45

CABLE CONNECTION

All cable connections should be adequately sized, insulated, and undamaged. The cable

connectors should be clean and properly mated with the battery terminals to ensure a snug

connection. Terminal connections should be torqued to the recommended specification

below. Although Rolls S-Series LFP ESS batteries do not require maintenance, routine

inspection of cabling and terminal connections is recommended.

Amperage 25 30 40 55 75 95 130 150 170 195 260

Wire Gage 14 12 10 8 6 4 2 1 1/0 2/0 4/0

TERMINAL TORQUE

Rolls batteries using M6 fasteners should be torqued to 8-10Nm.

DO NOT OVERTORQUE: If a terminal is damaged, do not attempt to repair the terminal. Do

not use the battery if the recommended torque specification cannot be met.

SINGLE BATTERY INSTALLATION

Rolls S-Series ESS rack-mount batteries are compatible with standard 19” rack hardware.

For single battery installation, connect the positive and negative terminal of the battery

pack to the positive and negative terminal of the system bus with the appropriately sized

red and black cable, respectively. If you intend to use a combiner box, directly connect the

positive and negative terminals of the battery pack to the combiner box terminals.

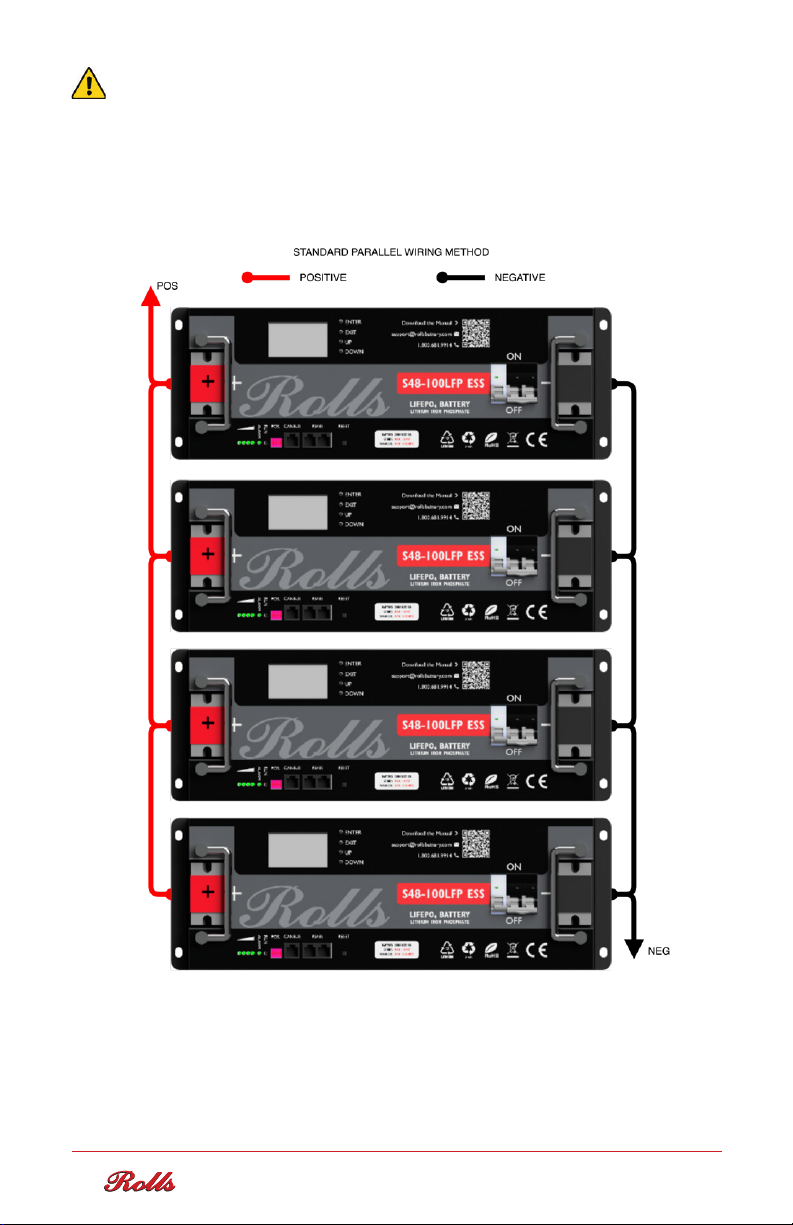

PARALLEL BATTERY INSTALLATION

Rolls S-Series ESS rack-mount batteries are compatible with standard 19” rack hardware.

Rolls S-Series ESS batteries can be combined in parallel to increase system capacity and

power delivery. Rolls S-Series S48-100LFP ESS can support up to 16 battery packs in parallel

and is certified to UL 1973. Parallel batteries can be installed in the modular Rolls LFP ESS

cabinet, and expandable up to 32U per cabinet (i.e., Eight S48-100LFP ESS batteries can be

configured in a single rack).

The standard cabinet comes with a high current combiner box to connect the positive

and negative terminals from the battery to the outlet terminal at the top of the cabinet.

Refer to the connection diagram below and use appropriate cable sizing and length during

installation. The length, thickness, material, and resistance of all the cables connected in

parallel must be the same.

NOTE: Refer to the Communication Interface section for the parallel communication

cable connections.

NOTE: Undersized cables may lead to cable and/or battery damage, charging issues,

terminal heating, or fire.