3.0 Product Disassembly Process

3.1 List the basic steps that should typically be followed to remove components and materials requiring selective treatment:

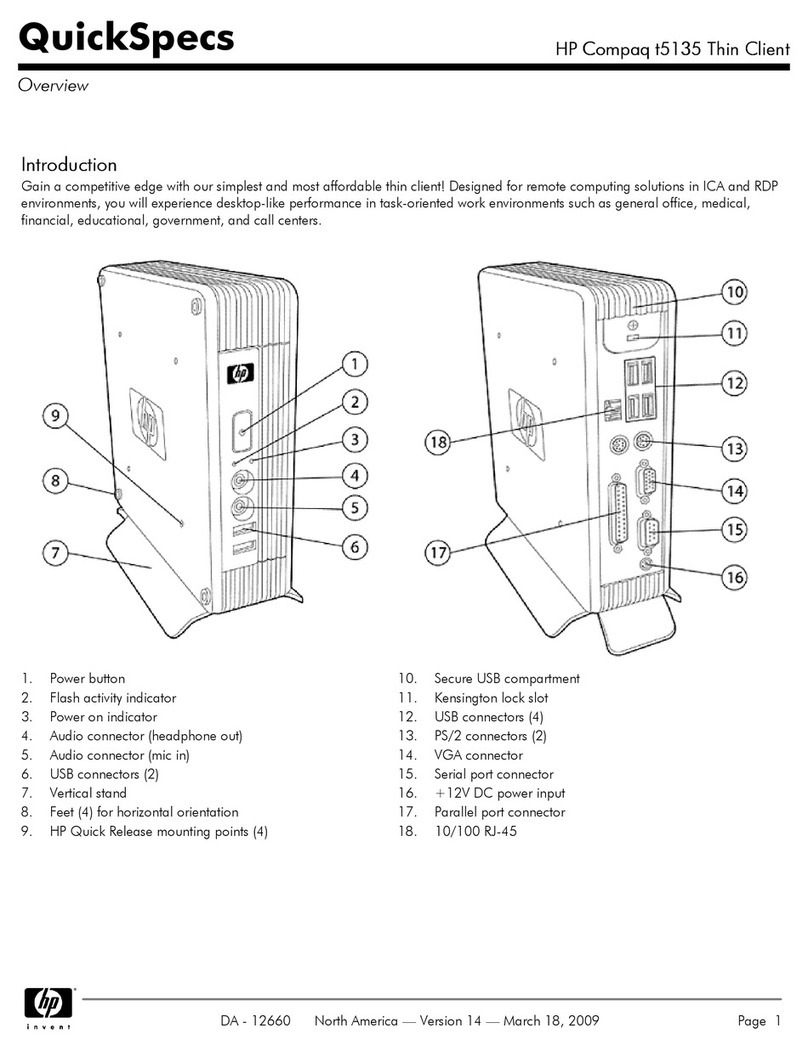

Compute enclosure front components (See Figure 1)

Compute Enclosure Rear Components (See Figure 2)

Remove power supplies

•Press the release button

•Pull down the handle

•Remove the power supply (quantity 12) (SEE Figure 3)

Removing DVD Module

•Remove USB cables from DVD to OA

•Remove the DVD module bezel

•Press the button on the front of the DVD module to release handle

•Pull the handle and slide the DVD module out enclosure (SEE Figure 4)

Remove the Server Blades(s)

•CAUTION:

After you press the release buttons, the server blade is unlocked from the enclosure. Use both hands to support the server

blade when you remove it from the enclosure. The Server Blade weighs approximately 15.4 kg (34 lb) (SEE Figure 5)

•Lay Server Blade on flat surface

•Remove the access panel by lifting it straight up and off the server Blade (SEE Figure 6)

•Locate the two processors

oRemove the processor heat sink: (SEE Figure 7)

Lift the load bail (1).

Lift the load bar (2).

If necessary, break thermal interface between the heat sink base and processor. If necessary use a small screw driver

(3).

Lift the heat sink (4).

oRemove the processor: (SEE Figure 7)

Open the load bar (1).

Open the load bails (2).

Lift the load plates (3).

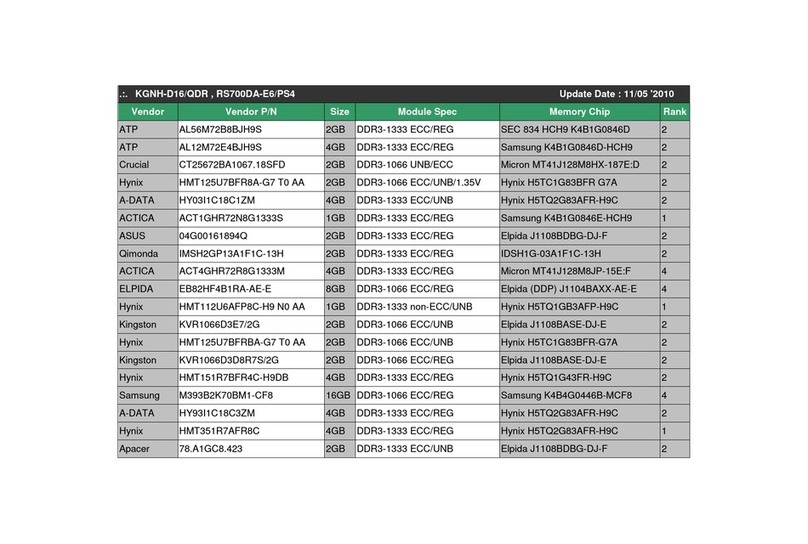

oRemove the DIMMs, maximum quantity 32 (SEE Figure 8)

oRemove the one battery (SEE Figure 9)

Remove the active cool fans, quantity 15

•Turn the handle counterclockwise

•Remove the fan

Remove the interconnect switch (maximum quantity 8)

•Disconnect all cables from component

•Press the release tab

•Open the handle

•Remove the interconnect switch (See figure 2 for location)

Remove Onboard Administrator modules (quantity 2) and Onboard Administrator tray

•Disconnect all cables

•Press the release tab and open handle and remove onboard administrator; quantity 2 (See Figure 2 for location)

•On the Onboard Administrator Modules that were removed, depress the button in the center and remove the top panel.

oRemove the PCB and look for the Yellow battery. This battery can be removed from its corresponding IC by using

(See Figure 10)

•Press the release handle on the onboard administrator tray and open handle. Note: This is the assembly that the onboard

administrator installs into (See Figure 11)

Remove the GPSMs

•Disconnect all cables

•Press the button on the front of the GPSM to release handle

•Pull the handle and slide the GPSM out of the enclosure

Remove the XFM; quantity of 4

•Disconnect all X-Bar Flex-connect cables

•Press buttons on the front of the XFM to release the handles

•Pull the handles and slide the XFM out of the enclosure

Remove the ac input modules

•Completely unscrew the three thumbscrews that secure the ac input module. The screws remain captive after they are unscrewed

•Remove the ac input modules (See Figure 2 for location; See Figure 12 for component removal)

Remove the I/O Chassis (Enclosure tear down)

•Unscrew the ten thumbscrews and open the hinges completely

•Use the handles to extend the I/O chassis until the release levers engage on both sides of the I/O Chassis

•Grasp the handholds below the release levers

•Disengage the release levers on both sides of the rear chassis

oCAUTION: When removing and lifting the I/O chassis, always grasp

the handholds as far forward as possible. The frontend

of the I/O chassis is heavy and the handholds provide a more balanced location to distribute the weight

•Use the handholds to extend and remove the I/O Chassis from the enclosure (See figure 13)

Remove the midplane brick assembly

•WARNING: At least two people are required to safely move the midplane to avoid personal injury

•Pull the plunger pins in each corner and rotate ¼ turn to lock them in position

•Use the handles to extend and remove the midplane assembly from the enclosure (See figure 14)

•Place midplane brick flat on table to allow disassembly