Rittal CMC-TC User manual

CMC-TC Master

DK 7320.000

Installation and Operating Instructions

- Last update: 10 January 2006 -

All rights related to this technical documentation are reserved for us. Without our previous consent it must neither be reproduced nor made

available for third parties. Nor must it be put to any other misuse by the receiver or third parties. Any violation of the above obliges the

violating party to pay compensation and may lead to penal action.

R i t t a l GmbH & Co.

KG

Auf dem Stützelberg

D – 3 5 7 4 5 H e r b o r n

Germany

Email: [email protected]

http://www.cmc-tc.com

Service Tel. : (+49) - (0)2772 / 505 - 0

Service Fax : (+49) - (0)2772 / 505 - 2319

FRIEDHELM L O H GROUP

A29669 11 IT 74

Index [xx]

TCP/IP, SNMP

2

Table of Content

0. Introduction ........................................................................................................... 4

1. Safety instructions ............................................................................................ 5

2. Service and Service Address...................................................................... 6

3. CMC-TC Master.................................................................................................... 7

3.1

Description ...................................................................................................................7

3.2

Design .............................................................................................................................8

3.3

Functions.......................................................................................................................9

Optional: ................................................................................................................................ 9

4. Assembly............................................................................................................... 10

4.1

Mechanical components......................................................................................10

4.2

Electrical components ..........................................................................................10

5. Start-up................................................................................................................... 11

6. Operation............................................................................................................... 11

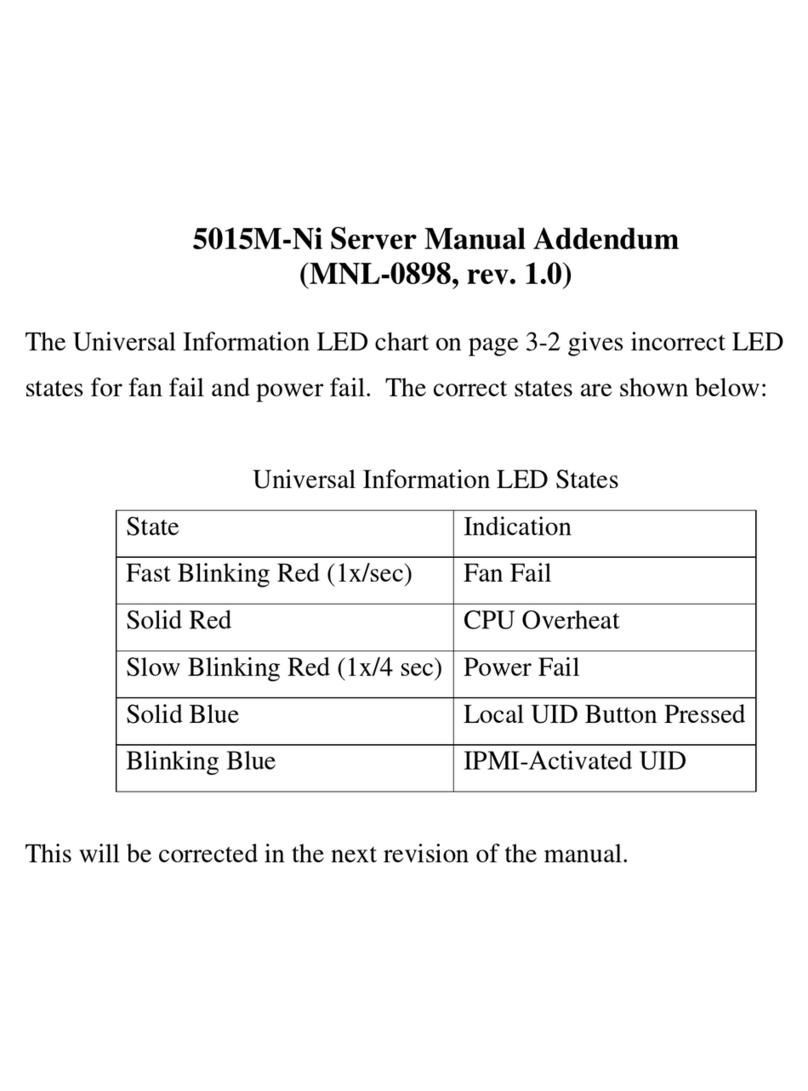

7. Fault messages ................................................................................................. 12

8. Maintenance ........................................................................................................ 12

9. Cleaning ................................................................................................................. 12

10. Disposal .............................................................................................................. 12

A 1 Scope of supply/ Accessories – CMC-TC Master...................... 13

B 1 Technical data – CMC-TC Master ........................................................ 14

C 1

Functional diagram - Central application in the network

.................... 15

C 2

Functional diagram – Local operation via console

................................ 16

C 3

Functional diagram – Operation by network and console

................... 17

D 1 Installation instructions – Master........................................................ 18

E 1 Electrical connection: CMC-TC master............................................ 19

E 2 Configuration via serial interface RS 232....................................... 21

E 3 Setting up of the CMC-TC Processing Units

for operation with the Master................................................................. 22

F 1 Check list – Commencing operation of CMC-TC Master....... 24

G 1 Display and operating elements enclosure................................... 25

H 1 Display and operation by terminal program ................................. 26

I 1 Operation of CMC-TC master by browser ......................................... 28

Explanation info window............................................................................................28

Explanation info window – Certification information...................................29

3

Logging in to the CMC-TC Master .........................................................................30

Structure of the HTML pages ...................................................................................31

Tab – Trap..........................................................................................................................32

Trap list of CMC-TC Master ................................................................................................................. 32

Setting severity of a trap message ..................................................................................................... 33

Tab – Overview................................................................................................................34

Tab – Status......................................................................................................................35

Tab – Setup .......................................................................................................................36

Setup page of the selected CMC-TC sensor unit and its CMC-TC PU ............................................ 36

Changing access codes of the selected PU online........................................................................... 37

Tab – Setup .......................................................................................................................38

Changing access codes of the selected PU online........................................................................... 38

Tab – Setup .......................................................................................................................39

Changing access codes of the selected PU online (initial startup) ................................................ 39

Tab – Setup .......................................................................................................................40

Changing access codes of the selected PU online........................................................................... 40

Changing access codes of the selected PU online........................................................................... 41

Tab – Setup .......................................................................................................................42

Changing access codes of the selected PU offline (initial startup) ................................................ 42

Tab – Setup .......................................................................................................................43

Changing access codes of the selected PU offline (initial startup) ................................................ 43

Tab – Setup .......................................................................................................................44

Changing access codes of the selected PU offline (initial startup) ................................................ 44

Tab – Setup .......................................................................................................................45

Changing access codes of the selected PU offline .......................................................................... 45

Tab – Images ....................................................................................................................46

Displaying the Webcam photos stored in the master....................................................................... 46

Download or delete the Webcam photos saved in the master ........................................................ 47

Tab – Alarms ....................................................................................................................48

Tab – Admin......................................................................................................................50

General: Overview of administration page ........................................................................................ 50

General setup........................................................................................................................................ 51

User management................................................................................................................................. 52

Alarm notification receiver .................................................................................................................. 54

Remote shutdown settings.................................................................................................................. 55

General information on the shutdown of computers........................................................................ 56

Alarm actions ........................................................................................................................................ 57

Webcam settings .................................................................................................................................. 59

Logfile management............................................................................................................................. 60

Overview page setup............................................................................................................................ 60

Update connected device .................................................................................................................... 61

Firmware update ................................................................................................................................... 62

J 1 Software functions ....................................................................................... 63

K 1 Fault messages Master Unit ................................................................... 64

4

0. Introduction

The stable flow of information and production is the 'lifeline' of an enterprise.

Loss of data, failure of function and production cause extensive and in many cases life-

threatening damage. Therefore, it is the declared company objective to ensure a maximum of

safety and reliability.

RITTAL offers the support to achieve this: By means of universal competence in effective

prevention, comprehensive safety, and centralized organization, i.e. teamwork for IT safety

and reliability! This results are the optimum combination of enclosure monitoring, server

administration, and climate control components.

The solution for enclosure monitoring carries the Name RITTAL CMC-TC. This concept

includes complete physical monitoring of the enclosure, i.e. temperature, humidity, vibration,

smoke, voltage up to complete enclosure locking and access control. All these items of

information are transmitted via SNMP to a management station and can easily be

administered from this point.

The system is rounded off by its modular structure. Basic monitoring can be implemented in

next to no time. When the requirements grow, the system can easily be expanded and can

also be combined with other components of the Rittal production range.

For more comprehensive systems the CMC-TC Master is ready, acting as a central

management station. It can manage up to 10 self-contained monitoring systems via one IP

address in a network. Alarm signals and monitoring-relevant data of the monitoring systems

are centrally collected and partly documented. The data collected and prepared can then be

called over the 10/100 BaseT connection or directly over a KVM console (Keyboard-Video-

Mouse console). The RITTAL SSC console is suited to this purpose. In addition, the Master

can be connected to a KVM switch.

The significant features of the RITTAL CMC-TC Master are:

• Central administration of larger enclosure monitoring systems in interlocked networks or

stand-alone

• Ethernet network connection 10/100BaseT

• Central web server for configuration

• Local administration via KVM console (2xPS/2 and VGA connection)

• Maximum expansion:

Up to 160 temperatures can be measured or

up to 80 doors can be administered

• Total compatibility with RITTAL enclosure monitoring system CMC-TC and with the

RITTAL enclosure system

• (Room) Monitoring by WebCam

5

1. Safety instructions

Rittal

CMC-TC

General remarks

The installation and operating instructions contain basic information for installation,

for putting into operation, and for operating the RITTAL CMC-

TC Master. It is a

must to make the instructions available to the installation technician and the

administrative operating personnel and that they should read these carefully.

RITTAL cannot accept liability for personal injury and material damage resu

lting

from non-

observance of the safety advice in the installation and operating

instructions.

It is essential to observe not only the general safety advice given

in this chapter, but also the special safety advice given in the other chapters.

Personnel qualification and authorization

Operation and any changes may be c

arried out only by authorized specialist

personnel or by authorized trained operating personnel.

!

Risks due to non

-

observance of safety advice

Non-observance of the safety advice may result in risks for the personnel,

as well

as to the RITTAL CMC-TC Master together with the connected equipment. Non-

observance of the safety advice involves loss of the right to claim for all and any

damages.

IPxx

ϑ

min

ϑ

max

Working at the CMC

-

TC

The generally applicable electrical regulations of the country i

n which the unit is

installed and operated must be observed, just as the existing national regulations

for the prevention of accidents and any internal rules (work, operating, safety

regulations) issued by the operator. Prior to working at the unit this mu

st be

disconnected from the supply and secured against being switched on again.

Original accessories and accessories authorized by the manufacturer ensure

safety. The use of other parts may make void the liability for consequences

resulting from this. Repa

ir work at the unit may be done only by RITTAL or by

authorized personnel.

Operating reliabilit

y

The operating reliability of the unit supplied is only warranted in case of use as

intended and according to the rules. The limit values quoted in the technical data

(see Appendix B Technical data

) must not be exceeded under any

circumstances. This appli

es particularly to the allowed ambient temperature range

and the allowed IP protection category. For applications with a higher specified IP

protection category the Rittal CMC-

TC must be installed in an enclosure of a

higher IP protection category, complyi

ng with the specified protection category.

Operation of the CMC-

TC system in direct contact with water, aggressive media,

or inflammable gases and fumes is prohibited.

6

2. Service and Service Address

If you have any questions concerning technical or other issues related to our product range

RITTAL will of course support you. You may contact us by e-mail or via the address or phone

and fax numbers indicated below.

RITTAL GmbH & Co. KG

PM IT-Service

Auf dem Stützelberg

D-35745 Herborn

Germany

http://www.RITTAL.de

Email: Info@RITTAL.de Caution: please always specify the article number in

the reference line!

Phone: +49 (0)2772/505-0

Fax: +49 (0)2772/505-2319

Further information and the updated operating instructions for the RITTAL CMC-TC Master

are ready for downloading from the RITTAL homepage.

7

3. CMC-TC Master

3.1 Description

The RITTAL CMC-TC Master is a function block making the administration, co-ordination,

documentation, and alarm indication of the monitoring system CMC-TC more comfortable

and supporting additional functions. The configuration is consisting of an Embedded Linux

PC with integrated 10-fold hub in the 1 U 482.6 mm (19”) enclosure, to which up to 10

processing units can be connected. An integrated 10/100 BaseT interface (Ethernet

interface) allows the Master to integrate the connection into the network environment of the

company. The Master can be operated off the network using the console connections

(2xPS/2, 1xVGA). This means the Master can be accessed locally or via the network.

A visible or audible alarm can be implemented using the integrated alarm relay.

The CMC-TC Processing Units are linked up by Cat5 cabling with the CMC-TC Master

installation. The data connection into the network is made via the Embedded-Linux PC. To

guarantee the connection to the network is secure, 128-bit SSL encryption is integrated.

Access to the integrated web browser of the Master is possible through a standard browser

(Internet Explorer, Mozilla Firefox, etc.). The CMC-TC Master supports the TCP/IP, SNMP,

TELNET (TeraTerm), SSH and HTTPS protocols.

The network protocols are used for communication (password and status query, switching

commands, and alarm signals) between the CMC-TC system and the authorized users in the

network (network, internet and intranet).

See Appendix C Functional diagram

The Rittal CMC-TC Master is platform-independent as long as the platform has a network

connection and a web browser available. The SNMP functionality is also platform-

independent and must support the SNMP V1.0 network management protocol. In addition,

the CMC-TC Master supports the Standard-MIB II. The private MIB is part of the scope of

supply; see CD Rom (CMC-TC-Master.MIB).

8

3.2 Design

The Master is delivered in a 482.6 mm (19”) aluminum enclosure. The Master is based on an

embedded Linux PC with integrated 10-fold hub. For future further development of the

Master, several interfaces such as PCMCIA, serial, infrared and sound interfaces are

preconfigured.

At the front the various status conditions like alarm status, network connection, and

connected monitoring systems are shown by 13 LEDs. The functions are described in detail

in Appendix G 1 Display and operating elements enclosure.

The IEC mains connection is located on the rear side of the Master. The power pack is

integrated into the Master enclosure. The IEC connection cable is available in various country

versions and must be chosen according to the country-specific specifications (see Appendix

A1 Scope of supply/Accessories – Master).

A connection point is available to ground the enclosure of the Master.

All important operating parameters (e.g. application limit, temperature and humidity, etc.) are

described in more detail in Appendix B Technical data –Master.

9

3.3 Functions

The functions of the RITTAL CMC-TC Master are focused on the management of up to 10

Processing Units and of the components connected to these, such as sensors, access

controls, and climate control components. These functions are administered and controlled

by means of the protocols listed below:

• Terminal programs

• through serial interface RS232: e.g. Hyperterminal

• in Ethernet network: e.g. through TELNET (Tera Term), SSH

• SNMP V1.0, compatible with the usual management systems

• HTTPS

• TFTP

Optional:

• WebCam support (USB version) up to 2 units (see Appendix A 1 Scope of supply

accessories – CMC-TC Master)

See Appendix C 1 Functional diagram

See Appendix I 1 Operation of CMC-TC Master by browser

The more detailed description of the software functions is given in Appendix J 1 Software

functions, and also the explanation of the layout of the table structure as follows.

Item:

Call: Telnet,

Hyperterminal

To-Do Software function

Value

range

Factory setting

Hyperterminal

Telnet

Browser

0 Login

0.1

Query

User name

see table below.

0.2

Query

Password

see table below.

1 Network c

onfiguration

1

1.1.1

Setting

IP Address

192.168.30.100

2

1.1.2

Setting

IP Subnetmask

255.255.255.0

3

1.1.3

Setting

IP Router

0.0.0.0

For complete list, see Appendix J 1 Software functions

Function is supported

by …

Position

Call of menu

items in ...

Possible action

Description of software functions

Settable value range

Default

ex works

10

4. Assembly

The Rittal CMC-TC Master is mounted in the 482.6 mm (19”) level of a 482.6 mm (19”) rack.

Attention must be paid to maintaining the allowed ambient temperature and humidity ranges,

as well as the IP protection category as required for the specific application. The appropriate

information is given in Appendix B Technical data. Compliance with a higher required IP

protection category can be achieved by installation in an enclosure or enclosure system

having the required protection category.

In addition, the following points must be observed:

When using accessories in connection with the RITTAL CMC-TC, the installation and

operating instructions for the accessories and for the RITTAL CMC-TC must be observed.

Repair work on the RITTAL CMC-TC may be carried out only by authorized specialist.

The number of RITTAL CMC-TC Masters in the network is optional, assuming that there

are sufficient free IP addresses available.

In case of modification at or inside the enclosure, e.g. installation of a new CMC-TC

monitoring component, it is a must to observe the operating instructions of the enclosure.

4.1 Mechanical components

Note: The RITTAL CMC-TC Master can be mounted optionally in the front or the rear

482.6 mm (19") level.

See Appendix D Installation instructions

4.2 Electrical components

Note: During installation the existing national regulations of the country, in which the RITTAL

CMC-TC Master is to be installed and operated, must be observed.

In addition the following points must be observed:

• Existing safety devices must not be put out of action.

• The RITTAL CMC-TC may be operated only with PE conductor connection. The PE

conductor connection is made by plugging in the IEC connection cable. The requirement

for this is that the IEC connection cable is connected on the mains-side with the PE

conductor. The enclosure grounding point must be connected to the potential equalization

of the enclosure system to prevent electric shock due to residual hazardous voltages

following a malfunction.

• The electric supply voltage and frequency must correspond to the rated values given on

the rear side of the device and in Appendix B 1 Technical Data.

11

• Prior to working on the RITTAL CMC-TC this must be made voltage-free and secured

against reclosing. Furthermore, the absence of electrical power must be checked.

• Cable clamping and protection is made by means of commercial cable ties at the casing

or enclosure used.

See Appendix E 1 Electrical connection: CMC-TC master

5. Start-up

Note: The RITTAL CMC-TC is an independent system without mains switch and

automatically loads the firmware (operating system) into the main memory when the mains

voltage is connected.

Please follow the steps set out in Appendix F 1 Check list Commencing operation.

See Appendix F 1 Check list Commencing operation of CMC-TC Master

See Appendix E 2 Configuration of serial interface RS 232

6. Operation

The RITTAL CMC-TC can be operated by means of the following devices:

Terminal program by serial connection, e.g. Hyperterminal, this operating mode

necessitates a direct connection between the PC operator workstation and the CMC-TC

Master Intended use: First startup.

Terminal program by network connection, e.g. TELNET (Tera Term), restricted to the

required network configuration setups.

Standard browser, affords via a simple graphic surface the more comprehensive

administration of the RITTAL CMC-TC Master using service-proven, widely used standard

software (browser). Recommended for the administrator and the user.

Professional management software, as e.g. HP OpenView and others, see operating

instructions for the corresponding management software.

See Appendix G 1 Display and operating elements enclosure

See Appendix H 1 Display and operation by terminal program

See Appendix I 1 Operation of CMC-TC Master by browser

See Appendix J 1 Software functions

12

7. Fault messages

Note: By means of the fault messages it is possible to read from the summary of fault

messages (see Appendix K 1 Fault messages) the kind of the current fault as well as the

cause and measures to be taken.

See Appendix K 1 Fault messages

8. Maintenance

The RITTAL CMC-TC is a maintenance-free system which must not be opened for

installation or during operation. If the housing or any of the accessory components are

opened, all warranty and liability claims will become void.

9. Cleaning

In case of dirtiness, the CMC-TC Master can be wiped clean using a slightly moist cloth. The

use of aggressive substances or acids for cleaning will cause damage or destruction of the

unit and is absolutely prohibited.

10. Disposal

As the CMC-TC Master mainly consists of the housing and the PCB, the unit is to be

disposed of through electronic waste recycling.

13

A 1 Scope of supply/ Accessories – CMC-TC Master

Supply includes

Accessories

DK 7320.000

Item 1: One CMC-TC Master with network interface RJ 45 socket (10/100 BaseT)

Item 2: Captive nuts and bolts M6x14 (4x ea.)

Item 3: CD ROM File name

MIB II Management Information Base II CMC-TC-Master.MIB

Operating instructions German: A29669_xx_IT74_G.pdf

English: A29669_xx_IT74_E.pdf

Item 4: A startup check list German/English A29668 xx IT 74

Item 5: Packaging

Accessories

Description

P. of

required Model No.

DK

Connection

cable

Connection cable IEC connector

Country version D

1 7200.210

Connection cable IEC connector

Country version GB

1 7200.211

Connection cable IEC connector

Country version F/B

1 7200.210

Connection cable IEC connector

Country version CH

1 7200.213

Connection cable IEC connector

Country version USA/CDN UL

approved FT1/VW1

1

Yes, 1x

7200.214

IEC extension cable 1 7200.215

Programming

cable

Programming cable D-Sub 9 to RJ

11

1 Yes, max. 1 7200.221

Connection cable Master /

Processing Unit Cat5 Cable 0.5 m

4 7320.470

Connection cable Master /

Processing Unit Cat5 Cable 2 m

4 7320.472

Connection

cable

Network

Connection cable Master /

Processing Unit Cat5 Cable 10 m

1

Optional, max. 1

cable per connected

Processing Unit

(DK 7320.100)

Condition:

Cable length up to

10 m is sufficient.

7320.481

WebCam WebCam (USB version) 1 Optional, max. 2 on request

Processing unit

Processing Unit 1 Yes, at least 1

max. 10 units

7320.100

Accessories for processing unit, see scope of supply and

accessories in the operating and installation instructions of the

Processing Unit (DK 7320.100)

Note:

The RITTAL CMC-TC Master can be operated using te

rminal programs, as e.g.

Hyperterminal and TELNET by SW Tera Term (see Appendix

G 2 Display and operation by

terminal program

), and also TFTP (is part of commercial operating systems) or a

commercial browser. No further software is required.

14

B 1 Technical data – CMC-TC Master

Technical specifications

DK 7320.000

Enclosure Aluminium

Height 1 U, approx. 4.45 cm

Width 482.6 mm (19“), 447 mm

Depth approx. 200 mm

Weight approx. 0.35 kg without packaging

Potential equalization by enclosure earthing connection at the rear

Earthing by IEC connection socket (IEC 320) at the rear

IP protection category IP 40 according to EN 60529

Keys 1x Reset key with contact hazard protection

Front sockets 1x Microphone input (3.5 mm jack)

1x Speaker input (3.5 mm jack)

1x RJ 11 socket (serial interface RS 232)

LED display 3x, (Alarm, 10/100 Mbit/s, Link)

10x, (per Processing Unit that can be connected)

Infrared interface 1x IrDA 1.0 (SIR)

Acoustic display 1x, Piezoelectric signal generator

Temp. application range + 5 °C to 35 °C/+ 41 °F to 95 °F

Humidity application range 5 % to 95 % relative humidity, non-condensing

Storage temperature range -20 °C to 60 °C/ -4 °F to 140 °F

Voltage connection:

Power supply 1x, AC 100 V - 230 V, +/-10% 50/60 Hz

Network connection 1x, RJ 45 socket (Ethernet according to IEEE 802.3, 10BaseT/100BaseT),

shielded

Processing Unit-Ports:

10x, RJ 45 sockets, shielded 10BaseT

Processing Unit connection

cable

Shielded twisted pair patch cable, category 5,

see Appendix A 1 Scope of supply/accessories Processing Unit

Maximum line length ...

..Master to Processing Unit 90 m (UL 3 m)

Output Alarm relays 1x RJ 12 socket, shielded

Type of relay Potential-free change-over contact

Max. current consumption 1 A with external power connection

Max. voltage 30 V with external power connection

USB interfaces 2x USB sockets, shielded - USB 1.1 -

Console connection:

Keyboard interface 1x PS/2

Mouse interface 1x PS/2

Monitor interface 1x D-Sub 15 socket (HD15) VGA

Serial interfaces: 1x D-Sub 9 - RS 232 – (second port is internally assigned)

PCMCIA-Ports: 2x Type I/II or 1x Type III

Protocols TCP/IP, SNMP V1.0 (incl. MIB II), TELNET (by Tera Term), SSH, TFTP, HTTP

with SSL

15

C 1 Functional diagram –

Central application in the network

DK 7320.000

Central Network Management

System (NMS)

TCP / IP, SNMP,

TFTP, Telnet über

Tera Term, SSH,

HTTP

16

C 2 Functional diagram – Local operation via console

DK 7320.000

Via the co

nsole connection it is possible to use a

keyboard, mouse and monitor directly at the RITTAL

CMC-

TC Master. Optionally it is possible to install a

keyboard-monitor-mouse switch in between.

(Keyboard: PS/2, Mouse: PS/2 and Monitor:

DSub15)

17

C 3

Functional diagram –

Operation by network and console

Via the console connection it is possible to use a

keyboard, mouse and monitor directly at the RITTAL

CMC-TC Master. Optionally it is possible to install a

keyboard-monitor-mouse switch (SSC series) in

between.

(Keyboard: PS/2, Mouse: PS/2 and Monitor:

D-Sub15)

DK 7320.000

TCP / IP, SNMP,

TFTP, Telnet über

Tera Term, SSH,

TFTP, HTTP

Central Network Management

System (NMS)

18

D 1 Installation instructions – Master

DK 7320.000

19

E 1 Electrical connection: CMC-TC master

Note: Prior to making the electrical connection of the RITTAL CMC-TC Master it is

indispensable to observe the notes in Chapter 4.2 Electrical components.

1. Connection Network connection

2. Connection Processing Unit (DK 7320.100)

3. Connection local console (Monitor, mouse and keyboard) – optional

DK 7320.000

Die Netzwerkverbindung erfolgt per Netzwerkkabel mit

RJ45-Stecker in die vorhandene, kundenseitige

Ethernet-Netzwerk-Struktur (siehe Bild links).

Nach Anlegen der Netzspannung leuchtet die Link-LED

an der Frontseite bei einer 10 Mbit-Verbindung grün und

bei 100 Mbit-Verbindung orange. Erfolgt der

Datenaustausch beginnt die Link-LED zu blinken.

Es können bis zu 10 Processing Units an einen Master

angeschlossen werden. Die Verbindung vom Master zu

den einzelnen Processing Units erfolgt über Cat5-

Netzwerkkabel. Je Processing Unit wir ein Cat5-

Netzwerkkabel benötigt. Im RITTAL CMC-TC Master ist

ein 10-fach 10BaseT-Hub zum Anschließen der

Processing Units integriert (siehe Bild links). Wenn der

Master mit Netzspannung versorgt wird, leuchten die

Status-LEDs des 10-fach Hub an der Frontseite des

Masters.

Die vorinstallierten PS/2 und VGA-Schnittstellen sind für

eine Monitor, Maus und Tastatur-Konsole, die lokal

betrieben werden kann.

Hinweis:

Maus und Tastatur müssen vor dem Booten des

Masters angeschlossen werden, da die

Komponenten im laufenden Betrieb nicht erkannt

werden. Durch das Einstecken der Komponenten an

die PS/2-Schnittstellen im laufenden Betrieb können

die

Schnittstellen

Schaden

nehmen.

10BaseT/100BaseT

1

9

2

10

PS/Mouse connection

D

-

Sub15

monitor connection

PS/Keyboard connection

The network connection is made by means of network cable

wit

h RJ 45 connectors into the existing Ethernet network

structure (by client) (see photograph on left).

After connecting the supply voltage, the Link LED on the front

lights up green for a 10 Mbit connection and orange for a 100

Mbit connection. When data is exchanged, the Link LED

starts to blink.

It is possible to connect up to 10 Processing Units to a

Master. The connection between the Master and the

individual Processing Units is made via network cable

Cat5. One network cable is required per Processing Unit.

A 10 port 10BaseT hub is integrated into the RITTAL

CMC-

TC Master to connect the Processing Units (see the

figure on the left). When the Master is connected to the

power supply, the status LEDs of the 10 port hub are lit

on the front of the Master.

The preinstalled PS/2 and VGA interfaces are for a

monitor, mouse and keyboard console that can be

operated locally.

Note:

The mouse and keyboard must be connected before

the Master is booted since these components are not

detected once the Master is running. Plugging in

components to the PS/2 interfaces during operation

can damage the interfaces.

20

E 1 Electrical connection: CMC-TC master

4. Connection Alarm relay (potential-free changeover contact)

5. Voltage connection and PE conductor connection

6. WebCam connection using USB cable

DK 7320.000

The enclosure earthing is to be connected to the

potential equalization of the enclosure system. For this

purpose an earthing pin is provided at the rear side of

the enclosure. The earthing conductor is not part of the

scope of supply. The power supply of the Master is

made by a country-specific IEC cable, as named in

Appendix A1 Scope of supply/Accessories. The

integrated power pack is to be used exclusively for the

voltage supply of the CMC-TC Master!

When on voltage, the Master automatically starts the

boot

procedure.

Note: The alarm relay enters the

release condition as soon as the

master is on mains voltage. In case of

mains failure the alarm relay drops out

once, triggering an alarm. Using this

function it is possible to

implement an

on-

wire message, e.g. to a central

station.

The connection cable of the RITTAL WebCam is plugged in directly in a vacant USB port of the RITTAL CMC-

TC Master. Up to 2 Rittal WebCams are supported.

Maximum admissible cable length: 5 m.

Note:

The master unit can be set by the definition of alarm

actions so that the alarm relay is actuated with arbitrary

sensor states set by the user. The alarm relay remains

actuated as long as such a state exists.

With the actuation of the alarm relay the alarm LED on the

front of the master unit is switched to red.

The alarm relay is connected through the RJ 12 sockets

using

RJ 12 connectors. The technical specification of the

alarm relay is shown in Appendix B1 Technical data,

which

you must not exceed for technical and safety-

relevant

reasons. The assignment of the alarm relay is made by

software parameterization, see Append

ix I 1 Operation

CMC-TC by browser

. The internal circuitry of the alarm

relay is shown below.

Other manuals for CMC-TC

1

This manual suits for next models

1

Table of contents

Other Rittal Server manuals