Robopop 25 user manual Nov-20

TA B L E O F C O N T E N T S

Safety requ rements.......................................................................................3

1. Overv ew.......................................................................................................4

1.1. Purpose.................................................................................................4

1.2. Techn cal spec f cat ons.....................................................................4

1.3. Del very set...........................................................................................4

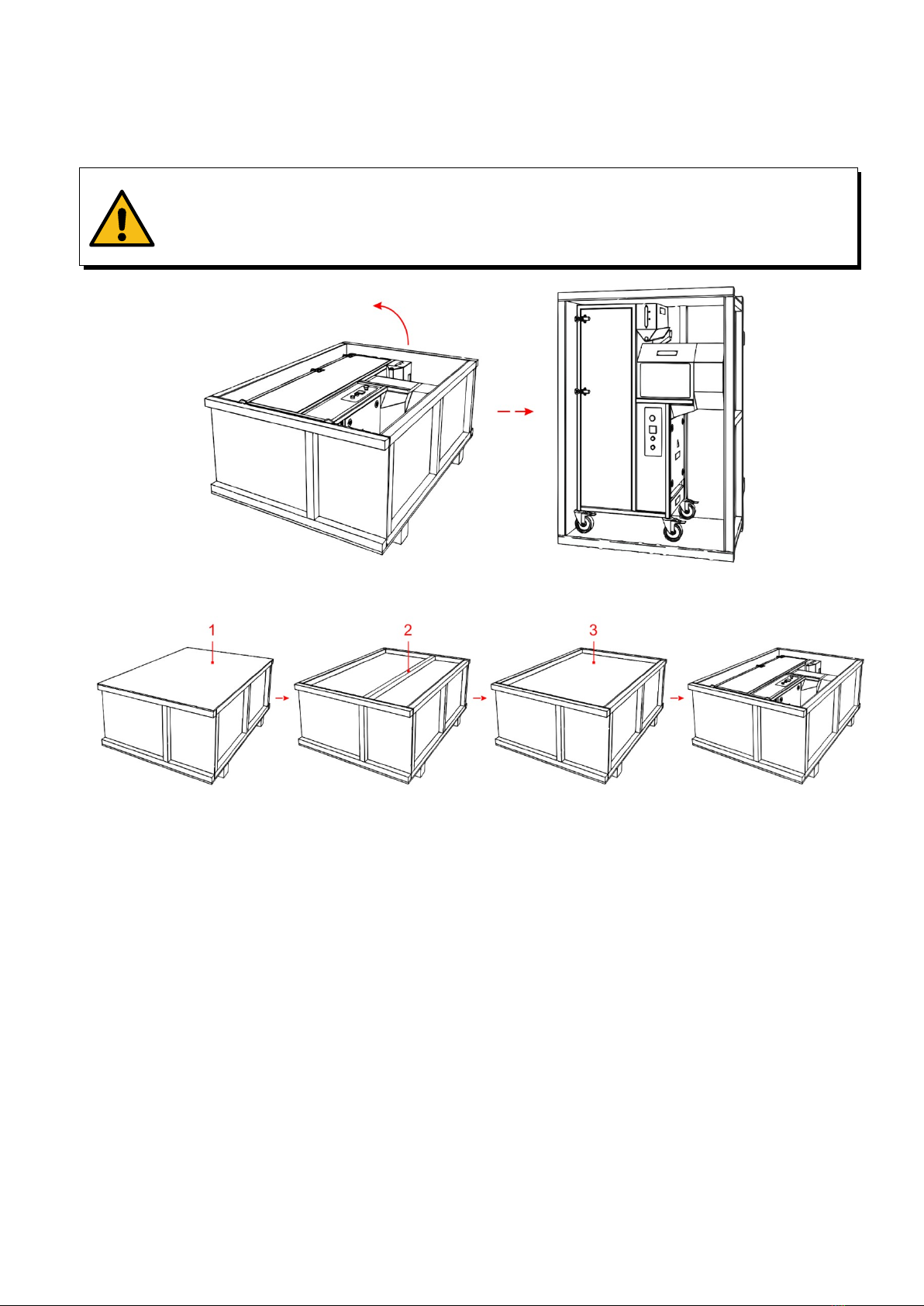

1.4. Unpack ng.............................................................................................5

1.5. Power requ rements............................................................................6

1.6. Amb ent cond t ons..............................................................................6

1.7. Safety components.............................................................................6

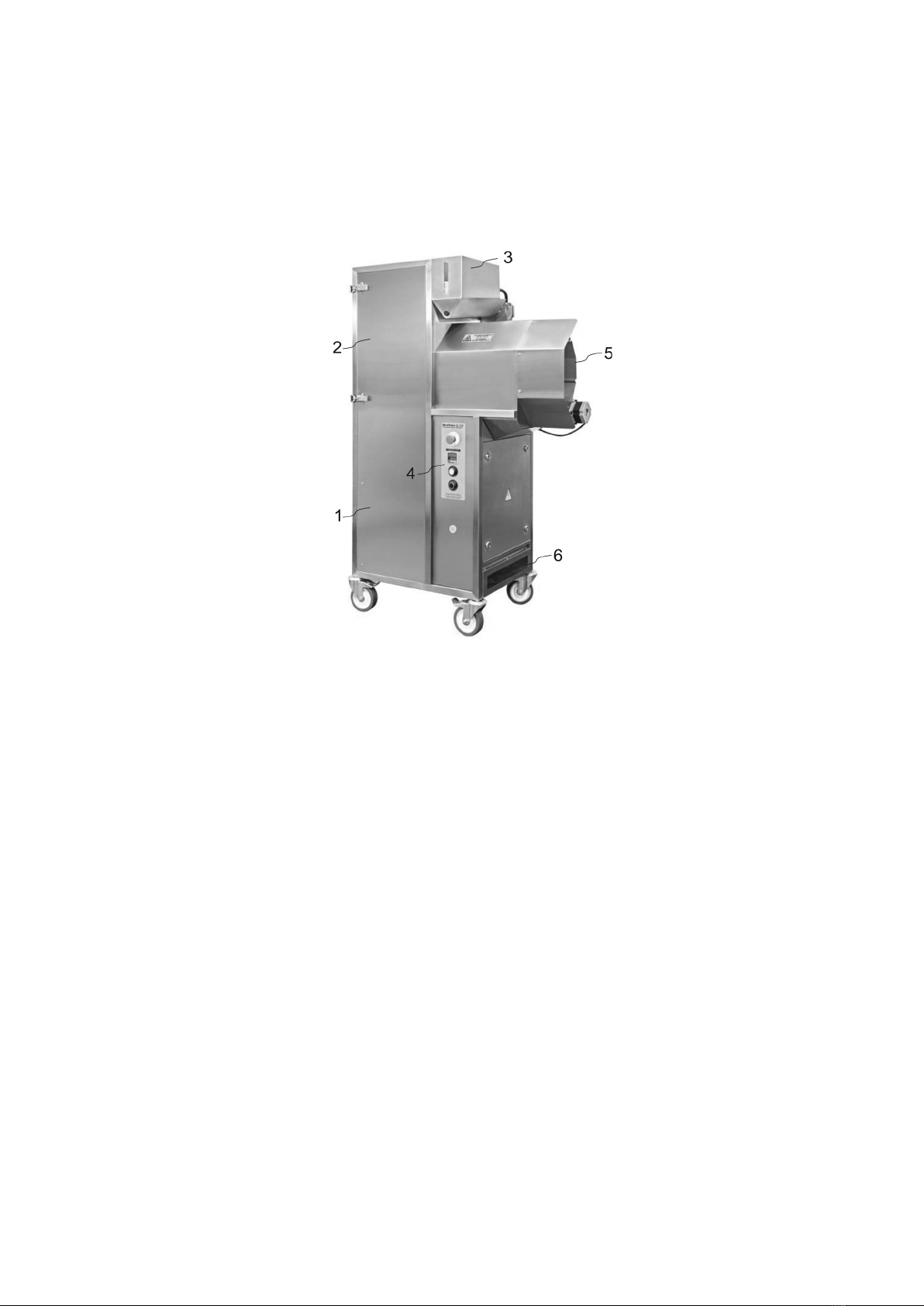

1.8. Ma n components................................................................................8

2. Intended use..............................................................................................10

2.1. Operat on modes...............................................................................10

2.2. Popp ng mode....................................................................................10

2.3. Qu ck start gu de...............................................................................11

2.4. Parameters.........................................................................................12

2.5. Test ng mode......................................................................................13

2.6. Popcorn qual ty..................................................................................14

3. Techn cal ma ntenance...........................................................................15

3.1. Clean ng gu de...................................................................................15

3.2. L ght bulb replacement....................................................................16

3.3. Conservat on......................................................................................17

3.4 Serv ce, repa r, spare parts.............................................................17

4. Troubleshoot ng........................................................................................18

5. Transportat on and storage....................................................................18

6. Qual ty control cert f cate.......................................................................19

7. Warranty obl gat ons................................................................................20

8. Manufacturer deta ls................................................................................20

Annex A. Chamber clogg ng.......................................................................21

2