10

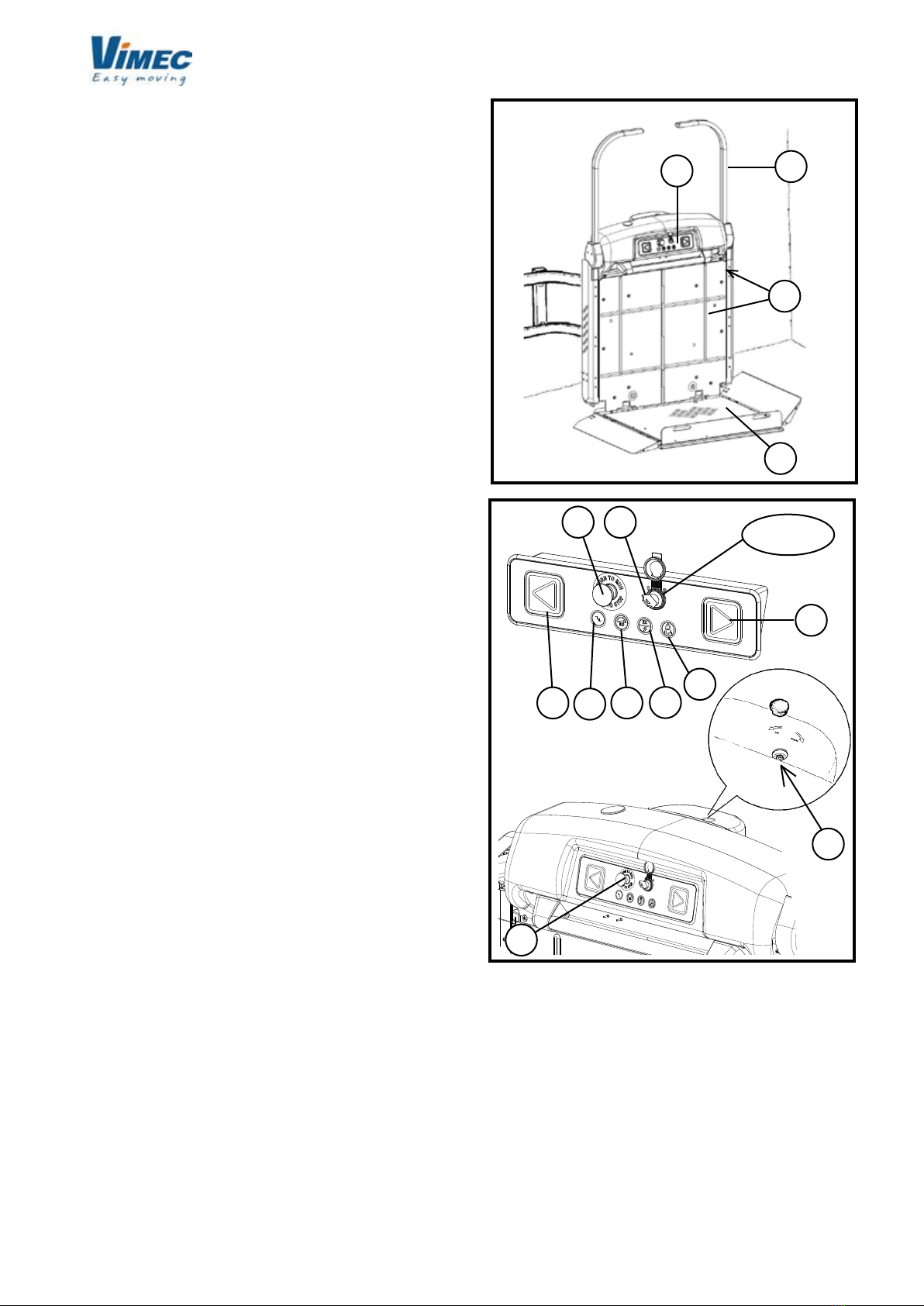

b

a

a

c

g

c

e

b

d

i

h

ih

m

l

FIG.10

FIG.9

FIG.8

7) CORRECT USE OF THE STAIRLIFT IN INDEPEN-

DENT BAR AND RETRACTABLE BAR VERSIONS

WARNING: BEFORE USING THE STAIRLIFT,

READ THIS MANUAL CAREFULLY. The stairlift must

only be used in accordance with the intended uses

described in section 5.

7.1) Starting position

The stairlift is parked at one end of the staircase with

the platform folded up (Fig. 8/a) and the bars in rest

position (Fig. 8/b) with the master key turned to ON.

The stairlift is powered up.

7.2) Using the stairlift

WARNING: Always keep access to the plat-

form and the master switch unrestricted.

NEVER overload the stairlift.

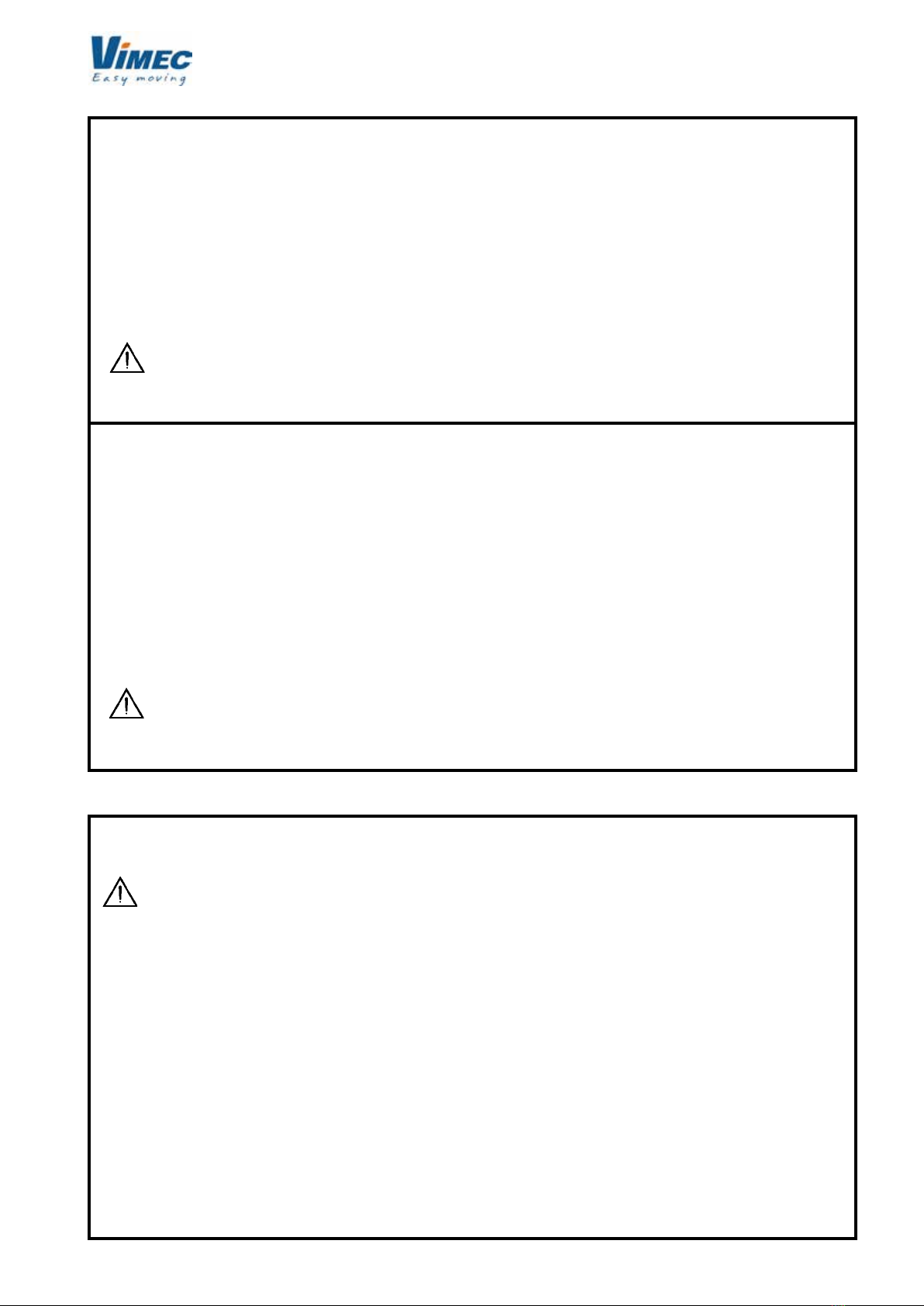

1) For stairlifts with manual platform (standard).

- Bring the down side bar into the working position by

pressing the button (Fig. 9/d) on the control board at

the oor.

- Lower the platform by hand.

- If the stairlift is at the lower oor, bring the down side

bar into the rest position to allow the wheelchair to

move onto the platform.

1)

For stairlifts with motor-operated platform (optional)

- Insert the key and turn it to position (1) ON using the control

board at the oor.

- Open the platform by pressing the button provided (Fig. 9/e).

The side guard moves to the drive-on position and the down

side bar to the working position.

If the stairlift is at the lower oor, return the down side bar

to the rest position to allow the wheelchair to move onto the

platform.

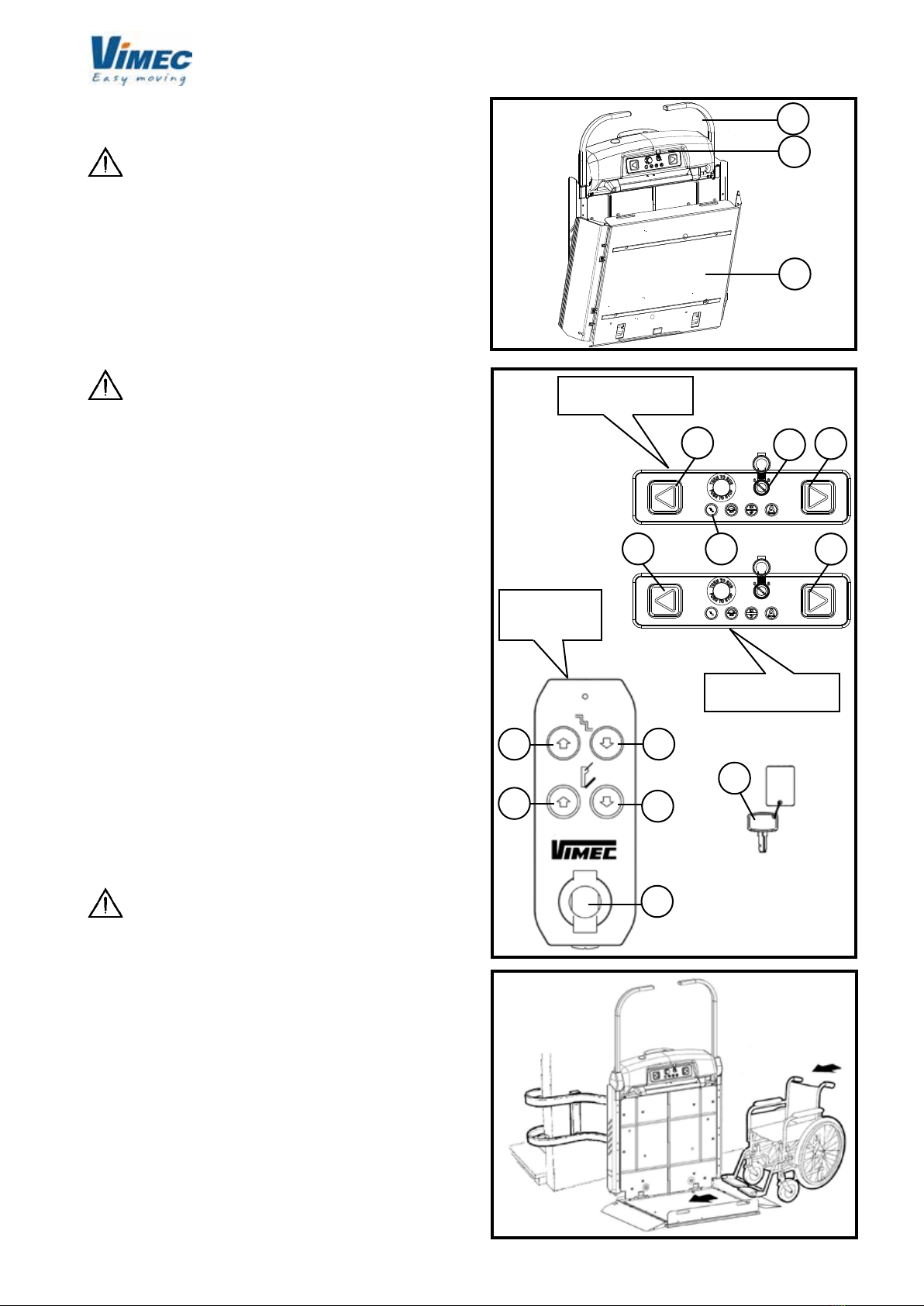

2) Get onto the platform, facing in the travel direction

and in a central position (Fig. 10) to allow the guard

to move into its sensor position. Lock the wheelchair

brakes. If the wheelchair is electric, turn it off.

WARNING: The wheelchair must be positio-

ned on the platform so that no part of the body or

the wheelchair projects from the platform. When

the stairlift is in motion sit still without moving or

rocking.

3)

Insert the key (Fig. 9/m) and turn it to position (1) ON, then

turn to S and release.

4) Press the up button (Fig. 9/i); the guards and bars

automatically move to the safety position and the stai-

rlift sets off.

In stairlifts with an intermediate stop, press the button

(Fig. 9/l) once to select the rst stop, press twice for

the second stop, three times for the third stop, and so

on. Then keep the up/down button pressed until the

landing oor is reached.

The yellow light of the button (Fig. 9/l) ashes upon

selection and until arrival to the selected oor, then the

light is on without ashing.

In case the oor selection is wrong, keep the button

pressed for 3 seconds to reset, then select again

RH CONTROL

BOARD ON LIFT

LH CONTROL

BOARD ON LIFT

FLOOR

CONTROLS