3©2009,1996 BRUNO INDEPENDENT LIVING AIDS, INC.®

SRE-1550 02-09-2009

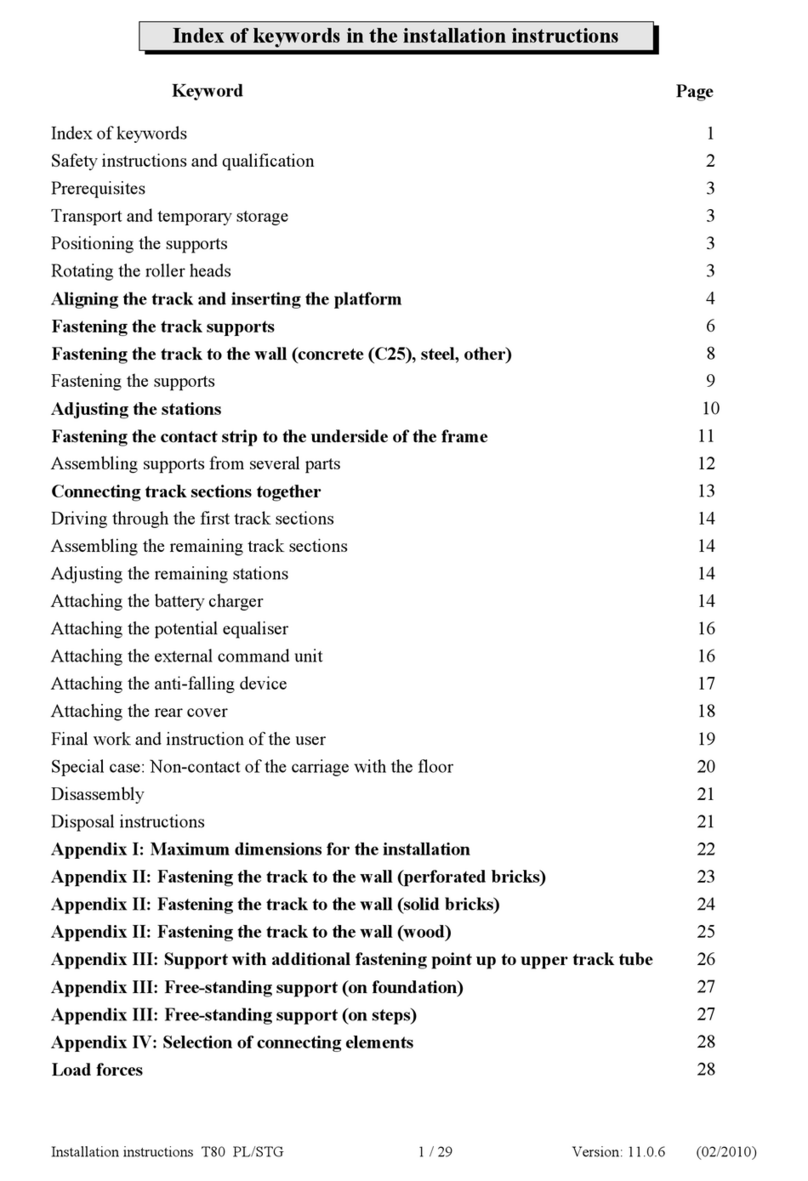

SPECIFICATIONS AND REGULATORY INFORMATION ..........4

CARTON CONTENTS ...................................5

INSTALLATION

Tools Necessary for Installation . . . . . . . . . . . . . . . . . . . . . . . . .6

Mounting the Lower Bumper Bracket . . . . . . . . . . . . . . . . . . . . .7

FittingtheRail.....................................7

ApplicationGuide.................................8-9

CuttingtheRail ...................................10

Rail Joint Assembly .................................11

Positioning Foot Clamp Assemblies ......................12

Mounting the Carriage on the Upper Rail ..................13

Adjusting the Carriage Angle . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Mounting the Upper Bumper Bracket.....................14

Installing the Seat and Footrest Assemblies ............. 16-17

Seat Swivel and Seat Arm Adjustment . . . . . . . . . . . . . . . . . . . 18

Final Limit Switch and Ramp Actuation . . . . . . . . . . . . . . . . 19-20

UpperBumperBracket ..............................24

ELECTRICAL

Connecting the Battery Charger ........................14

Routing the Wiring Harness ........................ 14-15

Safety Switches ...................................17

Call/Send Transmitters . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-23

Circuit Board Diagnostics.......................... 24-25

Battery Charger LED's and Fuse ........................26

Learning the Remote IR Transmitter .................. 27-28

Circuit Breaker....................................28

LUBRICATION ......................................29

TESTING ELEVATOR OPERATION ........................30

CONVERSION TO RIGHT-HAND OPERATION ...............31

OVERSPEED (COMMERCIAL ONLY) .......................32

ADJUSTMENTS

Speed ..........................................33

Seat Height ......................................33

YEARLY MAINTENANCE OPERATIONS ....................34

BELT REPLACEMENT NOTE .............................34

TROUBLESHOOTING............................... 35-36

WIRING SCHEMATIC .................................37

EXPLODED VIEW AND BILL OF MATERIALS ............. 38-41

LIMITED WARRANTY .................................42

TABLE OF CONTENTS