RKC INSTRUMENT AC2000 User manual

WAC2000INS V1 18/03/15 LH E&OE Copyright © 2014 RKC Holdings Pty Ltd

FITTING INSTRUCTIONS AC2000

It is recommended that only a properly qualified person installs the product and carries out maintenance. If you are not

qualified and attempt to carry out such work ensure that all safety equipment is used and safety standards are met.

Ensure that you have read the full Product Manual before attempting to fit the product.

Ensure the Product Manual is kept with the vehicle and that any vehicle owner and/or operator are fully advised on the

system and its operation before attempting to drive or operate it.

DO NOT connect any electrical components to the vehicle without preparing the electrical system as per the vehicle

manufacturer’s instructions. Connecting without preparing the vehicle could lead to component failure, vehicle

damage or fire.

If you use a sharp utility knife or razor blade great care must be taken in all cases not to cut yourself during this

operation.

In some Countries, States or Territories it may not be legal to position the switches inside a vehicle or within reach

while operating the vehicle. Confirm with your relevant authorities.

The gauge is NOT weatherproof and is best mounted inside the cabin for easy pressure monitoring.

The switches should be mounted in a protected area to minimise the effect of moisture and dirt E.g. in or under a tray,

in tool box or canopy. If you mount them in the cabin please check local government regulations.

Air compressors get hot - avoid any flammable liquid or burn risk areas.

Incorrect use of this product can result in damage to the components associated parts

and/or the vehicle, which is not covered under warranty.

Ensure suspension airbags are maintained at the stated ride height at all times and maintain the minimum pressure

required and never exceed the maximum, as required by the particular airbag product.

WAC2000INS V1 18/03/15 LH E&OE Copyright © 2014 RKC Holdings Pty Ltd

GENERAL ADVICE

AIRLINE TUBING & FITTINGS - GENERAL NOTES

CUTTING

Only cut the airline tubing with a sharp blade making the cut as square as

possible.

Always trim the tubing before re-inserting into the fitting.

If you use a sharp utility knife or razor blade great care must

be taken in all cases not to cut yourself during this

operation.

Contact Airbag Man for our recommended tube cutter tool.

CUT TUBING

SQUARE WITH

SHARP BLADE

OR TUBE

CUTTER

DO NOT USE

PLIERS, SIDE

CUTTERS OR

PIPE CUTTERS

PUSH TO CONNECT FITTING

CONNECTING & REMOVING

To connect:

Push the cleanly trimmed tubing firmly into the fitting as far as possible.

To remove:

First release the air pressure from the system.

To withdraw the tubing, push and hold the collar on the fitting away from the tube and pull out the tubing.

In confined spaces an open ended spanner can be used to evenly depress the collar and remove the airline tubing.

BARB FITTING

To install the airline onto the barb fitting start by cutting a nice square edge on one end of the airline, Work the airline onto the barb by

using a side to side motion until it is fully seated on the barb. DO NOT kink the airline when doing this.

Heating of the end of the airline with hot water will soften it sufficiently

making it easier to connect to the barb.

Ensure you do not burn yourself when working with hot liquid.

REMOVING BARB FITTING

If the airline must be removed from the barb fitting for any reason ensure an

appropriate method is used.

DO NOT use pliers or a utility knife on the barb as there is

a good chance the barbs will be damaged and

permanently degrade their sealing ability.

WARRANTY IS VOID IF BARB IS DAMAGED

Cut the airline tube down to about 2” in length and immerse the

tube and barb in hot water to soften, making it easier to remove

from the barb. Pliers can be used to grip the airline away from

the barb once it is heated up.

Care must be taken not to submerge the paddle switch body or damage the barb.

WAC2000INS V1 18/03/15 LH E&OE Copyright © 2014 RKC Holdings Pty Ltd

SEE OTHER WARNINGS AND IMPORTANT INFORMATION IN THE PRODUCT MANUAL

LHS = LEFT SIDE OF THE VEHICLE WHEN FACING FORWARD

STEP 1 – PREPARE THE VEHICLE

Please note it may be necessary to remove components from the vehicle to fit this kit, ensure this is carried out according to the

vehicle manufacturer’s instructions regarding electrical connection and component positioning and mounting.

DO NOT connect any electrical components to the vehicle without preparing the electrical system as per the vehicle

manufacturer’s instructions. Connecting without preparing the vehicle could lead to component failure, vehicle

damage or fire.

STEP 2 - AIR CONTROL PANEL POSITIONING AND GAUGE WIRING

Select a location for the air control panels to be mounted that provides good access and space for the electrical and pneumatic

connections to be routed. To aid in positioning of the parts the air control panels are configured to allow the switches to be positioned

in a different location to the gauge. The switches can also be removed from the supplied switch panel and mounted directly into a

vehicles existing switch blank, or existing panel. Note that the switch can only be mounted to a maximum material thickness of 2mm

and if thinner material thickness is used the switch may have a loose fit.

Included in this kit for your convenience are mounting fasteners and snap wiring connectors. These parts can be used, or utilise your

own methods to suit the installation, vehicle and equipment available.

In some Countries, States or Territories it may not be legal to position the switches inside a vehicle or within reach

while operating the vehicle. Confirm with your relevant authorities.

The gauge is NOT weatherproof and is best mounted inside the cabin for easy pressure monitoring.

The switches should be mounted in a protected area to minimise the effect of moisture and dirt E.g. in or under a tray,

in tool box or canopy. If you mount them in the cabin please check local government regulations.

GAUGE TO VEHICLE WIRING CONNECTION

The gauge illumination can be connected with the supplied wire and terminals to allow illumination at night. If this is required, connect

it to an illumination source on the vehicle such as the dash illumination circuit (check the vehicles systems allow this first).

WAC2000INS V1 18/03/15 LH E&OE Copyright © 2014 RKC Holdings Pty Ltd

STEP 3 – AIR CONTROL AIRLINE AND WIRING CONNECTION

The paddle switches have two groups of white wires linked together from each switch as shown. One group of wires is to be

connected to the black wire from the compressor (remove the ring terminal fitted) using the crimp terminal supplied. The second

group of wires is to be connected to Earth using the crimp terminal and ring terminal (if required). It DOES NOT matter which group of

wires from the paddle switches is connected to the compressor or Earth to create the compressor on circuit. These connections can

be extended using the white wire supplied (if required).

The paddle switch plumbing and sensor readout can be configured to suit your preference and vehicle layout using the below diagram

as a guide.

When the air control switch levers are pushed up this causes the compressor to be triggered on through the white wires and air to flow

from the compressor to the airbags, via the switches. When the switch levers are pushed down they release air from the airbags via a

hole in the back of the switch body.

TUBE AND FITTINGS

Ensure the airline route is chosen and measured up before connecting the airline to the barbs as it is critical for the fittings to be in an

accessible position for leak check and maintenance purposes. Refer to the previous pages for airline to fitting installation.

STEP 4 – POSITION AIR COMPRESSOR

MOUNTING LOCATION

Select a mounting position considering the following:

1. Mounting surface needs to be Flat, Rigid and Secure (preferably horizontal).

2. As close to the Battery as possible. It is better to use more air line tubing than more electrical wiring as longer runs of wiring

require heavier wiring to maintain voltage.

3. Cool location away from Heat Sources with good natural ventilation.

4. Protected location - avoid positions that objects may strike and where excessive dust or debris can collect.

5. Water ingress will damage the air compressor - the air filter may need remote mounting in an elevated position, away from

the elements.

The outlet of the compressor must be routed to ensure condensation does not drain back to the compressor.

Air compressors get hot - avoid any flammable liquid or burn risk areas.

WAC2000INS V1 18/03/15 LH E&OE Copyright © 2014 RKC Holdings Pty Ltd

STEP 5 – MOUNT AIR COMPRESSOR

1. Disconnect ground (-i.e. earth) cable from the vehicle's

battery(s).

2. Temporarily position the air compressor where it will be

mounted and mark the mounting bolt hole positions. Check air

filter position and hose routing as required.

3. Mount the air compressor using the supplied bolts, washers

and nuts as shown.

STEP 6 – CONNECT COMPRESSOR OUTLET

1. If not already fitted connect the check valve to the

compressor.

2. Connect push to connect fitting to the check valve for

compressor outlet.

3. Connect air line tubing to the compressor air fitting and route

and connect to the control panel supply inlet.

When connecting check valve and fittings use a suitable

liquid thread sealant and allow setting before running the

compressor.

WAC2000INS V1 18/03/15 LH E&OE Copyright © 2014 RKC Holdings Pty Ltd

STEP 7 – CONNECT AIR COMPRESSOR INLET

FILTER

1. Confirm the air filter configuration based on the compressor

mounting location.

2. If in a protected location the filter can be mounted close to the

compressor inlet as shown to the right.

3. If the compressor is mounted where water or debris ingress

may occur the air filter must be remote mounted using the

supplied parts as shown below. The same barb connection

technique can be used as shown for the paddle switches.

4. Ensure air filter and airline mounting is secure and leak free.

The air filter element must be checked regularly and replaced

as required. A blocked air filter will effect compressor

performance and lead to compressor failure which is not

covered under warranty.

Air filter condition is directly related to compressor

location, driving environment and compressor usage.

For high debris applications inspect the air filter every

month.

STEP 8 – CONNECT WIRING

Select a possible position for the air compressor then loosely lay the supplied wired fuse holder between each of the connection

points. If the wiring can be fitted then proceed with installation. If not select a different air compressor location or modify the wiring

according to standard auto electrical practices.

Only carry out electrical wiring on the vehicle if you are suitably qualified and experienced in doing so. We recommend

that an Auto Electrician or Qualified Mechanic carries this out - note that incorrect wiring can lead to component

failure, vehicle damage or a fire.

Please note that any electrical components supplied in the kit are common standard components. However, you need to check that

these are suitable for the installation and application for which they are being used and that the electrical system you are connecting

to can supply the required current and voltage and will not be damaged. Please check the compressor label for current and voltage

details.

WAC2000INS V1 18/03/15 LH E&OE Copyright © 2014 RKC Holdings Pty Ltd

STEP 9 – LEAK TEST

INFLATE the system and the airbags to their maximum allowed pressure (See Pressure Advice in Airbag Owner's Manual) and check

for leaks at all connections using soapy water spray. We recommend a soapy water spray solution of 25% soap to 75% water.

DEFLATE If no leaks deflate airbags to required height. If leak detected, deflate airbags and air supply, check and tighten the air

fittings (if required), remove the airline tubing, re-cut and re-test.

Ensure airbags are returned to correct height (see Airbag Kit Fitting Instructions) after Leak Test is completed.

STEP 10 – FITMENT COMPLETION

Reattach all components removed earlier and return the vehicle to driving position. Ensure this operation is carried out according to

the vehicle manufacturer’s instructions.

STEP 11 – USE & MAINTENANCE

Periodically check that the air filter for the air compressor is clean. Spare filters are provided for replacements and they may be

needed often if the compressor is operating in a dusty environment.

Regularly clean dust and debris from the compressor fins and motor housing.

Periodically check the electrical and pneumatic connections are tight and not damaged.

Periodically check the fasteners for the compressor and control panel are tight.

The air compressor is equipped with a permanently lubricated, maintenance-free motor. Never try to lubricate the air compressor.

In the event of the compressor repeatedly turning off early or blowing fuses check that the battery voltage is sufficient, the wiring is

suitable and in good condition.

If all the electrical components appear correct then check that the compressor has adequate ventilation and is clean. If problems still

occur the compressor may be worn out and in need of replacement.

CAUTION: Never touch the air compressor or fittings connected to the air compressor with bare hands during or

immediately after use. The leader hose (where fitted) and fittings connected to the leader hose or pump head will

become very HOT during and after use. If necessary wear heat resistant gloves to handle fittings, airline and leader

hose.

Incorrect use of this product can result in damage to the components associated parts and/or the vehicle, which is not

covered under warranty.

Ensure suspension airbags are maintained at the stated ride height at all times and maintain the minimum pressure

required and never exceed the maximum, as required by the particular airbag product.

Table of contents

Popular Extender manuals by other brands

Network Technologies

Network Technologies ST-C5USBD-250 Installation and operation manual

HiBoost

HiBoost Easy Vehicle 2S C27G-CP user manual

TP-Link

TP-Link TL-WPA9610 KIT user guide

CEL-FI

CEL-FI GO M quick start guide

StarTech.com

StarTech.com STUTPRXL instruction manual

OCEAN CONTROLS

OCEAN CONTROLS KTA-296 quick start guide

Edimax

Edimax EW-7238RPD Quick installation guide

SY Electronics

SY Electronics SY-HDBT-231-70 user manual

Patton electronics

Patton electronics 1173R user manual

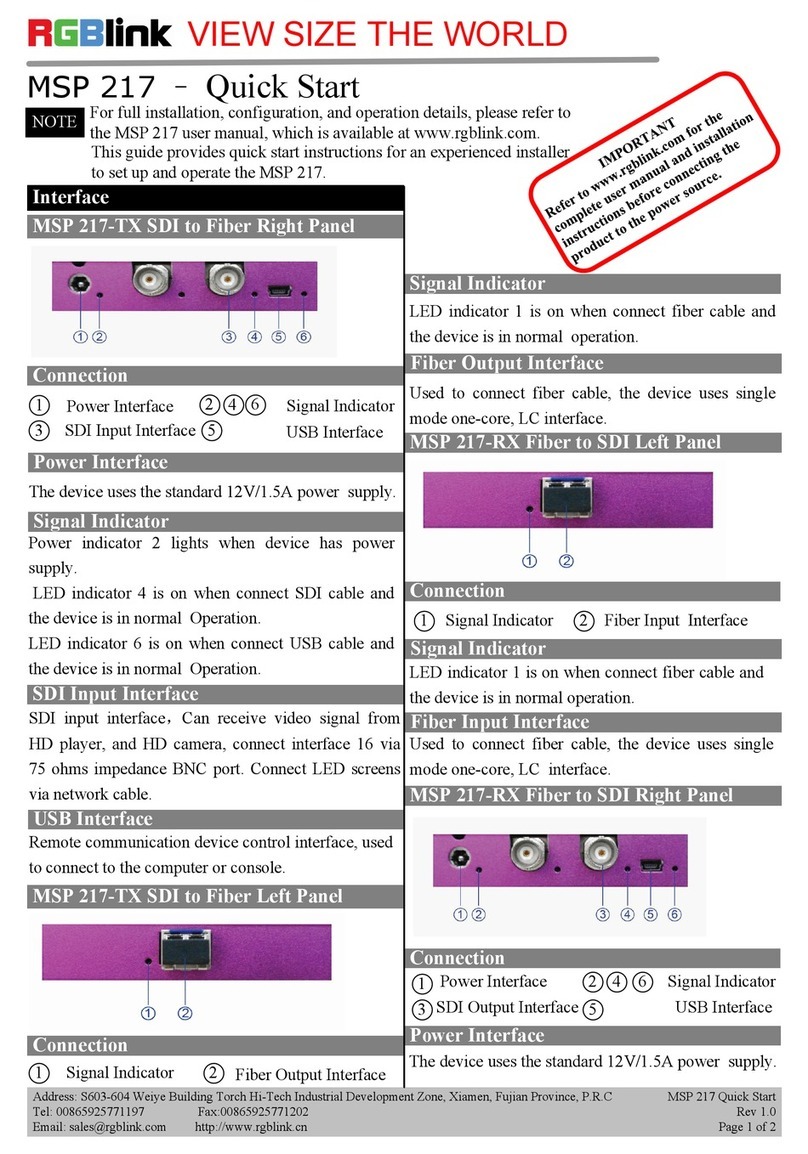

RGBlink

RGBlink MSP 217 Series quick start

TP-Link

TP-Link RE205 user guide

Network Technologies

Network Technologies XTENDEX ST-C5V-600 Installation and operation manual