RIX Industries MAN-2PS2B-N2 User manual

4900 Industrial Way, Benicia, CA 94510 | www.rixindustries.com | 707.747.5900

MAN-2PS2B-N2

Operating Instructions

For RIX Compressor Family: 2PS2B-N2

Models: 2PS-L-N2, 2PS-L50-N2, 2PS-H-N2, 2PS-H50-N2 &

2PS-HH-N2

Rix Industries

2 Stage, Oil-Less

Air-Cooled

Nitrogen Compressor

This manual, including information and products referenced herein, to be provided by Seller

(“Products”) are subject to U.S. export control laws and will not be resold, re-exported, or

retransferred, directly or indirectly, to any person in violation of U.S. Export Administration

Regulations.

RIX Industries MAN-2PS2B-N2 Page i

Revision History

Revision

Date

Approved

Pages

Revised

Brief Description

-

Initial Release

A

1/18/10

SS

Content update

B

8/19/11

CJC

Content update

C 5/19/21 ICB

Major formatting and content update;

see ECO-010962

D 7/12/2021 ICB Parts List

Check Valve Replacement, BOM; ECO-

011049

E 10/26/21 AV

Revision

History

Revision Catch-Up; ECO-011231

F 10/26/21 AV

Parts List, Fig.

12, 4.5

New Beltguard, Crankcase, RV

Setpoint Correction; ECO-011231

G 01/20/22 AV

Revision

History

Revision Catch-Up; ECO-011705

H

01/20/22

AV

Appendix

Update Rev of 24923; ECO-011705

J 04/13/22 AV ii, iii, 8-44

Addition of Section 5.9 and 7.11, Page

Renumbering; ECO-011912

K 08/19/22 AV

Revision

History

Revision Catch-Up; ECO-012423

L

08/19/22

AV

COC Sheets

Removed COC Sheets; ECO-012423

M 01/12/23 AV

Revision

History

Revision Catch-Up; ECO-012534

N 07/25/23 AV

Sections 7.7

and 7.8, Parts

List

Revised Main Bearing Section, Parts

List Table, and Piston Assy Section;

ECO-013271

RIX Industries MAN-2PS2B-N2 Page ii

Table of Contents

Revision History.........................................................................................................................................................................i

Table of Contents..................................................................................................................................................................... ii

Parts, Service & Technical Support ................................................................................................................................. iv

Safety Precautions....................................................................................................................................................................v

Compressor Warranty.......................................................................................................................................................... vi

Compressor Specifications ................................................................................................................................................vii

Chapter 1 - Compressor Overview ................................................................................................................................... 1

1.1 Introduction............................................................................................................................................................ 1

1.2 Description.............................................................................................................................................................. 1

1.3 Cooling ...................................................................................................................................................................... 1

1.4 Gas Compression .................................................................................................................................................. 1

1.5 Crankcase Lubrication ....................................................................................................................................... 2

Chapter 2 – Installation......................................................................................................................................................... 3

2.1 Mounting.................................................................................................................................................................. 3

2.2 Gas Plumbing ......................................................................................................................................................... 3

2.3 Electrical Connections........................................................................................................................................ 4

2.4 Storage ...................................................................................................................................................................... 4

Chapter 3 - Start-Up & Operating Parameters............................................................................................................. 5

3.1 Pre-startup System Inspection ....................................................................................................................... 5

3.2 Start-Up .................................................................................................................................................................... 5

3.3 Normal Operating Conditions ......................................................................................................................... 5

Chapter 4 - Control System.................................................................................................................................................. 6

4.1 System Overview.................................................................................................................................................. 6

4.2 Manual Operation Mode.................................................................................................................................... 6

4.3 Auto Operation Mode ......................................................................................................................................... 6

4.4 Control logic Description .................................................................................................................................. 7

4.5 Safety Device Set Points..................................................................................................................................... 7

Chapter 5 - Routine Inspection & Scheduled Maintenance.................................................................................... 8

5.1 Introduction............................................................................................................................................................ 8

5.2 Routine Inspection............................................................................................................................................... 8

5.3 Scheduled Maintenance..................................................................................................................................... 8

5.4 Gas Filter Service.................................................................................................................................................. 9

5.5 Compressor Valve Service ................................................................................................................................ 9

5.6 Running Gear Inspection................................................................................................................................... 9

5.7 Piston Ring Replacement .................................................................................................................................. 9

5.8 Compression Cylinder Inspection ................................................................................................................. 9

5.9 Connecting Rod Bearings Inspection .........................................................................................................10

5.10 Instrument Calibration ....................................................................................................................................10

Chapter 6 - Troubleshooting.............................................................................................................................................11

6.1 Compressor Symptoms....................................................................................................................................11

Chapter 7 - Corrective Maintenance..............................................................................................................................13

7.1 Introduction..........................................................................................................................................................13

7.2 Gas Leak Check....................................................................................................................................................13

7.3 Cylinder Heads ....................................................................................................................................................13

7.4 Compressor Valves ............................................................................................................................................14

7.5 Compression Cylinders....................................................................................................................................15

7.6 Compression Rings............................................................................................................................................15

7.7 Piston Assembly..................................................................................................................................................16

RIX Industries MAN-2PS2B-N2 Page iii

7.8 Main Bearings ......................................................................................................................................................17

7.9 Piston to Head Clearance ................................................................................................................................18

7.10 Clearances & Tolerances .................................................................................................................................19

7.11 Connecting Rod Bearings................................................................................................................................20

Appendix ...................................................................................................................................................................................21

RIX Industries MAN-2PS2B-N2 Page iv

Parts, Service & Technical Support

Manufacturer: RIX Industries

4900 Industrial Way

Benicia, California 94510 USA

Phone: 707-747-5900

Fax: 707-747-9200

Parts Fax: 707-748-0398

www.rixindustries.com/request-spare-parts/

Parts Dept. Hours: 6:30-15:30 PST

Compressor model and serial number must be provided with all inquiries.

Compressor Model Family

2PS2B-N2

Serial Number

Note: Parts recommended for routine service are indicated in the parts lists. The customer is

advised to maintain these parts at their facility or procure them in advance as lead times and

availability can vary. RIX also offers service and overhaul kits to support other scheduled

maintenance requirements.

RIX is an AS9100C:ISO9001-2008 registered company. All compressors are designed and

manufactured in accordance with the requirements of the AS9100C:ISO9001-2008 quality system

ensuring the highest quality products.

RIX Industries MAN-2PS2B-N2 Page v

Safety Precautions

Safety precautions are necessary for the protection of personnel and equipment. Prior to any

attempt to install, operate, maintain, troubleshoot, or repair any part of the compressor, all

warnings and cautions included here and/or appearing throughout this manual should be

thoroughly reviewed and understood.

DANGER

This symbol means if the danger is not avoided, it will cause death, serious

bodily injury, or severe damage to the machine.

1. Before working on the compressor, all internal pressure must be relieved, and compressor

must be isolated or disconnected from all external pressure sources.

2. All electrical components associated with this equipment shall be installed and grounded in

accordance with applicable codes and regulations.

3. Before working on electrical equipment, take steps to ensure system is de-energized and

will remain so while work is in progress. All circuits not known to be DEAD must be

considered LIVE and dangerous at all times.

WARNING

This symbol means if the warning is not heeded, it can cause death, bodily

injury, or damage to the machine.

4. Do not operate unit if safety guards are removed, damaged, or modified.

5. Do not reset relief valves for any pressure higher than as specified in this manual.

6. Do not make any unauthorized alteration to equipment.

CAUTION

This symbol means if precaution is not taken, it may cause bodily injury or

damage to the machine.

7. Do not touch cylinder heads or discharge gas lines from the heads up to the heat exchanger

inlets. These are hot and can cause serious burns.

RIX Industries MAN-2PS2B-N2 Page vi

Compressor Warranty

RIX Industries warrants this compressor as follows:

A. (Field Service/Overhaul) Exclusive of normal wearing parts - Seller warrants that its work

when performed and services when rendered will meet all specific requirements, if any, of this

agreement, and will be done in a good and workmanlike manner. Seller warrants its work for a

period of 90 days from completion of the work and all claims for defective work must be made in

writing immediately upon discovery and in any event within 90 days from date of completion

thereof by Seller. Upon Buyer’s submission of a claim as provided above and its substantiation,

Seller shall at its option either (i) repair Buyer’s equipment at the original F.O.B. point of delivery,

(ii) refund an equitable portion of the contract price, (iii) furnish F.O.B. Seller’s facility or other

point of shipment any necessary repaired or replacement parts or, (iv) in the case of service, re-

perform the service.

B. (Parts/Material and New Equipment) Exclusive of normal wearing parts - Seller warrants

that any parts manufactured by Seller and delivered hereunder will be free from defects in material

and workmanship. Seller warrants its parts for a period of twelve (12) months from operation and

all claims for defective parts under this warranty must be made in writing immediately upon

discovery, and in any event, within eighteen (18) months from shipment of the applicable item,

whichever shall first occur. Upon Buyer’s submission of a claim as provided above and its

substantiation, Seller shall at its option either repair or replace its part at the original F.O.B. point of

delivery. Defective items must be held for Seller’s inspection and returned to the original F.O.B.

point upon request.

C. With respect to parts not manufactured or services not performed by Seller, Seller assigns to

Buyer whatever warranty Seller receives from the Supplier of such parts or services. However,

Seller agrees to be Buyer’s primary contact on all warranty claims.

D. The foregoing warranties are exclusive and in lieu of all other warranties, whether written, oral,

implied, or statutory. No implied warranty of merchantability or fitness for purpose shall apply.

E. Seller makes no performance warranty and the effects of corrosion, erosion and normal wear

and tear are specifically excluded from Seller’s warranty.

F. Seller will not be liable to Buyer for any loss or injury to persons or property (including the

machinery which is the object of the work) caused in whole or part by (1) the acts of buyer or its

agents, (2) failure to observe Seller’s instructions, or (3) failure or malfunctioning of anything not

furnished by Seller.

G. The preceding paragraphs set for the exclusive remedies for warranty claims, and upon the

expiration of the warranty period, all such liability shall terminate.

H. Normal Wearing parts are defined, but not limited to the following: Seals, Gaskets, O-rings, piston

rings and riders, bulbs, fuses, and anti-corrosion devices such as zincs. RIX Industries reserves the

right to evaluate these items for material workmanship and defects on a case-by-case basis.

I. FOB Destination Service Items are limited to the Continental United States (CONUS). Service

outside the CONUS is at the discretion of the seller, and or at buyer’s expense.

RIX Industries MAN-2PS2B-N2 Page vii

Compressor Specifications

This document is valid for the following RIX compressor(s):

2PS2B-N2—models 2PS-L-N2, 2PS-L50-N2, 2PS-H-N2, 2PS-H50-N2 & 2PS-HH-N2

Design Specifications

Cylinder Size(s): 1 ¼” & ½”

Stroke Length: 2”

Motor Power: 1 ½ HP

Rotation: Clockwise from flywheel side

Nominal Compressor Speed: 2PS-L-N2: 190 RPM

2PS-L50-N2: 190 RPM

2PS-H-N2: 390 RPM

2PS-H50-N2: 390 RPM

2PS-HH-N2: 390 RPM

Input Power:

2PS-L: 115VAC/1PH/60HZ

2PS-L50: 220VAC/1PH/50HZ

2PS-H: 115VAC/1PH/60HZ

2PS-H50: 220VAC/1PH/50HZ

2PS-HH: 230VAC/1PH/60HZ

Gas Input

Gas to be compressed: Nitrogen, clean and dry

Suction Pressure Range: 30 to 70 psig

Suction Temperature Range: 0 to 100 °F

Gas Output

Nominal Flow Rate: 2PS-L-N2: 30 SCFH** @ 30 psig, 70°F Suction

2PS-L50-N2: 30 SCFH** @ 30 psig, 70°F Suction

2PS-H-N2: 60 SCFH** @ 30 psig, 70°F Suction

2PS-H50-N2: 60 SCFH** @ 30 psig, 70°F Suction

2PS-HH-N2: 60 SCFH** @ 30 psig, 70°F Suction

Discharge Pressure: 2200 psig maximum

**Design basis of SCFH is 70°F and 14.7 psia

Operating Environment

Installation: Indoors

Ambient Temperature: 32 to 104 °F

Altitude: Sea Level to 4500’

RIX Industries MAN-2PS2B-N2 Page 1

Chapter 1 - Compressor Overview

1.1 Introduction

This manual is intended to provide all necessary information and documentation pertinent to the

installation, operation, and maintenance of the RIX compressor family 2PS2B-N2—models 2PS-L-

N2, 2PS-L50-N2, 2PS-H-N2, 2PS-H50-N2 & 2PS-HH-N2. Ensure all operators of this compressor

package read and understand the entire manual prior to installation, operation, and/or servicing.

All servicing shall be performed only by trained and qualified personnel.

1.2 Description

This is a 2 stage, 2 cylinder, air-cooled, oil-less compressor. This package is approximately 16

inches wide by 20.5 inches long by 29 inches tall and weighs approximately 172 lbs. See

Compressor Specifications for design operating pressures, flow rate, and gas type. Note the flow

rate will vary with the suction pressure, temperature, and compressor condition. This unit was

packaged by RIX as a ready to operate package with control and safety devices.

WARNING

Pneumatic energy hazard. Unit is designed to compress and store

high pressure gas. When pneumatic energy is released in an

uncontrolled manner, individuals may be crushed or struck by

moving machinery, equipment, or other items. If maintenance is

attempted on a pressured line without isolating the line and relieving

pressure, the sudden release of pressure can propel fittings or

rupture lines or vessels. Ensure unit is depressurized and locked out

prior to performing any maintenance.

1.3 Cooling

Due to the heat generated during compression it is necessary to cool both the compression

cylinders and the compressed gas. Cooling fans are installed to blow air over the compression

assemblies and then route the air over the cooling coils. Ambient cooling air is required to be within

the range given in Compressor Specifications. Cooler air is desirable as it will increase

compressor component life.

1.4 Gas Compression

RIX compressors are designed to safely compress gas without cylinder oil lubrication. Teflon based

piston rings are used in all stages. Since oil is not used in the compression cylinders, the

compressor will not contaminate the compressed gas; however, it is the responsibility of the user to

ensure that clean gas is supplied to the compressor suction at all times. A small amount of inert

piston ring dust will pass into the gas stream; this can be filtered out if desired.

RIX Industries MAN-2PS2B-N2 Page 2

1.5 Crankcase Lubrication

This oil-less compressor utilizes sealed bearings. Oil-less compressors contain absolutely no oil

within the whole compressor package removing the likelihood of any oil carry over, thus

eliminating contamination.

RIX Industries MAN-2PS2B-N2 Page 3

Chapter 2 – Installation

2.1 Mounting

The compressor must be firmly bolted down to a rigid foundation through all 4 mounting holes to

minimize vibration. Any allowed movement will generally increase vibration which can lead to

component damage.

2.2 Gas Plumbing

Be sure all process lines are free from contamination. Plumbing to the compressor must be sized so

that pressure at the compressor suction is within the range given in Compressor Specifications.

Discharge plumbing must be large enough to pass design flow at lowest expected back pressure

without choking the flow. User’s suction and discharge plumbing should be designed to

accommodate compressor vibration.

CAUTION

If flexible lines are used, user is responsible to secure those lines

to prevent whipping in case of breakage.

Safety relief valves are installed on the compressor at each stage of compression: suction,

interstage, and discharge. Do not start the compressor without these items properly installed. All

plumbing and components must be rated for pressures greater than the connected relief valve

setting.

Provisions must be in place to relieve all internal pressure and isolate the compressor from all

external pressure sources to ensure that the unit can be safely disassembled for maintenance. It

may be helpful to install a hand valve in the gas line downstream of the compressor to create back

pressure for testing and calibration.

DANGER

Do not install ball valves in either suction or discharge plumbing. If

closed quickly, these valves can cause explosion.

RIX Industries MAN-2PS2B-N2 Page 4

2.3 Electrical Connections

The motors and instrumentation are wired to a crankcase mounted control box. User to supply

power to the control box in accordance with the electrical requirements specified in Compressor

Specifications. All electrical connections should be made in compliance with local electrical codes.

2.4 Storage

If the compressor is taken out of service, provision should be made to protect against corrosion. At

a minimum gas suction and discharge lines should be capped and belt tension relieved. The

compressor should be rotated at least once every month. In corrosive environments, the unit

should be nitrogen purged.

After extended storage, or if stored without climate control, the compressor heads and valves

should be removed and inspected for corrosion. Bearings should also be inspected and/or replaced

and the relief valves should be cleaned, rebuilt, and/or replaced.

RIX Industries MAN-2PS2B-N2 Page 5

Chapter 3 - Start-Up & Operating Parameters

3.1 Pre-startup System Inspection

1. Visually inspect the entire system for obvious damage or leakage. Fix all issues that are

found. If major shipping damage is found contact RIX for repair or replacement parts.

2. Ensure that any safety guards are securely attached.

3. Ensure supply pressure is within the range stated in Compressor Specifications.

3.2 Start-Up

After performing the pre-startup system inspection, start the unit. When starting the compressor

for the first time or after servicing, check for leaks in the plumbing – see Section 7.2 for

recommended leak check procedure. After correcting any leaks in the system, restart the unit and

observe gas pressures and temperatures. The pressure will increase based on back pressure from

the User’s downstream plumbing. Gas temperature will also rise in conjunction with the

compression ratio of each stage.

All shutdown devices and control logic should be tested before the system is put into autonomous

operation.

3.3 Normal Operating Conditions

The table below shows theoretical operating conditions—actual pressures and temperatures may

vary. Due to the inclusion of a back-pressure regulator in the compressor package, the discharge

pressure should always be a minimum of 1500 psig. Do not adjust the back-pressure regulator

setpoint as it keeps the 2nd stage floating piston from hitting the 2nd stage valve during normal

operation.

Stage

Pressure

(psig)

Temperature

(°F)

Suction

30 - 70

70

Interstage

300-600

300

Discharge

1500-2200

225

CAUTION

Cylinder heads and discharge lines are hot. Touching any part of

the cylinder heads or discharge lines can cause burns.

It is recommended that the Service Log in the appendix of this manual be used to note operating

pressures, temperatures, and maintenance done at hours of compressor operation. If pressures do

not fall near the above stated values, or vary from your historical pressures, see Chapter 6 –

Troubleshooting for corrective action.

RIX Industries MAN-2PS2B-N2 Page 6

Chapter 4 - Control System

4.1 System Overview

This unit has an integrated control box wired for auto stop/start capability. Pressure switches

prevent the unit from operating outside of design ranges if discharge pressure rises too high or

suction pressure falls too low. The unit is also equipped with an hour meter to log cumulative run

time.

WARNING

The control box contains high voltage. Before working on electrical equipment,

take steps to ensure the system is de-energized and will remain so while work is in

progress. All circuits not known to be dead must be considered live and dangerous

at all times.

Suction pressure must be supplied to compressor before startup to keep the rod loading and/or

compression ratios within limits. Ideally the pressure in the discharge plumbing should be bled

down to the level of the suction pressure before startup. User should include provisions to allow an

unloaded start up when connecting to the compressor.

The control system is designed for two modes of operation:

1. Manual start / automatic stop

2. Auto start / stop based on both suction and discharge pressure

A HOA (Hand/Off/Auto) switch is located on the front of the control box and allows operator choice

of modes. A remote contact is installed in the control box and can tied into to an ancillary control

system for remote start/stop, signal line use, etc. If such control is desired, remove pink jumper

wired between contact blocks 1 and 3 in the control box.

4.2 Manual Operation Mode

With the selector switch in the HAND position, the compressor is in manual mode and will start

when the START pushbutton is pressed. The unit will continue to run until one of the safety

switches stops the unit. At that point the compressor will not restart until the START pushbutton is

pressed again. If any switch remains past its trip setting the compressor will not start. To manually

stop the unit, switch the HOA switch to the OFF position.

4.3 Auto Operation Mode

With the selector switch in the AUTO position the compressor will automatically start and stop

based on the signals from both the suction and discharge pressure switches. When shutdown by

either switch, the compressor will remain on standby until the pressure reverts back to the "closed"

point of the switch at which point the compressor will restart. To manually stop the unit, switch the

HOA switch to the OFF position.

RIX Industries MAN-2PS2B-N2 Page 7

4.4 Control logic Description

The following explains the logic sequence as reflected on the electrical schematic (Figure 16 in

Appendix):

1. With power applied to the unit and the HOA selector switch (HOA) in HAND, push

the START pushbutton.

2. The two pressure switches, suction (PSIL) and discharge (PSR) are connected in

series to the motor controller. If the suction pressure is high enough to close the

suction pressure switch, and the discharge switch remains closed (pressure below

the switch "closed" setting) the compressor will start.

3. Current passes through the two closed pressure switches, the closed time delay

relay (TDR), and energizes the starter coil (C-1). The starter coil starts the main

drive motor. The fan motor and hour meter also operate at this point. The green

light (LG) will energize indicating the compressor is running. Tripping of either the

suction or discharge switch will break current to the coil (TDR) which will stop the

drive motor.

4. The compressor may also be run in the automatic mode by selecting AUTO on the

HOA switch. All features are the same as described above except that after the inlet

or discharge switch shut down the unit, the compressor will automatically restart

when the switches are moved to the "closed" setting. The compressor will continue

cycling until the selector switch is moved to either HAND or OFF.

5. The unit may be stopped at any time by switching the HOA to OFF.

4.5 Safety Device Set Points

The following safety devices have been provided at the set points noted below. Pressure switch

settings may be adjusted to User’s needs but set points shall not exceed the design constraints given

in Compressor Specifications. Do not adjust relief valve settings.

Device

Stage

Set Point

Function

Relief Valve

Suction

75 psig

Relieve excess

pressure build up

Interstage

700 psig

Discharge

2200 psig

Motor Overload

N/A

Motor FLA

Shutoff

Pressure Switch

Suction

30 falling

Shutoff

Discharge

2200 rising

Shutoff

RIX Industries MAN-2PS2B-N2 Page 8

Chapter 5 - Routine Inspection & Scheduled Maintenance

5.1 Introduction

The purpose of this chapter is to provide the operator with the routine inspection and scheduled

maintenance information required to ensure a long service life of the subject compressor. RIX

recommends documenting and tracking service history using the Service Log in the appendix of

this manual.

5.2 Routine Inspection

1. Visually inspect the system for obvious damage or leakage. Fix any issues that are found.

2. Check pressures and temperatures against normal operation.

3. Check cooling air flow. Verify cooling fans blow air over the heads.

4. Inspect for loose fittings or components. Fix any issues that are found.

5. Inspect for unusual noises or vibrations.

5.3 Scheduled Maintenance

Section

Time Interval

Operation

2000

hours

3000

hours

4000

hours

Annually

5.4

Gas Filter Service

*

5.5

Compressor Valve Service

*

5.6

Running Gear Inspection

*

5.7

Piston Ring Replacement, 1

st

Stage

*

5.7

Piston Ring Replacement, 2

nd

Stage

*

5.8

Compression Cylinder Inspection

*

5.8

Instrument Calibration

*

5.9

Connecting Rod Bearings

Inspection

*

DANGER

Before performing any maintenance, the compressor power supply

should be locked Out of Service to prevent starting which could cause

injury to personnel or damage to the equipment. Relieve all internal

pressure and allow piping to cool before repair.

RIX Industries MAN-2PS2B-N2 Page 9

5.4 Gas Filter Service

Every 2000 hours of running time, the interstage and discharge filters should be inspected and

cleaned or replaced. Failure to do so at the specified interval may result in poor valve performance

or process plumbing constriction in extreme cases of filter element contamination.

5.5 Compressor Valve Service

The valves should be inspected, cleaned, and, if necessary, replaced every 4000 hours or if

pressures vary from normal, noise is detected, or abnormally high temperatures are observed.

Severe leakage will cause overheating of the suction plumbing just prior to the cylinder head.

5.6 Running Gear Inspection

All compressor running gear should be inspected every 2000 hours. Belt alignment and tension as

well as all bearings should be inspected at this time. Belt should deflect ½-¾” at the mid span with

approximately 10 lbs. force applied. Bearings should be inspected to verify smooth rotation and

adequate lubrication. At a minimum relubricate the connecting rod needle bearing after 4000 hours

of operation and replace after 8000 hours operation.

5.7 Piston Ring Replacement

Every 2000 hours the 2nd stage piston rings, expanders, and riders should be replaced and every

3000 hours the 1st stage piston rings, expanders, and riders should be replaced. As the compression

rings wear their ability to seal is diminished. Excessive wear will result in lower compressor

capacity, more frequent compressor operation, and unnecessary wear on other components. With

extreme wear the compressor will not be able to compress to the design pressure. If the

compressor starts and stops more frequently, fails to make pressure, or has degraded flow capacity,

the rings should be replaced. There is risk of damaging the cylinder liners if the rings wear out

completely.

Note: piston rings are design to seal dynamically only. Leakage in standby is normal.

5.8 Compression Cylinder Inspection

Excess piston to cylinder clearance, caused by wear to cylinder bores, will significantly decrease

ring life. Cylinder bores should be observed for wear at ring change-outs or if ring life has

significantly decreased. It is good practice to measure the diameter and surface finish of the

cylinder bores whenever the cylinders are removed or when ring life drops from normal. Maximum

wear will normally occur 1/3 to 1/2 way down the bore. A bore gauge is the best way to measure

wear. Check diameter at several depths for wash-boarding – see Section 7.10 for wear limits. Some

surface roughness is needed to allow engraining of seal material in the bore. Both cylinders should

have a surface finish of 12-16 µin Ra crosshatch. If the cylinder bore surface finish is out of

tolerance it will reduce ring life.

RIX Industries MAN-2PS2B-N2 Page 10

5.9 Connecting Rod Bearings Inspection

Every 2000 hours of running, the Connecting Rod bearings should be inspected and replaced if

necessary. To inspect the Needle Bearing (smaller), remove the Connecting Rod assembly – see

Section 7.11, inspect the Wrist Pin outer diameter for deformation, if no bumps or dents are

present, insert the Wrist Pin through the needle bearing and rotate while holding the Connecting

Rod still. Notable bumpiness, roughness, knocking, or resistance to rotation would indicate this

bearing needs to be replaced. If the Wrist Pin outer diameter contains dents or bumps, replace both

the Wrist Pin and Needle Bearing. To inspect the Ball Bearing (larger), rotate the inner race of the

bearing by hand while holding the Connecting Rod still. Like before, notable bumpiness, roughness,

knocking, or resistance to rotation would indicate this bearing needs to be replaced.

Note: if bearings are not being replaced, re-pack with (RIX P/N 45-110) Polyurea grease before

installation – see Section 7.11.

5.10 Instrument Calibration

Control instruments should be verified for accuracy annually. Pressure gauges, switches, and relief

valves can be bench tested on a hydro fixture to confirm the accuracy of each device. Use only

deionized water for these tests.

RIX Industries MAN-2PS2B-N2 Page 11

Chapter 6 - Troubleshooting

6.1 Compressor Symptoms

Abnormal compressor conditions can be evaluated more quickly and accurately by looking at

interstage pressures and temperatures. Use the table below to aid in determining the cause of any

problems with the compressor and the necessary corrective action.

Item

Symptom

Probable Causes

Corrective Action

1

Compressor stops running

before system pressure is

reached

The discharge pressure

switch is set too low

Adjust pressure switch set

point

The power source stopped

supplying power

Investigate power supply

source

The compressor has seized

Inspect compressor internal

components

2

Compressor does not reach

design flow or pressure

System plumbing is leaking

Check system for leaks

Supply pressure is too low

Adjust supply pressure to

range stated in Compressor

Specifications

Lack of back pressure in

user’s downstream piping

If downstream should be

pressurized, look for leaks in

downstream system.

If downstream should not be

pressurized, no problem.

Restricted filters or piping

Clean or replace filters and

upstream piping

Belt is loose

Inspect and tighten belt to

proper tension

Excessive piston to head

clearance

Measure and adjust piston

clearance

Piston rings are worn

Replace piston rings

Compressor valve has

failed

Replace compressor valve

3

High pressures

Restricted discharge filter

or piping

Clean filter and downstream

piping

Compressor valve has

failed

Replace compressor valve

4

Relief valve opens

High pressures were

reached

See item 3

Relief valve is set too low

Adjust relief valve set point

Relief valve has failed

Replace relief valve

5

Compressor is vibrating

excessively

Crankcase mounting bolts

are loose

Tighten crankcase mounting

bolts

Motor mounting bolts are

loose

Tighten motor mounting

bolts

Piston clearances not

properly adjusted

Measure and adjust piston

clearance

RIX Industries MAN-2PS2B-N2 Page 12

Item

Symptom

Probable Causes

Corrective Action

Mechanical failure internal

to the compressor

Inspect compressor internal

components

6

High Temperatures

Low suction pressure to

compressor

Adjust supply pressure to

range stated in Compressor

Specifications

Fans are inoperative

Repair or replace fans

High ambient temperature

Ensure ambient temperature

is within design limits

Compressor valves have

failed

Replace compressor valves

7

Loud metallic knocking

Piston is hitting valve

Measure and adjust piston

clearance

Replace back pressure

regulator

8

Ticking noise from cylinder

head

Compressor valve is worn

or broken

Replace compressor valve

This manual suits for next models

6

Table of contents

Other RIX Industries Air Compressor manuals

Popular Air Compressor manuals by other brands

Ozito

Ozito DMC-1000 instruction manual

Pentair

Pentair Hoffman VC-0916-04XH Operation and safety instructions

Air Lift

Air Lift WirelessONE 25870 installation guide

Draper

Draper DA100 instructions

Synairgy

Synairgy SACDD-24 Operation manual

Schneider Airsystems

Schneider Airsystems UNM STS 1000-10-270 XDK operating manual

California Air Tools

California Air Tools 10020CAD owner's manual

Dover

Dover PSG Mouvex Enterprise E140 Installation operation & maintenance

RIDGID

RIDGID R0230 Operator's manual

Scheppach

Scheppach HC24 Translation of original instruction manual

Sealey

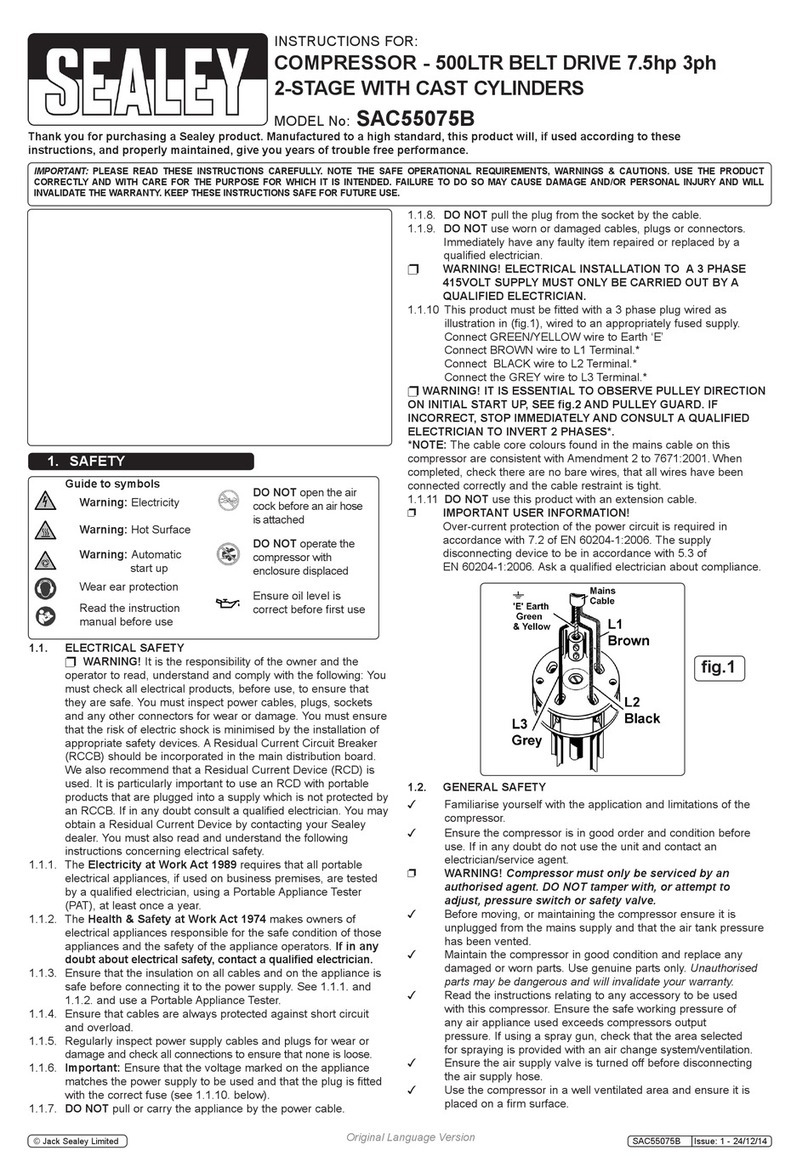

Sealey SAC55075B instructions

AllTrade

AllTrade 835408 instruction manual