Rivtec RNT 120 User manual

1

INTENDED USE

GLOSSARY OF TERMS AND SYMBOLS

SAFETY PRECAUTIONS

SAFETY INSTRUCTIONS

FEATURES

SPECIFICATIONS

DIMENSIONS

MAIN PARTS

PARTS LIST

OPERATION INSTRUCTIONS

MAINTENANCE

TROUBLESHOOTING

DISPOSAL

EC DECLARATION OF CONFORMITY

PAGE INDEX

1. INTENDED USE

3. SAFETY PRECAUTIONS

2. GLOSSARY OF TERMS AND SYMBOLS

1

1

1-3

3

4

5

6

7

8-9

10-14

15-18

19-21

21

22

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

This pneumatic-hydraulic rivet nut tool is designed to be driven by the appropriate compressed air pressure for secure

fastening a rivet nut containing enough female threads in the thin base metals and pipes with weldless, tapping-free and

one-side work in order to fasten with a bolt or a screw. The applications are widely used in the production and repairs of

aircraft, automobiles & vehicles, boats, construction, electric/electronic appliances, even the DIY work, etc.

This pneumatic-hydraulic rivet nut tool is designed and produced primarily for the professional users, the non-professional

users must read the operation manual thoroughly, and consult the manufacturer, authorized local agent or distributor for

real understanding. A half hour long hands-on training session with qualified personnel is essential and strongly

recommended before using this tool.

1.

2.

For multiple hazards, read and understand the safety instructions before installing, operating, repairing, maintaining,

changing accessories, or working near the assembly power tool. Failure to do so can result in serious bodily injury.

Only qualified and trained operators should install, adjust or use the assembly power tool.

Do not modify this assembly power tool. Modifications can reduce the effectiveness of safety measures and increase the

risks to the operator.

Do not discard the safety instructions; give them to the operator.

Do not use the assembly power tool if it has been damaged.

Tools shall be inspected periodically to verify that the ratings and markings required, by this part of ISO 11148 are legibly

marked on the tool, and that listed in this manual. The employer/user shall contact the manufacturer to obtain replacement

marking labels when necessary.

1.

2.

3.

4.

5.

6.

: READ MANUAL carefully prior to using

this tool.

: EYE PROTECTION IS REQUIRED when

using this tool.

: HEARING PROTECTION IS REQUIRED

when using this tool.

: HAND PROTECTION IS REQUIRED

when using this tool.

WARNING

3.1 SAFETY PRECAUTIONS

2

Disconnect the assembly power tool from the energy source when changing inserted tools or accessories.

Be aware that failure of the work piece or accessories, or even of the inserted tool itself can generate high-velocity projectiles.

Always wear impact-resistant eye protection during operation of the tool. The grade of protection required should be

assessed for each use.

The risks to others should also be assessed at this time.

Ensure that the work piece is securely fixed.

Check that the means of protection from ejection of fastener and/or stem is in place and is operative.

There is possibly forcible ejection of installed nuts from the front of the assembly power tool.

1.

2.

3.

4.

5.

6.

7.

3.2 PROJECTILE HAZARDS

Use of the tool can expose the operator's hands to hazards, including crushing, impacts, cuts and abrasions and heat.

Wear suitable gloves to protect hands.

Operators and maintenance personnel shall be physically able to handle the bulk, weight and power of the tool.

Hold the tool correctly; be ready to counteract normal or sudden movements and have both hands available.

Maintain a balanced body position and secure footing.

Release the start-and-stop device in the case of an interruption of the energy supply.

Use only oils and lubricants recommended by the manufacturer.

Avoid unsuitable postures, as it is likely for these positions not to allow counteracting of normal or unexpected movement

of the tool.

If the assembly power tool is fixed to a suspension device, make sure that the fixation is secure.

Beware of the risk of crushing or pinching if nose equipment is not fitted.

1.

2.

3.

4.

5.

6.

7.

8.

9.

3.3 OPERATING HAZARDS

When using an assembly power tool, the operator can experience discomfort in the hands, arms, shoulders, neck or other

parts of the body.

While using an assembly power tool, the operator should adopt a comfortable posture whilst maintaining a secure footing

and avoiding awkward or off-balance postures. The operator should change posture during extended tasks; this can help

avoid discomfort and fatigue.

If the operator experiences symptoms such as persistent or recurring discomfort, pain, throbbing, aching, tingling,

numbness, burning sensations or stiffness, these warning signs should not be ignored. The operator should tell the

employer and consult a qualified health professional.

1.

2.

3.

3.4 REPETITIVE MOTIONS HAZARDS

Disconnect the assembly power tool from the energy supply before changing the inserted tool or accessory.

Use only sizes and types of accessories and consumables that are recommended by the manufacturer of assembly power

tools; do not use other types or sizes of accessories or consumables.

1.

2.

3.5 ACCESSORY HAZARDS

Exposure to high noise levels can cause permanent, disabling hearing loss and other problems, such as tinnitus (ringing,

buzzing, whistling or humming in the ears). Therefore, risk assessment and the implementation of appropriate controls for

these hazards are essential.

Appropriate controls to reduce the risk may include actions such as damping materials to prevent work piece from “ringing”.

Use hearing protection in accordance with employer's instructions and as required by occupational health and safety regulations.

Operate and maintain the assembly power tool for non-threaded mechanical fasteners as recommended in the instruction

handbook, to prevent an unnecessary increase in the noise level.

Select, maintain and replace the consumable/inserted tool as recommended in the instruction handbook, to prevent an

unnecessary increase in noise.

If the power tool has a silencer, always ensure that it is in place and in good working order when the power tool is being

operated.

1.

2.

3.

4.

5.

6.

3.7 NOISE HAZARDS

Slips, trips and falls are major causes of workplace injury. Be aware of slippery surfaces caused by use of the tool and also

of trip hazards caused by the air line or hydraulic hose.

Proceed with care in unfamiliar surroundings. There can be hidden hazards, such as electricity or other utility lines.

The assembly power tool is not intended for use in potentially explosive atmospheres and is not insulated against contact

with electric power.

Ensure that there are no electrical cables, gas pipes, etc., which can cause a hazard if damaged by use of the tool.

1.

2.

3.

4.

3.6 WORKPLACE HAZARDS

3

4. SAFETY INSTRUCTIONS

Exposure to vibration can cause disabling damage to the nerves and blood supply of the hands and arms.

Wear warm clothing when working in cold conditions and keep your hands warm and dry.

If you experience numbness, tingling, pain or whitening of the skin in your fingers or hands, stop using the assembly power

tool, tell your employer and consult a physician.

Support the weight of the tool in a stand, tensioner or balancer, because a lighter grip can then be used to support the tool.

1.

2.

3.

4.

3.8 VIBRATION HAZARDS

Air under pressure can cause severe injury:

(1) Always shut off air supply, drain hose of air pressure and disconnect tool from air supply when not in use, before

changing accessories or when making repairs;

(2) Never direct air at yourself or anyone else.

Whipping hoses can cause severe injury. Always check for damaged or loose hoses and fittings.

Cold air shall be directed away from hands.

Whenever universal twist couplings (claw couplings) are used, lock pins shall be installed and Whip Check Safety Cables

shall be used to safeguard against possible hose-to-tool or hose-to-hose connection failure.

Do not exceed the maximum air pressure stated on the tool.

Never carry an air tool by the hose.

The limitations of environmental conditions on Tool are the temperature 0-40˚C (32-104˚F), and Tool can

not be used in the water.

Tool weight over 2.0 kg or 4.4 lb is suggested to be supported by two hands, one hand to hold handle grip

and the other hand to support the bottom of Tool, whilst lifting or operating Tool.

1.

2.

3.

4.

5.

6.

7.

8.

The tool must be checked and maintained in a safe working condition at all times.

Do not use the tool outside the intent of design and use.

Do not dismantle the tool without prior reference to this manual.

Any modification to the tool and tool parts shall be prohibited.

Always use original spare parts to ensure safe operation and satisfactory performance.

Be sure to disconnect the tool from air supply before attempting to adjust, change nosepiece or dismantle tool’s parts.

For safety work, the operator and other persons in the vicinity are always required to wear the safety goggles to protect

against spent mandrel ejection.

Be sure to adopt a firm footing or stable position before and during operating the tool.

Do not point the tool towards any person(s) or operator.

Do not operate the tool without firmly installing and locking the threaded mandrel (1), nosepiece lock nut (4), stroke

adjuster lock nut (6), front head (7), oil cylinder end cap (25), noise silencer lock nut (34), valve end cap (51), air cylinder

end cap (59), air inlet end cap (61), and speed-adjust swivel air fitting (62).

Be sure to properly adjust the Stroke.

The Operating Air Pressure shall not exceed 7.0 bar or 100 psi.

Excessive priming of hydraulic oil in the tool should be avoided.

After setting each rivet nut, turn the rotation knob (26) counterclockwise to unscrew the threaded mandrel (1) from the

fastened rivet nut, so that the same size rivet nut can be installed onto the threaded mandrel (1) by turning knob clockwise,

and then to continue the next fastening work.

Take care to ensure the deformed Rivet Nut is not to create any hazards.

Ensure that noise silencer (33) and vent holes of noise silencer lock nut (34) do not become blocked or covered, and that

air hose is always in good condition.

Always keep the tool and grip (64) dry and clean for the best possible grip and operation.

Take care to avoid entanglement of loose clothes, ties, long hair, cleaning rags, etc. In the moving parts of the tool.

When carrying the tool from place to place, always keep hands away from the trigger (35, 35L) to avoid inadvertent start up.

Take care to use the tool. Do not drop the tool. Do not use the tool as a hammer or other uses that will damage and wear

the tool.

The tool should be examined at regular intervals for function and damage. Any question regarding the correct operation of

tool and operator safety should consult the manufacturer, authorized local agent or distributor.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

3.9 SAFETY INSTRUCTIONS FOR PNEUMATIC-HYDRAULIC RIVET NUT POWER TOOLS

4

6. SPECIFICATIONS

Traction Force: 21,000 N at 6.2 bar or or 4,720 lbf at 90 psi compressed air pressure, and 23,500 N at 7.0 bar or 5,280 lbf

at 100 psi compressed air pressure.

Stroke: 0 ~ 9 mm or 0 ~ 0.36˝.

Working Compressed Air Pressure: 5.5 ~ 7.0 bar or 80 ~ 100 psi.

Air Consumption: Approx. 3.10 liter per rivet nut or 0.11 cuft per rivet nut.

Hydraulic Oil, ISO VG-46 or VG-32: Approx. 40 ml.

Working Temperature: 0 - 40 ˚C or 32 - 104 ˚F.

Noise Level:

Sound pressure level, LPA: 72.5 dB(A)

Uncertainty : KPA = 3.0 dB

Sound power level, LWA: 83.5 dB(A)

Uncertainty : KWA = 3.0 dB

Vibration:

Hand-arm vibration value: Less than 2.5 m/s²

Uncertainty : K = 1.5 m/s²

Air Inlet: 1/4˝ PT or 1/4˝ NPT or other specified thread.

Hose Size: Inner diameter 10 mm or 3/8˝.

Net Weight: Approx. 2.24 kg / 4.93 lb.

Standard Parts: 6 or 7 Threaded Mandrels (M4, M5, M6, M8, M10, M12 or 8-32, 10-24, 10-32, 1/4-20, 5/16-18, 3/8-16,

1/2-13) (1), 6 Nosepieces (M4, M5, M6, M8, M10, M12 or #8, #10, 1/4, 5/16, 3/8, 1/2) (3), Speed-Adjust Swivel Air Fitting

(62), Oil Bottle (63, without Oil), Service Wrench (65), Small Rule (66), Fixing-Hole Pin (67), Pin Retainer (68), Oil Injector

(69, without Oil), Parts Plastic Box (70).

Additional Standard Parts: Threaded Sockets (M4, M5, M6, M8 or 8-32, 10-24, 10-32, 1/4-20, 5/16-18) (2).

RIVETING CAPACITY:

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

Aluminum Steel Stainless

Steel/Inox

Thread Size

Rivet Nut/Bolt

Material

Remark: Work piece hole diameter should be 0.1 mm or 0.004˝ larger than rivet nut outer diameter.

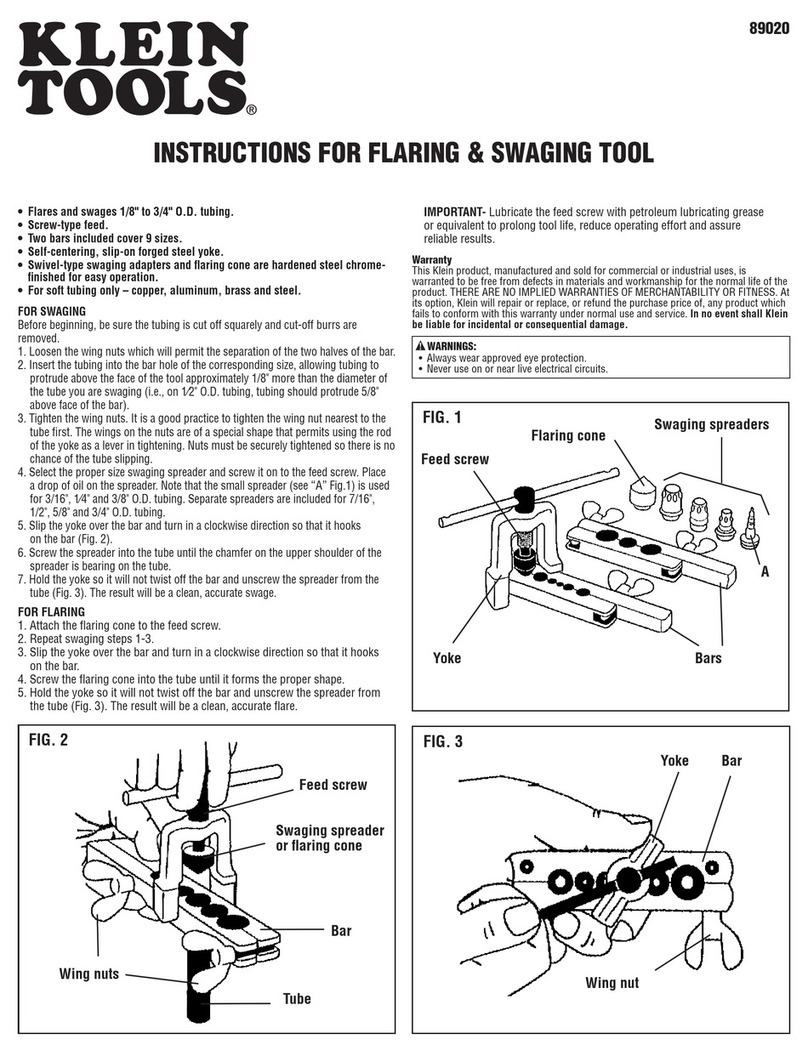

5. FEATURES

This pneumatic-hydraulic rivet nut tool features powerful traction force 21,000 N at 6.2 bar or 4,720 lbf at 90 psi, and

23,500 N at 7.0 bar or 5,280 lbf at 100 psi, and equips with interchangeable 6 or 7 threaded mandrels and 6 nosepieces

for setting M4 ~ M12 Rivet Nut or 8-32 ~ 1/2 Rivet Nut in all materials (aluminum, copper, steel and stainless steel), also

can set M4 ~ M8 Rivet Bolt (Stud) or 8-32 ~ 5/16 Rivet Bolt (Stud) in all materials with optional threaded sockets. The

optional M4 ~ M8 or 8-32 ~ 5/16 threaded sockets are available on request.

Unique Adjustable Fastening Speed Design can control slow or fast fastening speed. Slow speed is ideal for setting

rivet nut in the repaired painted car body or thin work piece, and other same application purpose.

Special Hand Spin-Pull-Hand Spin Design to screw rivet nut onto or unscrew fastened rivet nut from threaded mandrel

by hand rotation that can prevent the repaired painted car body or thin work piece from being scratched. Straight Pulling

can ensure nice fastening work.

Adjustable Stroke Design to prevent rivet nut from insufficient fastening or rivet nut from being stuck with threaded mandrel.

Innovative Fix-Hole Design to offer great solution to solve the headache problem of rivet nut stuck with threaded mandrel

and great assistance of exchanging threaded mandrels.

Shock-Free Design to minimize hand fatigue.

Innovative Noise Silencer Design for working pleasure.

Smart Twin Air Inlets to meet individual operating hobby, such as the right-handed operators or left-handed operators.

Oil Cylinder Body are made of super strength forged aluminum alloy and Air Cylinder Body are made of high strength

aluminum alloy, Inner walls all have wear-resistant mirror finish for durability.

Oil Piston Rod and Air Piston Rod all have hard chrome plating and wear-resistant mirror finish for speedy motion.

High grade Steel Alloy Key Parts

(threaded mandrel, etc.) with advanced heat treatment for strength and durability.

Valuable

Hard Anodized finish on Forged Aluminum

Hydraulic Oil Cylinder Body and Powder Coating finish on Air

Cylinder Body for nice looking and better scratch-resistant.

PAHs-Free (non-toxic to hand skin) Soft Plastic Hand Grip for comfortable and safe operation.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

M4 x 0.7 or 8-32 Rivet Nut / Rivet Bolt (Stud)

M5 x 0.8 or 10-24, 10-32 Rivet Nut / Rivet Bolt (Stud)

M6 x 1.0 or 1/4-20 Rivet Nut / Rivet Bolt (Stud)

M8 x 1.25 or 5/16-18 Rivet Nut / Rivet Bolt (Stud)

M10 x 1.5 or 3/8-16 Rivet Nut

M12 x 1.75 or 1/2-13 Rivet Nut

5

7. DIMENSIONS

39.0

UNIT: mm

240.3

303.4

Ø91.0

121.4

115.2

8. MAIN PARTS

2

Threaded

Socket

Stroke

Indicator

Rivet Bolt

Rivet Nut

7

Front Head

Fixing Hole

6

Stroke

Adjuster

Lock Nut

37

Trigger Lever

34

Noise Silencer

Lock Nut

43AY

Valve Assembly

59

Air Cylinder End Cap

30

Air Cylinder

35 Trigger

Air Inlet

4

Nosepiece

Lock Nut

24

Hanging Bracket

62

Speed-Adjust

Swivel Air Fitting

62

Speed-Adjust

Swivel Air Fitting

15

Oil Cylinder

64

Grip

26

Rotation Knob

26

Rotation Knob

1

Threaded

Mandrel

3

Nosepiece

5

Stroke

Adjuster

35L

Trigger,

Long Type

6

9. PARTS LIST

63

65 66 67 68

7069

1 2 3

1

3

4

5

6

7

8

9

10

10A

11 12 13 13

14

27

29

28

15

64

18

16

17

24

19

25

20

26

21

22

23

30

32

32A

42

35

40

38

36

41

34 33

31

60

61

37

39

43

44

45

29

46

47

48

49

50

51

52

53

55

58

59

54

57

56

62

35L

40

38 35AY

(35~41)

35LAY

(35L~41)

43AY

(29, 42~51)

55AY

(52~57)

18AY(18~20)

15.5

mm

3/5˝

1

9

8

11 12

18

15

7

No.

1-M4

1-M5

1-M6

1-M8

1-M10

1-M12

1-832

1-1024

1-1032

1-1420

1-51618

1-3816

1-1213

2-M4

2-M5

2-M6

2-M8

2-832

2-1024

2-1032

2-1420

2-51618

3-M4

3-M5

3-M6

3-M8

3-M10

3-M12

3-8

3-10

3-14

3-516

3-38

3-12

4

5

6

7

8

9

10A

10

11

12

13

14

15

16

17

18

19

20

18AY

21

22

ANS120-01-M4

ANS120-01-M5

ANS120-01-M6

ANS120-01-M8

ANS120-01-M10

ANS120-01-M12

ANS120-01-832

ANS120-01-1024

ANS120-01-1032

ANS120-01-1420

ANS120-01-51618

ANS120-01-3816

ANS120-01-1213

ANS120-02-M4

ANS120-02-M5

ANS120-02-M6

ANS120-02-M8

ANS120-02-832

ANS120-02-1024

ANS120-02-1032

ANS120-02-1420

ANS120-02-51618

ANS120-03-M4

ANS120-03-M5

ANS120-03-M6

ANS120-03-M8

ANS120-03-M10

ANS120-03-M12

ANS120-03-8

ANS120-03-10

ANS120-03-14

ANS120-03-516

ANS120-03-38

ANS120-03-12

ANS120-04

ANS120-05

ANS120-06

ANS120-07

ANS120-08

ANS120-09

ANS120-10A

ANS120-10

ANS120-11

ANS120-12

ANS120-13

ANS120-14

ANS120-15

ANS120-16

ANS120-17

ANS120-18

ANS120-19

ANS120-20

ANS120-18AY

ANS120-21

ANS120-22

23

24

25

26

27

28

29

30

31

32

32A

33

34

35

35L

36

37

38

39

40

41

35AY

35LAY

42

43

44

45

29

46

47

48

49

50

51

43AY

52

53

54

55

56

57

55AY

58

59

60

61

62

63

64

65

66

67

68

69

70

ANS120-23

ANS120-24

ANS120-25

ANS120-26

ANS120-27

ANS120-28

ANS120-29

ANS120-30

ANS120-31

ANS120-32

ANS120-32A

ANS120-33

ANS120-34

ANS120-35

ANS120-35L

ANS120-36

ANS120-37

ANS120-38

ANS120-39

ANS120-40

ANS120-41

ANS120-35AY

ANS120-35LAY

ANS120-42

ANS120-43

ANS120-44

ANS120-45

ANS120-29

ANS120-46

ANS120-47

ANS120-48

ANS120-49

ANS120-50

ANS120-51

ANS120-43AY

ANS120-52

ANS120-53

ANS120-54

ANS120-55

ANS120-56

ANS120-57

ANS120-55AY

ANS120-58

ANS120-59

ANS120-60

ANS120-61

ANS120-62

ANS120-63

ANS120-64

ANS120-65

ANS120-66

ANS120-67

ANS120-68

ANS120-69

ANS120-70

Hanging Bracket O-ring

Hanging Bracket

Oil Cylinder End Cap

Rotation Knob

Oil Cylinder Upper O-Ring

Oil Cylinder Back-Up Ring

Oil Cylinder Lower O-ring

Air Cylinder

Lock Screw

Oil Cylinder Lock Nut

Lock Nut O-Ring

Noise Silencer

Noise Silencer Lock Nut

Trigger

Trigger, Long Type (Option)

Trigger Link

Trigger Lever

Upper Link Pin

Lower Link Pin

Trigger Pin

Lever Pin

Trigger Assembly (35~41)

Trigger Assembly (35L~41), Long Type (Option)

Valve Pusher Upper O-ring

Valve Pusher

Valve Pusher Lower O-ring

Valve Pusher Spring

Valve Sleeve O-Ring

Valve Sleeve

Valve Ball O-ring

Valve Ball

Valve Spring

Valve End Cap O-ring

Valve End Cap

Valve Assembly (29, 42~51)

Buffer Ring

Air Piston Ring

Air Piston Rod

Air Piston

Lock Washer

Air Piston Lock Nut, Long Type

Air Piston Assembly (52~57)

Air Cylinder End Cap O-ring

Air Cylinder End Cap

Air Inlet End Cap O-ring

Air Inlet End Cap

Speed-Adjust Swivel Air Fitting

Oil Bottle (without Oil)

Grip

Service Wrench

Small Rule

Fixing-Hole Pin

Pin Retainer

Hydraulic Oil Injector (without Oil)

Parts Plastic Box

Threaded Mandrel, M4x0.7

Threaded Mandrel, M5x0.8

Threaded Mandrel, M6x1.0

Threaded Mandrel, M8x1.25

Threaded Mandrel, M10x1.5

Threaded Mandrel, M12x1.75

Threaded Mandrel, 8-32

Threaded Mandrel, 10-24

Threaded Mandrel, 10-32

Threaded Mandrel, 1/4-20

Threaded Mandrel, 5/16-18

Threaded Mandrel, 3/8-16

Threaded Mandrel, 1/2-13

Threaded Socket, M4x0.7 (Option)

Threaded Socket, M5x0.8 (Option)

Threaded Socket, M6x1.0 (Option)

Threaded Socket, M8x1.25 (Option)

Threaded Socket, 8-32 (Option)

Threaded Socket, 10-24 (Option)

Threaded Socket, 10-32 (Option)

Threaded Socket, 1/4-20 (Option)

Threaded Socket, 5/16-18 (Option)

Nosepiece, for M4

Nosepiece, for M5

Nosepiece, for M6

Nosepiece, for M8

Nosepiece, for M10

Nosepiece, for M12

Nosepiece, for #8

Nosepiece, for #10

Nosepiece, for 1/4

Nosepiece, for 5/16

Nosepiece, for 3/8

Nosepiece, for 1/2

Nosepiece Lock Nut

Stroke Adjuster

Stroke Adjuster Lock Nut

Front Head

Collet Case

Mandrel Seat

Snap Ring Washer

Snap Ring

Collet Case Lock Nut

Lock Nut

Oil Cylinder O-ring

Oil Cylinder Back-up Ring

Oil Cylinder

Sealing Washer

Oil Screw Plug

Oil Piston

Oil Piston O-ring

Oil Piston Back-up Ring

Oil Piston Assembly (18~20)

Large Return Spring

Small Return Spring

PART No. PART NAME No. PART No. PART NAME

8

1) Means wearing parts or possible missing parts.

2) Part No. 35 Trigger is the Standard Part, Part No. 35L Trigger Long Type is the Optional Part for choice.

3) Order Example: ANS120-01-M6 Threaded Mandrel M6x1.0, 10 pcs.

4) Part No. 32 Oil Cylinder Lock Nut needs to replace a new one after repeated fastening 3 ~ 4 times.

5) Part No. 32A Lock Nut O-Ring needs to replace a new one when dismantling Part No. 32 Oil Cylinder Lock Nut.

REMARKS:

Air Compressor

Air

Pressure

Regulator

Main Air

Supply Line

3 Meters or 10 Feet Maximum

Air

Filter

Air

Lubricator

Air

Hose

Tool

NOTE:

Drain

Daily

COMPRESSED AIR SUPPLY SYSTEM

10. OPERATION INSTRUCTIONS

The tool is well assembled and tested before delivery; however, the necessary setting and testing are still strongly suggested

before operating tool. Carefully read this OPERATION INSTRUCTIONS 10.2 - 10.9 to check the setting of tool, follow the 10.8

OPERATION PROCEDURE to do the pilot test before operating tool.

The compressed air pressure should be in the suggested working range; tool’s working threaded mandrel size, nosepiece

size, rivet nut size and work piece’s hole diameter must be well matched, so that the pilot test can verify the fastening work

is firmed or not.

1.

2.

10.1 SETTING AND TESTING

This pneumatic-hydraulic rivet nut tool is operated with compressed air at an optimum air pressure of 6.5 bar or 95 psi.

This pneumatic-hydraulic rivet nut tool is recommended to connect with COMPRESSED AIR SUPPLY SYSTEM including

air compressor, main air supply line, air preparation unit (air filter, air pressure regulator with gauge, air lubricator) and air

hose. These should be fitted within 3 meters or 10 feet from air pressure regulator to the tool to ensure maximum tool life

and minimum tool maintenance.

The air pressure regulator is used to adjust the operating air pressure not to exceed the maximum operating air pressure

7.0 bar or 100 psi.

The air hose should resist a minimum 150% of maximum operating air pressure (7.0 bar or 100 psi) produced in the

COMPRESSED AIR SUPPLY SYSTEM, that is to resist the highest air pressure 10.5 bar or 150 psi. The air hose should be

oil resistant, and have an abrasion resistant exterior. The air hose must have a minimum inner diameter of 10 mm or 3/8” .

Be sure to expel the accumulated dirt and water from air pipeline before connecting air hose to the tool.

1.

2.

3.

4.

10.2 COMPRESSED AIR SUPPLY SYSTEM

1. Disconnect the tool from the compressed air supply

system. Use service wrench (65) to loosen nosepiece

lock nut (4) by turning counter-clockwise.

10.3 SELECT AND EXCHANGE THREADED MANDREL AND NOSEPIECE

1. 65

4

2.

4

3

5

1

2

2. Unscrew nosepiece (3) and nosepiece lock nut (4)

together from stroke adjuster (5) , then dismount

nosepiece lock nut (4) from nosepiece (3) .

1

2

9

Check the thread size of bolt to be fastened and thickness of work piece to determine the thread size, grip range,

material, and type of rivet nut, then drill or punch the correct size of hole in the work piece for fastening rivet nut.

The working size of threaded mandrel and nosepiece should be same as the thread size of rivet nut.

[ PRECAUTION ]

4.

Use service wrench (65) to loosen and disassemble

threaded mandrel (1) from mandrel seat (9) by turning

clockwise (NOTE: Mandrel seat (9) has left-handed

internal threads.). Now the tool is ready for changing

another size of threaded mandrel (1) and nosepiece (3).

5. Use service wrench (65) to assemble and fasten the

new working threaded mandrel (1) into mandrel seat

(9) firmly by turning counter-clockwise (NOTE: Mandrel

seat (9) has left-handed internal threads.).

6. Assemble nosepiece lock nut (4) onto the working

nosepiece (3).

7. Screw nosepiece (3) into stroke adjuster (5) by turning

clockwise.

8. Finally, take off pin retainer (68) and pull fixing-hole pin

(67) from the fixing-holes.

Now the new working threaded mandrel (1) and

nosepiece (3) are ready for application.

7.

35

1

5

67

68

1

1

2

2

3.

8.

67

68

4.

1

65

5.

1

65

6.

3

4

3. Slowly rotate threaded mandrel (1) to align 2

fixing-holes of stroke adjuster (5) with inside long

fixing-hole of mandrel seat (9) , then

insert fixing-hole

pin (67) through the fixing-holes

and put pin retainer (68)

onto fixing-hole pin (67) end . The free rotation of

mandrel seat (9) is locked.

1

2

nut has its own grip range, the maximum grip and minimum grip.

grip of rivet nut for safe and firm installation.

If the work piece thickness is larger than the maximum grip of rivet nut, the rivet nut threads or threaded mandrel

might be damaged, and the rivet nut also cannot be well gripped in the work piece.

the work piece.

stroke distance cannot fasten rivet nut firmly in the work piece.

10.4 ADJUST THE PROPER STROKE DISTANCE

[ WARNING ]

10

1.Use a wrench (30 mm) to loosen Stroke Adjuster Lock Nut (6) by turning counter-clockwise . Connect the Tool to the

compressed air supply system. Depress trigger (35/35L) and hold it , then rotate stroke adjuster (5) clockwise all the way

until cannot move it , now the stroke is 0 (zero).

2.Still hold Trigger (35/35L), then rotate stroke adjuster (5) counter-clockwise to increase and get the proper stroke distance .

NOTE: Rotate 1 circle of stroke adjuster (5) = 1 mm or 0.04” stroke. For example, rotate counter-clockwise 5 circles to

increase 5 mm or 0.20” stroke.

3.Release Trigger (35/35L) and use a wrench (30 mm) to fasten stroke adjuster lock nut (6) by turning clockwise . Now

the stroke adjustment is completed.

4.Also can follow the above steps by depressing Trigger (35/35L) to adjust the stroke from the current stroke distance simply

by rotating stroke adjuster (5) clockwise to decrease stroke or counter-clockwise to increase stroke .

NOTE: 1 circle = 1 mm or 0.04” stroke.

1.

35

655

1

2

3

4

5

6

SMALL RULE

HOLE IN

WORK PIECE

WORK PIECE

THICKNESS 4 mm

4 mm

II

66

2.

2

1

34

4

56

3

NOTE

The small rule (66) is specially designed

to measure the work piece thickness.

1. Disconnect the tool from the compressed air supply

system. Use service wrench (65) to loosen nosepiece

lock nut (4) by turning counter-clockwise.

2. Rotate nosepiece (3) to adjust the protruding length (L)

of threaded mandrel (1) to be same as the rivet nut

height (H), L = H.

3. Finally use service wrench (65) to fasten nosepiece

lock nut (4) by turning clockwise.

4. After adjusting the protruding length (L) of threaded

mandrel (1), the screwed rivet nut should be flush with

the threaded mandrel (1).

10.5 ADJUST THE PROTRUDING LENGTH (L) OF THREADED MANDREL

2.

L

H

L = H

31

4

65

1.

3.

4

65

4.

1

Flush With

Screwed

Rivet Nut

11

for setting Rivet Nut in the repaired painted car body or thin work piece, and other same application purpose.

The Pilot Test is always recommended before setting different sizes of rivet nut for perfect fastening work.

1. Install the Speed-Adjust Swivel Air Fitting (62) to the air inlet of tool, connect the tool to the

compressed air supply system.

2. The fastening speed is adjusted to the “slow” speed in the tool assembly for nice

installation of rivet nut in the repaired painted car body or thin work piece.

3.

User can follow the

“

-

” and “+” marks to decrease or increase speed for suitable fastening speed.

10.6 ADJUST FASTENING SPEED

The hanging bracket (24) is designed for hanging the tool to the suspension device of

assembly line to decrease the physical strain placed on the operator by the weight of tool.

10.7 SUSPENSION DEVICE

Slow

-

+ Fast

62

[ PRECAUTION ]

3. Insert the screwed rivet nut into the prepared hole of work piece to touch work piece . Fully depress the trigger

(35/35L) to drive threaded mandrel (1) backward to deform rivet nut a bulge against the back of work piece to fasten

rivet nut in the work piece .

4. Release the trigger (35/35L) . Turn rotation knob (26)

counter-clockwise to unscrew threaded mandrel (1)

from the gripped rivet nut completely .

5. The rivet nut is therefore gripped in the work piece

firmly and the rivet nut thread is built up securely.

Complete the fastening work with a bolt or a screw to

the gripped rivet nut.

1. Drill or punch a hole on work piece, hole diameter

should be 0.1 mm or 0.004” larger than rivet nut

diameter .

2. Connect the tool to the compressed air supply system.

Screw rivet nut onto threaded mandrel (1) by turning

rotation knob (26) clockwise . It is strongly

suggested the rivet nut to touch the nosepiece (3)

slightly, not heavily. The screwed rivet nut should be

flush with the top of threaded mandrel (1) .

Before operating this tool, it is strongly requested to follow the above 10.3 to install the correct size of threaded mandrel

and working nosepiece, the above 10.4 to adjust the proper stroke distance, the above 10.5 to adjust the protruding

length (L) of threaded mandrel, and 10.6 to adjust the suitable fastening speed to ensure the perfect installation work.

10.8 OPERATING PROCEDURE

WORK PIECE

= + 0.1mm

112

2

1.

5.

BOLT

GRIPPED RIVET NUT WORK PIECE

2. 3

26

RIVET NUT

1

1

2

4.

35

1

GRIPPED RIVET NUT

+ WORK PIECE

1

2

3

SCREWED

RIVET NUT

PREPARED

HOLE

GRIPPED

RIVET NUT

BULGE

WORK PIECE

THREADED

MANDREL

BACKWARDS

WORK PIECE

13

3

WORK

PIECE

SCREWED RIVET NUT

3.

35

1

2

1

21

2

1

2

3

1

2

3

[ PRECAUTION ]

12

NOTES

10.9 FASTEN THE SAME SIZE OF RIVET NUT

If the next gripping rivet nut is same size as the previous one, just repeat the above 10.8 steps. Don’t Need Any

Adjustment!

NOTE

The PILOT TEST is always recommended before setting different sizes of rivet nut for perfect fastening work and

protecting this precious Tool and Rivet Nut Thread from damage.

Pour a few drops of the light lubricating oil to the threads of threaded mandrel (1) and nosepiece (3). If the tool is in

continuous use, the thread of threaded mandrel (1) should be lubricated every two or three hours.

If no air lubricator is fitted on the compressed air supply system, it is suggested to pour a few drops of the light lubricating oil

into the air inlet fitting of tool before daily operation. If the tool is in continuous use, the air inlet fitting should be lubricated

every two or three hours.

Check for air leaks. If damaged, replace the air hoses and air couplings.

If there is no air filter on the compressed air supply system, bleed the air line to clear the accumulated dirt or water before

connecting the air hose to the tool. If there is an air filter, drain it.

Carefully check and firmly tighten the threaded mandrel (1), nosepiece lock nut (4), stroke adjuster lock nut (6), oil cylinder

end cap (25), noise silencer lock nut (34), valve end cap (51), air cylinder end cap (59), air inlet end cap (61) and

speed-adjust swivel air fitting (62) before daily operation.

Check to ensure the trigger (35/35L) operation is normal.

1.

2.

3.

4.

5.

6.

11. MAINTENANCE

11.1 DAILY CHECKS

Check the thread of threaded mandrel (1). NOTE: If the tool is operated frequently, it is suggested to check and replace the

threaded mandrel (1) daily.

Unscrew the noise silencer lock nut (34), and take out the noise silencer (33) to clean it. See 11.4 for detailed operation.

Check the oil leaks and the air leaks in the compressed air supply system.

1.

2.

3.

11.2 WEEKLY CHECKS

Disconnect the tool from the compressed air supply system.

Unscrew the noise silencer lock nut (34), and take out the noise silencer (33) to clean it. If the

noise silencer (33) is blocked or covered badly, replace it.

Reverse the above step to reassemble these two parts. Ensure that the noise silencer lock nut

(34) is fastened firmly.

1.

2.

3.

11.4 CLEAN AND REPLACE THE NOISE SILENCER

The Twin Air Inlets Design is offered to meet individual operating hobby, such as the right-handed operators or

left-handed operators.

Disconnect the tool from the compressed air supply system.

Use the wrench to unscrew the speed-adjust swivel air fitting (62) and air inlet end cap (61) along with the o-ring (60), and

then install the speed-adjust swivel air fitting (62) to the preferable air inlet.

Fasten the air inlet end cap (61) along with the o-ring (60) to the vacant air inlet firmly.

1.

2.

3.

11.3 EXCHANGE THE AIR INLET FITTING TO THE TWIN AIR INLETS

When the shortage of hydraulic oil causes the decrease of the stroke, the normal stroke can be recovered by filling the

hydraulic oil into the oil refill hole on the side of oil cylinder (15).

11.5 REFILL HYDRAULIC OIL THROUGH THE OIL REFILL HOLE

Always disconnect the tool from the COMPRESSED AIR SUPPLY SYSTEM before maintaining the tool.

[ WARNING ]

Be sure to disconnect the tool from the compressed air supply system before unscrewing the oil screw plug (17).

[ WARNING ]

TWIN AIR INLETS

60 & 61

60 & 61

NOISE SILENCER

33

34

13

Connect the tool to the compressed air supply system, and depress the trigger (35/35L) twice to

move the inner oil piston assembly (18AY) and air piston assembly (55AY).

Disconnect the tool from the compressed air supply system.

Push the piston of the hydraulic oil injector (69) forwards to the end, and then immerse the fitting of

hydraulic oil injector (69) in the new hydraulic oil and slowly pull the piston backwards to suck the

new hydraulic oil around 25 ml into the hydraulic oil injector (69). Make sure that the hydraulic oil

injector (69) contains no air bubbles in the oil.

Carefully unscrew the oil screw plug (17) and remove the sealing washer (16).

Gently rotate to screw the fitting of hydraulic oil injector (69) into the oil refill hole of oil cylinder (15) firmly.

Depress the piston of hydraulic oil injector (69) forwards to inject oil until the piston cannot

move further.

Gently unscrew to remove the fitting of hydraulic oil injector (69) from the oil refill hole of oil cylinder

(15). Wipe away the spilt oil, if any.

Restore the sealing washer (16), and carefully tighten the oil screw plug (17) firmly.

Reconnect the tool to the compressed air supply system, and depress the trigger (35/35L) twice. Then, the normal stroke is

recovered.

1.

2.

3.

4.

5.

6.

7.

8.

9.

Disconnect the tool from the compressed air supply system.

Use a wrench 27 mm to unscrew the air cylinder end cap (59) & o-ring (58), and use a pair of pliers to slowly pull out the air

piston assembly (55AY) in a straight line (Fig. 1). Be careful not to scratch the air piston rod (54) and the inner wall of

air cylinder (30). Drain the dirty hydraulic oil out of the tool through the air cylinder (30).

Clean and grease the inner wall of air cylinder (30) (Fig. 2), also clean and grease the air piston ring (53).

Put the tool upside-down, and use the oil bottle (63) with new hydraulic oil to refill into the oil cylinder (15) through

the air cylinder (30) until oil is flushed with the upper oil cylinder o-ring (29) (Fig. 3). Make sure not to overfill oil,

and rest for a while until the oil stops releasing air bubbles.

Use a pair of pliers to clamp the air piston lock nut (57), and slowly plug the air piston assembly (55AY) in a straight line into

the oil cylinder (15) through the oil cylinder lock nut (32) (Fig. 1). Then, depress the air piston assembly (55AY) 2 ~ 3 times.

Repeat above steps to check again the oil level, and add a little hydraulic oil if necessary, but not to add too much oil. Finally

reassemble the air cylinder end cap (59) & o-ring (58) with a wrench 27 mm.

1.

2.

3.

4.

5.

rings, return springs (21 & 22), also the hydraulic oil should be replaced.

11.7 REPLACE THE OIL CYLINDER, AIR CYLINDER, O-RINGS, BACK-UP RINGS, RETURN SPRINGS

AND HYDRAULIC OIL TOGETHER

Disconnect the tool from the compressed air supply system.

Use a wrench 30 mm to unscrew the stroke adjuster lock nut (6) to separate part no. 3 ~ 6 together from front head (7),

and use a wrench 30 mm to unscrew front head (7) from oil cylinder (15), and then use a wrench 17 mm and a wrench 22

mm to separate collet case (8) from the collet case lock nut (11), now the mandrel seat (9) connected with threaded

mandrel (1) can be dismantled from rotation knob (26). Take out the snap ring washer (10A) and the snap ring (10), and

then pull out the rotation knob (26) from the oil cylinder end cap (25). Use a wrench 17 mm and a wrench 22 mm to

dismantle collet case lock nut (11) and lock nut (12) from oil piston (18) (Fig. 1).

Put the tool upside-down, use a wrench 27 mm to unscrew the air cylinder end cap (59) & o-ring (58) from air cylinder

(30), and use a pair of pliers to slowly pull out the air piston assembly (55AY) in a straight line (See 11.6 Fig. 1). Be careful

not to scratch the air piston rod (54) and the inner wall of air cylinder (30). Drain the dirty hydraulic oil out of the

tool through the air cylinder (30).

Check and replace the worn buffer ring (52), air piston ring (53), and air cylinder end cap o-ring (58). Also check

and replace the worn or scratched air piston rod (54) and the damaged air piston (55). Finally, check and replace

the worn air piston lock nut (57) and lock it firmly.

1.

2.

3.

4.

11.6 REPLACE THE HYDRAULIC OIL ONLY

2.

GREASE

30

55AY

(52~57)

30

54

32

1. 3.

63

Oil

Bottle

30

32

15

17

16

69

14

15

Use a long stem socket wrench 35 mm to unscrew the oil cylinder lock nut (32), and then use a suitable diameter pin

carefully to punch out the lever pin (41) to separate the trigger lever (37) from air cylinder (30). Carefully use a hex wrench

3 mm to unscrew the lock screw (31) behind the trigger lever (37) (See 11.6 Fig.1), and then vertically pull the oil cylinder

(15) out of the air cylinder (30) with care, the lock nut o-ring (32A) is jumped out from the thread of oil cylinder (15). Check

and replace the worn or scratched air cylinder (30) on the inner wall.

Carefully use a wrench 27 mm to dismantle the oil cylinder end cap (25), remove the hanging bracket (24) and hanging

bracket o-ring (23), take out the large & small return springs (21 & 22), and slowly press the threaded end of oil piston (18)

to take out the oil piston assembly (18AY). Pay special attention to dismantle the oil cylinder end cap (25), do not let

the strong force of large & small return springs (21 & 22) jump out to hurt people. Be careful not to scratch the

rod of oil piston (18) and the inner wall of oil cylinder (15) (Fig.2).

Check and replace the worn oil cylinder o-rings (13, 27, 29) and oil cylinder back-up rings (14, 28) in the front part and

lower part of oil cylinder (15), as well as the oil piston o-ring (19) and oil piston back-up ring (20). Check and replace

the worn or scratched oil piston rod (18) and oil cylinder (15) on the inner wall. Also check and replace the weak or

broken large & small return springs (21 & 22). Finally check and replace the worn hanging bracket o-ring (23).

Clean and grease on the inner walls of oil cylinder (15) and air cylinder (30) (Fig. 3), the oil piston o-ring (19) and air piston ring (53).

Reverse above steps to reassemble the oil piston assembly (18AY), large & small return springs (21 & 22), oil cylinder end

cap (25) along with hanging bracket (24) and hanging bracket o-ring (23). Pay special attention to the strong force of

large & small return springs (21 & 22) which might jump out to hurt people.

Reverse above steps to reassemble the oil cylinder (15) and air cylinder (30) together by aligning and using a hex wrench

3 mm to fasten the lock screw (31) behind the trigger lever (37) carefully (See 11.6 Fig.1), put a new lock nut o-ring (32A)

onto the thread of oil cylinder (15) and carefully move it (32A) down to touch the top of air cylinder (30), and then fasten the

oil cylinder lock nut (32) with a long stem socket wrench 35 mm. Finally, reassemble the trigger lever (37) back to the air

cylinder (30) by punching the lever pin (41) into the original pin holes carefully (See 11.7 Fig.1).

Put the tool upside-down, and use the oil bottle (63) with new hydraulic oil to refill into the oil cylinder (15)

through the air cylinder (30) until the oil is flushed with the upper oil cylinder o-ring (29) (See 11.6 Fig. 3). Make

sure not to overfill oil, and rest for a while until the oil stops releasing air bubbles.

Use a pair of pliers to clamp the air piston lock nut (57), and slowly plug the air piston assembly (55AY) in a straight line into

the oil cylinder (15) through the oil cylinder lock nut (32) of air cylinder (30) (See 11.6 Fig. 1), then depress the air piston

assembly (55AY) 2 ~ 3 times. Finally, use a wrench 27 mm to reassemble the air cylinder end cap (59) & o-ring (58).

Reverse above steps to reassemble the collet case lock nut (11) and lock nut (12) to the threaded end of oil piston (18), then

use a ruler to measure distance 15.5 mm or 3/5˝ (Fig. 4) and fasten collet case lock nut (11) and lock nut (12) together. Insert

the rotation knob (26) into the oil cylinder end cap (25) and lock rotation knob (26)

with a snap ring washer (10A) and a snap

ring (10), then

insert the mandrel

seat (9) connected with threaded mandrel (1) into collet case (8) from the rear end, then

screw collet case (8) clockwise all the

way to touch collet case lock nut (11), and fasten these 2 parts (8 & 11) firmly by using

a 17 mm wrench and a 22 mm wrench

(Fig.4). Screw front head (7) into oil cylinder (15) and fasten it firmly by using a 30

mm wrench. Finally screw part no. 3 ~ 6 together back to front head (7) and use a wrench 30 mm to fasten firmly. Now the

reassembly process is completed.

5.

6.

7.

8.

9.

10.

11.

12.

13.

1345

6

78

9

10

10A 11 12

17

16 2425

15

18

26

1.

2.

13 13

17

16

15

14

27

29

28

18

24

19 20 21

22

23 25

GREASE

30

15

3.

15.5

mm

3/5˝

4.

1

9

8

11 12

18

15

16

Disconnect the tool from the compressed air supply system.

Firstly use a suitable diameter pin carefully to punch out the lever pin (41) to separate the trigger lever (37) from air cylinder

(30), and use a suitable diameter pin carefully to punch out the trigger pin (40) to separate trigger (35/35L) from oil cylinder

(15), and then to punch out the lower link pin (39) to separate trigger link (36) from trigger lever (37). Finally, pull out the

trigger (35/35L) connected with trigger link (36) and upper link pin (38) from the upper side of grip (64). Check and replace

any worn parts of the trigger assembly (35AY/35LAY).

Dismantle the valve assembly (43AY) by unscrewing valve end cap (51), and carefully take out valve assembly (43AY) from two

ends. Check and replace any worn parts of the valve assembly (43AY), such as o-rings (42, 44, 47, 50), springs (45, 49), etc.

Reverse above steps, firstly reassemble the valve assembly (43AY), and then to reassemble the trigger assembly

(35AY/35LAY) by pluging the trigger (35/35L) connected with trigger link (36) and upper link pin (38) into the upper side of

grip (64), and punch the trigger pin (40) into the original pin holes of oil cylinder (15) and trigger (35/35L), then carefully

punch the lower link pin (39) into the original pin holes of trigger link (36) and trigger lever (37).

Finally, reassemble the trigger lever (37) back to the air cylinder (30) by punching the lever pin (41) into the original pin holes

of air cylinder (30) and trigger lever (37) carefully. Now the reassembly process is completed.

1.

2.

3.

4.

5.

11.8 DISMANTLE AND REPLACE THE PARTS OF THE TRIGGER ASSEMBLY (35AY/35LAY)

AND THE VALVE ASSEMBLY (43AY)

42

35 38

40

36 64

15

30

37

39

41

43

44

45

29

46

47

48

49

50

51

43AY

(29, 42~51)

35AY

(35~41)

35LAY

(35L~41)

35L

40

38

31

12. TROUBLESHOOTING

POSSIBLE CAUSES: Insufficient stroke distance.

SOLUTION: Increase stroke distance. Turn rotation knob (26) clockwise 1 circle and depress trigger (35, 35L) to check if the

rivet nut is set firmly or not. If not, step by step to turn rotation knob (26) clockwise 1 circle and depress trigger (35, 35L) until the

rivet nut is set firmly. Also can follow the above 10.4 instruction to re-adjust and increase the stroke.

12.1 MALFUNCTION:

The rivet nut is not set firmly at the first fastening operation.

POSSIBLE CAUSES: Too long stroke distance.

SOLUTION: Decrease stroke distance. If rivet nut is stuck with threaded mandrel, follow the below 12.3 and 12.4 instructions to

unscrew the stuck rivet nut and replace a new rivet nut. If the threaded mandrel is damaged, follow the above 10.3 instruction to

replace a new threaded mandrel. Then follow the above 10.4 instruction to re-adjust and decrease the stroke.

12.2 MALFUNCTION:

The rivet nut thread is damaged or threaded mandrel is broken at the first fastening operation.

17

POSSIBLE CAUSES: Poor rivet nut thread or damaged threaded mandrel.

SOLUTION: Unscrew the stuck rivet nut from the threaded mandrel by using the patented Fixing-Hole Design.

Firstly insert the fixing-hole pin (67) into any hole of stroke adjuster (5) and turn the rotation knob (26) to align and let the

fixing-hole pin (67) go through the holes, and then put the pin retainer (68) onto the end of the fixing-hole pin (67) . Now the

free rotation of threaded mandrel (1) is stopped (Fig.1). Use a pair of pliers to clamp the stuck rivet nut , and then turn whole

Tool counter-clockwise to unscrew the threaded mandrel (1) from the stuck rivet nut. (Fig.2). Finally take off pin retainer (68)

and pull fixing-hole pin (67) from the fixing holes.

12.3 MALFUNCTION:

The rivet nut stuck on the threaded mandrel when screwing rivet nut onto the thread of threaded mandrel.

12

3

4

5

POSSIBLE CAUSES: Poor rivet nut thread or damaged threaded mandrel.

SOLUTION: Unscrew the stuck rivet nut from the threaded mandrel by using the patented Fixing-Hole Design.

Firstly insert the fixing-hole pin (67) into any hole of stroke adjuster (5) and turn the rotation knob (26) to align and let the

fixing-hole pin (67) go through the holes, and then put the pin retainer (68) onto the end of the fixing-hole pin (67) . Now the

free rotation of threaded mandrel (1) is stopped (Fig.1). Turn whole Tool counter-clockwise to unscrew the threaded mandrel (1)

from the stuck rivet nut (Fig.2). Finally take off pin retainer (68) and pull fixing-hole pin (67) from the fixing holes.

12.4 MALFUNCTION:

The rivet nut stuck on the threaded mandrel when fastening rivet nut in the work piece.

12.5 MALFUNCTION: Tool fails to fasten Rivet Nut

12.6 MALFUNCTION: Slow Cycle

4

2.

67

5

68

12

3

1.

WORK

PIECE

STUCK

RIVET

NUT

67

26

68

5

Possible Causes:

Low Air Pressure or Air Pressure lost

Hydraulic Oil Pressure lost

Exceed Tool’s Capacity

Solutions:

Check Compressed Air Supply System, adjust Air Pressure

to in specification, check Air Cylinder (30) leak and replace it

if necessary, clean Air Cylinder (30) inside, clean or replace

O-Rings (53, 58, 60)

Insufficient Oil and refill Oil, check Oil Cylinder (15)

leak and replace it if necessary, replace all O-rings

(13, 19, 27, 29) and Back-Up Rings (14, 20, 28)

Use more powerful Tool

Possible Causes:

Low Air Pressure

Solutions:

Check Compressed Air Supply System, adjust Air Pressure

to in specification, check Air Cylinder (30) leak and replace it

if necessary, clean Air Cylinder (30) inside, clean or replace

O-Rings (53, 58, 60)

12

3

4

4

5

167

68

2.

5

1

2

3

1.

1

5

68

67

26

STUCK

RIVET NUT

18

Possible Causes:

Grip Range of Rivet Nut is too long

Low Air Pressure

Insufficient Hydraulic Oil leads to Stroke decreased

Air bubbles in Hydraulic Oil

Oil Cylinder (15) leaks

Improper assembly of Valve Assembly (43AY)

Worn O-Rings in Valve Assembly (43AY)

Solutions:

Check suitable Grip Range of Rivet Nut to match work

piece’s thickness. It is nothing to do with Stroke of Tool

Check Compressed Air Supply System, adjust Air Pressure to in

specification, check Air Cylinder (30) leak and replace it if necessary,

clean Air Cylinder (30) inside, clean or replace O-Rings (53, 58, 60)

Refill Hydraulic Oil through Oil Refill Hole, see 11.5 solutions

Bleed Oil from Air Cylinder (30), and refill New Hydraulic Oil

See below 12.9 solutions

Reassemble Valve Assembly (43AY)

Replace all O-Rings (42, 44, 29, 47, 50)

12.7 MALFUNCTION: No operation after triggering (Stroke lost), or more than one operation of Trigger to

fasten Rivet Nut (Stroke decreased)

12.9 MALFUNCTION: Oil Cylinder (15) leaks Hydraulic Oil

Possible Causes:

Oil Cylinder (15) damaged

Improper assembly of O-Rings (13, 19, 27, 29) and Back-Up

Rings (14, 20, 28) in front & rear ends of Oil Cylinder (15)

Worn O-Rings (13, 19, 27, 29) and Back-Up Rings (14, 20,

28) in front & rear ends of Oil Cylinder (15)

Solutions:

Replace a new Oil Cylinder (15)

Reassemble O-Rings (13, 19, 27, 29) and Back-Up Rings

(14, 20, 28) in front & rear ends of Oil Cylinder (15)

Replace new O-Rings (13, 19, 27, 29) and Back-Up Rings

(14, 20, 28) in front & rear ends of Oil Cylinder (15)

12.11 MALFUNCTION: Valve Assembly (43AY) and Noise Silencer (33) leak Air

Possible Causes:

Improper assembly of Valve Assembly (43AY)

Worn O-Rings (42, 44, 29, 47, 50) in Valve Assembly (43AY)

Weak Springs (45, 49) in Valve Assembly (43AY)

Solutions:

Reassemble Valve Assembly (43AY)

Replace new O-Rings (42, 44, 29, 47, 50) in Valve

Assembly (43AY)

Replace new Springs (45, 49) In Valve Assembly (43AY)

12.12 MALFUNCTION: Air Inlet and Air Inlet Fitting leak Air

Possible Causes:

Wrong thread size of Air Inlet Fitting

Air Inlet thread damaged

Solutions:

Change correct thread size of Air Inlet Fitting

Tap thread and wrap Tape Seal around Air Inlet

Fitting’s male thread

12.10 MALFUNCTION: Air Cylinder (30) and Noise Silencer (33) leak Hydraulic Oil

Possible Causes:

Improper assembly of O-Rings (27, 29) and Back-Up Ring

(28) in lower end of Oil Cylinder (15)

Worn O-Rings (27, 29) and Back-Up Ring (28) in lower

end of Oil Cylinder (15)

Worn Lock Nut O-Ring (32A)

Solutions:

Reassemble O-Rings (27, 29) and Back-Up Ring (28) in

lower end of Oil Cylinder (15)

Replace new O-Rings (27, 29) and Back-Up Ring (28) in

lower end of Oil Cylinder (15)

Replace New Lock Nut O-Ring (32A)

12.8 MALFUNCTION: Slow operation or no operation of Air Piston Assembly (55AY) in Air Cylinder (30)

Possible Causes:

Improper assembly of Valve Assembly (43AY)

Worn O-Rings in Valve Assembly (43AY)

Improper assembly of Air Piston Assembly (55AY)

Worn Air Piston Ring (53) and Buffer Ring (52)

Low Air Pressure

Noise Silencer (33) blocks air exhaust

Weak or broken Return Springs (21 & 22)

Solutions:

Reassemble Valve Assembly (43AY)

Replace all O-Rings (42, 44, 29, 47, 50)

Reassemble Air Piston Assembly (55AY)

Replace Air Piston Ring (53) and Buffer Ring (52)

Check Compressed Air Supply System, adjust Air Pressure to in

specification, check Air Cylinder (30) leak and replace it if necessary,

clean Air Cylinder (30) inside, clean or replace O-Rings (53, 58, 60)

Clean or replace a new Noise Silencer (33)

Replace new Return Springs (21 & 22)

Table of contents

Other Rivtec Tools manuals

Popular Tools manuals by other brands

Kurt

Kurt VERSATILELOCK 3410V Operating instructions manual

Festool

Festool OF 1010 Q Original operating manual

Parkside

Parkside 353783 2010 Assembly and Safety Advice

HiCoup

HiCoup Double Hinge Waiter user manual

Jackson

Jackson 224W Assembly, Safety & Operating Instructions

VERITAS

VERITAS Prairie Dog 05G10.22 quick start guide