1) Entire document: general formatting and grammatical improvements.

2) Section 1: added DB-9 description

3) Section 2.1: made this a section

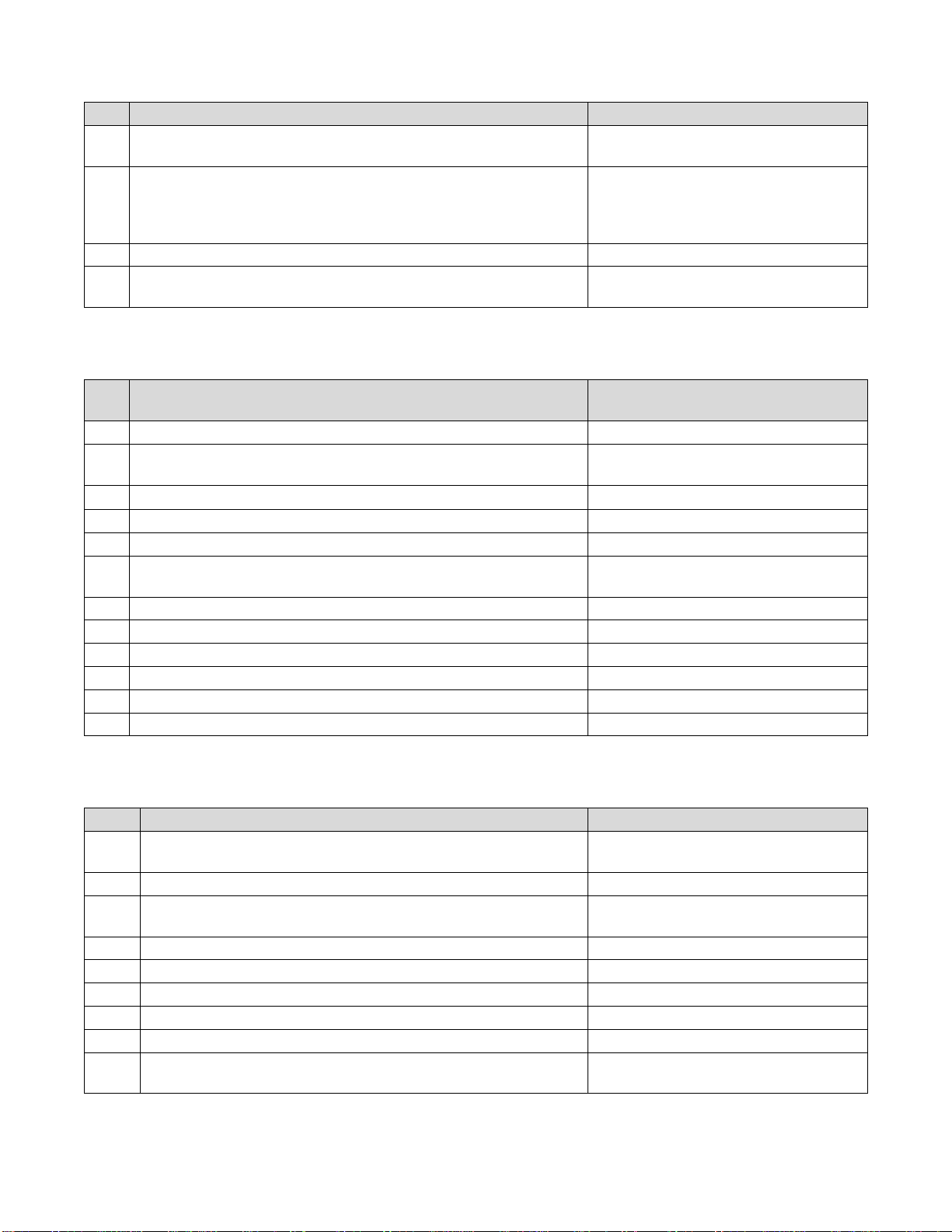

4) Table 2-1: updated descriptions, added Mate operation, electrical

column and section references

5) Section 2.3: added this section

Table 2-3: added flatness and circularity equipment

6) Table 2-4: incorporated previous Preparing to Compress equipment,

added PSC equipment

7) Table 2-5: added video camera, increased recommended qty. of

several items for test circuits

8) Section 3: added adjoining structure attachment warning

9) Section 4: added support@ contact email

10) Section 5: added Sep Spring and Retaining Cord handling precautions,

added permitted flange contact

11) Section 6: added flatness and circularity recording, added reminder for

Sep Connector and Switch attachment

12) Section 7: incorporated prior section 12 (Preparing to Compress)

13) Section 7: used to be a part of the Stow section

14) Step 7.1.4: increased measurement locations from 4 to 6

15) Step 7.1.7: this step used to be later in the procedure

16) Sections 8, 9, 10: added several test circuits to account for the various

Lightband switch states. Used to be only one test circuit per operation.

17) Sections 8, 9, 10: added step checking DB-9 cleanliness prior to

Lightband attachment.

18) Sections 8, 9, 10: added step to remove power and measurement

circuit from Lightband after each operation.

19) Step 8.4.4: added rechecking pre-Stow distance

20) Table 8-1: updated allowable values

21) Table 8-2,Table 9-2,Table 10-2: moved to relevant sections, increased

OL resistance to match inspection report

22) Table 9-1: increased allowable time

23) Table 10-1: added note 2 permitting temporary switch reactivation

24) Figure 13-1: updated to include intermediate switch states and

operation directions

25) Section 16: added unintended electrical warnings.

26) Step 17.2.1: now references User Manual for LCT qty.

27) Section 17.5: added instructions to reverse the mate w/ LCTs