To order parts and supplies: 800.343.9353 >> eastwood.com 5

OPERATION

• Depress Throttle Paddle inward with fingers to operate tool.

• Keep the broad work surface of the Abrasive Belt parallel to the work surface whenever

possible to minimize uneven wear and maximize usable life.

• Always maintain a firm grip while operating tool, do not force but allow the rotational speed

of the Abrasive Belt to do the work.

• Be sure that the workpiece is clamped down or held securely to minimize the danger of injury

while operating tool.

ABRASIVE BELT REPLACEMENT

The Abrasive Belts are quickly and easily changed. No

tools are required.

The following steps describe how to do this:

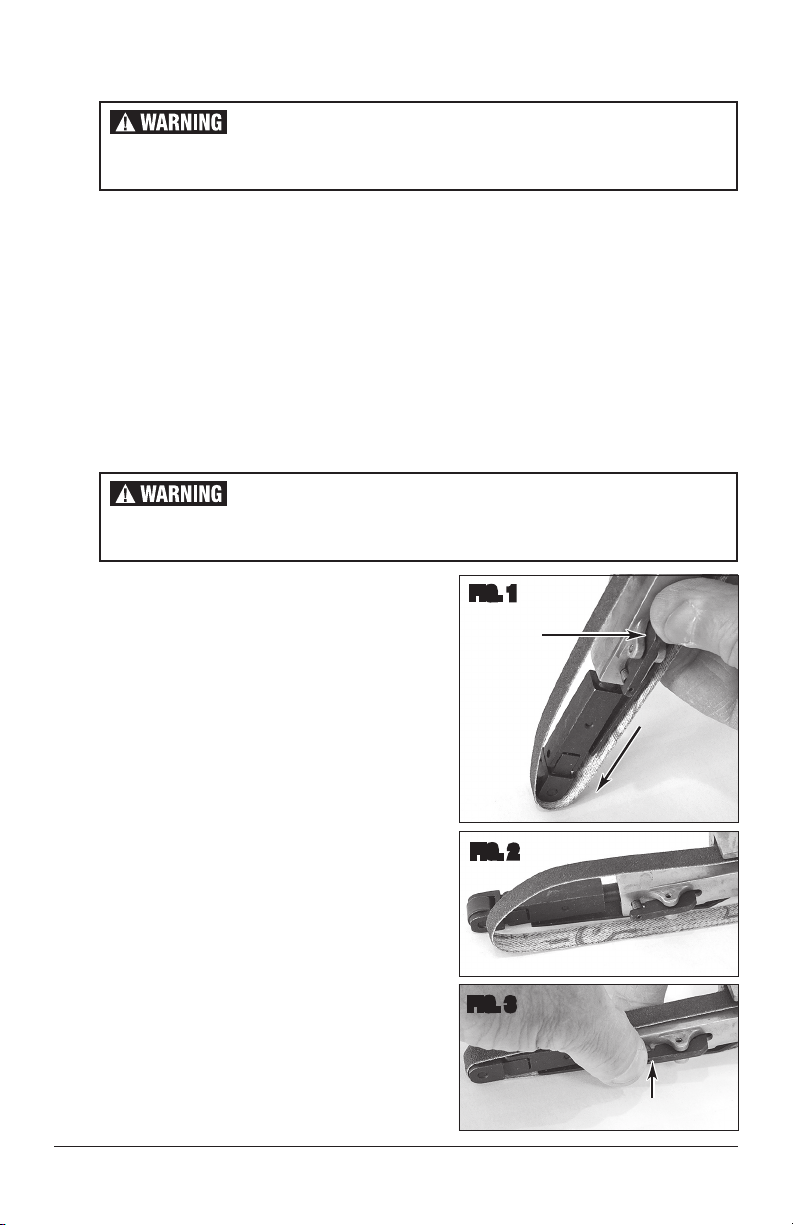

• The end of the Abrasive Belt Arm is spring loaded

to keep the proper tension on the Abrasive Belts.

While holding the tool firmly, push inward on the

end of the Abrasive Belt Arm while depressing

the Thumb-Lever Latch (FIG 1). NOTE: The Guide

Pin will move inward until it locates under the

Latch portion of the Thumb-Lever Latch holding

it in the retracted position while the Abrasive Belt

is changed (FIG 2).

• Pull the worn Abrasive Belt free of the Drive

Drum and discard.

• Slide the replacement Abrasive Belt over the

Drive Drum and Idle Roller at the end of the Abra-

sive Belt Arm (FIG 2). NOTE: Be sure the Abra-

sive Belt is slid fully over the Guide Bar located on

the upper surface of the Abrasive Belt Arm.

• Depress the Thumb-Lever Latch to release the

Guide Pin restoring full spring pressure (FIG 3).

INJURY HAZARD!

Disconnect air supply from the tool to prevent accidental starting and

potential injury while installing or removing Abrasive Belts.

FIG. 1

INJURY HAZARD!

Disconnect air supply from the tool to prevent accidental starting and

potential injury while installing or removing Abrasive Belts.

Push In

to Latch

Push Down

to Compress

Push In to Unlatch

FIG. 2

FIG. 3