To order parts and supplies: 800.343.9353 >> eastwood.com 5

SET-UP & CONNECTION

• Wrap white thread sealing tape (not included) around the threads of a 1/4” Male NPT quick dis-

connect fitting (not included) then thread it into the 1/4” NPT inlet threads of the Sander Body.

• Attach Air Supply to Inlet Fitting.

OPERATION

• To apply a PSA (pressure sensitive adhesive) Polishing and Sanding Disc, remove the protective

backing film, be certain the Disc is centered over the Backing Pad and press it in place with

no wrinkles or air bubbles.

• The PSA sanding Discs are

removed by gripping the edge

and pulling away from the

backing pad.

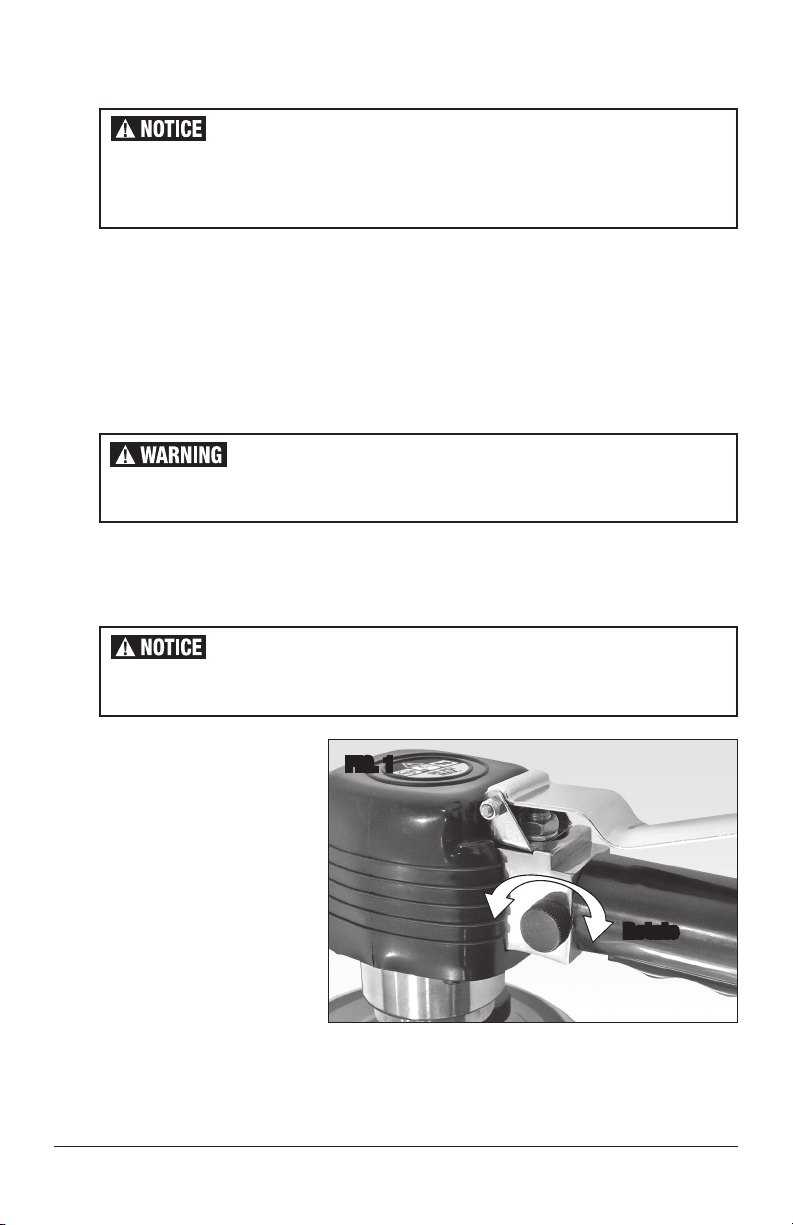

• Reconnect air supply; depress

the throttle to begin polishing

or sanding action. Speed is

controlled by pressure applied

to the Paddle while the Knob

mounted at the left side of the

body is used to regulate maxi-

mum speed. Rotating the Knob

Clockwise raises the speed

limit while rotating it Counter-

Clockwise lowers it (FIG 1).

FIG. 1

Be sure that the air supply to the tool is clean and dry. Moisture in the supply

line will quickly damage the air motor and valves.

A minimum 3/8” I.D. air line should be used for optimal performance.

INJURY HAZARD!

Disconnect air supply from the tool to prevent accidental starting and

potential injury while installing or removing Sanding Discs.

Sanding Discs must be centered over the backing pad or a dangerous out of

balance condition can occur.

Rotate