www.SteamPoweredRadio.Com

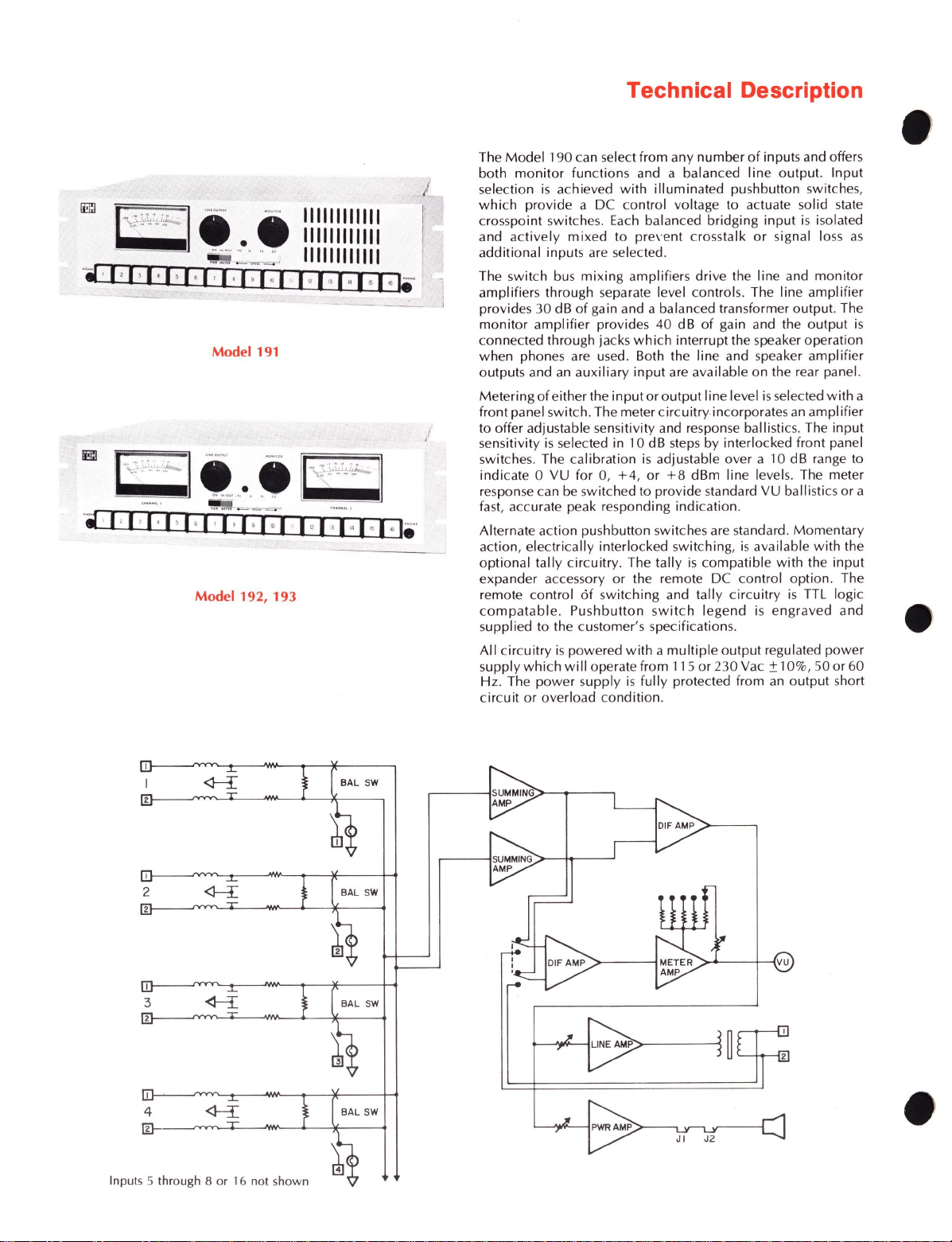

Model 191

·• ·I,1,I·1,t,1,1,I·I•I

··

I·1,,

,.

1

,,

1•I•·

Model

192

, 193

BAL

SW

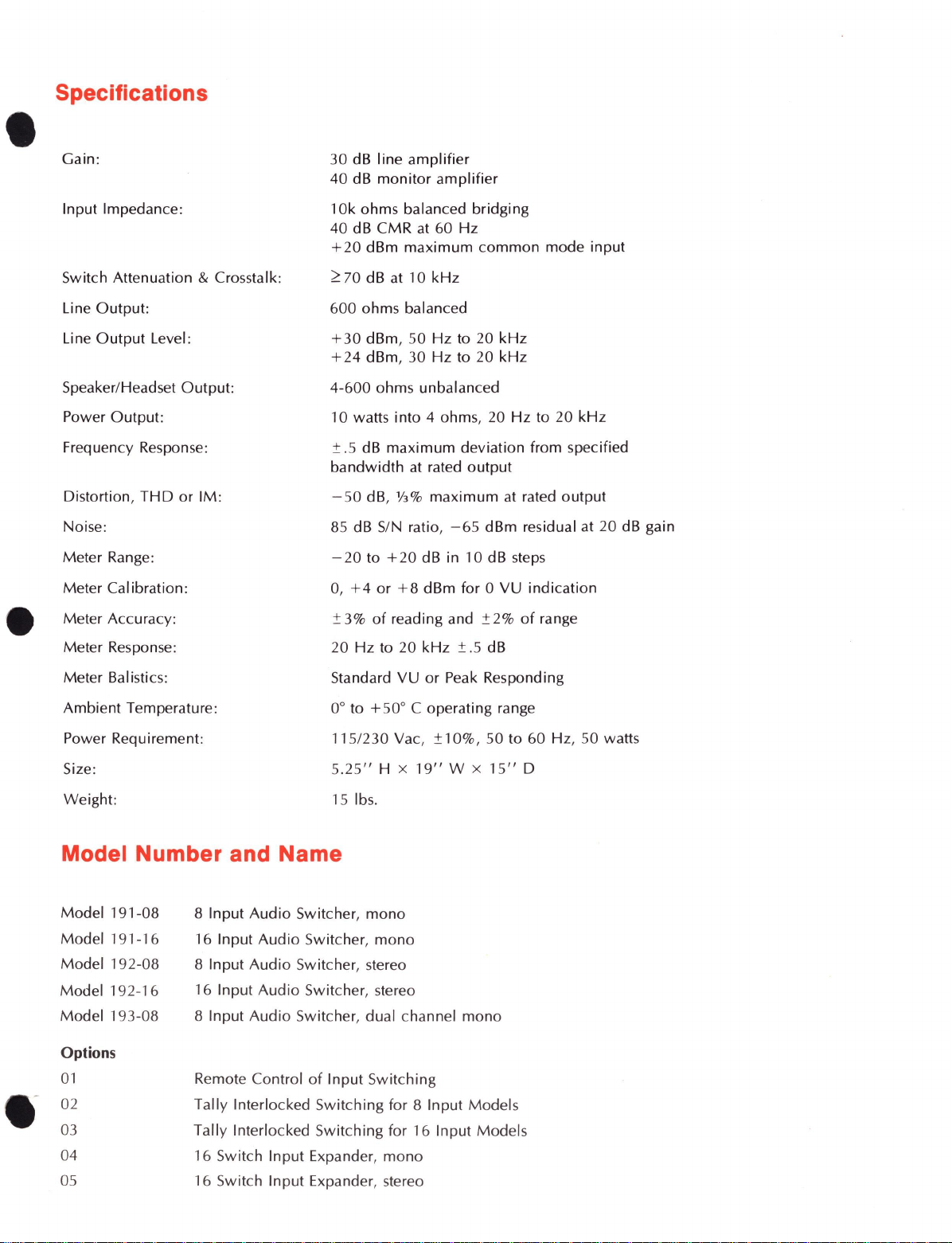

Inputs 5 through 8

or

16 not shown

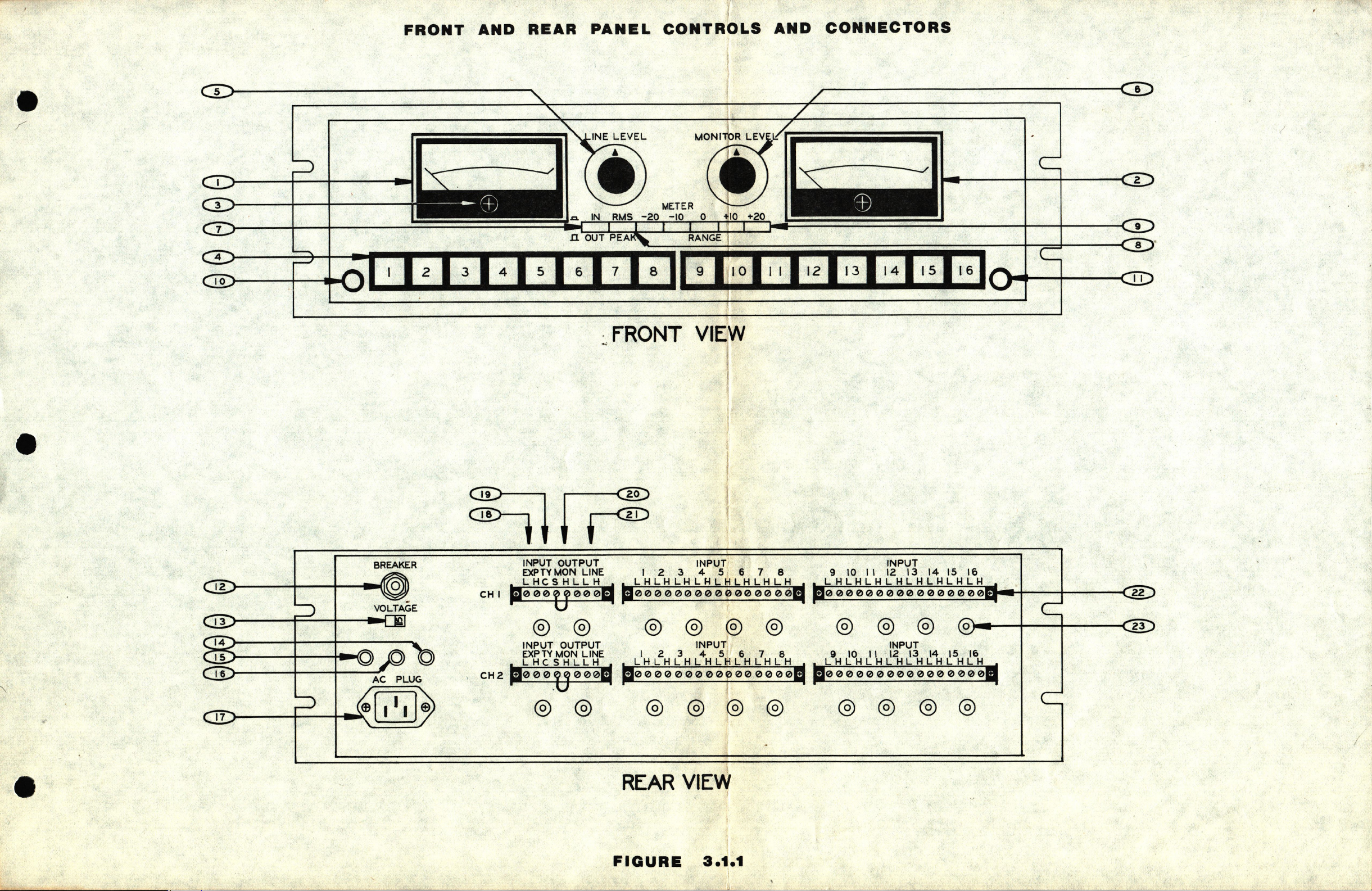

Technical Description

The

Model

190can select from any number

of

inputs and offers

both

monitor

functions and a balanced

line

output. Input

selection

is

achieved

with

illuminated pushbutton switches,

which

provide a DC control voltage to actuate solid state

crosspoint switc

hes.

Each

balanced bridging

input

is

isolated

and

actively

mixed

to

pre,

·e

nt

crosstalk

or

signal loss

as

additional inputs are selected.

The switch bus

mixing

amplifiers drive the line and

monitor

amplifiers through separate level controls. The line

amplifier

provides 30 dB

of

gain and a balanced transformer output. The

monitor

amplifier provides 40 dB

of

gain and the

output

is

connected through jacks

which

interrupt the speaker operation

when phones are used. Both the line and speaker

amplifier

outputs and an auxiliary

input

are available on the rear panel.

Metering

of

eitherthe

input

or

output

Iine level

is

selected

with

a

front panel switch. The meter

circuitry

incorporates

an

amplifier

to offer adjustable sensitivity and response ballistics. The input

sensitivity

is

selected in 10 dB

steps

by interlocked front panel

switches. The calibration

is

adjustable over a 10 dB range to

indicate 0 VU for 0,

+4,

or

+8

dBm line levels. The meter

response

ca

n

be

switched to provide standard VU ballistics

or

a

fast, accurate peak responding indication.

Alternate action pushbutton switches are standard. Momentary

action, electrically interlocked switching,

is

available

with

the

optional tally circuitry. The

tally

is

compatible

with

the

input

expander accessory or the remote DC control option. The

remote control

of

switching and tally

circuitry

is

TTL logic

compatable

.

Pushbutton

switch

legend

is

engraved

and

supplied

to

the customer's specifications.

All

circuitry

is

powered

with

a

multiple

output

regulated

power

supply

which

will

operate from 115

or

230 Vac ±10%, 50 or 60

Hz

. The

power

supply

is

fully

protected from

an

output short

circuit

or

overload condition.

•

•