Rioned flexJET+ User manual

USER’S MANUAL

/

Edition: 08

Date: Wednesday 24 January 2018

RIONED

P.O. Box 5070

5004 EB Tilburg

The Netherlands

Telephone: +31 13 5479100

e-mail: [email protected]

Internet: www.rioned.com

01/18 2

©Copyright 01/18 Rioned/Rior B.V.Tilburg - Netherlands

All rights reserved. No part of this publication may be copied or published by means

of printing, photocopying, microfilm or otherwise without the prior written consent of

RIONED. This restriction also holds for the corresponding drawings and diagrams.

RIONED has the right to change parts at any time without any prior or direct warning

to the client. Also, the contents of this manual can be changed without any prior warn-

ing.

This manual is to be used only for this machine.

For extra information on adjustments, maintenance and repair, please contact the

technical department of your dealer.

01/18 3

Foreword

This user’s manual is a manual for the professional user.

This user’s manual has the purpose to control the machine in a safety manner and

must be saved with the machine.

The photos and drawings help you understand the text easier.

First the user’s manual gives you an overview of the most important safety aspects.

Then we explain how the machine is built up and the global working of the machine.

Chapter “Technical specifications” gives you information about the working character-

istics, performance under normal use and construction specifications.

“Control” is the next chapter. This chapter explains how to use the machine system-

atically.

In the chapter “Maintenance”, the user can do small maintenance on the machine.

Chapter “Trouble shooting” has the purpose to solve simple defects.

With the “Exploded views” you can order original spare parts, are also useful for

mounting, and disassemble the machine.

Finally gives the chapter “Appendix” information about electrical and/or hydraulic

01/18 4

01/18 1

TABLE OF CONTENTS

1 INTRODUCTION..........................................................................3

1.1 Use......................................................................................3

2 SECURITY...................................................................................5

2.1 Instruction indications in this manual........................................5

2.2 Descriptions security measures................................................5

2.3 Personnel protection outfit ......................................................5

2.4 Warnings..............................................................................6

2.5 Personnel qualification and education .......................................6

2.6 Danger that can occur if the security regulations aren’t observed .6

2.7 Working safely.......................................................................6

2.8 Security regulations for the user and technical service ................6

2.9 Security regulations for maintenance, inspection and mounting ac-

tivities..................................................................................7

2.10 Making changes and fabricate spare parts .................................7

2.11 Improper use ........................................................................7

3 TECHNICAL SPECIFICATION.......................................................9

3.1 General ...............................................................................9

3.2 Engine...............................................................................10

3.3 Pump ................................................................................11

4 CONSTRUCTION .......................................................................13

5 CONTROL..................................................................................17

5.1 Hitching up the trailer...........................................................17

5.2 Check before departure ........................................................ 18

5.3 Unhitching and setting up ..................................................... 18

5.4 Control box.........................................................................19

5.5 Radio remote control............................................................19

5.6 Before starting ....................................................................19

5.7 Starting the machine............................................................ 20

5.8 Unclogging a drain ...............................................................26

5.9 Stop spraying:.....................................................................28

5.10 Cleaning a wall, terrace or floor. ............................................29

5.11 Spray with spray lance .........................................................31

5.12 Stop the engine................................................................... 33

5.13 Ending duties ......................................................................34

5.14 Using the device during periods of frost ..................................34

5.15 Additional preparations when preparing for use:.......................35

6 SYMBOLS..................................................................................37

6.1 Control box.........................................................................37

6.2 Pressure gauge....................................................................39

6.3 Pressure regulator................................................................39

6.4 Security sticker....................................................................40

7 OPTIONS ..................................................................................41

7.1 Hydraulic reel control ...........................................................41

01/18 2

7.2 Hose guide..........................................................................41

7.3 Hour counter.......................................................................42

7.4 Run dry protection ...............................................................42

7.5 Water level control...............................................................42

7.6 Suction Ventury...................................................................43

7.7 2e HP-reel instead of supply reel............................................ 44

7.8 Check valve in supply pipe ....................................................44

7.9 License Plate Holders............................................................44

7.10 Working lamp......................................................................44

7.11 Warning beacon...................................................................44

7.12 Pulsator system................................................................... 45

7.13 Radio remote control............................................................45

7.14 Radio remote control (Flexmote)............................................47

7.15 Water circuit circulate........................................................... 48

8 MAINTENANCE .........................................................................51

8.1 Daily maintenance ...............................................................51

8.2 Weekly maintenance ............................................................51

8.3 Minor servicing .................................................................... 51

8.4 Maintenance wheel bearings and wheel nuts............................52

8.5 Check the brake drums and the brakes...................................52

8.6 Replacing lamps in the lighting unit ........................................ 53

8.7 Maintenance remote control ..................................................54

8.8 Hydraulic system .................................................................54

8.9 Extensive periodical maintenance...........................................55

8.10 Maintenance scheme ............................................................ 56

9 TROUBLESHOOTING .................................................................57

10 AUXILIARIES............................................................................61

11 APPENDIX ................................................................................63

11.1 EC declaration Of Conformity For Machinery ............................63

11.2 Contact sales representatives ................................................64

11.3 After Sales Service...............................................................64

11.4 Dimension FlexJet................................................................65

11.5 Dimension FlexJet+..............................................................66

11.6 .....................................................Sound level report FlexJet67

11.7 Sound level report FlexJet+................................................... 68

11.8 COC...................................................................................69

12 INDEX ......................................................................................73

01/18 3

1INTRODUCTION

RIONED wishes to thank you for your purchase of the RIONED drain and sewer-

clearing machine. We recommend that you read this manual thoroughly and

see that the machine is handled and maintained in the proper manner. If your

machine should give trouble and need servicing, when you want to order parts,

or if you have any questions, contact your RIONED dealer.

The machine is built by:

RIONED

P.O. Box 5070

5004 EB Tilburg

The Netherlands

Telephone: +31 13 5479100

e-mail: [email protected]

Internet: www.rioned.com

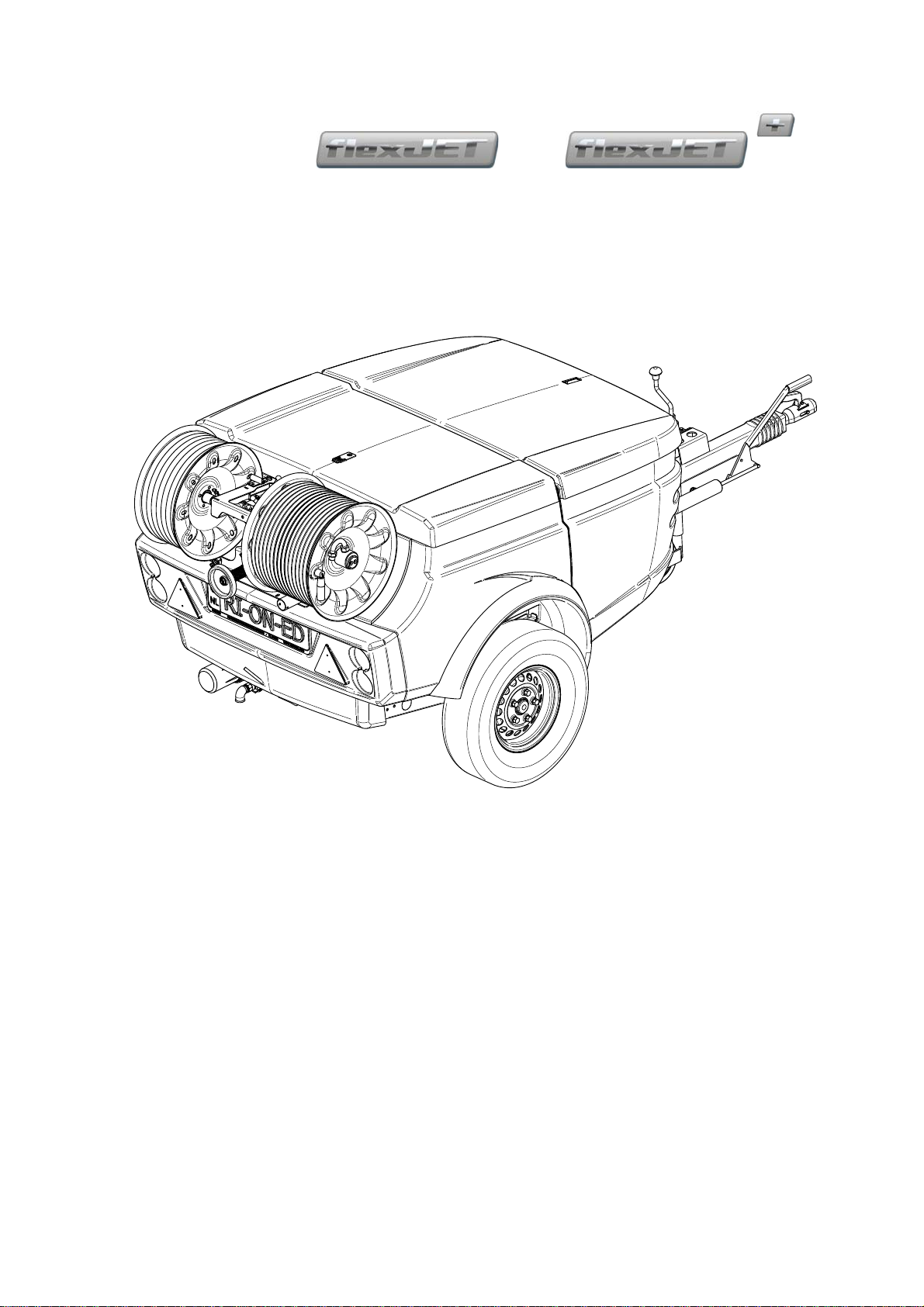

The Rioned high-pressure device has been especially designed and manufac-

tured for cleaning drains, walls, floors and terraces with cold or hot water. For

cleaning drains, special nozzles are included in the delivery; for all other pur-

poses, the spray-gun which is also included, can be used.

This manual contains all the necessary information concerning control and

maintenance. If the device is positioned correctly, properly controlled, and reg-

ularly maintained, a warranty will be given according to the general conditions

of delivery. However, should it arise that the control and maintenance proce-

dures are not diligently followed, the warranty will become invalid.

The machine may only be used by authorized personnel.

The machine can not be used in an explosive environment.

In this manual you will find all necessary information concerning operations and

maintaining your machine. If handled properly, your machine is guaranteed ac-

cording the general delivery conditions.

1.1 Use

The integrated engine drives the high-pressure pump via a V-belt. This pump

receives water from the water tank via the water filter and pressurizes it. The

pressure can be continuously adjusted. The pressurized water leaves the ma-

chine via the high-pressure hose on the reel.

01/18 4

01/18 5

2SECURITY

Be responsible for other people when you are working with this machine.

This manual contains instructions for fundamental conditions that must be fol-

lowed by use and maintenance of this machine.

That is why it is necessary that authorised and qualified personnel must read

the user's manual and the user’s manual must always be available with the ma-

chine. Near the general regulations in this chapter, you must also follow the se-

curity regulations in the other chapters.

2.1 Instruction indications in this manual

The in this manual containing security instructions, which are dangerous if they

are not obeyed, are marked with general security signs.

Security sign DIN 4844-W9.

2.2 Descriptions security measures

• Emergency stop

This machine is equipped with an emergency stop. By operating the emergency

stop, the machine will stop immediately. Do not use this button for normal stop-

ping. Only use it when dangerous situations occur. After use, remove the dan-

ger and pull the emergency stop in order to be able to start up again. Make sure

the emergency stop can always be reached.

•Pressureregulator

The pressure regulator ensures that the pressure never gets too high and thus

acts as a safety valve.

• Security covers

This machine is equipped with several security covers over parts that are rotat-

ing. It is forbidden to remove these security covers during operating this ma-

chine. You can only remove them if there is maintenance on the machine. Stop

the machine.

2.3 Personnel protection outfit

• Protection looking glasses

• Ear protector (recommended)

• Gloves (recommended)

• Water tight clothes (recommended)

01/18 6

2.4 Warnings

It is strongly forbidden to spray on humans and animals.

Fix the control levers never in any way whatsoever, except if it is indicated.

The cover must always remain closed while working with the machine.

Always use the auxiliary coupler during transport of the trailer.

Never drive faster than 80 km/h with the trailer.

2.5 Personnel qualification and education

Personnel that use, maintain and inspect the machine must have the right qual-

ifications for this job.

Responsibility and authorisation of the personnel and the supervision on the

personnel must be embedded. If the knowledge is not present, the user must

provide for the necessarily education.

2.6 Danger that can occur if the security regulations aren’t

observed

If the security regulations are not observed, danger can occur for personnel and

for the environment.

No amends are given if the regulations are not observed.

If the regulations are not observed, this can results in:

• Failure of important functions of the machine.

• Failure of prescribes methods for maintenance.

• Exposure of persons to dangers of electrical or mechanical failures

• Danger to the environment due to leakage of hazardous substances.

2.7 Working safely

The in this manual named security prescriptions, the national prescriptions to

prevent accidents and the internal labour, company and security prescriptions

must be followed by the user.

2.8 Security regulations for the user and technical service

• Protections of moving parts (for example couplings) may not be re-

moved if the machine is working.

• Leakage of dangerous mediums must disposed in a manner that there

is no danger for the personnel and environment. Statutory regulations

must be followed.

• Danger caused by electricity must be excluded.

01/18 7

2.9 Security regulations for maintenance, inspection and

mounting activities

• The user sees to it that qualified technicians do all maintenance, in-

spection and mounting activities. They must study the manual thor-

oughly.

• Maintenance may only be done when the machine is not functioning.

• The in the user’s manual mentioned handling to stop the machine must

be notified.

• The pump must be cleaned if it has pumped fluids that may endanger

health.

• Directly after maintenance of the machine, all the security and protec-

tion facilities must be functionally.

• Before starting the machine again, you must follow the instructions

correctly.

2.10 Making changes and fabricate spare parts

Changes to the machine are only permitted if Rioned has given written author-

isation. The use of original spare parts and accessories are for the safety nec-

essary. Rioned is not responsible for injuries or damages if other spare parts

are used.

2.11 Improper use

The security during working with the machine is only guaranteed if the use of

the machine is conform the user’s manual. The limits that are written in chapter

“Technical Specifications” and “Appendix” may never be overstepped.

If the machine does not work or give troubles, it is forbidden to work further

with the machine. Telephone your dealer or the technical department of your

dealer.

This manual contains all the necessary information concerning control and

maintenance. If the device is positioned correctly, properly controlled, and reg-

ularly maintained, a warranty will be given according to the general conditions

of delivery. However, should it arise that the control and maintenance proce-

dures are not diligently followed, the warranty will become invalid.

01/18 8

01/18 9

3 TECHNICAL SPECIFICATION

3.1 General

Description (symbol) Unit

Dimension : see chapter 11.4 Dimension FlexJet

page: 65

Weight (dry and without options) (m) : ~340 kg /~ 540 kg (FJ+)

Total weight (without options) (m) : ~ 750 kg / ~1200 kg (FJ+)

Quantity water tank : Max 400 l / Max. 550 l (FJ+)

Supply medium : Water

Maximum temperature medium : 60 °C

Standard colours : Yellow/gray or white/gray

Type tyre : 155R13C 89/91N

Recommended tyre tension : 4,5 bar

Total length high-pressure hose : 40-80 m

Diameter high-pressure hose : 1/2”

Total length supply hose : 35 m

Diameter supply hose : 3/4”-5/8”

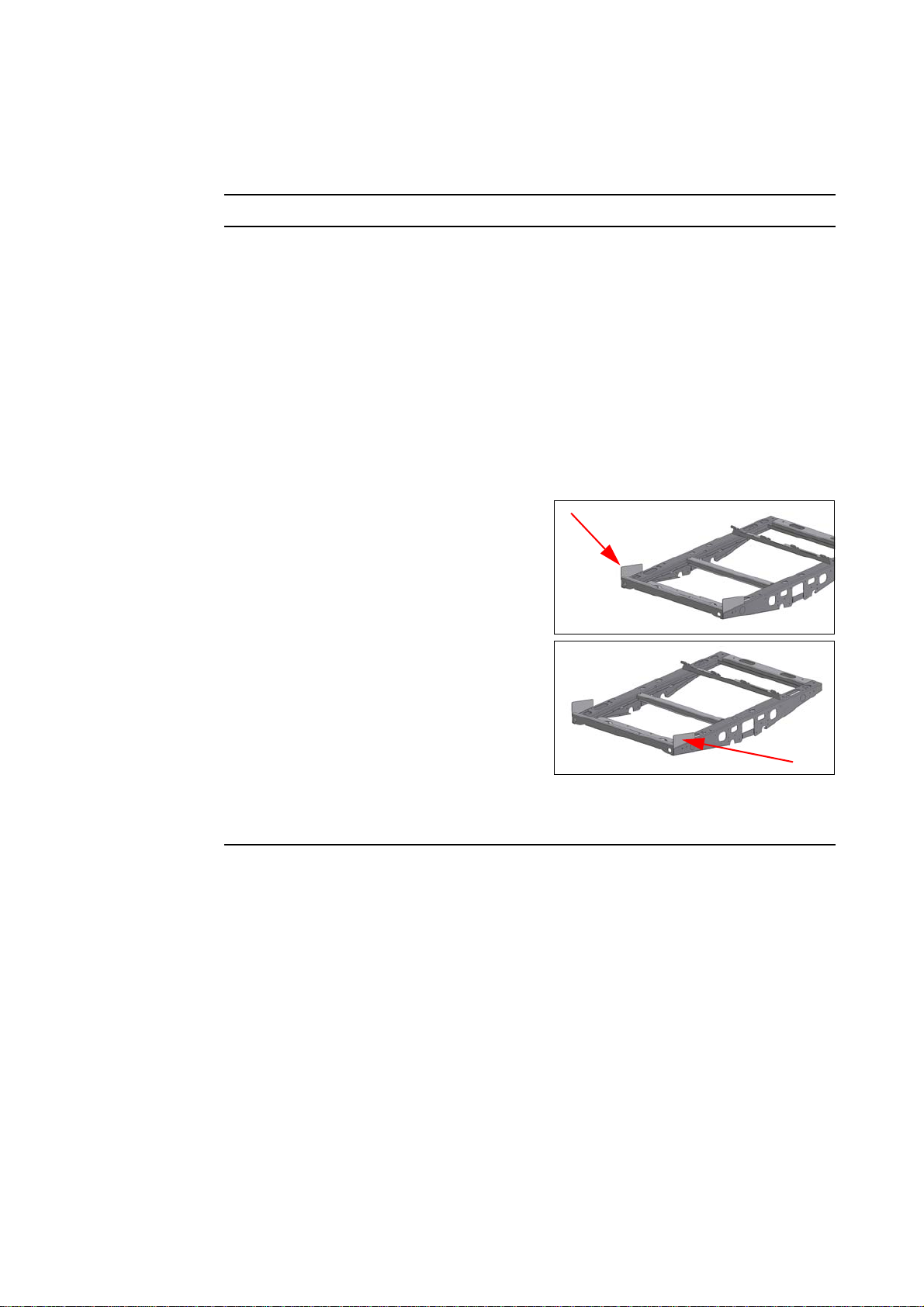

Place type plate :

Place chassis number :

Quantity oil tank : 5,5 l

Supply medium oil tank : Hydraulic oil HESTIA 46

Sound level and measure position : see chapter 12 Appendix page: 65

Year of construction (month/year) : 01/18

For more data FlexJet+ see chapter 11.8 COC page: 69

01/18 10

3.2 Engine

Description (symbol) Unit

Type : Vanguard Briggs & Stratton Model

350400

Number of cylinders : 2

Bore x stroke (d x l) : 72 x 70 mm

Displacement (V) : 570 cm3(0,57 . 10-6m3)

Power (P) : 13,4 kW (18 PK) at 3600 1/min

Fuel : Normal of unleaded petrol (Euro 95)

Quantity fuel tank (V) : 13 l (13 . 10-6m3)

Cooling : Air cooled

Weight (m) : 33,3 kg

Battery (U,I) : 12 V, 45 A

Oil : 10W30 API/SF-CC or better

Quantity oil : 1,7 l (1,7 . 10-6m3)

Dimensions (l x b x h) : 331 x 406 x 439 mm

Type : Honda GX630

Engine type : Air cooled 4-stroke OHV

Bore x Stroke : 78 x 72 mm

Displacement : 688 CC

Compression ratio : 9.3:1

Power : 20.2 PK (15.1kW)/ 3,600 rpm

Starting system : Electric

Oil capacity : 2,2 litters

Battery : 12 V, 45 A

Oil : 10W30 API/SF-CC

Dimensions (l x b x h) : 405 x 410 x 438 mm

Dry weight : 44,4 kg

Type : Honda GX690

Engine type : Air cooled 4-stroke OHV

Bore x Stroke : 78 x 72 mm

Displacement : 688 CC

Compression ratio : 9.3:1

Power : 22.4 PK (16.5kW)/ 3,600 rpm

Starting system : Electric

Oil capacity : 2,2 litters

Battery : 12 V, 45 A

Oil : 10W30 API/SF-CC

Dimensions (l x b x h) : 429 x 450 x 438 mm

Dry weight : 45,3 kg

For more information concerning the engine you can find it in the book deliv-

ered with this machine.

01/18 11

3.3 Pump

Description (symbol) Unit

Type : Speck P30

Number of plungers : 3

Number of valves : 6

Number of revolutions (n) : 1420 min-1

Maximum pressure (p) : See type plate on frame

Maximum output (V/t) : See type plate on frame

Oil : GX 80W90

Quantity : 0,7 l (0,7 . 10-6m3)

Weight (m) : 19 kg

Dimensions (l x b x h) : 342 x 282 x 140 mm

Maximum water temperature (T) : 70 °C (343,15 K)

Type : Speck P41

Number of plungers : 3

Number of valves : 6

Number of revolutions (n) : 1200 min-1

Maximum pressure (p) : See type plate on frame

Maximum output (V/t) : See type plate on frame

Oil : GX 80W90

Quantity (V) : 1 l (1,0 . 10-6m3)

Weight (m) : 30 kg

Maximum water temperature (t,T) : 80 °C (353,15 K)

Type : Speck NP25

Number of plungers : 3

Number of valves : 6

Number of revolutions (n) : 1450 min-1

Maximum pressure (p) : See type plate on frame

Maximum output (V/t) : See type plate on frame

Oil : GX 80W90

Quantity (V) : 0,9 l (0,9 . 10-6m3)

Weight (m) : 17 kg

Maximum water temperature (t,T) : 70 °C (353,15 K)

For more information concerning the pump, you can find it in the pump appen-

dix delivered with this machine.

01/18 12

01/18 13

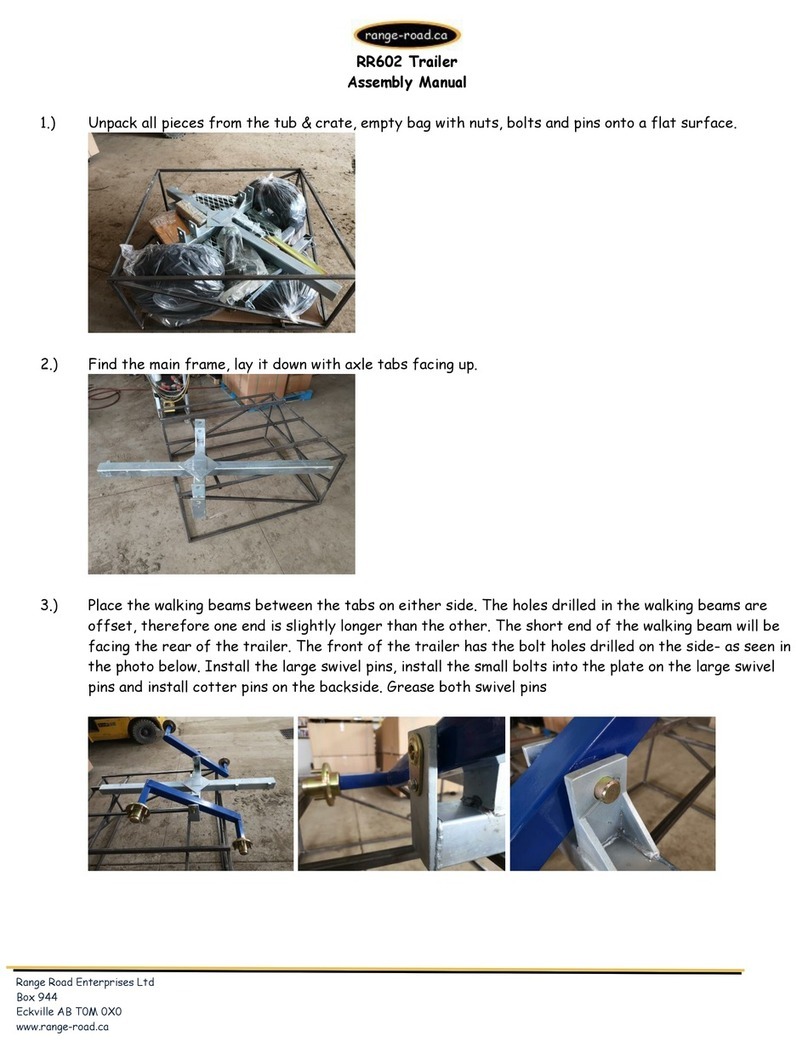

4CONSTRUCTION

This machine contains the following main parts:

1. Tool box

2. Water tank

3. Opening water tank

4. Reel with high-pressure hose

5. Reel with supply hose

6. Valve supply reel

7. High-pressure (HP)-valve

8. Machine cover

9. Control box

10. Pressure regulator

11. Pressure gauge

12. Water filter

13. Supply valve water filter

14. Drain valve

15. Engine

16. Pump

17. Nose wheel support

18. Swing nose wheel support

19. Tow bar

20. Coupling

21. Emergency stop

22. Fuel tank

23. Level indicator fuel tank

24. Battery

19 17

8415

2

20 18

01/18 16

This manual suits for next models

1

Table of contents

Other Rioned Utility Vehicle manuals

Popular Utility Vehicle manuals by other brands

Woodford Trailers

Woodford Trailers GALAXY owner's manual

HAUL MASTER

HAUL MASTER 38897 Assembly and operating instructions

Kärcher

Kärcher KM 150/500 R Bp instructions

Club Car

Club Car CARRYALL 294 Owner's manual supplement

Club Car

Club Car Cafe Express Owner's manual supplement

Toro

Toro WORKMAN GTX 07131 Operator's manual