GB

84

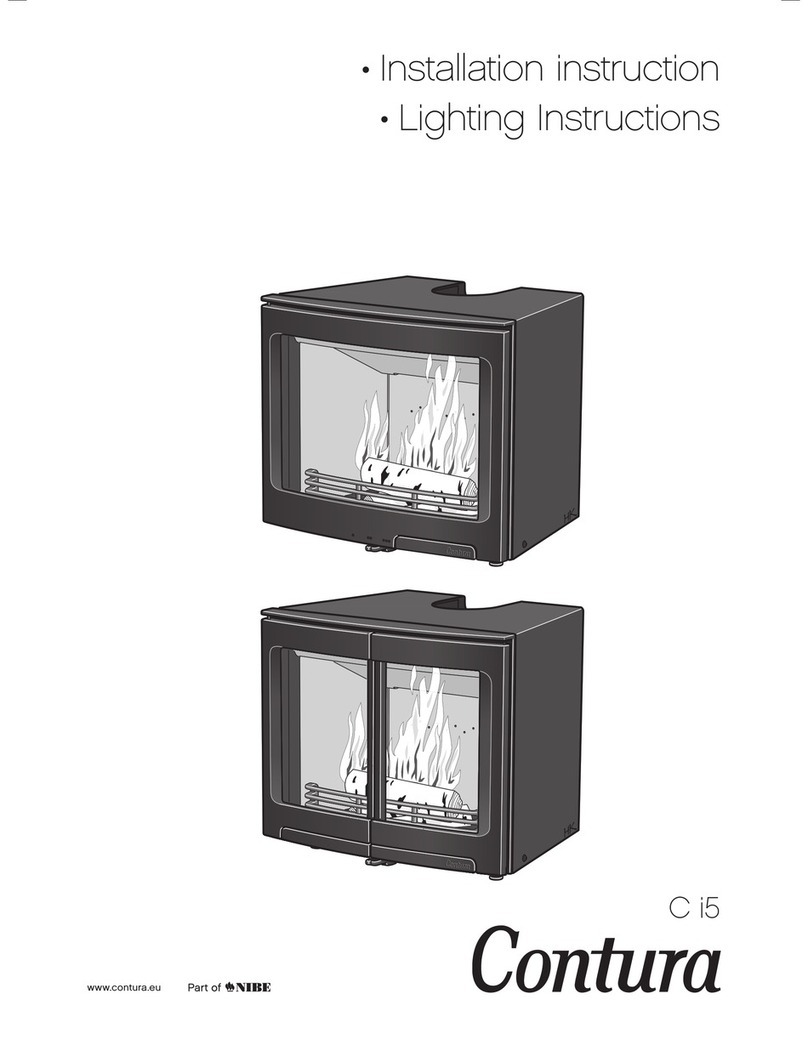

Handle

(removable on modern)

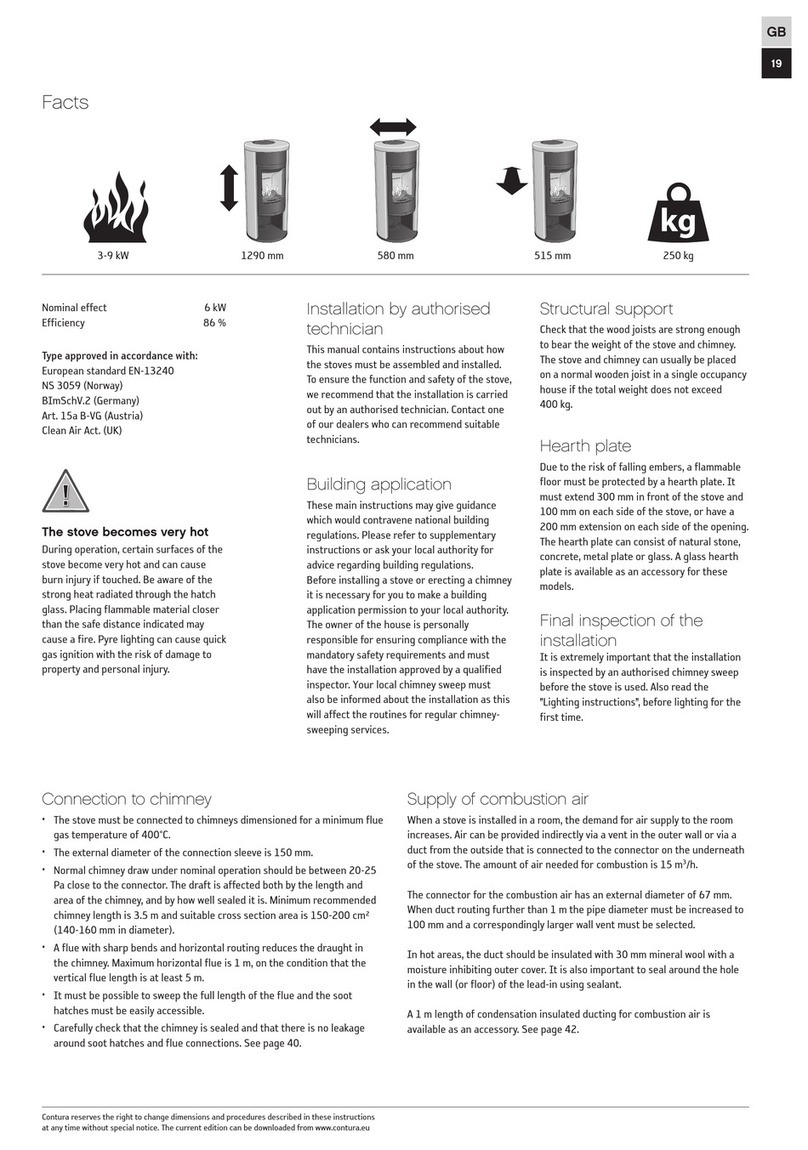

FACTS

Building application

Before installing a stove or erecting a

chimney it is necessary for you to apply

for planning permission from your local

authority. Ask your local authority for

advice regarding building regulations and

the application.

Technical data

Output 3-5 kW

Nominal output 4 kW

Efficiency level Up to 78%

Model Classic

Weight (kg) 77

Width (mm) 490

Depth (mm) 420

Height (mm) 600

Model Modern-3-sided frame

Weight (kg) 71

Width (mm) 490

Depth (mm) 380

Height (mm) 590

Model Modern-4-sided frame

Weight (kg) 72

Width (mm) 490

Depth (mm) 380

Height (mm) 635

The connector’s inner diameter is Ø126 mm

Type approved in accordance with:

European standard EN-13 229

(DE/A) DINplus, Art. 15a B-VG

RRF-29 11 2751

DEFRA exempted

The stove can be used in Smoke Control

Areas.

Fire-box insulation panels

Convection box

Grate

Ash-pan

Log guard

Type plate

Primary air

inlet control

Secondary air

inlet control

WOOD COAL

Chimney

Note! The stove installation and connection

to a chimney must be accomplished with

the current edition of Building Regulations.

We recommend that you consult a local

chimney sweep before the installation

to make sure that the chimney is in good

condition.

The stove is type approved and must be

connected to a chimney dimensioned

for at least 350°C. The connector on

the appliance is suitable for pipes with

diameter of 125 mm.

A flexible flue liner or steel flue

certified for use with solid fuel is highly

recommended. The stove requires a

draught in the chimney of at least –12

Pa. The draught is affected both by the

length and area of the chimney, and by how

well sealed it is. Minimum recommended

chimney length is 3.5 m and a suitable

cross section area is 120-175 cm² (125-

150 mm in diameter). Carefully check that

the chimney is sealed and that there is

no leakage around soot hatches and flue

connections.

Note that a flue with sharp bends and

horizontal routing reduces the draught in

the chimney. Maximum horizontal flue is 1

m, on the condition that the vertical flue

length is at least 5 m. It must be possible

to sweep the full length of the flue and the

soot hatches must be easily accessible.

General

In this manual you will find instructions

about how your Contura i4 shall be

installed. Before you start the installation

it is important that you read this

instruction carefully and fully understand

the requirements. All European, national

and local standards and regulations needs

to be fulfilled when the appliance are

installed.

To guarantee the function and safety of

the stove we recommend that it is installed

by a professional. Our Contura agents can

recommend a suitable installer.

The room or space containing a stove shall

have a permanent air supply sufficent to

ensure proper combustion, to determine

correct amount of air supply use current

edition of Building Regulations.

Remember to use only for the appliance

recommended fuel as wood logs

or smokeless fuel as anthracite or

manufactured smokeless fuel briquettes.

Do not ever burn bituminous coal, “petro-

coke” or other petroleum based fuels!