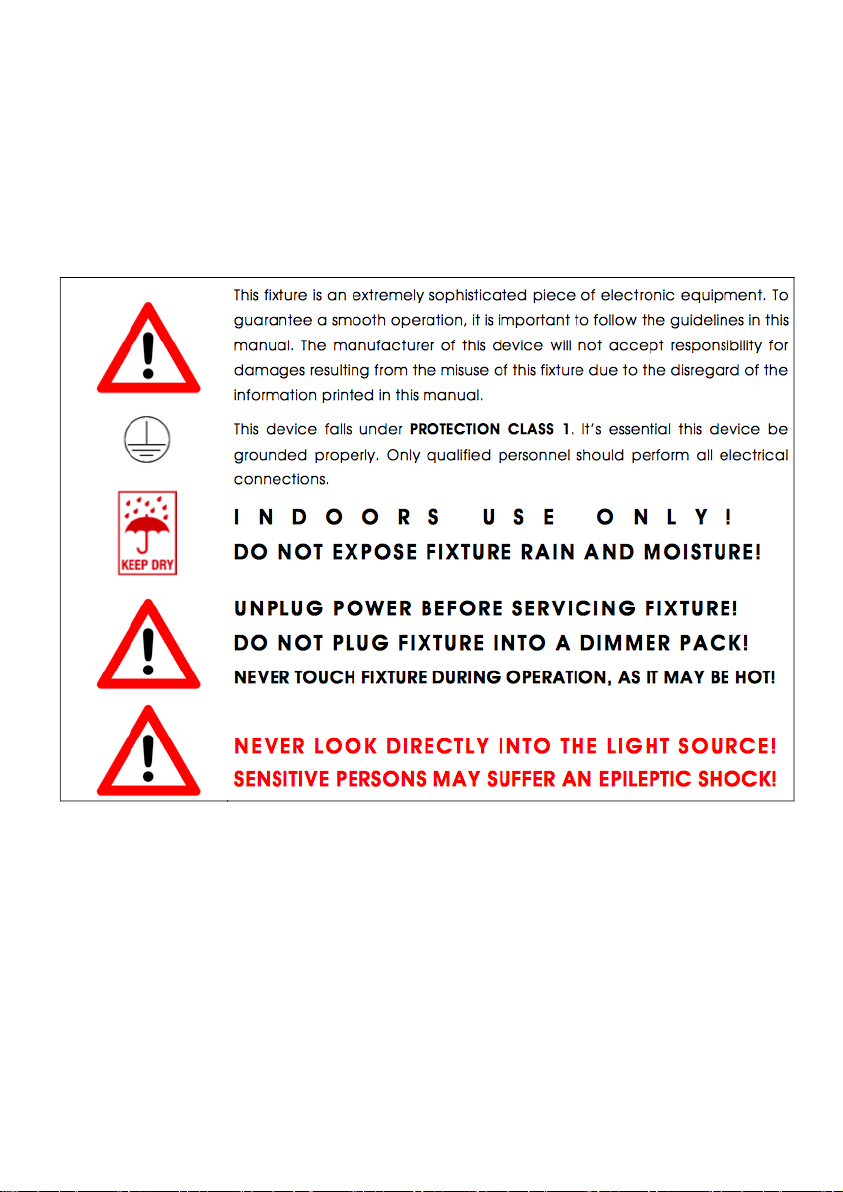

During the initial operation of this fixture, a light smoke or smell may emit

from the interior of the fixture. This is a normal process and is caused by

excess paint in the interior of the casing burning off from the heat

associated with the lamp and will decrease gradually over time.

This fixture is a professional lighting effect designed for INDOOR / DRY

LOCATIONS ONLY on stage, in nightclubs, theatres, etc.

Please make sure there are NO FLAMMABLE MATERIALS close to the

fixture while operating, to prevent any fire hazard.

The fixture must be installed in a location with adequate ventilation, at

least 1.5 feet (.5m) from adjacent surfaces. Be sure no air ventilation slots

are blocked.

DO NOT attempt installation and/or operation without knowledge how to

do so.

DO NOT permit operation by persons who are not qualified to operate this

type of fixture. Most damages are the result of operations by

nonprofessionals. Consistent operational breaks may ensure the fixture

will function properly for many years to come.

DO NOT shake fixture, avoid brute force when installing and/or operating

fixture.

Always install the fixture with an appropriate safety cable. When installing

the fixture in a suspended environment, always use mounting hardware

that is no less than M10 x 25 mm, also be sure the hardware is insert in

the pre-arranged screw holes in the bracket of the fixture.

Use the original packaging and materials to transport the fixture in for

service.

DO NOT TOUCH the housing bare-hand during its operation. Turn OFF

the power and allow approximately 15 minutes for the fixture to cool down

before replacing or serving.