tm2692 Jan-20

2

Table of contents

Safety requirements...........................................................................................3

1. Overview........................................................................................................4

1.1. Purpose...................................................................................................4

1.2. Technical Specifications..........................................................................4

1.3. Delivery Set.............................................................................................4

1.4. Power Requirements...............................................................................5

1.5. Ambient Conditions.................................................................................5

1.6. Safety Components.................................................................................5

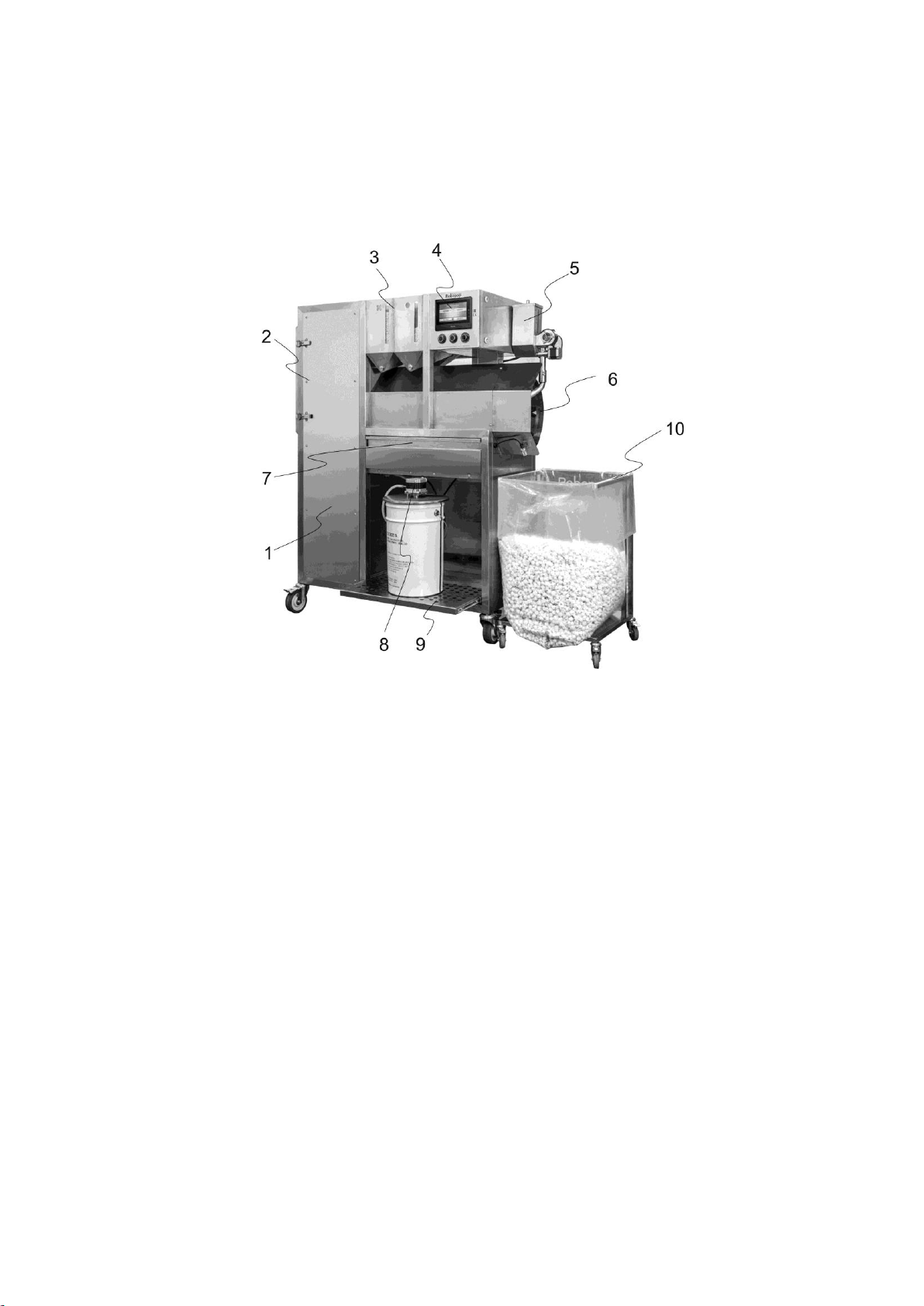

1.7. Main Components...................................................................................7

1.8. Getting Started........................................................................................9

2. Intended Use...............................................................................................10

2.1. Operation Modes...................................................................................10

2.2. Quick Operation Guide..........................................................................10

2.3. Program settings...................................................................................14

2.4. System settings.....................................................................................14

2.5. Operation indicators..............................................................................17

2.6. Display notifications...............................................................................18

2.7. Popcorn quality .....................................................................................20

3. Technical maintenance................................................................................22

3.1. Cleaning guide......................................................................................22

3.2. Light bulb replacement..........................................................................24

3.3. Preservation..........................................................................................24

4. Troubleshooting...........................................................................................25

5. Transportation and storage..........................................................................26

6. Acceptance certificate..................................................................................26

7. Warranty obligations....................................................................................27

8. Manufacturer details....................................................................................27

Annex A. Electric component list......................................................................28

Annex B. Safety temperature regulator settings...............................................29

Annex C. VFD settings ....................................................................................30

Annex D. Testing mode ...................................................................................31

Annex E1. Chamber optical sensor setup........................................................32

Annex E2. Corn hopper sensor setup..............................................................33

Annex F. Parts list............................................................................................34