ROBIN WOOD PYROMAX 22kW User manual

Index

General 3

Safety Instructions 4

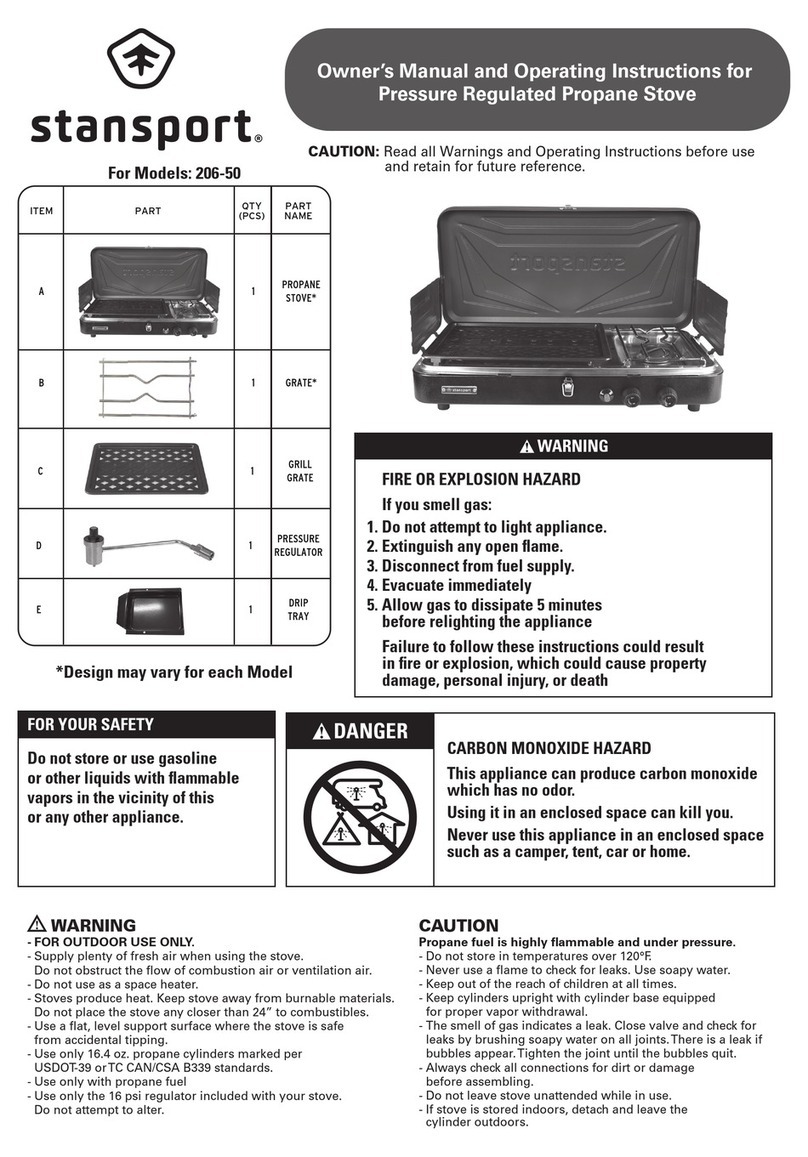

PYROMAX Image Gallery 7

Welcome to PYROMAX: Your Power and Flames Expert 8

Key Features 10

Technical Data 11

Dimensions 14

Overview of PYROMAX Wood Gasication Boiler Components 15

General Information on Using the PYROMAX Gasication Boiler 18

Positioning and Installation of the PYROMAX Gasication Boiler 19

Installation of the Combustion Fan 20

Connection to the Chimney 21

Combustion Air Inlet 23

Connection to the Central Heating System 23

Thermal Protection and Overheating Protection 26

Boiler Return Temperature Increase (Anti-condensation) 26

Ignition Method 27

Maintenance and Cleaning of the PYROMAX Gasication Boiler 29

Use and Functions 31

The following document has been translated from the original German language

3https://robinwood-gmbh.com

General

General Notes

This manual is intended for:

• ROBIN WOOD system partners

• End consumers

Here you will nd the necessary information for the correct operation, installation, and maintenance of the ROBIN WOOD

PYROMA gasication boiler.

The essential requirement for a safe and proper installation of the gasication boiler is the participation of the installing

company in a training course at ROBIN WOOD GmbH.

The initial commissioning and annual maintenance can only be performed by a ROBIN WOOD GmbH certied system

partner installer.

Note: If the initial commissioning and annual maintenance are not carried out, the warranty will be voided.

This manual contains all the information necessary for the proper operation and use of the system.

Please read the manual carefully. If you have any questions, please contact the competent sales partner.

Keep this manual safe so that it is available when needed.

To ensure smooth system operation, it is crucial to use clean and suitable fuel.

Make sure to use only dry and natural wood for maximum eciency.

Compliance with our instructions is also a condition for the factory warranty. No warranty is provided for damage caused by

the failure to follow the above-mentioned safety, usage, or maintenance instructions.

Our customer service is at your disposal for any questions at any time.

ROBIN WOOD GmbH, Überaucher Straße 9, 78052 Villingen-Schwennignen - +49 (0) 7705 9769692

[email protected] www.robinwood-gmbh.de

https://robinwood-gmbh.com

4

The safety instructions must be read before operating the appliance!

Failure to follow the safety instructions can result in personal injury, life-threatening situations, or damage to the

appliance. Strictly adhering to the instruction manual ensures customer safety and is an integral part of the warranty

conditions.

• Initial commissioning, setting, and maintenance must only be carried out by certied system partners of ROBIN WOOD GmbH!

• If the appliance is damaged, it should not be further operated.

• Work on live parts must only be performed by qualied electrical personnel.

• Installation must be carried out by a certied specialized company.

• The wood boiler requires the use of a heat accumulator (buer) with a capacity of at least 55 liters per kilowatt of boiler power

to function correctly.

• Safety devices must be checked at least once a year to ensure proper operation.

• There are rotating parts on the appliance driven by motors. These parts pose a “crushing” risk.

• Unauthorized modications to the appliance are prohibited as they can endanger people and cause damage to the appliance.

Non-compliance results in the loss of approval and warranty of the appliance.

• The accessory used must comply with technical regulations and be approved by the manufacturer for use with this appliance.

Only genuine spare parts should be used.

• Safety components must not be repaired or tampered with but should be replaced by authorized personnel.

• During work on the appliance, it must be disconnected from the power supply.

• Fire regulations of the relevant country (e.g., rewalls, etc.) must be adhered to.

• Air supply for combustion must be calculated in accordance with local ventilation system regulations and laws.

• Children, individuals with physical, sensory, or mental limitations, or those without experience/knowledge of appliance oper-

ation should not use it.

• The installation location and type of installation of the wood boiler must be selected in accordance with safety instructions.

The boiler must be installed away from ammable objects.

• Before each use of the appliance, carefully read the instruction manual. Improper installation can lead to hazardous situations

and/or incorrect boiler operation.

• Do not clean the boiler with water. Water can penetrate the boiler, damage electronics, and cause an electric shock.

• The user is responsible for the correct use of the product. In case of improper use, incorrect behavior, or omissions by the

user, the company disclaims all liability.

• Unauthorized intervention or replacement by unauthorized individuals or the use of non-original spare parts can cause per-

sonal injury and void the company’s liability.

• Almost all surfaces of the wood boiler become very hot (door handle, glass, smoke exhaust pipe, etc.). Avoid direct contact

with these surfaces. Always wear heat-resistant gloves and use suitable, heat-resistant tools.

• Under no circumstances should you light a re with the door open or with broken glass.

• The product must be connected to an electrical system with eective grounding.

• In case of a malfunction or malfunction, turn o the wood boiler.

• During product installation, all re regulations must be observed.

• Properly respond in the event of a chimney re:

Immediately notify the re department at the emergency number 999. Close the boiler doors and remove all ammable

objects at an adequate distance. Under no circumstances attempt to extinguish the re on your own.

• Regularly inspect and clean the smoke exhaust ducts of the wood boiler (connection to the smoke exhaust pipe).

• Never use the wood boiler for cooking.

• Always keep the doors closed.

!!! Safety Instructions - WARNING !!!

5https://robinwood-gmbh.com

Behavior After a Power Interruption

After a power interruption, the PYROMAX gasication boiler will automatically attempt to restart and optimize combustion.

Follow these steps to get the boiler back into operation:

(a) Wait for an appropriate period after power is restored to ensure that the electrical supply is stable..

(b) Keep the loading door closed as instructed and monitor the display along with the restart of the combustion exhaust fan.

If there is enough ember in the loading chamber, the boiler will try to stabilize combustion and return to normal mode.

(c) If the embers have gone out (during a prolonged power interruption), clean the loading chamber before restarting following

the instructions, which also apply to the initial commissioning.

WARNING: During a power interruption, the fuel may continue to burn, which could lead to high concentrations of carbon

monoxide in the exhaust gases. There may be a risk of explosion!

Behavior in Case of Chimney Fire:

Call the emergency number 999!

Keep the boiler doors closed and remove all ammable objects from the boiler. Under no circumstances attempt to extinguish

the re on your own!

Important Warning Regarding Heating System Modications:

It is strictly prohibited to make changes to the heating system or make modications independently.

This is for your personal safety and to ensure the proper operation of the gasication boiler

https://robinwood-gmbh.com

8

Welcome to PYROMAX: Your Power and Flames Expert

Excellence and Low Emissions Experience

Thanks to our high-temperature combustion chamber, we oer you an excep-

tional heating experience characterized by high performance and reduced emis-

sions. You can enjoy eco-friendly and ecient combustion, contributing to envi-

ronmental preservation.

Generous Loading Space

Our Pyromax oers ample loading space, allowing you to burn logs up to half a

meter long. This means longer relling intervals and greater convenience for you.

Automatic and Programmable Ignition

Fire ignition has never been easier. Our Pyromax features an automatic ignition

system programmable through an integrated timer or a temperature sensor. This

makes starting the re a breeze, allowing you to relax while your Pyromax takes

care of everything.

Intelligent Combustion Control

Our advanced combustion control ensures unparalleled combustion quality.

Numerous hydraulic functions, such as temperature dierence control and tank

management, ensure ecient and optimized performance.

Precise Primary Air Control

With our convenient manual regulator, you have precise control over the primary

air. It‘s in your hands to ensure optimal combustion.

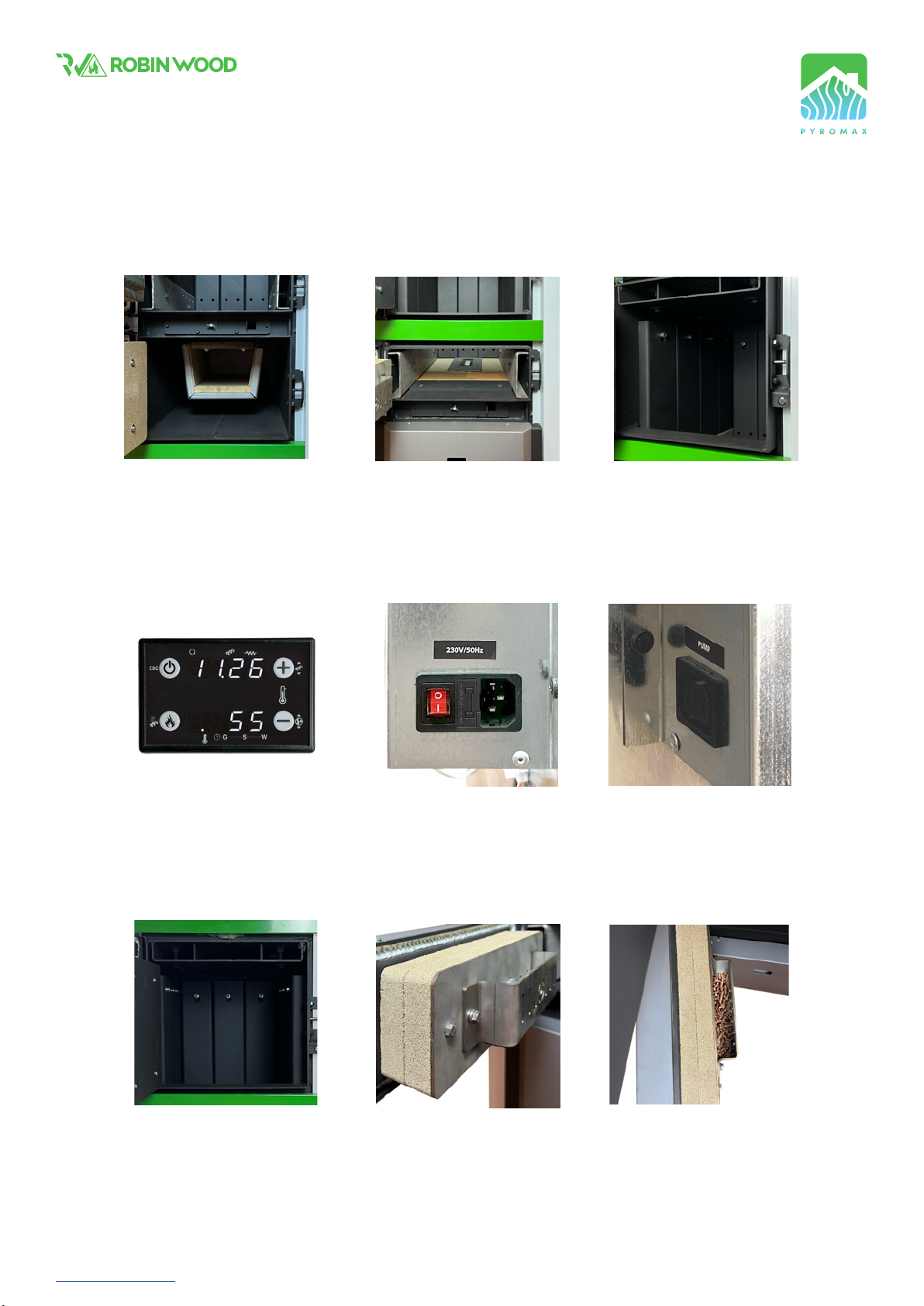

Protection and Eciency

Our attachable ame arrestors not only protect the inside of the boiler but also

ensure logs ow correctly, eliminating concerns about possible interruptions.

Safety During Relling

The aspiration of pyrolysis gases during log reloading prevents the release of

harmful fumes, ensuring maximum comfort and safety.

Precise Draught Control

Our variable-speed draught fan oers precise draught control, allowing you to

create the ideal combustion environment to maximize eciency.

Maximum Eciency with Turbulator Technology

Our innovative turbulator technology further increases eciency, allowing you to

get the most out of your re.

High-Quality Thermal Insulation

Our Pyromax features high-quality thermal insulation that minimizes heat loss,

ensuring optimal utilization of produced heat and ecient heating.

Easy and Quick to Clean

Cleaning our Pyromax is a simple and fast operation, allowing you to fully focus

on the re experience. We oer convenient cleaning options to make mainte-

nance a breeze.

9https://robinwood-gmbh.com

Discover the perfect synergy between performance, comfort, and eciency: PYROMAX.

Your dependable companion for an unparalleled re experience

The high-temperature combus-

tion chamber ensures excep-

tional performance and mini-

mal emissions.

Thanks to air preheating, Py-

romax provides high-eciency,

eco-friendly combustion.

The generous loading space

comes with attachable aprons.

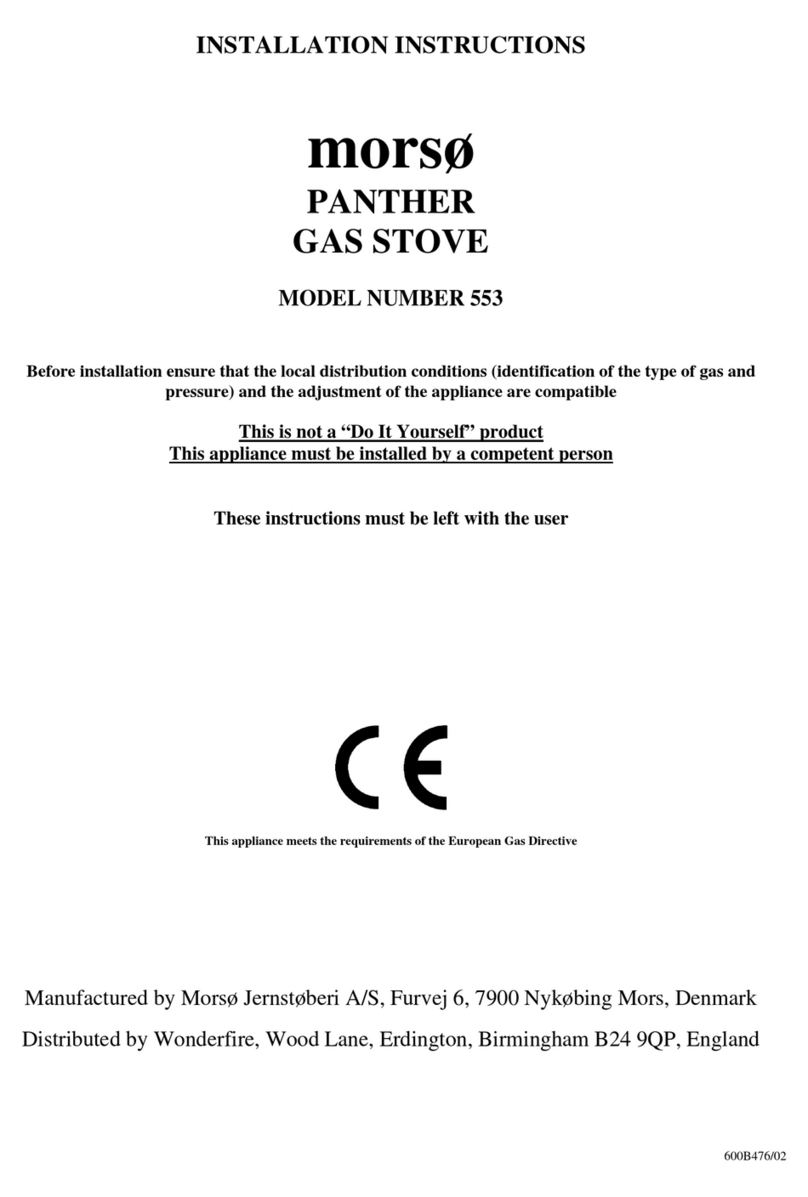

Our advanced combustion controller ensures exceptional combustion quality through precise monitoring and control of com-

bustion processes. It optimally regulates air intake and minimizes harmful emissions. Additionally, the controller comes with a

standard power plug and an integrated fuse for easy installation and enhanced safety. Pump connection is pre-installed, simpli-

fying integration into the heating system.

The spacious loading space of the Pyromax allows for the combustion of half-meter logs, ensuring longer relling intervals. You

can prepare the re by lling the combustion chamber and loading the ignition basket with pellets. The combustion can be initi-

ated and controlled through a timer or the buer temperature.

https://robinwood-gmbh.com

10

Thanks to the convenient manual control lever of the Pyromax, you have complete and precise control over the primary air in-

take. Pyrolysis gas suction technology prevents any smoke leakage during log reloading. The variable-speed fan ensures precise

draught control, allowing you to create the ideal combustion environment. This way, you can enjoy exceptional comfort and total

safety without compromises.

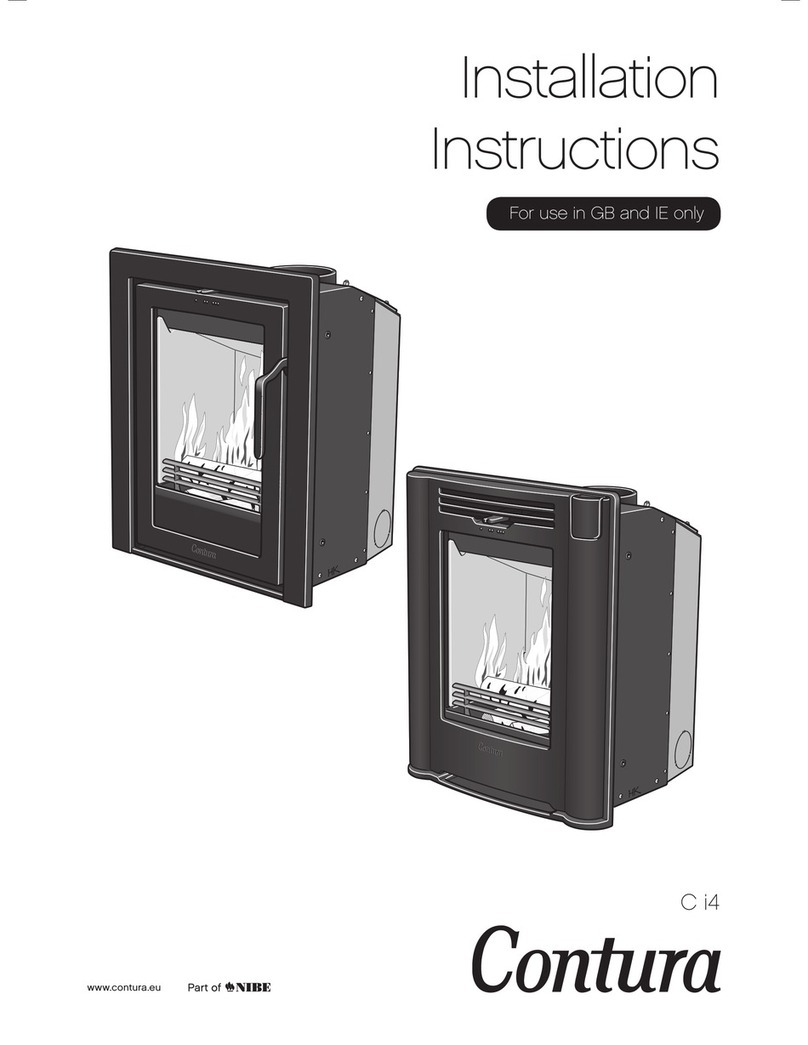

Thanks to the innovative turbulator technology, you achieve clean and ecient combustion with maximum eciency. This technol-

ogy also simplies the cleaning of Pyromax‘s heat exchangers. Turbulators also help reduce soot buildup and deposits in the heat

exchanger tubes, making appliance cleaning and maintenance easier. Make the most of your re, enjoying eco-friendly heating,

and benet from easy-to-use heat exchanger cleaning.

11 https://robinwood-gmbh.com

The main features

1

2

4

6

7

3

5

89

Intelligent combustion control for excellent combustion and numerous hydraulic functions such as temperature dierence

adjustment and buer loading.

10

11

12

3

5

8

1

2

4

6

7

9

10

11

12

High-temperature combustion chamber for exceptional performance and minimal emissions.

Programmed automatic ignition via the integrated timer or temperature sensor.

Generous loading space for wood logs up to half a meter (50 cm) long.

High-quality thermal insulation to minimize radiant heat losses.

Innovative turbulator technology for optimized eciency enhancement.

Attachable aprons for protecting the interior of the boiler and ensuring safe wood log placement

The aspiration of pyrolysis gases prevents smoke from escaping during wood log reloading.

Convenient manual control knob for precise adjustment of primary air.

Variable-speed draught fan for precise draught control.

Reliable ignition with a high-quality ceramic ignition element and pellets.

Easy and convenient cleaning options.

https://robinwood-gmbh.com

12

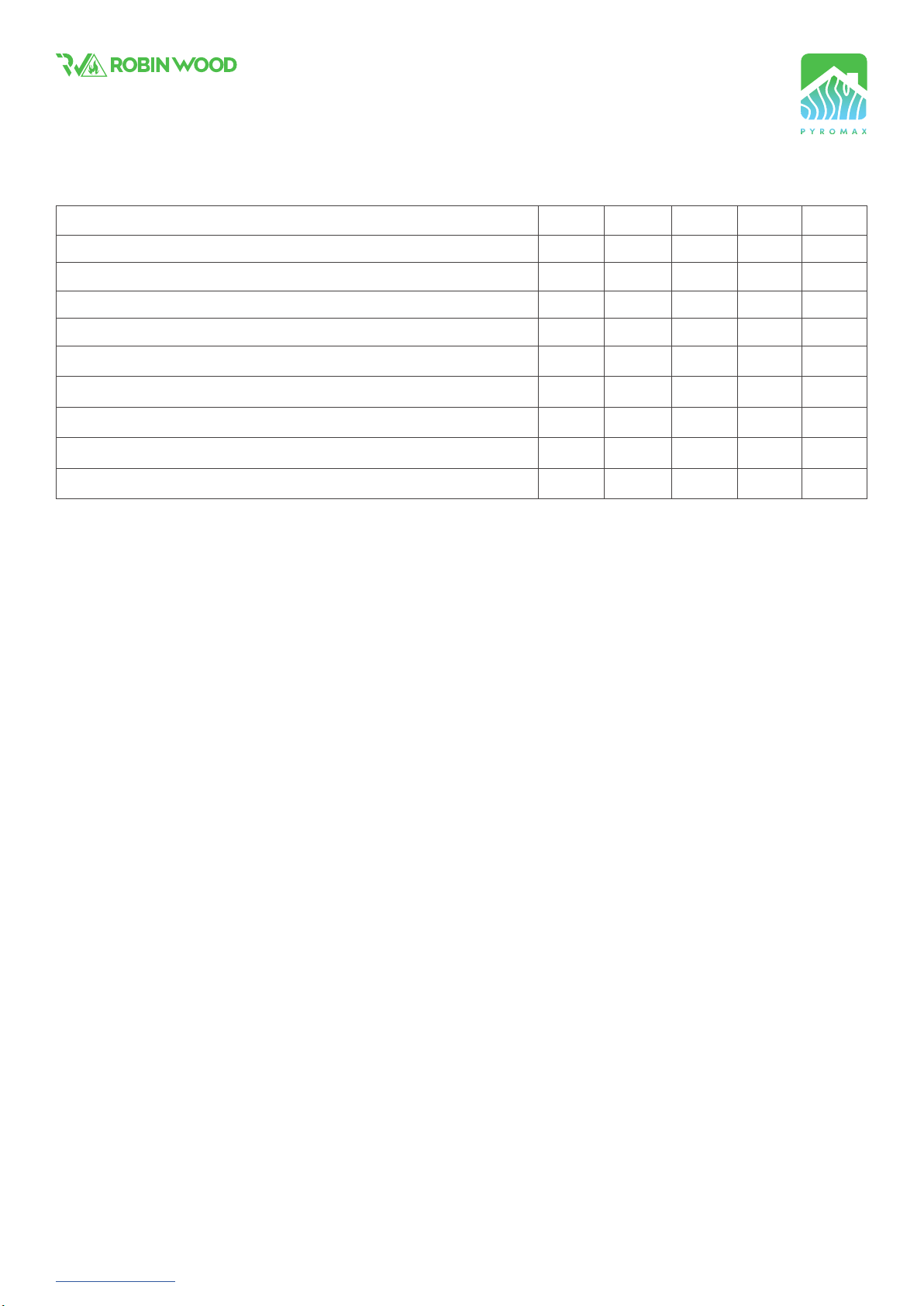

Technical data

ROBIN WOOD PYROMAX 22 32 40 49

Nominal thermal power kW 22 32 40 49

Range of thermal power kW 11-22 16-32 20-40 25-49

Boiler class EN 303-5:2021 5

Minimum draft required in the chimney at nominal power Pa 14 18 18 21

Minimum draft required in the chimney at reduced power Pa 10 12 12 10

Quantity of water in the boiler Liter 120 130 140 150

Exhaust gas temperature at nominal thermal power °C 165 160 150 150

Exhaust gas temperature at minimum heating power °C 100 100 100 95

Minimum operating time at nominal power (nominal power-Q) hours 3 3 3 3

Minimum supply temperature (return temperature) °C 60

Maximum water temperature °C 90

Type of fuel

Natural split rewood, with a residual

moisture content <20%,

compliant with standard 14964-5.

Fuel moisture content % max 20 %

Length of rewood mm 500 500 500 500

Combustion chamber volume Liter 103 103 103 136

Type of combustion chamber sealed chamber

Minimum required buer tank volume according to EN 303-5:2021

Supply voltage V 230

Frequency Hz 50

Weight kg 424 449 479 526

Maximum operating pressure bar 3

Outer diameter of the combustion gas pipe mm 149

Heating appliance operation kW with draft fan

Boiler energy eciency class A+

Energy eciency index (EEI) 111 111 113 112

Annual eciency for space heating ⴄs % 80 80 80 80

Eciency at nominal thermal power % 92 92 93 92

Eciency at reduced power % 95 95 95 95

CO₂ emissions at nominal thermal power % 13,71 13,71 14,44 14,61

CO₂ emissions at reduced power % 14 14,39 10,83 14,54

CO emissions at nominal thermal power (13% / O2) mg/Nm³ 94,95 110,71 101,96 297,90

CO emissions at reduced power (13% / O2) mg/Nm³ 106,63 378,61 128,65 118,29

13 https://robinwood-gmbh.com

NOx at nominal thermal power (13% / O2) mg/Nm³ 136,24 131,91 139,75 135,83

NOx at reduced power (13% / O2) mg/Nm³ 126,89 79,60 136,28 109,93

OGC (Organic Gaseous Compounds) at nominal thermal power (13% / O2) mg/Nm³ 8,31 1,67 2,23 7,25

OGC (Organic Gaseous Compounds) at reduced power (13% / O2) mg/Nm³ 7,64 5,57 5,41 2,65

Particulate matter at nominal thermal power (13% / O2) mg/Nm³ 7,39 7,24 3,94 8,02

Particulate matter at reduced power (13% / O2) mg/Nm³ 9,37 4,76 6,41 12,25

Mass ow rate of exhaust gases at nominal thermal power g/s 26,04 35,77 15,57 63,49

Mass ow rate of exhaust gases at reduced power g/s 13,37 35,21 8,23 27,79

Velocity of exhaust gases at nominal thermal power m/s 1,79 1,62 2,54 1,84

Velocity of exhaust gases at minimum power m/s 1,88 1,71 1,94 1,88

Technical data

https://robinwood-gmbh.com

14

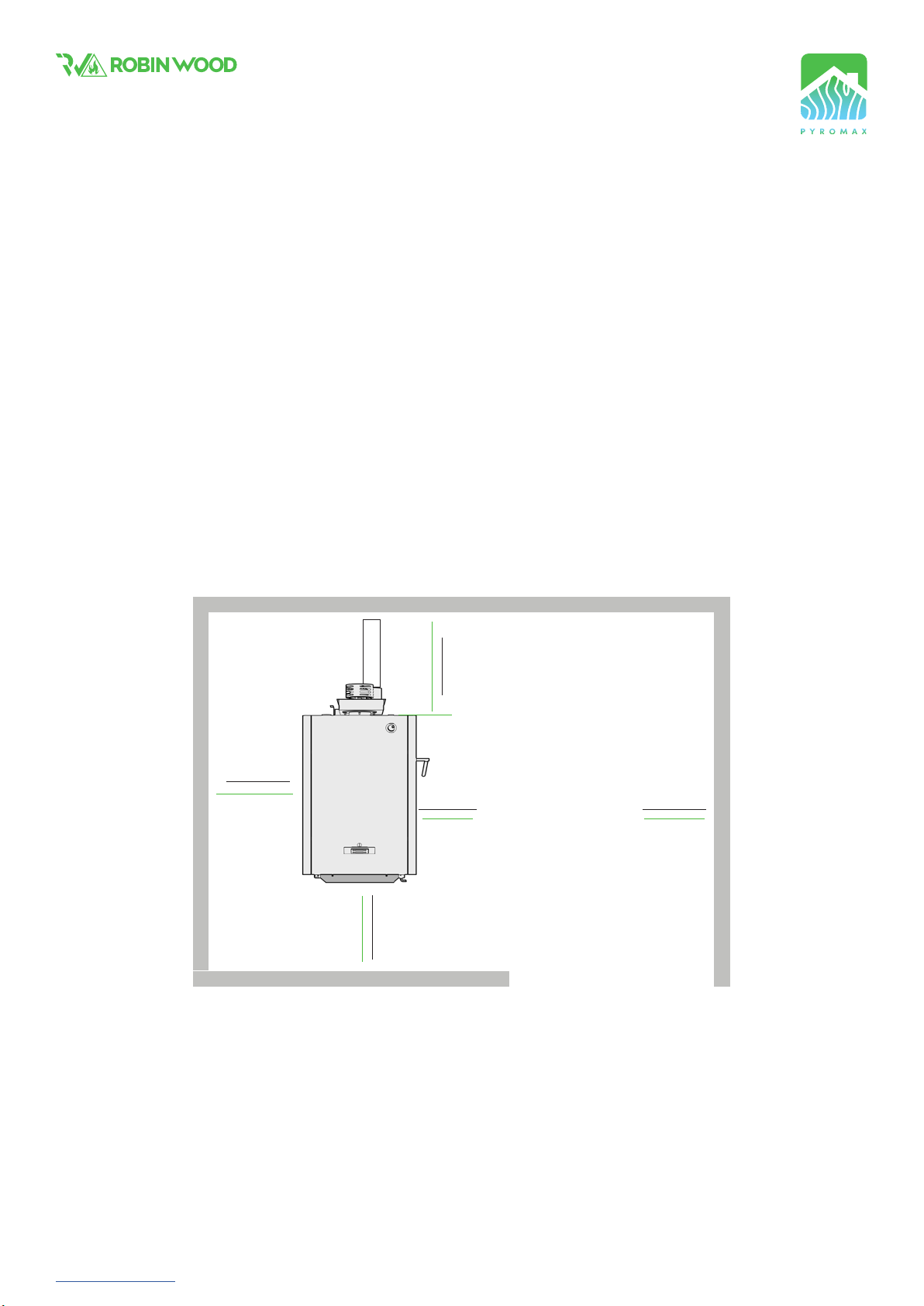

A

(mm)

A1

(mm)

B

(mm)

B1

(mm)

C

(mm)

C1

(mm)

D

(mm)

E1

(mm)

E2

(mm)

E3

(mm)

E4

(mm)

E5

(mm)

E6

(mm)

22 1135 1016 663 590 1387 1280 Ø 149 1180 480 165 943 210 1174

32 1185 1066 663 590 1387 1280 Ø 149 1180 480 165 943 210 1174

40 1255 1136 663 590 1387 1280 Ø 149 1180 480 165 943 210 1174

50 1255 1136 663 590 1537 1430 Ø 149 1330 630 165 1093 210 1324

Dimensions

15 https://robinwood-gmbh.com

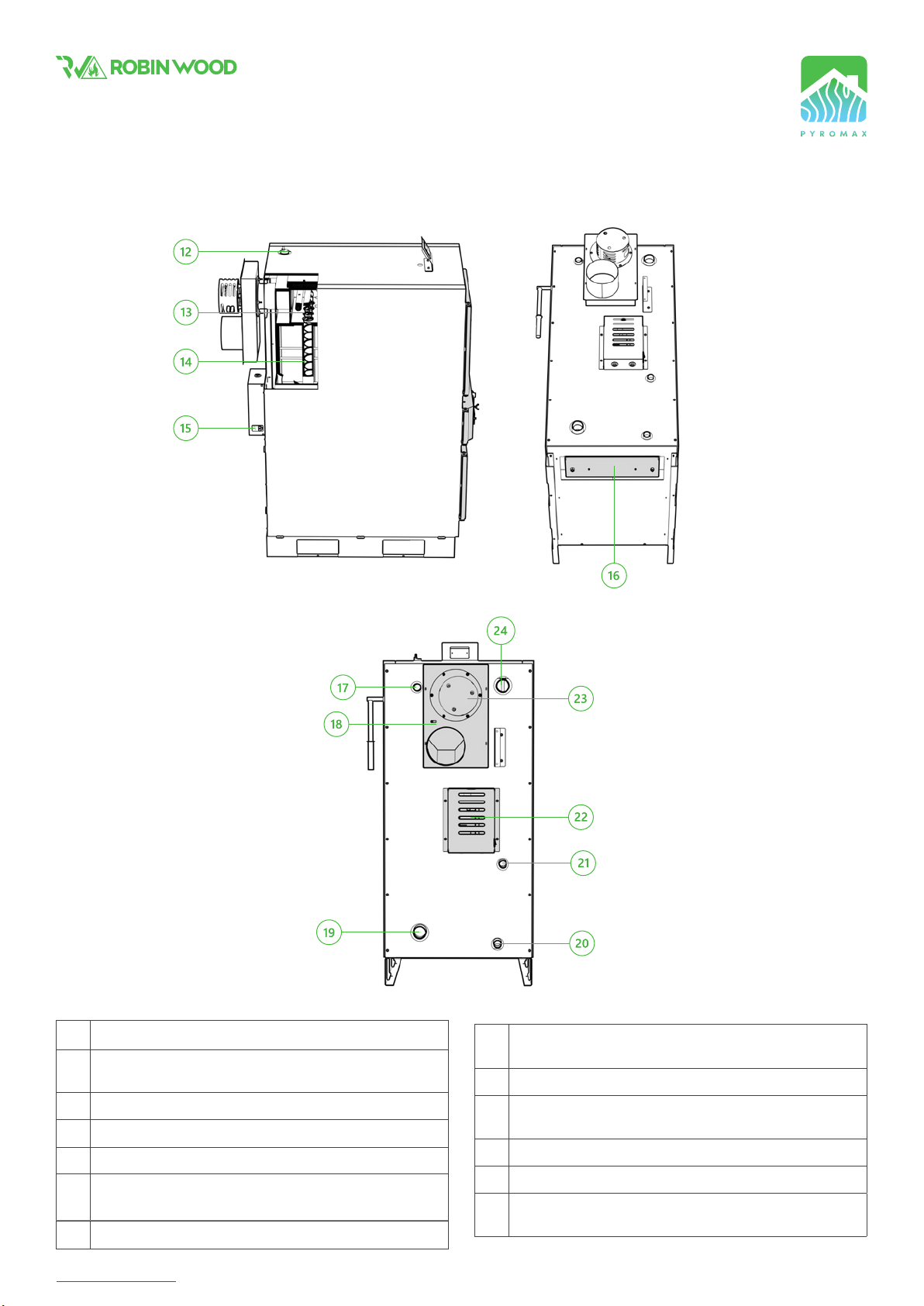

1Boiler digital display

2Flue gas pipe cleaning lever

3Door handle

4Upper boiler door

5Middle boiler door

6Lower boiler door

7Primary air slider

8Fastening screw for secondary air slider

9Secondary air slider

10 Cleaning tool

11 Electrical connection for pump (return)

31 Buer sensor connection

Overview of PYROMAX Wood Gasication Boiler Components

3

https://robinwood-gmbh.com

16

12 Vent

13 Cleaning mechanism for ue gas pipes (heat exchangers)

14 Turbulators

15 On/O switch

16 Lower maintenance door

17 Connection of the capillary tube of the TAS

(Thermal safety discharge device)

21 TAS - Thermal Safety Discharge Device

(Connected to the heating water inlet)

22 LCG Electronic Control Plate

23 Draught Fan

24 Heating water inlet

(Connected to the return temperature increase)

19 Heating water inlet

(Return temperature increase)

20 Drainage

18 Flue Gas Temperature Sensor

Overview of PYROMAX Wood Gasication Boiler Components

https://robinwood-gmbh.com

18

1. General Information on the Use of the PYROMAX Wood Gasication Boiler

The PYROMAX wood gasication boiler is a high-performance heating solution designed for ecient wood combustion. With

rated thermal outputs of 22, 32, 40, and 49 kW, it is ideal for heating small to medium-sized homes. This boiler is based on the

principle of wood gasication, also known as pyrolysis, which allows for the complete and environmentally friendly burning of

wood.

Key Features:

Ecient Wood Gasication: Thanks to pyrolysis technology, wood is fully burned in a large combustion chamber, achieving

optimal energy yield.

Long Combustion Duration: A single load of 50 cm rewood allows for at least 3 hours of burning. If needed, combustion can

be automatically adjusted throughout the day to meet heating requirements..

Automatic Regulation: Combustion is controlled by an integrated regulation system that ensures precise and ecient burning.

Storage Requirement: The PYROMAX boiler must be connected to a storage tank with a capacity of at least 55 liters per kilo-

watt of boiler power to ensure optimal heat distribution.

Compliance with Standards: The boiler complies with the requirements of EN 303-5 and features excellent gasication, result-

ing in minimal environmental impact.

Natural Wood Combustion: The boiler is specically designed for the combustion of natural wood and employs a system for

guiding exhaust gases and additional combustion of smoke gases to achieve high eciency.

User-Friendly: The PYROMAX boiler is designed with the user in mind and features a reliable built-in control system that en-

sures smooth operation.

Flexibility in Ignition: After loading the wood gasier, ignition can be programmed for any time of the day using a built-in

timer or the sensor in the storage tank.

The PYROMAX wood gasication boiler represents a reliable and cost-eective heating choice for those who want to heat their

homes in an environmentally friendly way. Thanks to its ecient wood gasication technology and automatic control, it oers a

convenient and sustainable method for heating your home.

19 https://robinwood-gmbh.com

min. 100 cm

min. 100 cmmin. 70 cm

min. 50 cm

min. 150 cm

Minimum Distance from Room Walls

2. Positioning and Installation of the PYROMAX Wood Gasication Boiler

The installation of the PYROMAX wood gasication boiler requires the expert knowledge of an authorized technician. It is

strongly recommended to place the boiler on a stable concrete base with a height of 50-100 mm. The boiler room must be

adequately protected from freezing and should have sucient ventilation. The arrangement of the boiler should ensure both

chimney connection and accessibility for maintenance, cleaning, and servicing operations.

Connecting the boiler to the central heating system requires the use of one or more storage tanks, depending on the boiler’s

power. It is recommended to connect a minimum water quantity of 55 liters per kW of rated power. For example, for a 40 kW

boiler, a minimum volume of 2200 liters is recommended. It is essential to note that the boiler should never be used without a

storage tank.

The connection between the boiler and the storage tank must be made exclusively through a three-way return valve, which

maintains the return temperature at a value above 60°C. This ensures the proper operation of the system and contributes to

the eciency of the heating process.

https://robinwood-gmbh.com

20

2.1 Installation of the Combustion Air Intake Fan

Installation of the combustion air intake fan

1. Place the combustion air intake fan on the designated connection points on the boiler.

2. Secure the fan with the provided threaded screws.

3. Use the 4 nuts (M8) provided with the boiler mounting kit to rmly attach the fan.

4. Tighten the nuts evenly to ensure a stable installation.

5. Verify that the combustion air intake fan is securely fastened and has no play.

6. Ensure that all tools have been removed, and the mounting area is clean.

7. If necessary, refer to the manufacturer’s instructions and follow safety precautions.

This manual suits for next models

3

Table of contents

Popular Stove manuals by other brands

Ecowood

Ecowood TROLLEY Installation, User’s and Maintenance Handbook

Blaze King

Blaze King ASHFORD 30 .1 Operation & installation manual

Kingsman

Kingsman FDV200N installation instructions

Avalon

Avalon Rainier 945 owner's manual

Napoleon

Napoleon GDS60-1N Installation and operation manual

Reading Stove Company

Reading Stove Company MAHANTONGO CS-45 owner's manual

Dometic

Dometic ORIGO 2000 operating manual

ACR Electronics

ACR Electronics The Buxton BX1MF Technical manual

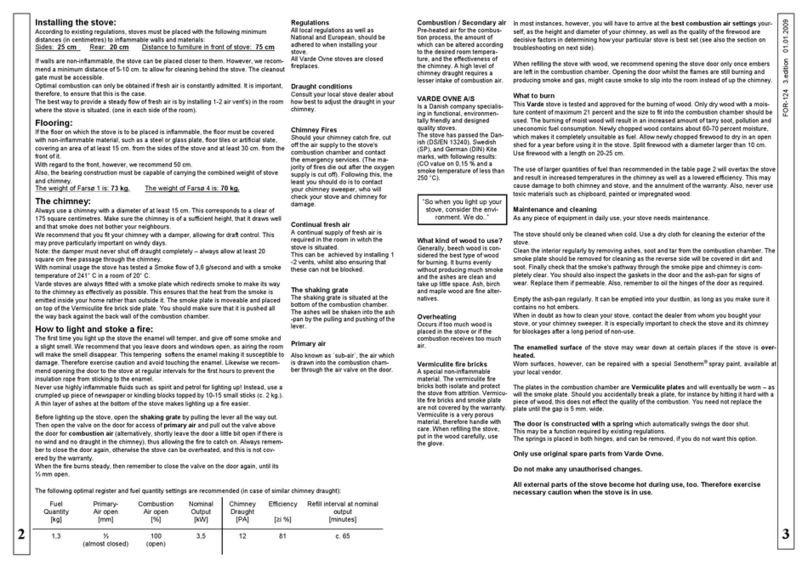

VARDE OVNE

VARDE OVNE Farso 1 quick guide

Dovre

Dovre 325MF Installation instructions and operating manual

KEKAI

KEKAI NOVA SLIM instruction manual

Lennox Hearth Products

Lennox Hearth Products BELLA Installation and operation manual