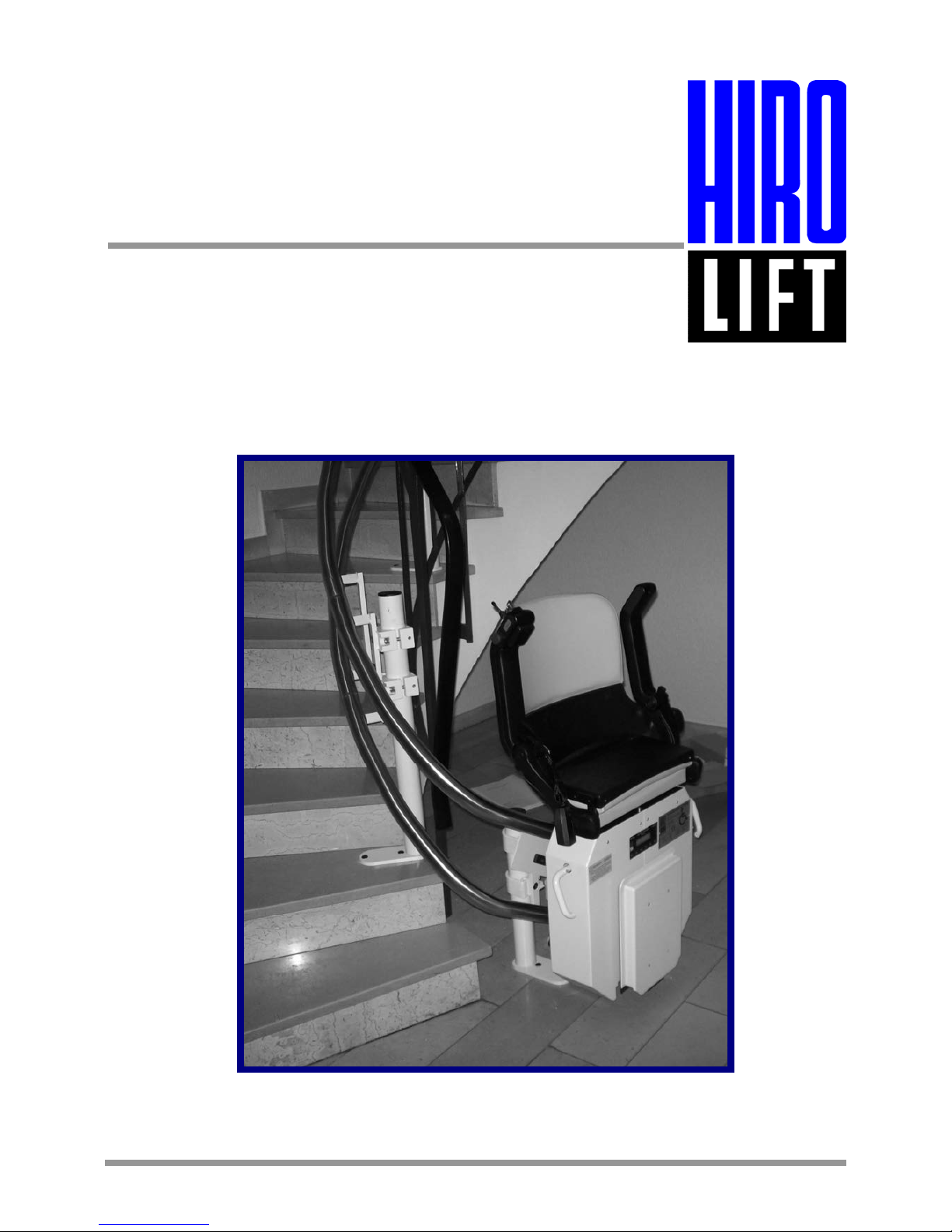

for stair lift

HIRO 160 Q

1. Contents

2

Contents

1. Contents............................................................................................................................. Page 2

2. Key to symbols.................................................................................................................. Page 3

3. Assembly and installation procedure HIRO 160 Q.......................................................... Page 4

3.1 Tools ............................................................................................................................ Page 4

3.2 Preparations for work.................................................................................................... Page 5

3.3. Installation of guide rails ............................................................................................... Page 7

3.4 Installation of drive unit ............................................................................................... Page 12

3.5 Installation of chair...................................................................................................... Page 18

3.6 Installation of upper/lower stops ................................................................................. Page 20

3.7 Setting and testing the safety switches ....................................................................... Page 24

Please keep these instructions for further reference!

2. Key to symbols

3

Key to symbols

Caution! Risk of personal injury!

Attention! Risk of material damage!

Note

HIRO LIFT Hillenkötter + Ronsieck GmbH

Tel. +

49

/

521/

9

65

52- 0 Fax +

49

/

521/

9

65

52-

40 Meller Straße 6

Service +

49

/

521/

9

65

52-39 D 33613 Bielefeld

Email: info@hiro.de

.

Internet: www.hiro.de

Germany

3. Assembly and installation procedure HIRO 160 Q

4

3.1 Tools

The following tools are required for assembling and

installing a HIRO 160 Q stair lift:

•Percussion drill

•Percussion drill bits 6 - 14 mm

•Power drill

•Set of drill bits and taps for metric thread sizes

M4 - M12

•Power screwdriver

•Angle grinder

•Vacuum cleaner

•Set of socket spanners

•Set of open-ended/ring spanners

•Torx spanner T40

•Set of screwdrivers

•Electric power tool

•2 x chain hoist 250 kg

•Set of metric Allen keys

•Hydraulic jack

•Spirit level

•Tape measure

3. Assembly and installation procedure HIRO 160 Q

5

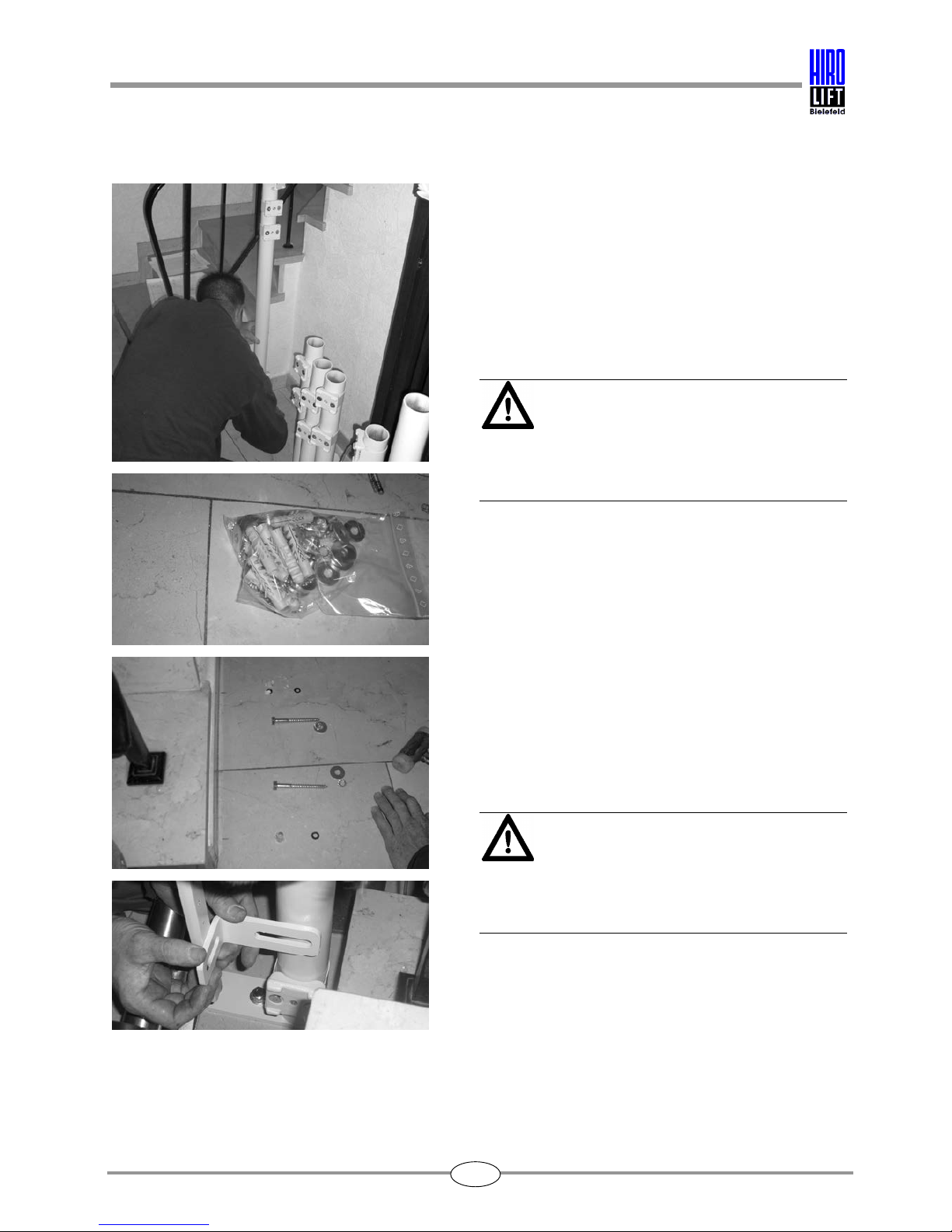

3.2 Preparations for work

The lift unit is supplied in the following packages:

1. Drive unit

2. Seat

3. Cover panels

4. Guide rail beams

5. Production parts list, lift unit drawing with list of

supports and fixing materials for the stops

6. Guide rail supports

7. Fixing brackets and screws for anchoring guide

rails and supports

8. Wall mount for charger unit

9. Electrical accessories kit with charger unit,

charging cable, charging bars, fixing materials,

magnets and bolts and screws

10. Lift unit drawing and documentation

11. Circuit diagram, list of parameters and

operating instructions for the control

12. Instructions and acceptance inspection

documentation

3. Assembly and installation procedure HIRO 160 Q

6

Before starting installation work, please check

whether the dimensions given in the lift unit drawing

agree with the actual dimensions on the installation

site.

Check against the lift unit drawing and the

production parts list to ensure that the lift unit

delivered is complete.

Arrange the guide rail supports according to length

and position.

Please refer to the list of supports to see which

support length is required in each case. The

position of the supports is shown in the lift unit

drawing.

All the dimensions relevant for the installation work

are shown in red on the lift unit drawing.

All dimensions on the lift unit drawing refer to the

centre of the guide rail tube.

The guide rail supports are shown as S1/S... in the

lift unit drawing and are indicated in the parts list

with their various lengths.

Take the fixing brackets out of the enclosed

accessories kit and take out the accompanying

screws for assembling the supports.

Place the guide rail supports, guide rail brackets,

clips and fixing screws on the staircase treads

specified in the lift unit drawing.

3. Assembly and installation procedure HIRO 160 Q

7

3.3 Installation of guide rails

In lift units where the guide rails are fixed to the

wall only, be sure to use through bolts or wall

anchors.

Where guide rails are fixed to the wall, the fixing

points are shown as W1 - W... on the lift unit

drawing.

If the guide rails are to be fixed to concrete, only

approved adhesive anchors or stud bolts must be

used.

When fixing the supports, they must be supported

with a bracket attached to the nearest wall

wherever possible.

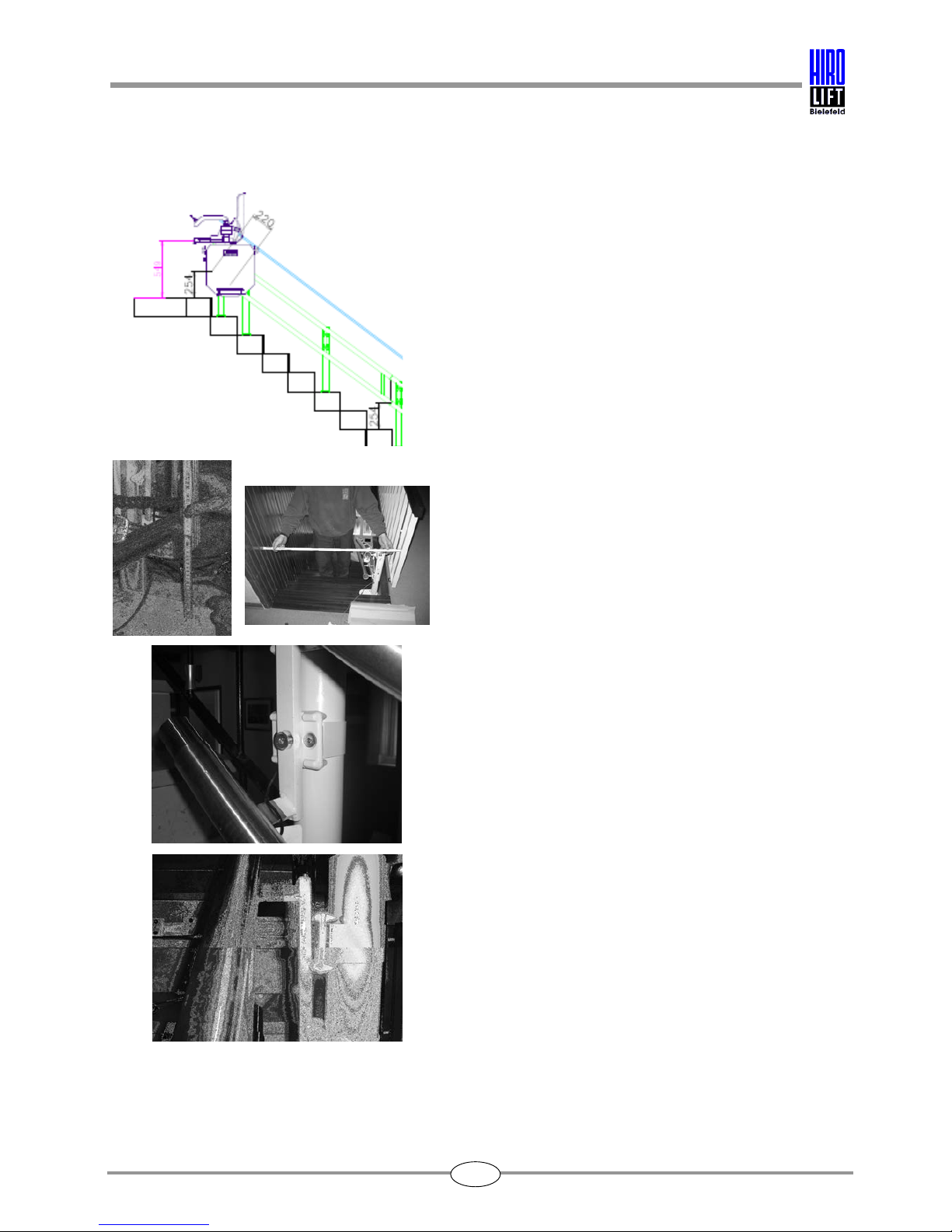

The lift unit drawing specifies the distances

between the guide rail and the staircase tread.

Lay the lower end of the guide rail track on the

floor. The lower edge of the guide rail track is

specified in the lift unit drawing from the outer

edge of the staircase tread (zero point).

For lifts with a horizontal travel path, the height

dimension specified is that of the guide rail track.

Adjust the guide rail track with the supports loosely

attached or using a hydraulic jack.

Particular attention must be paid to ensure that the

guide rail track and the supports are properly

anchored.

3. Assembly and installation procedure HIRO 160 Q

8

Note!

Before installing the guide rails, the lower guide rail

cap must first be attached.

For lift units with guide rail supports in the stairwell,

the supports must be fitted first as shown in the lift

unit drawing.

The dimensions for each of the supports are given

in the lift unit drawing.

All dimensions refer to the centre of the tubular

supports.

Mark the positions of the supports.

Place the supports on the pencilled in positions

and mark the position of the screw holes.

3. Assembly and installation procedure HIRO 160 Q

9

The size of drill bit to be used depends upon the

fixing materials contained in the enclosed

accessories kit and shown in the list enclosed with

the accessories.

Attention!

Before drilling, ensure that there are no cables or

underfloor heating present in the area concerned.

Different types of fixings are possible depending

on the subsurface and the floor covering.

Attention!

If the subsurface is loose, then the supports must

be fixed to concrete.

3. Assembly and installation procedure HIRO 160 Q

10

When fixing the supports, ensure that the supports

are correctly aligned both horizontally and

vertically.

If it is possible to brace the supports to the wall or

a similar surface, then the supports must also be

fixed by an additional means.

Refer to the drawing for the zero point (guide rail

starting point) and mark this point on the floor.

Align the guide rail on the zero point and install the

first guide rail beam as described above.

3. Assembly and installation procedure HIRO 160 Q

11

Align the guide rails in all directions using the spirit

level.

The lift unit drawing shows the height dimensions

at each join position between the guide rail beams.

Compare the clearance dimensions and the height

dimensions with the actual dimensions at the

installation site, and if necessary, adjust the guide

rail track.

To lay the charging cables, use a coiled cable or

the cable supplied.

After installing the first guide rail beam,

the charging cable must be laid inside the upper

guide rail tube.

3. Assembly and installation procedure HIRO 160 Q

12

3.4 Installation of drive unit

At the lift stops, a ready-drilled hole is provided in

the upper guide rail tube near the guide rail fixing

plate for the purpose of laying the charging cable.

Secure the cable to the guide rail fixing plate.

Carry out the following steps to install the drive

unit:

Remove the packaging.

To allow the drive unit to be set down, a transport

frame is attached underneath it.

Install the footrest contact tray.

3. Assembly and installation procedure HIRO 160 Q

13

To suspend the drive unit in the guide rail, the

transport frame must be removed as shown in the

picture.

Switch the main switch to ON and insert the

emergency operation key into the appropriate key

switch.

Check the direction of rotation of the rollers by

turning the key switch.

Before suspending the drive unit, adjust the set of

rollers to the same angle of incline as that of the

guide rail track.

Lift the drive unit together with the set of rollers

onto the ends of the guide rail track.

3. Assembly and installation procedure HIRO 160 Q

14

By turning the key switch to the DOWN direction of

emergency operation, you can insert the drive unit

into the guide rail track.

Attention!

Ensure that the drive unit and the rollers are not

tilted.

Use the emergency operation facility to move the

drive unit into the lowest position and switch the

main switch to OFF.

3. Assembly and installation procedure HIRO 160 Q

15

The remaining guide rail beams are identified by

consecutive numbers.

The job number and the guide rail beam number

are shown on each guide rail beam.

Before inserting the guide rail beam, the charging

cable must first be laid in the guide rail tube.

Take care not to damage the charging cable when

fitting the guide rail beams together.

Grease both the guide rail ends and sleeves

before fitting the guide rail beams together.

If necessary, pull the guide rails together carefully

with a chain hoist.

3. Assembly and installation procedure HIRO 160 Q

16

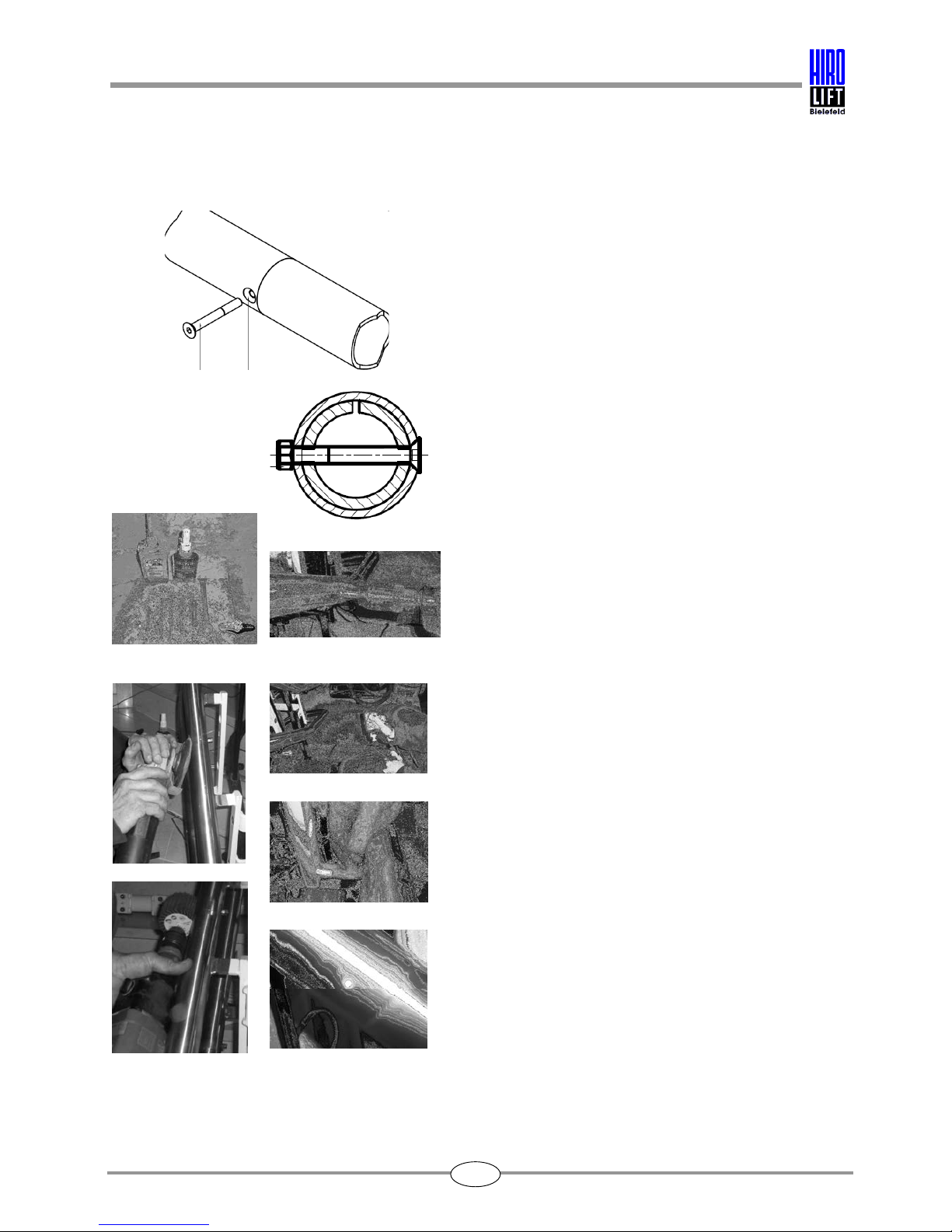

The ends of the guide rails must be fitted together

without leaving any gap between them.

If necessary, maintain the tension between the

guide rails using a chain hoist or a screw clamp.

For joining the guide rail tubes together, M6 x 50

mm countersunk bolts with M6 nuts are supplied in

the enclosed accessory kit.

The sleeve and the guide rail tube have a pre-

drilled bolt hole but the bore must be enlarged and

countersunk.

In order to drive in the M6 bolt, the bore in the

guide rail tube must be enlarged to 5.2 mm. The

front of the tube must be countersunk so that the

bolt head will be flush with the outside tube

surface, and the bore enlarged to 6 mm. The rear

hole must be tapped with a M6 thread.

After cutting the rear M6 thread, secure the M6

bolt with a medium-strength thread-locking

compound and tighten the bolt. The bolt must be

secured with a M6 counter nut to prevent the bolt

from loosening.

After fixing the bolt head, grind it with an angle

grinder and an abrasive brush to leave a surface

that is flush with the guide rail tube.

3. Assembly and installation procedure HIRO 160 Q

17

The dimensions for further aligning the guide rail

beams are given in the lift unit drawing.

At each join position between the guide rail beams,

the drawing gives the height dimension from the

stair tread to the centre of the lower guide rail tube.

The guide rail braces must be aligned

perpendicularly. The guide rails can be adjusted at

the fixings by altering the position of the clip.

Check all the dimensions specified in the drawing.

After adjusting the position of the guide rails, check

that all fixings and supports are tightened

sufficiently, and re-tighten all bolts and screws if

necessary.

Check the dimensions of the guide rail track for

accuracy (centre distance).

The centre distance, measured vertically from the

centre of the upper guide rail tube to the centre of

the lower guide rail tube, must be 250 mm.

3. Assembly and installation procedure HIRO 160 Q

18

3.5 Installation of chair

Please carry out the following steps to install the

swivel seat assembly:

Attach the swivel seat assembly to the drive unit

with four fixing screws.

Connect the armrest controls, swivel seat switch

and swivel seat motor to the drive unit using plug-

in connections.

Insert the seat assembly between the U-bolts of

the drive unit, as shown in the pictures.

Ensure that no cables are damaged.

Fix the seat assembly in position at the side with

the four hexagon socket screws.

3. Assembly and installation procedure HIRO 160 Q

19

Connect the plug-in connections for the armrest

controls, swivel seat switch and swivel seat motor,

as shown in the picture.

In the case of lift units with a swivel seat in a

centre position, there is an additional

potentiometer at the pivotal point for detecting the

position of the swivel seat. Connect this plug, too,

with its counterpart.

The lift can be moved to the lower access point

using the emergency operation key.

Once the desired position has been reached, mark

this position for installing the charging points and

the magnets (lift stop).

3. Assembly and installation procedure HIRO 160 Q

20

3.6 Installation of upper/lower lift stops

The positive/negative charging pins and the

emergency limit switch can be seen in the picture.

The accessories kit supplied contains the following

parts:

1. Charger unit

2. Wall mount for charger unit

3. Cable for the charging stations

4. Charging bars

5. Magnets

6. Radio transmitter and wall mount

7. Emergency end buffers

8. Bolts and screws and plug kit

9. Circuit diagram

Install the charger unit with the wall mount near the

guide rails (lift stop).

The plates for the magnets and charging bar at the

lift stops have been factory-fitted in the lift stop

area.

The emergency contact strip and the limit stops

(buffers) have been factory-fitted at the upper and

lower lift stops.

At the lower stop, the charging bars and the

magnets still have to be fitted.

Fit the long magnet approx. 120 mm before the

(round) magnet that is located at the lift stop.

After the learning run has been carried out, the lift

always stops at the centre of the round magnet.

Position the charging bars (positive pole at the

top/negative pole at the bottom) at the "centre of

the charging pins" and connect them to the

charger unit.

Table of contents