Computer and Robotics Aided Manufacturing

CONTENTS

1. EPNC Installation............................................................................................................ 5

2. Description of EPNC....................................................................................................... 6

2.1 Initialization window..................................................................................................... 6

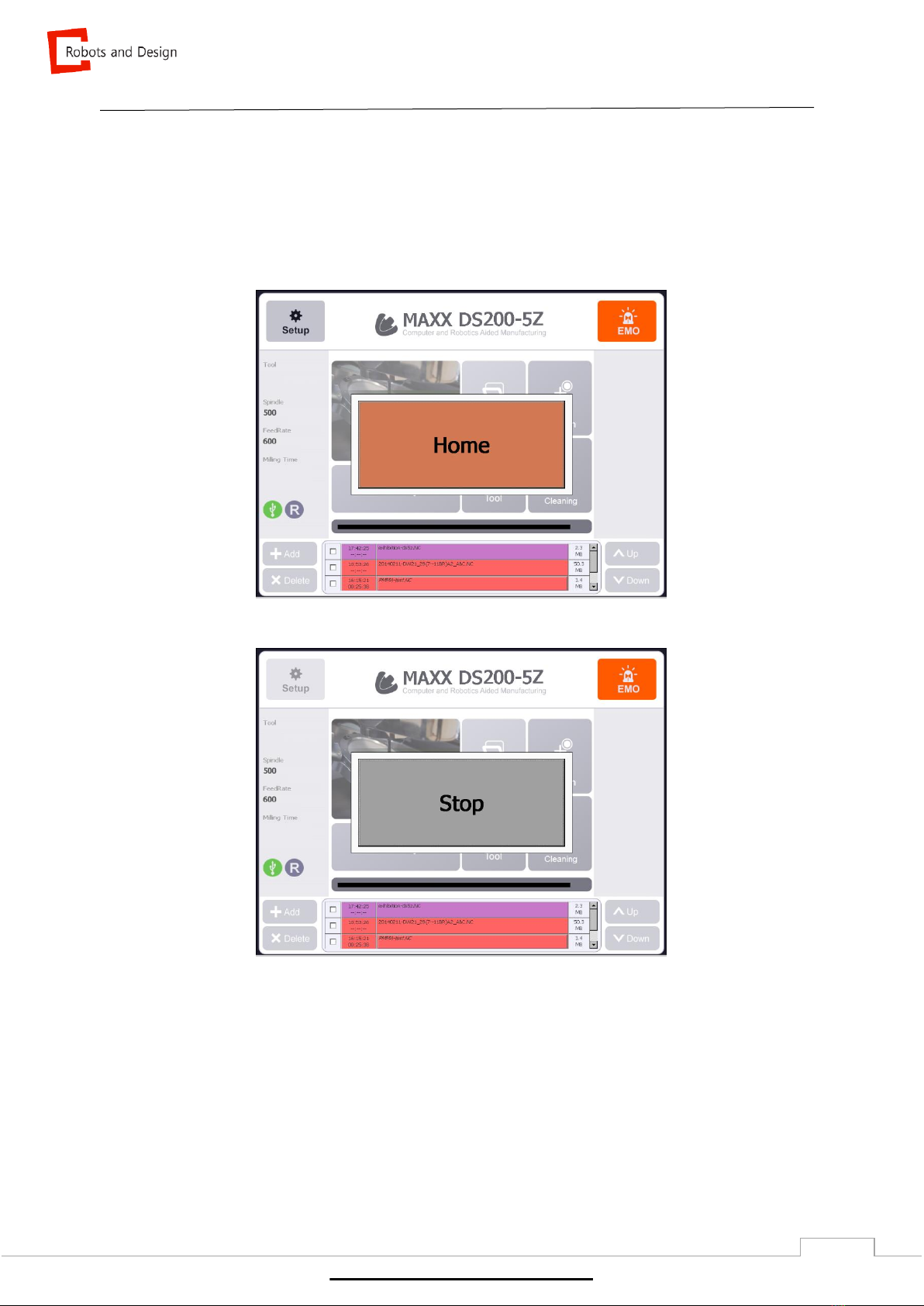

2.2 Main window................................................................................................................ 7

2.2.1 Functions of main window..................................................................................... 8

2.2.1.1 Operational setting & EMO............................................................................. 8

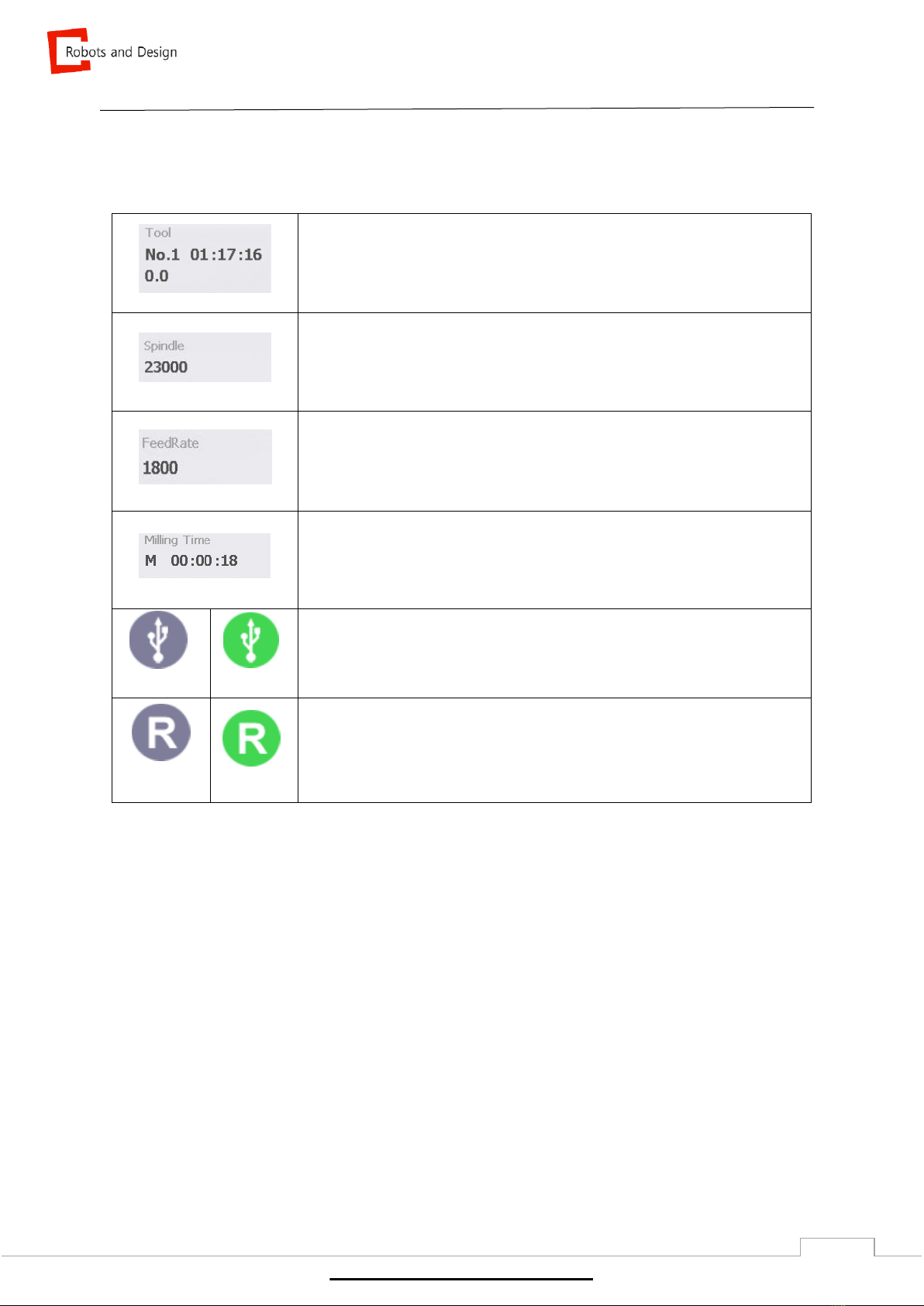

2.2.1.2 Machine status............................................................................................... 9

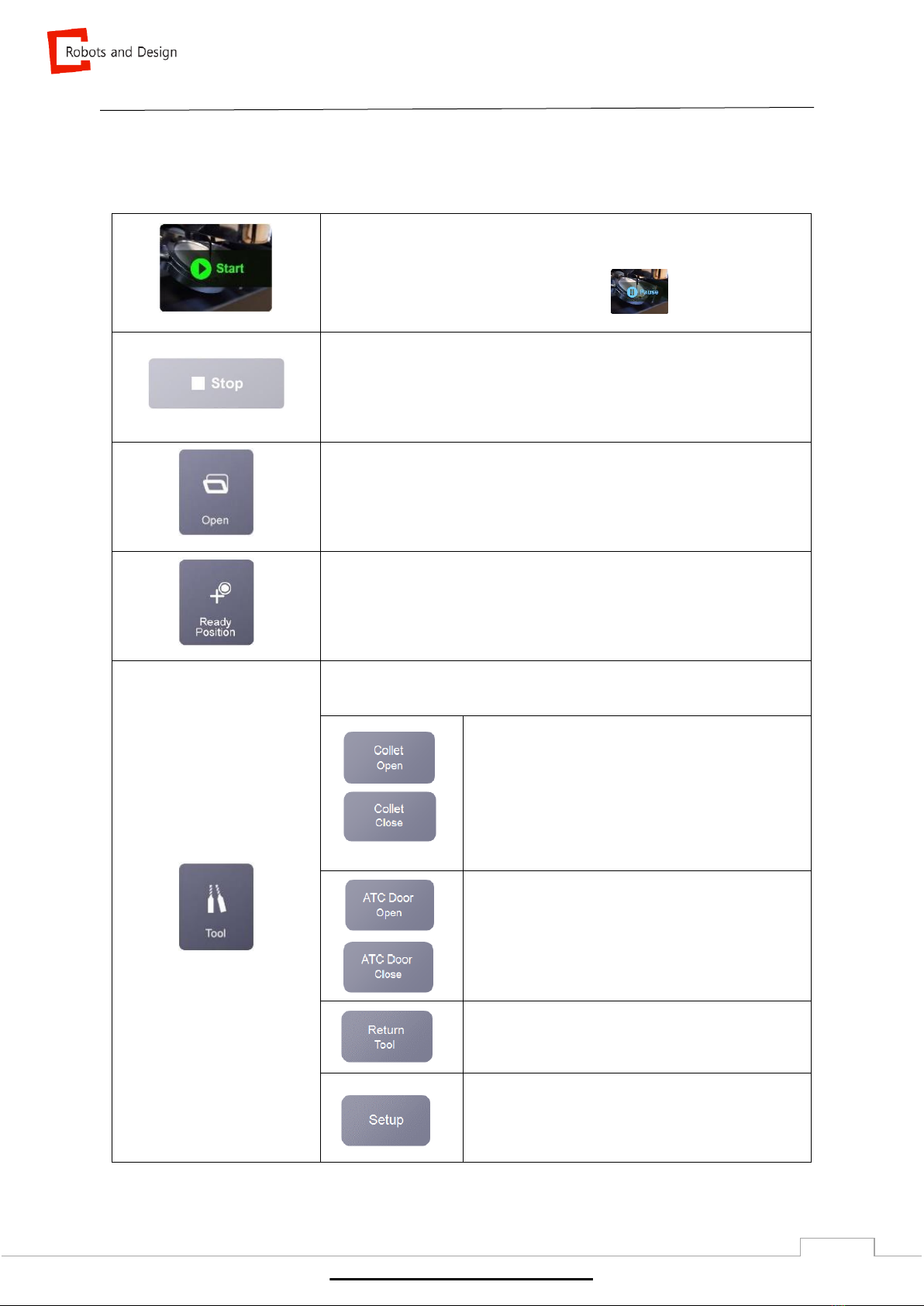

2.2.1.3 Commonly used functions ............................................................................ 10

2.2.1.4 NC file .......................................................................................................... 12

2.3 Setup......................................................................................................................... 14

2.3.1 Entering setup..................................................................................................... 14

2.3.2 Teaching............................................................................................................. 15

2.3.2.1 Functions of teaching ................................................................................... 15

2.3.2.2 Coordinate offset & Teaching point ............................................................. 16

2.3.2.3 Option........................................................................................................... 18

2.3.2.4 Jog ............................................................................................................... 19

2.3.2.5 Auto Calibration............................................................................................ 21

2.3.3 Tool..................................................................................................................... 22

2.3.4 Term................................................................................................................... 24

2.3.5 Option................................................................................................................. 25

2.3.6 I/O....................................................................................................................... 27

2.3.7 Log...................................................................................................................... 28

2.3.8 System................................................................................................................ 29

3. Milling ............................................................................................................................ 30

3.1 Machine power.......................................................................................................... 30