8ft Wide Polytunnel Assembly Instructions

Copyright © Robinson Polytunnels 2014 - 2018 4

2. FOUNDATION TUBES: Option B –Ground Anchor Plates

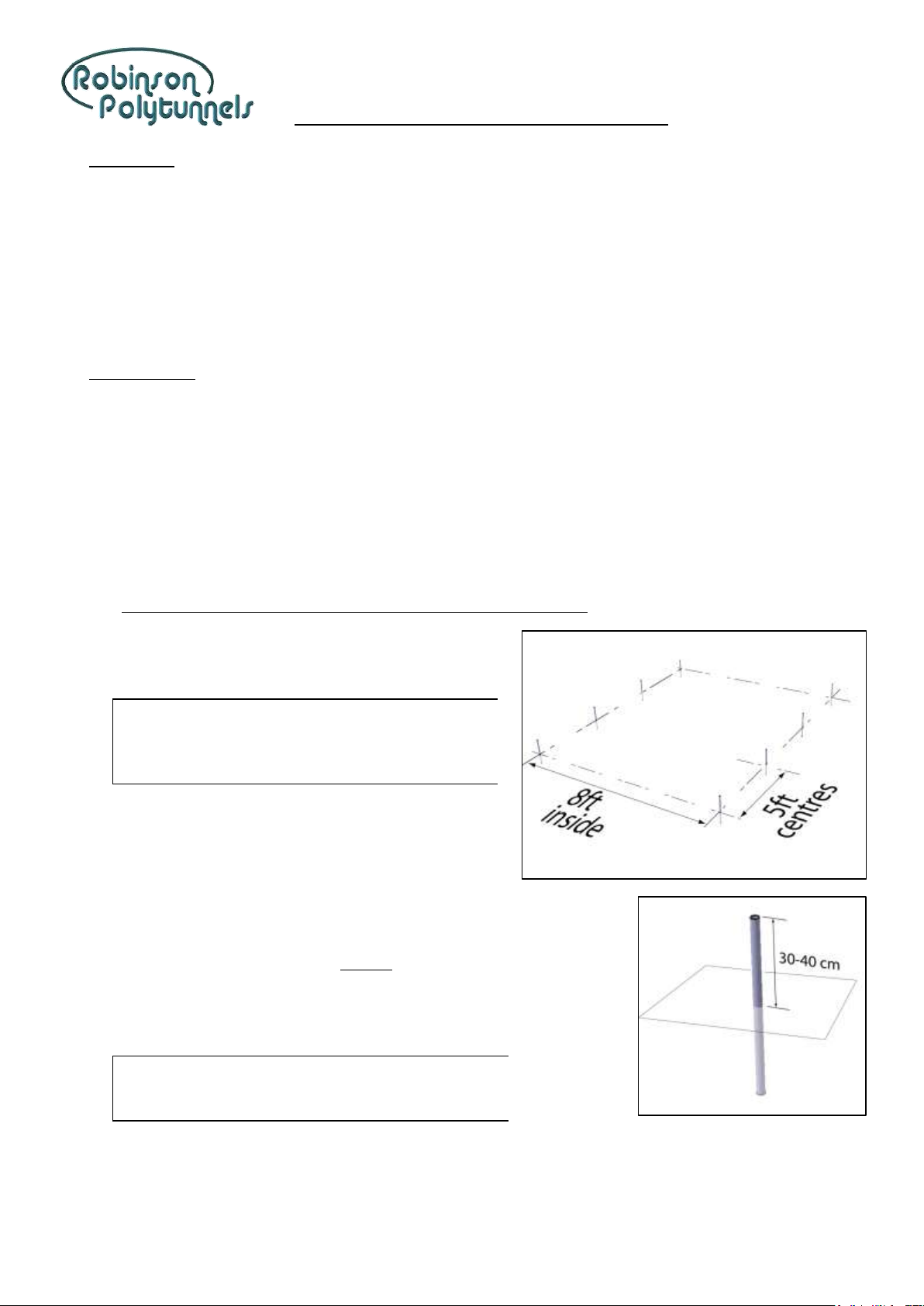

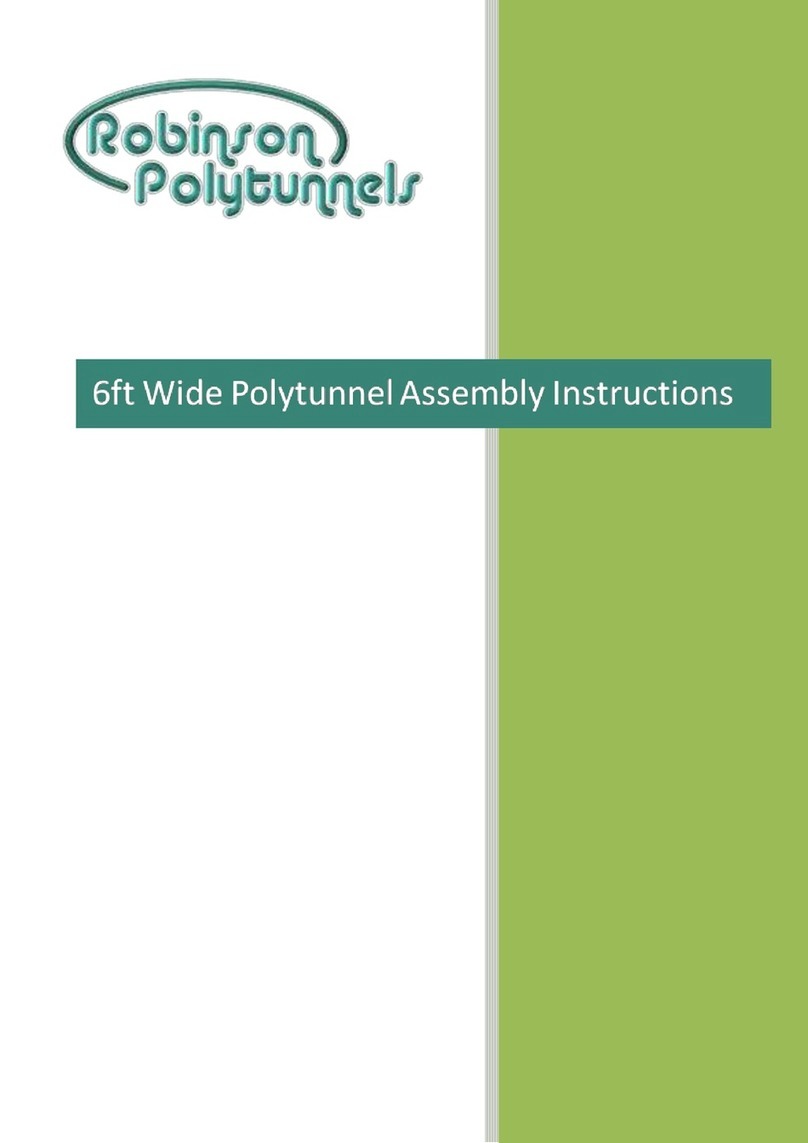

1Set two string lines to the width of the polytunnel.

Ensure they are parallel.

Tip! It’s best to put your polytunnel on a flat, level site.

A fall lengthways is easy to accommodate. A fall

sideways should be limited to about 10cm over the

width of the polytunnel.

2Set another string line for the end of the polytunnel.

Ensure the “end” string line is perpendicular to the

“length” string lines.

3Mark the ground at each foundation position, to the outside

of the “length” string lines at 5ft centres until the full length is

reached.

4Temporarily remove the string lines so they don’t get in the

way whilst digging.

5Dig a hole for each Foundation Tube, approximately 25cm

square x 35cm deep.

6Slot the ground anchor plates onto the bottom end of the

Foundation Tubes. And lock in place with the Starlock

Washers. Starlock Washers are inserted using the short piece

of tube.

a. With the foundation tube upside-down, slot the 6mm

Concrete Tie Bar (steel rod) into the pre-punched hole

in the Foundation Tube.

b. Slot the Ground Anchor Plate onto the bottom end of

the Foundation Tube, to rest on the Concrete Tie Bar.

c. Hold the short piece of tube over the starlock washer on the bottom end of the Foundation Tube

and tap the short tube with a hammer until the washer is located on the Foundation Tube, right

up to the Ground Anchor Plate.

7Reinstate the string lines.

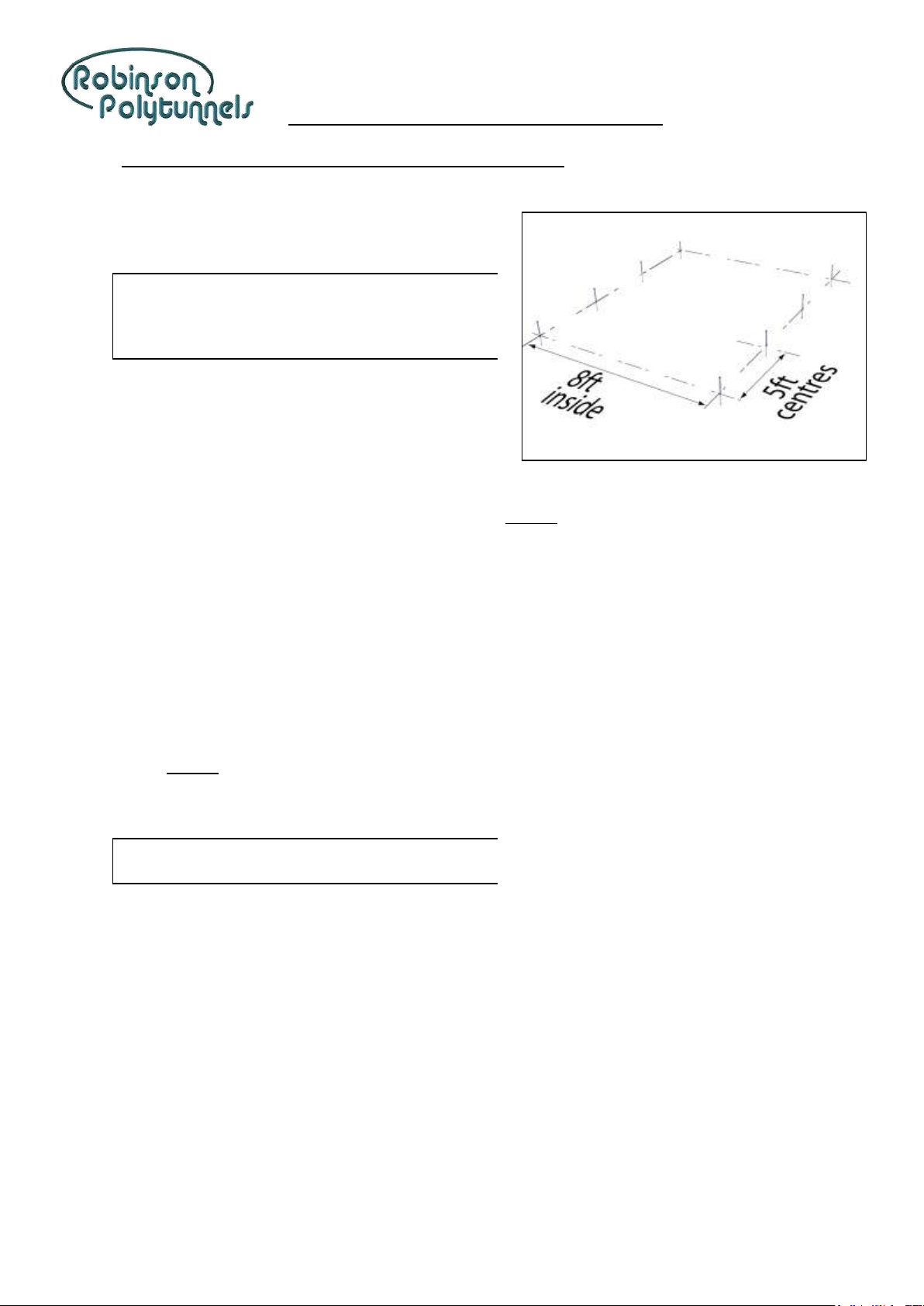

8Insert the Foundation Tube and anchor plate assembly into the excavated holes, to the outside of the

string line. Make sure the Foundation Tubes are vertical, touching the string line and spaced at 5ft

centres. The Foundation Tubes should be protruding above ground by approximately 40cm.

9Backfill the excavated holes, checking that the Foundation Tubes are still in the correct position. Stamp

on the soil to ensure the soil is well-compacted.