3

Do not use this machine for any operation which

is not described in the Operation manual.

If you have any questions about the operation of

this machine, contact the Etnyre Service Depart-

ment at 1-888-586-1899.

Operations that are not approved could cause

serious injury or death.

Important

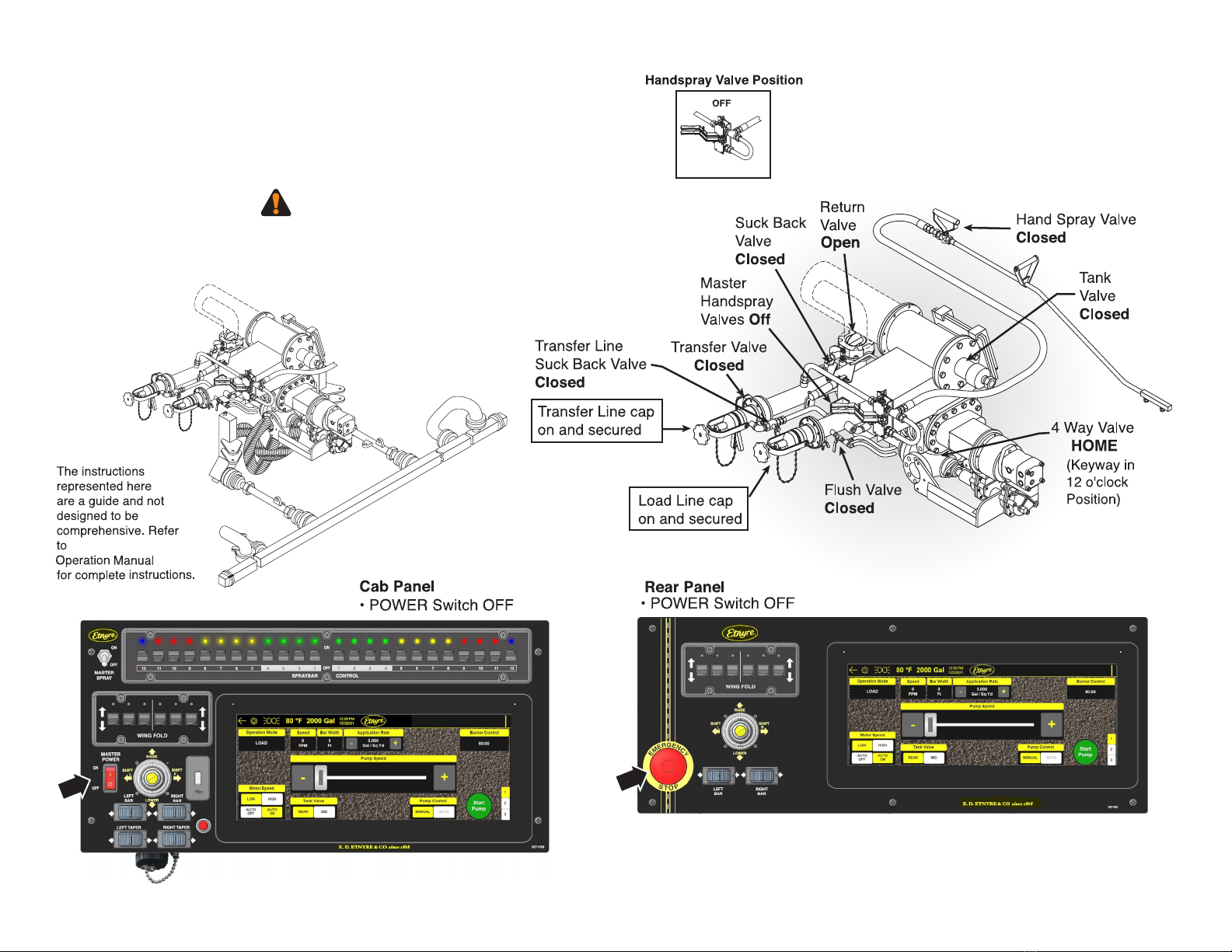

The instructions represented here are a guide and not designed

to be comprehensive. Refer to M-103-22 Asphalt Distributor

Operation, Maintenance and Safety manual for complete

instructions.

This pamphlet is provided as a tool to aid personnel in the

operation of the Etnyre Blacktopper Distributor, as with any type

of construction equipment, there are certain hazards associated

with improper or careless operation. The ability to read and

understand the instructions should be a required qualication

to become an operator. There are also functions that require

a certain amount of physical strength to accomplish. Persons

lacking the required strength may not only place themselves in

jeopardy, but also others in the vicinity. Read and understand

the Safety precautions found in M-103-22 Asphalt Distributor

Operation, Maintenance and Safety manual before operating

this machine.

If you have any questions regarding this pamphlet or the

operation of your unit, contact your Etnyre dealer or the

E. D. Etnyre Service Department at 1-888-586-1899.

WARNING

Contents

Etnyre Spray Bar Nozzles ...........................................2

Bar Suck Back Override ..............................................4

Control Panels.............................................................5

Load through Manhole.................................................6

Load through Load Line...............................................7

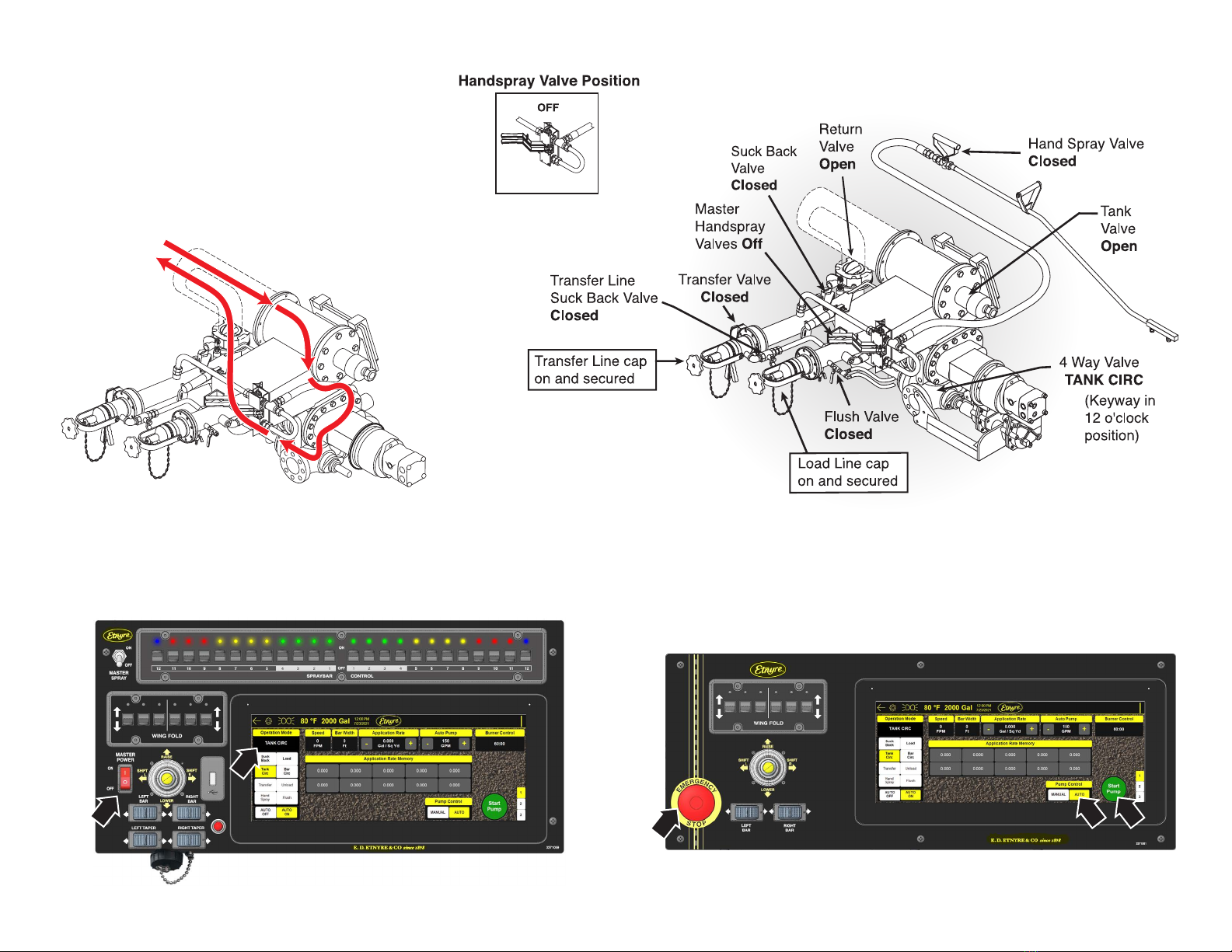

Circulate In Tank..........................................................8

Circulate In Bar............................................................9

Spray .........................................................................10

Suckback Spraybar ...................................................11

Handspray .................................................................12

Suckback Handspray ................................................13

Flushing Bar - AUTO .................................................14

Flushing Bar - MANUAL ............................................15

Unload (with External Pump).....................................16

Unload (with Distributor Pump)..................................17

Transfer .....................................................................18