TROUBLESHOOTING & SOLUTIONS

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Knocking 1. Lack of oil in crankcase

2. Worn piston pin

3. Worn main bearings

4. Worn connecting rod

5. Excessive crankshaft end play

6. Dirty or defective check valve

7. Piston hitting head due to foreign

matter or carbon deposits.

1. Add oil

2. Replace pin

3. Replace bearings

4. Replace inserts or rod assembly

5. Take to Service Center

6. Clean or replace

7. Inspect, repair or replace valves &

pistons

Overheating

Compressor

1. Poor ventilation

2. Dirty cooling surfaces

3. Dirty or defective check valve

4. Restricted air intake

5. Low oil level

6. Unit not run on level surface

7. Dirty or defective reed valve

1. Move compressor to allow for

better ventilation

2. Clean compressor pump

3. Clean or replace

4. Replace filter

5. Add non-detergent, single viscosity

oil

6. Level unit

7. Clean valve plate and replace valves

Low Discharge

Pressure or

Pumps Slowly

1. Air leaks

2. Broken or dirty valves

3. Restricted air intake

4. Blown gaskets

5. Defective gauges

6. Dirty or defective check valve

7. Compressor too small for application

1. Check system for air leaks.

2. Replace or clean valves & valve

plates

3. Replace filter element

4. Replace gaskets

5. Replace gauges

6. Clean or replace check valve

7. Consult dealer for larger ROLAIR

compressor

Compressor

Fails to Attain

Proper RPM’s

1. Defective check valve

2. Defective pilot valve

1. Repair or replace check valve

2. Repair or replace pilot valve

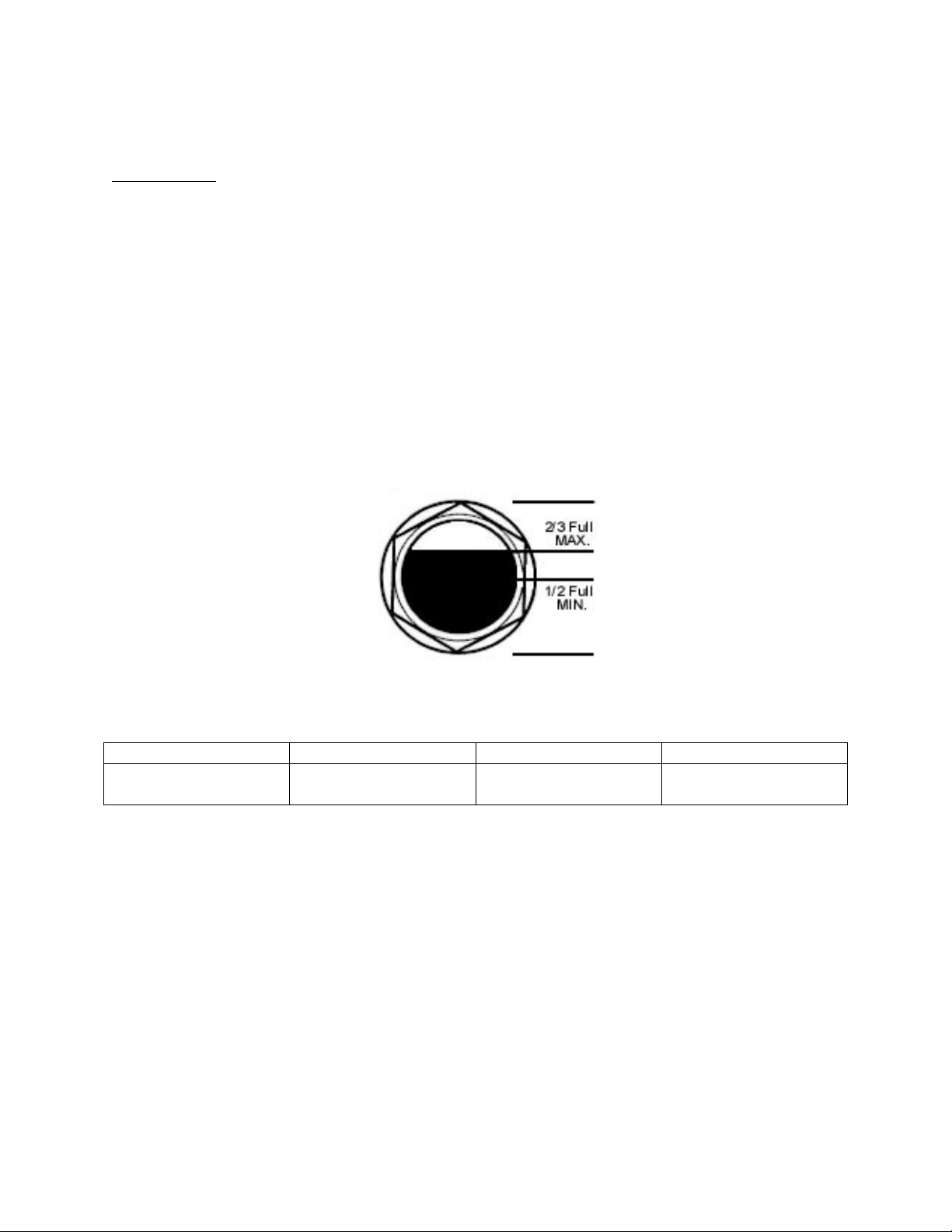

Oil in the

Discharge Air

1. Worn piston rings

2. Compressor air intake restricted

3. Restricted crankcase breather

4. Excessive oil in basic compressor

pump

5. Wrong oil viscosity

1. Replace rings

2. Replace filter

3. Clean crankcase breather

4. Check gauge and adjust to proper

oil level

5. Drain & replace with non-detergent

single viscosity oil

Excessive Oil

Consumption

1. Restricted or dirty air filter

2. Crankcase is over-filled with oil

3. Valves not seating properly

4. Worn piston rings

1. Clean or replace air filter

2. Drain oil & refill to proper oil level

3. Clean crankcase breather

4. See ROLAIR Service Center

Water in

Crankcase

1. Compressor does not run long

enough to get hot and vaporize the

moisture

2. Compressor too large for application

3. Incorrect or inferior grade of oil

1. Consult dealer about smaller ROLAIR

compressor

2. Consult ROLAIR dealer

3. Change oil in compressor