RKR BMX Installation instructions

RKR is very different from other mini bike brands on the market; It was

designed by riders, for riders and is the product of many years experience

in the BMX industry. This means it’s tough, VERY tough and it works.

A large number of our colourways are created by fans of RKR, making

RKR truly owned by the people who ride it. Everyone has the

opportunity to be involved, so please go to our social media for more

information. Don’t forget to subscribe!

Before you start to get to grips with assembling your new RKR BMX,

please take the time to read this instruction manual carefully. If you are

not proficient with tools and assembling bikes, we suggest you ask

someone who is, to give you a hand.

Tools required for basic assembly/checking

... and for choosing RKR BMX, you have

chosen wisely!

First up: the tools you need to assemble your RKR mini BMX.

• Knife/ scissors

• 5mm + 6mm Allen keys

• 15mm (irok+) or 19mm (R3+) ring/ open spanner

• Pump with Schrader attachment (normal BMX/ car valve)

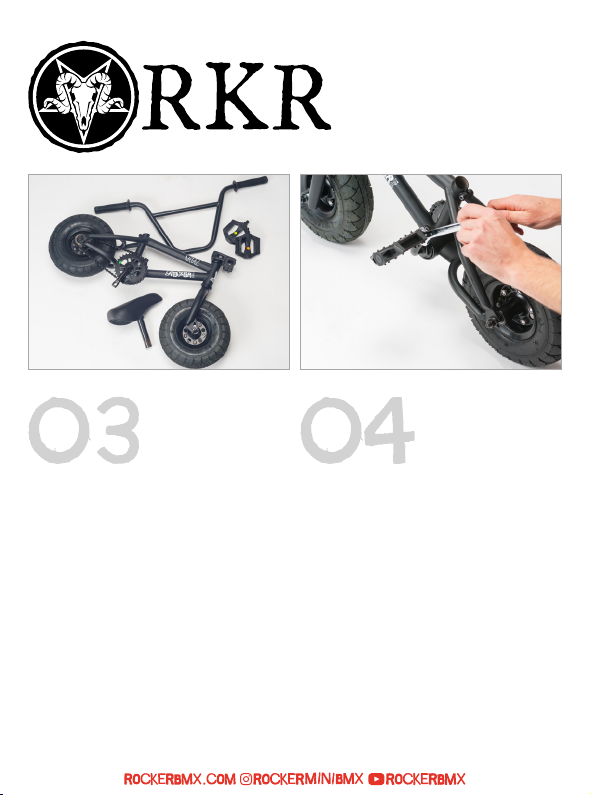

Carefully cut any straps from

around the box, pop open the

staples (WARNING! These staples

can be very sharp, take great care).

Open the box and lay out the con-

tents. It should look something like

the picture below.

Now carefully remove all foam,

card and plastic packaging using a

knife/scissors. Please be extremely

careful not to damage your new

paintwork. Once all packaging has

been removed, lay out the main

RKR assembly and loose

components and have a visual

check for any significant shipping

damage.

Please note: There may be minor scratches as a result of the courier’s heavy handedness, this is a

fact of mail order that sadly cannot be avoided. Therefore, please note we cannot replace bikes/parts as

a result of minor scratches. Touch up paint is available.

You should now have the main RKR

BMX assembly, some bars with pre

installed grips, a pair of pedals (one

stickered ‘L’, the other stickered ‘R’)

and a seat/post unit. If anything is

missing, now is the time to let us

know.

To make life easier, we are going

to install the pedals first. Thread

the left pedal (stickered ‘L’) into the

crank arm using the 15mm spanner.

Please note, to tighten a left (L)

pedal you must turn anti clockwise

NOT clockwise. Be careful not to

cross thread your crank arm or

pedal axle and make sure the pedal

is done up nice and tight. Running

loose pedals destroys threads very

quickly!

With the left pedal installed you can

now stand the bike up using the

pedal as a bike stand. This makes

the job a lot easier. Now install the

right hand pedal (marked ‘R’), this

time the pedal is turned clockwise

to tighten. Again be careful not to

cross thread the pedal and make

sure the pedal is done up nice and

tight.

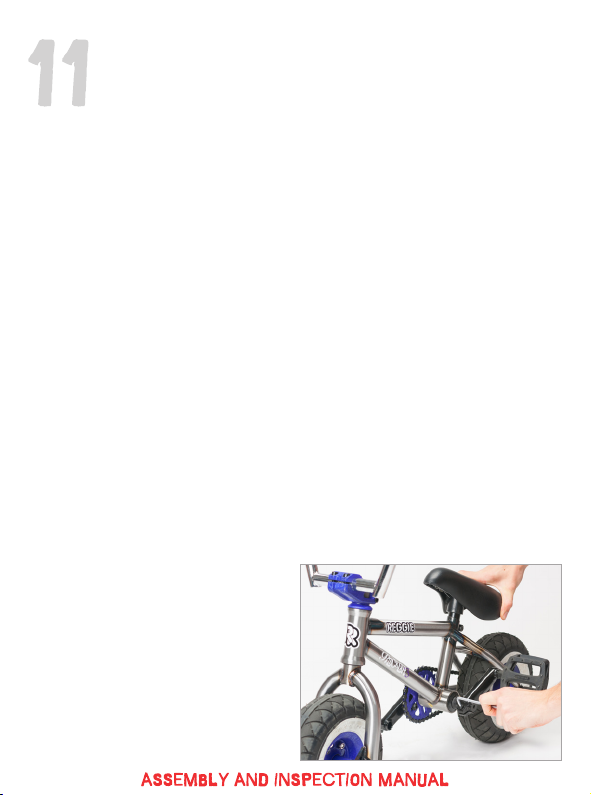

You can now pop the seat in, set to

your desired height & tighten with a

5mm Allen key.

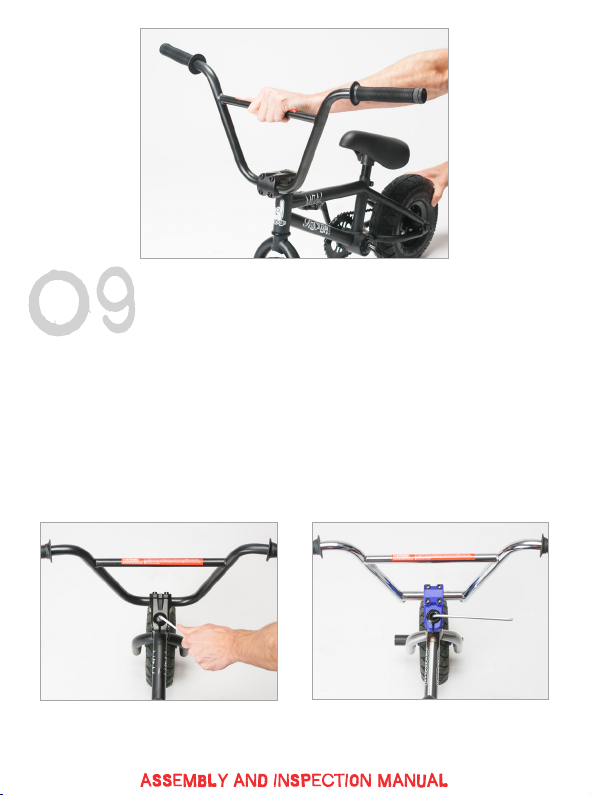

Now, carefully remove the stem

faceplate bolts (X4) with a 6mm

Allen key (their location is indicated

in the above image). If the bolts are

stiff to undo, try using a longer allen

key for more leverage. Ensuring

the correct orientation, hang the

handlebars in the stem bar recess

and carefully replace the stem face-

plate. Be very careful to ensure the

faceplate is tightened evenly and

there is an even gap at the top and

bottom of the faceplate.

Once the faceplate starts to bite

on the bars, spin them up into your

desired position and finally clamp

down the faceplate nice and tight.

Make sure you tighten the bolts in a

cross formation and that the gap at

the top and bottom of the faceplate

is equal to ensure even clamping.

If you find your bars move (later

when riding) you can try applying a

little grease to your faceplate bolts

(threads) which will allow you to

tighten them further still. If you do

apply more grease be sure not to

get any on the clamping area.

Check the front wheel alignment

and adjust as necessary (your stem

rear pinch bolts should still be loose

at this stage. If they are not, loosen

them, their location is indicated in

the above image). When you’re hap-

py that your front wheel is aligned,

nip up the rear bolts then grab your

bars and check for excessive play in

the headset bearings.

If there is excessive play, you can remove it by lightly tightening your

headset pre load bolt (stem pinch bolts MUST be loose during this

operation then re-tightened to check for headset play).

Irok+ and RKR 3+ pre-load bolts differ from each other. You will be able to

clearly see the hex for the Irok+ pre-load bolt after removing the dust cap.

The RKR 3+ features a hidden hex key for a smooth, clean look. This is

situated at the bottom of the recessed area of the pre-load bolt. You will

be able to reach it with a long 6mm Allen key.

Once any ‘rock’ has been dialled out from the headset, check your bars

turn freely left to right, then tighten your stem pinch bolts nice and tight.

irok+ R3+

If you have purchased an Irok+

Coaster or a RKR 3+/Reggie then

your bike has come fitted with a

free coaster. We suggest, for the

first few rides while you get used

too it, that you set the free-coaster

to the shortest engagement (la-

belled 1). This is done through the

access hole in the rear hub. If you

need further help please refer to the

instructional video on our website

and official youtube channel.

Irok+ models come fitted with a

freewheel from factory.

9t drive rear wheels are available

from our website.

Now check your bottom bracket/

crank assembly. If you have an

Irok+ model turn the cranks & look

at the locking nut and cone to make

sure they are not cross threaded.

If you find that they are please use

suitable tools to loosen, re-align

and then pre-load your crank

bearings. (This is very rare - please

call us if you require professional

assistance in such a case).

RKR 3+ models use a 3 piece crank

system with a sealed mid bottom

bracket (BB). Check the crank arm

pinch bolts on either side are tight.

Along with the crank axle bolts and

sprocket bolt on the reverse of the

right hand crank arm. If your cranks

become lose you can tighten them

by loosening the pinch bolts on the

crank arms and tightening the axle

bolts. (The pinch bolts on the crank

arm MUST be loosened before

tightening the axle bolts, otherwise

you will strip the thread from your

bolt and possibly the axle).

Irok+ models use a USA BB as

standard, we manufacture after

market 3 piece cranks and

conversion BB’s with fully sealed

cartridge bearings (USA to 19mm).

Please see our website for details

www.rockerbmx.com should you

wish to upgrade your cranks.

Whilst turning your cranks make

sure that the sprocket has been

installed correctly and runs straight

and true. Tight spots in your chain

will indicate incorrect centering of

your drive sprocket.

Check the rear wheel alignment

and correct as necessary using a

19mm (RKR 3+ and Irok+ coaster)

or 15mm spanner (Irok+) to loosen

the rear wheel nuts. Make sure

you re-tighten your rear wheel nuts

prior to riding your RKR BMX. At

the same time ensure you have the

correct chain tension. Irok+ models

use a freewheel and thus the chain

should NOT be as tight as it would

be on a normal BMX with a ‘driver’.

This will significantly slow down

your rear wheels free spin. Please

see photo, the chain should be

slightly loose but not flapping.

Once you are happy that everything

is aligned and the chain tension is

correct, fully tighten down all axle

nuts on the rear wheel.

Finally you are ready to test ride

your RKR BMX! Before you do so,

make sure your tyres are pumped

up to the desired pressure. Please

note standard RKR tyres have a max

pressure of 40psi. STREET PRO

tyres (found as standard on Rocker

3+ and Irok+ coaster

models) have a max pressure of

65psi. It is VERY important you DO

NOT exceed this pressure.

If you want to upgrade to STREET

PRO tyres at any time they are

available from www.rockerbmx.com

in a wide variety of colours.

If you need to repair a puncture at

any stage, please note that you will

need to split the rim to get the tyre

off. You cannot use tyre levers to

get the tyre off and if you do try to

do so, you may bend the steel rims.

Undo the 5 rim bolts and you will

see that the rim comes apart in

2 pieces with the hub assembly

welded to one side. You can now

replace/repair the inner tube

(available from www.rockerbmx.

com)

Upgrade parts & merch available:

stem, sprocket, bars, tyres, wheels

and a whole lot more!

Items included in your road kit (where supplied) :

• Chain Guard with fixings

• Front clear reflector

• Rear red reflector

• 4x pedal reflectors

• 4x rim reflector stickers

Installation Instructions for Additional Road Kit:

Install the chain guard using the fixings provided.

There are two clamps which need to be fixed onto the downtube and

chain stay. Ensure that there is clearance between the chain and the

chain guard and also the crank arm.

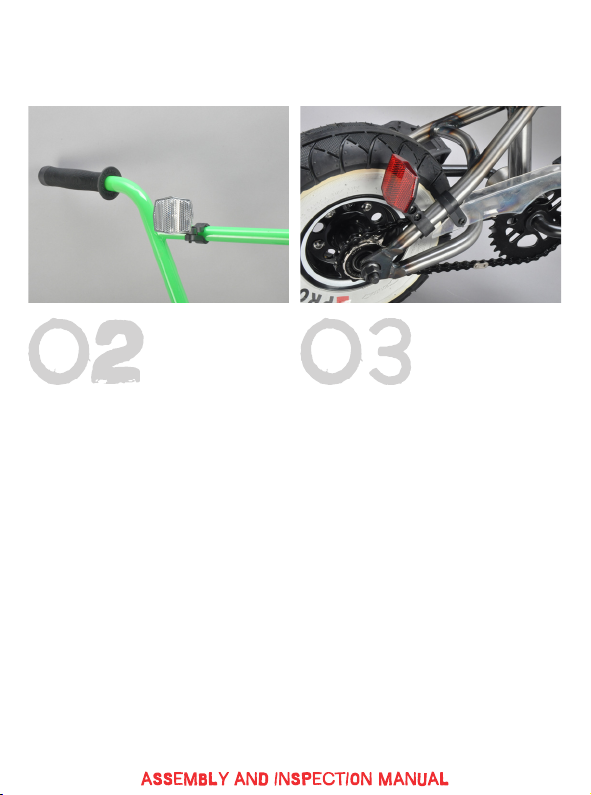

Fix front reflector on the crossbar

of the handlebars, and tighten until

secure.

Fix the rear reflector onto the seat

stay as shown in a suitable position.

Rotate the pedal gently with your

foot in your chosen riding posi-

tion and check it does not hit the

reflector.

Fix the 4 pedal reflectors to the

front a rear side of the pedals.

Press the reflector in firmly until it

clicks.

Apply the 4 reflective rim tape

stickers to each wheel on either

side.

Your road kit is now fully installed and your Rocker is ready to ride.

Thanks for reading this manual, now get riding/

learning some new tricks on your RKR!

Please tag us in any pics or video clips you may

post on instagram, we are always interested to

see what you have been up too and what you

have been learning!

Stomp Racing LTD

01730 720020

+44 1730 720020 (from outside UK)