tm2627 Jan-20

2

Table of contents

Safety requirements...........................................................................................3

1. Overview........................................................................................................4

1.1. Designation.............................................................................................4

1.2. Technical specifications ..........................................................................4

1.3. Delivery set .............................................................................................4

1.4. Ambient conditions..................................................................................5

1.5. Power supply requirements.....................................................................5

1.6. Protectors and lockups............................................................................5

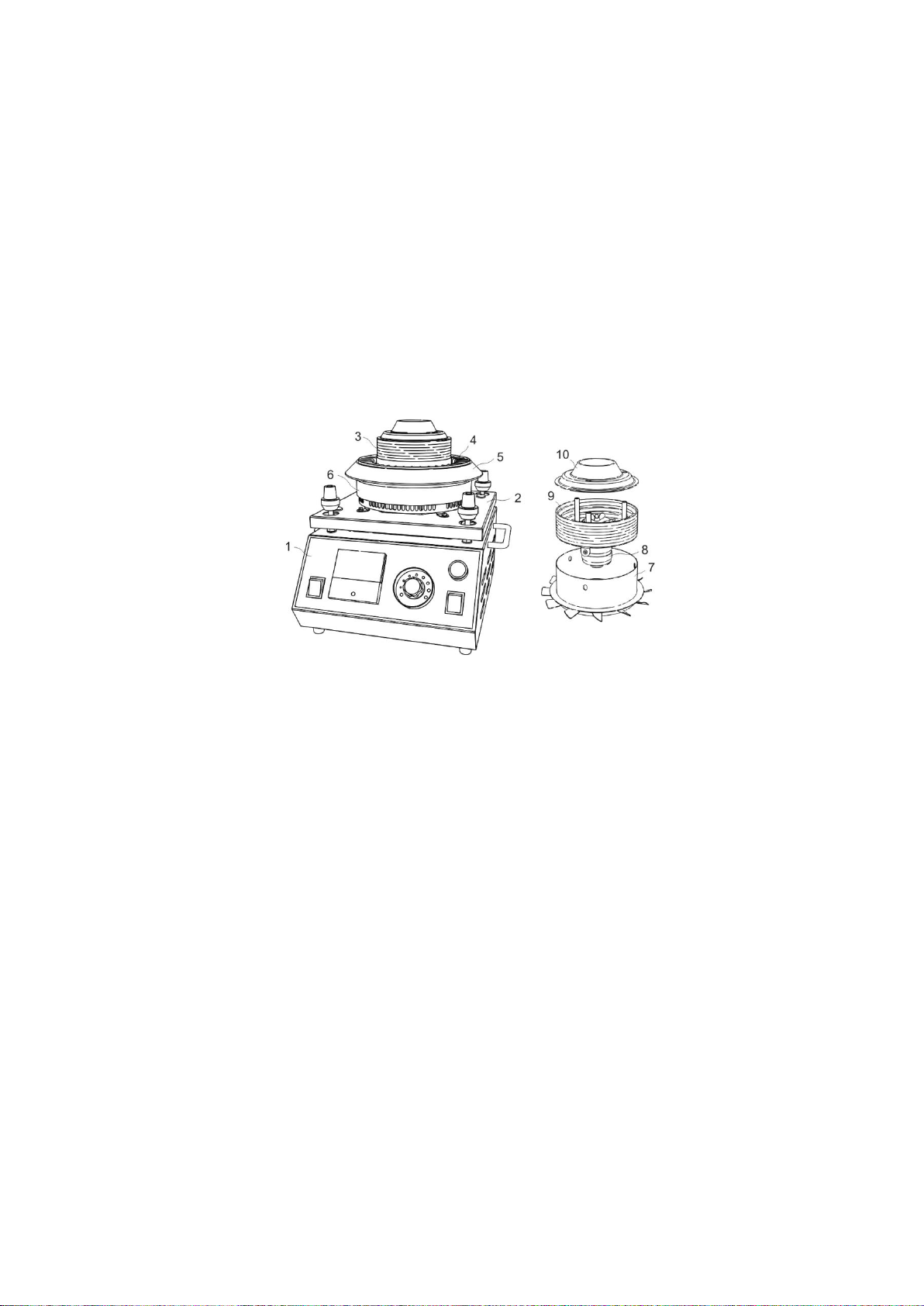

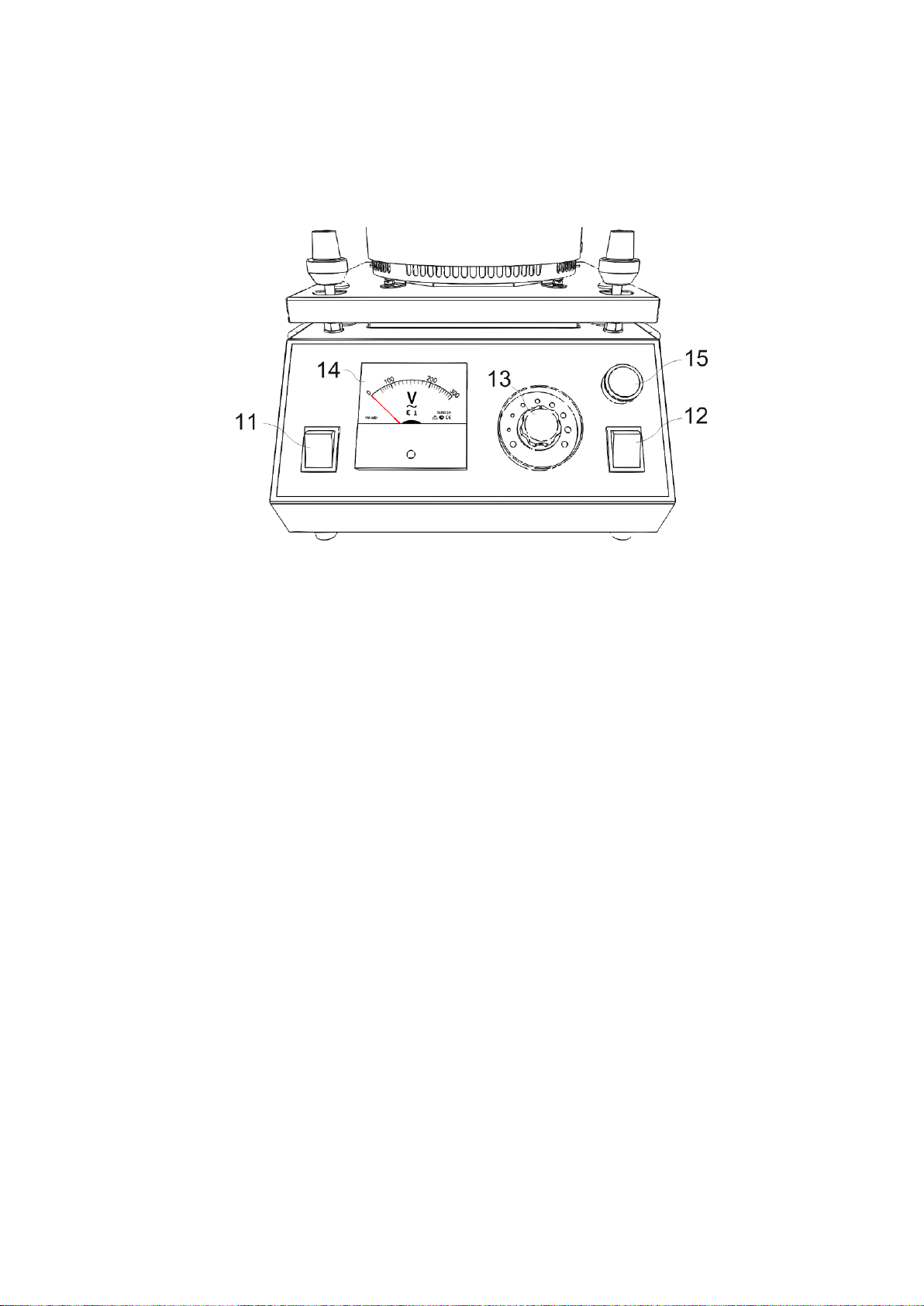

1.7. Machine design and operation principle ..................................................6

2. Intended use..................................................................................................8

2.1. Raw material requirements......................................................................8

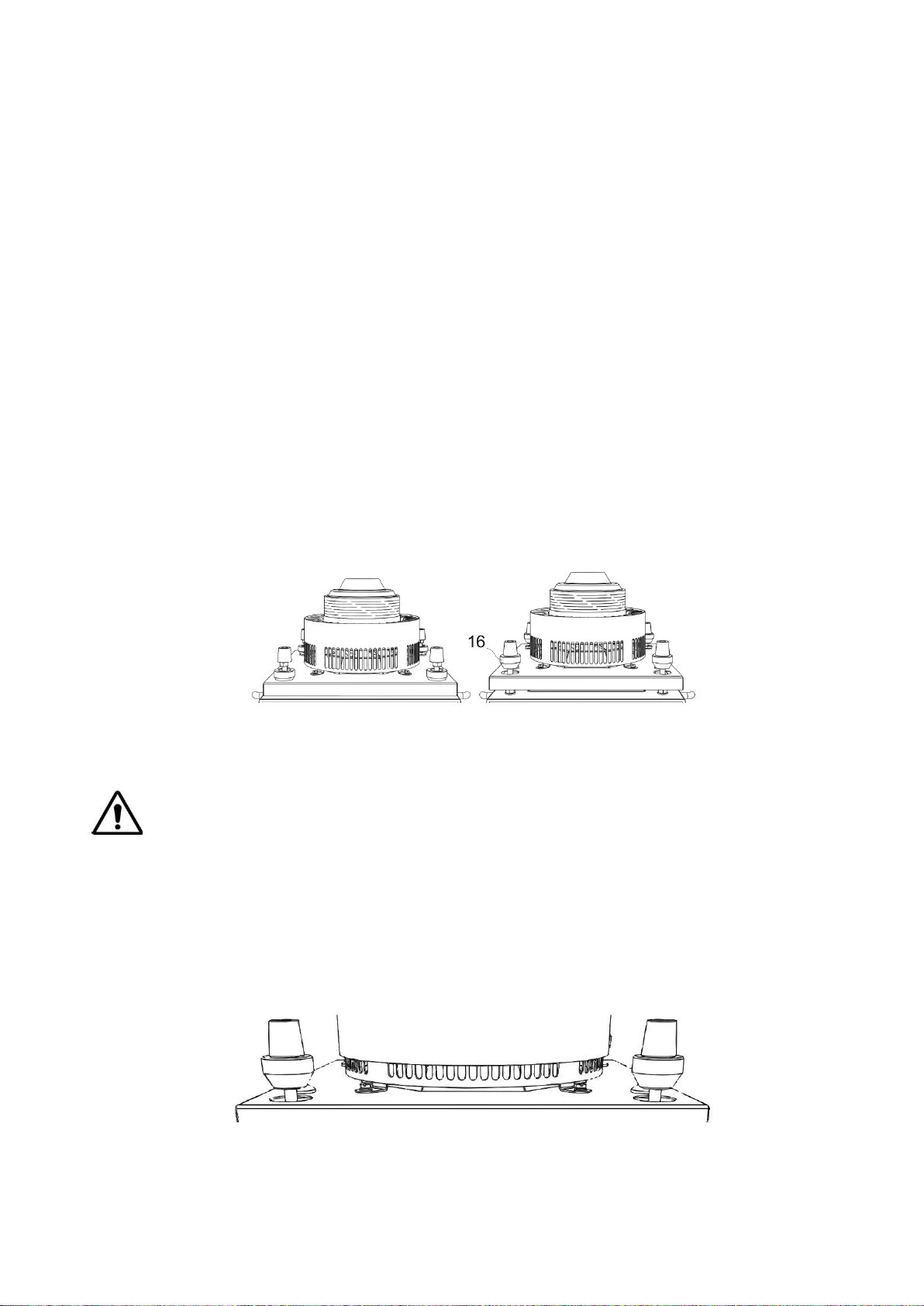

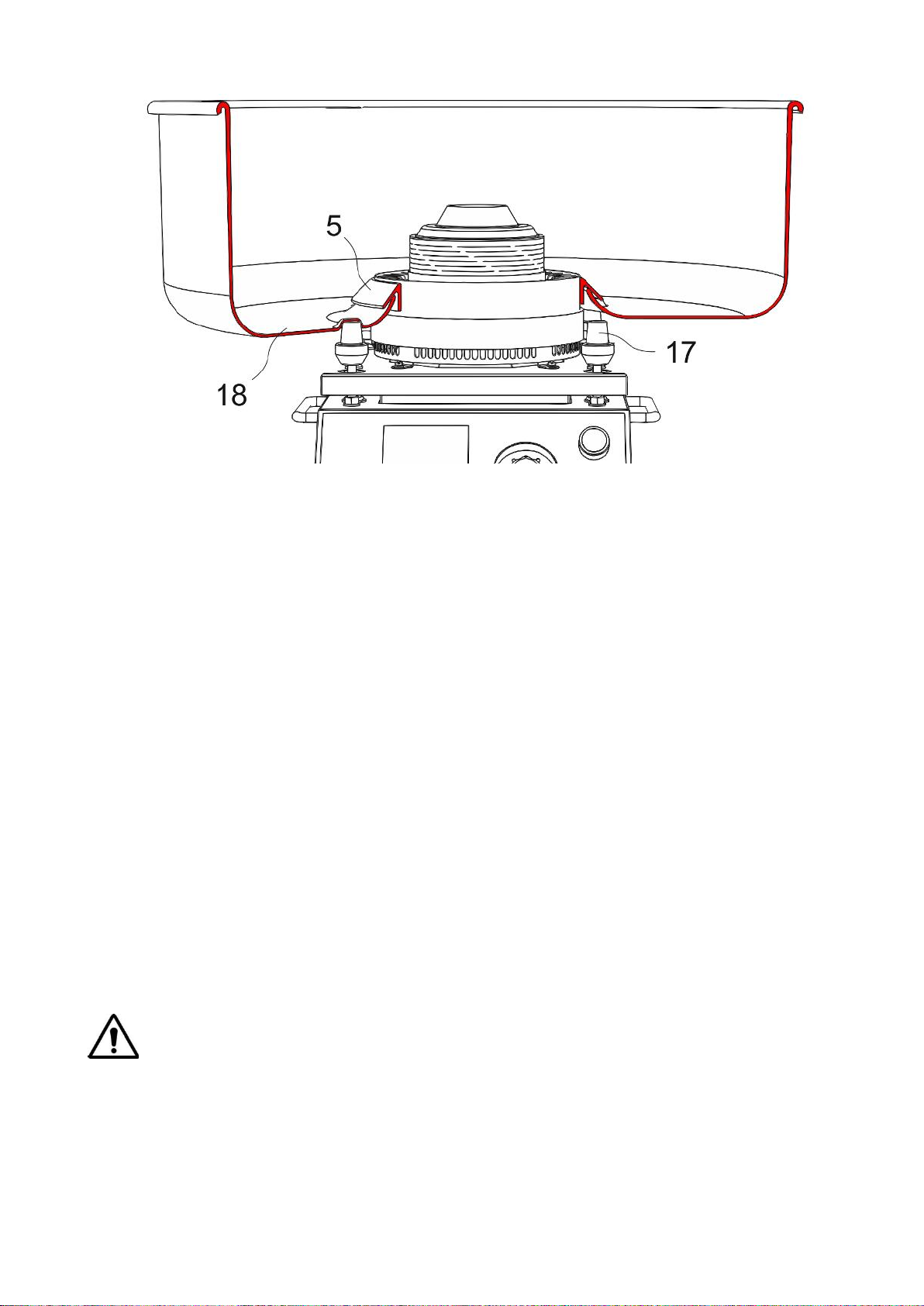

2.2. Getting started.........................................................................................8

2.3. Operation................................................................................................9

3. Technical maintenance................................................................................16

3.1. General instructions ..............................................................................16

3.2. Safety measures ...................................................................................16

3.3. Cleaning instructions.............................................................................16

3.4. Storage .................................................................................................19

3.5. Troubleshooting ....................................................................................19

4. Transportation and storage..........................................................................20

5. Acceptance certificate..................................................................................20

6. Warranty obligations....................................................................................21

7. Manufacturer details....................................................................................21

Annex A. Electric components list....................................................................22

Annex B. Parts list ...........................................................................................23